Scaling Up Your Vegetable Farm for Regional Markets

By Tammy Howard, NCAT Agriculture Specialist

Abstract

This publication helps farmers decide if they are ready to expand their operations to serve wholesale markets or produce more for direct markets. It describes how organization and planning can help a producer meet the challenges involved in scaling up. This publication addresses important considerations such as land, labor, food safety, marketing, and insurance.

Introduction: Scaling Up – Is It Right for You?

Local foods purchasing has moved beyond farmers markets to mainstream grocery stores. As consumers become more interested in purchasing local foods, chain grocery stores from Walmart to Safeway tout their support of local farmers. At the same time, many established farmers want to move out of time-consuming farmers markets into wholesale markets. A University of Wisconsin study points out that with the interest in local foods, “local food systems have the potential to borrow some of the economic and logistical efficiencies of the industrial food system while retaining social and environmental priorities” (Day-Farnsworth et al., 2009).

It is important to plan for the expansion of your farm. Every time you increase the scale of your operation, you will experience growing pains. Planning for improvements and growth within your operation can help alleviate these. Questions you might ask when you consider increasing your production:

-

-

- Do you have the ability to move more product through your washing and packing facility?

- Do you have enough space in your cooler, delivery truck, etc.?

- How many more people will you have to hire, and do you have the management skills to handle a larger crew

- Do you have a good farm administration system? As your farm increases in size, this will likely become more complex, including more taxes and stricter insurance requirements (Courtens, 2006).

-

This publication addresses these planning considerations, as well as providing some resources and worksheets to determine whether or not your operation is ready to scale up.

What is Scaling Up?

Scaling up can mean many things to a farm. It can mean simply producing more because your market demand is greater. In the context of this publication it means expanding production capacity and business to produce for wholesale markets or significantly expanding your farm to meet direct-market demands. It is important to keep in mind that there is not a one-size-fits-all approach to expanding your farm. This publication will include some strategies, but your approach will depend on your existing resources and markets, as well as how much risk you are comfortable with.

Photo: NCAT

Why Do You Want to Scale Up?

When economic prosperity is measured in economic growth, it is hard to question the expansion your farm. However, before considering expanding your farm, it is important to ask yourself why you want to do it. What are your farm and lifestyle goals? Is it going to significantly affect your quality of life—for better or for worse? Consider revisiting your goals. If you have not developed goals for your farm or written your goals down, see the ATTRA publication Evaluating a Farming Enterprise. The online tutorial titled “Goal Setting” can help you think through your goals with worksheets on this topic.

Before expanding your operation, it is important to consider your return on investment. In other words, will you make more money based on your investment if you expand? The Leopold Center for Sustainable Agriculture has a return-on-investment calculator for produce operations, the Produce Profitability Calculator.

This calculator, developed by the Iowa State University Hotel, Restaurant, and Institution Management Extension program, helps produce growers weigh their options when planning production for the coming year. The calculator can compare two production scenarios at one time and any number of variables: current and expanded production levels, increased acreage in produce, existing and modified marketing plans, or changes in pricing structures.

To most effectively use the features of the calculator, growers need to have data about their current and projected production levels, income, production-related expenses, and operation-related expenses based on current markets, or at least on educated assumptions. A users manual has been developed to help growers collect the necessary information available.

Brenton and Beth Johnson and family at their first farm. Photo: Scott David Gordan

Scaling Up with Direct Markets

Brenton Johnson, Johnson’s Backyard GardenBrenton Johnson, of Johnson’s Backyard Garden (JBYG), farms near Austin, Texas. Brenton and his family farm 186 acres of diversified vegetables—currently the largest Community Supported Agriculture (CSA) farm in Texas. They started out with an original garden of 30 by 50 feet in 2004 in Cedar Creek, Texas. Brenton started selling his excess produce at farmers markets in 2005. Originally, he did not have marketing experience. Not knowing what to charge at the farmers market, he let customers set their own prices.

Brenton worked at the Bureau of Reclamation and farming was a hobby. He had no intention of farming at his current scale. Now, he operates the largest CSA in Texas and sells through a number of other wholesale and direct markets. He is happy to be having a measurable impact on local food being sold and consumed in and around Austin.

Diversified Marketing Strategy

Johnson’s Backyard Garden is no longer a garden. Brenton has developed a diversified marketing strategy, which includes a 2,000 member CSA. He also sells to 200 restaurants, in 15 farmers markets, and wholesale through grocery stores in a tri-city area of Texas. This type of marketing strategy ensures that risk is kept low even if one of the markets performs poorly in a season.Farm Planning

At his smaller backyard garden, Brenton’s initial challenge was to try to figure out how to be efficient with space. Every inch was planted and, oftentimes, double cropped. He relied on The New Organic Grower by Eliot Coleman to help him manage multiple crops in a tight space. His initial gardening system was also influenced by John Jeavons, who wrote How to Grow More Vegetables, and Dr. Vern Grubinger, who wrote Sustainable Vegetable Production from Start-Up to Market.As Brenton grew the farm, the advice of other farmers throughout the country with similar sizes and marketing strategies was most helpful. From these farmers he learned about equipment essentials, soil fertility, rotations, and marketing strategies. These were the farming models he found to be most helpful: Full Circle Farm in Washington, Capay Organics in California, and Roxbury Farm in New York. Some of the ATTRA publications were also helpful as he transitioned to a larger scale.

Managing Labor

Initially, Brenton traded veggies for labor through an advertisement on the Internet website Craigslist. These original employees are now in managerial positions on the farm. Brenton also relied heavily on volunteers and has continued with an active volunteer party on the farm for their CSA harvest.He gradually progressed from volunteers to paid interns, then to paid staff. JBYG has started to hire employees with specialized training in agriculture as the business has grown and is able to afford skilled labor. Brenton comments that “spending money on talent is worth it.” The farm also offers health insurance to all of their full-time employees. Currently, the farm employs nearly 100 people in the peak of their season. They still have volunteers but have hired a volunteer coordinator.

JBYG has tried to be organized in managing labor by putting a lot of time into developing an organizational chart for the farm. Brenton’s background working within the government has helped in developing a defined organizational structure for the farm. JBYG actively works to improve their organizational structure annually. They leave training of individual farm workers up to the managers for each aspect of the farm. For example, the harvest crew manager trains the harvest crew.

Photo: Scott David Gordan

Equipment

To expand the farm, the Johnsons’ investment in their basic land, equipment, and facilities has been considerable. Brenton comments that it takes know-how and determination to develop many assets. Initially, he studied Roxbury Farm’s production guides and systems (see excerpt from Jean Paul’s Equipment Production Guide below). Brenton ended up adopting a lot of the same equipment that Roxbury Farm utilized. In general, his principles are to have a high horsepower tractor for primary tillage and an offset (to see the crop rows) tractor for cultivation. JBYG tries to have a separate tractor for seeding, and most tractors have creeper gears. Creeper gears allow the tractor to go very slowly to help the operator monitor seeding and planting.

The scale of the JBYG operation requires numerous coolers and refrigerated trucks. In addition, irrigation has been very expensive to set up. The farm has six wells from which to draw irrigation water.

Crop Rotation and Cover Cropping

Brenton’s goal is to maintain 50% of his land in production and 50% in cover crops. A longer-term goal is to utilize rotation and cover crops to better control weeds and to have a less-intensive tillage system. Because of the climate, crops can be grown year-round. Brenton would like to have more land and be less intensive in cropping area. Being at a larger scale already allows for less intensive cropping. Eventually, he aims to grow only one crop on a piece of ground each year (i.e., no double cropping).Financing Their Expansion

Brenton hired an operations manager to handle finances and to help with the farm’s growth and financing strategies. In his original garden, he had purchased his house with a conventional mortgage loan and grew veggies in the back yard (hence the name). After great success selling at farmers markets he looked for land to expand their farm. He was fortunate to find property on Craigslist at a great price. He obtained a loan from the USDA Farm Service Agency to buy land for his expansion. Since he was used to jumping through hoops as a government employee, it made the process easier. As the farm has expanded, Brenton has used a combination of financing. He has continued to get assistance from FSA, as well as loans from CSA members. He has also worked with the local farm credit office for financing. In addition, JYBG has participated in USDA Natural Resource Conservation Service (NRCS) cost-share programs to help finance their high tunnels and irrigation.Note: See the ATTRA publication Federal Working Lands Conservation Resources for Sustainable Farming and Ranching for more information on how federal programs can help with your farm expansion.

Organizing Your Farm

Typically, a farm that expands to sell through wholesale markets moves from a very diverse operation to one that is more specialized. Nationally, there are several regional CSAs that have scaled up to serve more than 1,000 members. Managing 50 + crops at that scale can be very difficult, but there are some farmers that have successfully pulled it off, such as the 160-acre Johnson’s Backyard Garden profiled in this publication.

Generally, however, most farmers that scale up decrease the diversity of their crops. While you may grow fewer crops, these crops should be available for a longer period of time to satisfy your markets. If you choose to grow fewer crops, it is also important to manage soil quality on your farm through crop rotations, cover cropping, and other measures.

Planning and Managing a Scaled-Up Operation

Land

Often, one of the limiting factors in farm expansion is access to land. This section will discuss different options for accessing land.

Leasing

Leasing land can be a great option if financing a land purchase is not possible. It also gives you the opportunity to try farming at a larger scale without committing to a piece of land through purchasing. When renting, however, it is important to have a lease that is fair and legal. Research the market price of land rentals in your region. Your county Cooperative Extension office or farmland preservation organizations may have local land-lease rates. The Drake University Agricultural Law Center, in collaboration with the Iowa-based Leopold Center for Sustainable Agriculture, has developed an in-depth Land Tenure Tool Box to help you understand the considerations of leasing farm land.

Another consideration when leasing land is the quality of the land and the existing infrastructure. If you are leasing, it is important to use land that will not take a lot of time and resources to improve. If the land is excessively weedy or has poor soil, it is likely not worth investing time because you will not get any equity out of your land improvements. It is also important to consider access to the land, as well as to water and electricity.

The ATTRA publication Tips for Farm Leases and Contracts: Creating Smart, Effective Documents can help you understand the considerations in developing an effective and fair farm lease.

Gardens of Eagan in Minnesota. Photo: NCAT

Buying Land

If expanding your farm has been a part of your long-term goals, buying land may be a better option than leasing. Purchasing can be costly, especially if you live in an area that has high land prices. Financing the purchase of land can be difficult. The USDA Farm Service Agency (FSA) can be a great option for obtaining a low-interest loan for the purchase of land or equipment for your expansion if you do not qualify for a conventional loan. Any financer will expect you to have a projected cash-flow statement to demonstrate that your expansion will be profitable.

The ATTRA publication Finding Land to Farm: Six Ways to Secure Farmland includes important considerations, as well as helpful resources on leasing or purchasing land.

Infrastructure and Equipment

Expanding your farm will require expansion of your infrastructure. If your current farm’s infrastructure consists of a rototiller and hand tools, your required investment will likely be extensive.

Jean Paul Courtens from Roxbury Farm in New York says, “The key to planning an efficient diversified farm is consistent bed sizes, access, and consistent tractor and irrigation wheel spacing.” He advises that good record-keeping is key to planning your expansion. He suggests determining your units of measurement—length of bed, bunches, and pounds—and creating greenhouse and field planting schedules that are easy to read, easy to use, and easy to update.

At Roxbury Farm, their acreage is laid out in 49-foot sections with 11-foot driving lanes. Each section is divided into eight beds. Each bed is 56 inches across, with 6-foot centers. Raised beds provide drainage during heavy rains. Farm workers never drive on top of their beds.

Roxbury Farm’s irrigation traveler can cover four sections in one pull. Their one-sided boom sprayer can spray four beds at a time. They always set aside a place to drive harvest trucks and tractors. The field arrangement is such that they can access fields in all weather and the crew never has to carry a full produce box more than 20 feet. The arrangement is also easier for recordkeeping.

Excerpt from Rosbury Farm Equipment Manual

©2006 By Jean Paul CourtensRoxbury farm is a 375-acre integrated farm in Kinderhook, New York. They serve 1500 families in the Capital District, Columbia, and Westchester County, as well as NYC, with vegetables, fruit, beef, pork, lamb, and chicken through the CSA model. In this excerpt, Jean Paul Courtens, the co-owner of Roxbury Farm, describes their approach to managing and purchasing equipment at that scale.

When you buy a piece of equipment research the different makes & models. Call farmers who use the equipment to find out the pros & cons of its operation. Make sure there are dealers in your area that stock or order replacement parts for your particular piece of equipment. When something breaks down and you have to wait a few weeks for the parts you can end up losing a lot of income.

If you are unfamiliar with a new piece of equipment have a farmer or a dealer come to your farm and teach you how to use it. Even new equipment will break down very quickly unless someone takes the time to make sure everything is in working order and knows how to operate it. At our farm, each apprentice maintains one tractor, and is responsible for the upkeep of other specific pieces of equipment. The only way a machine stays in good working condition is because we maintain it and replace worn parts. Before you take the equipment out to the field, look it over, check the fluids, the belts, the bearings. When you operate it, listen for any noise that sounds unfamiliar. While operating equipment can be fun, fixing and maintaining it means getting your hands full of grease and busting your knuckles on hard steel. Some people have so much fun doing it, they love hunting for bargains at the auctions so they have something to fix.

Photo: Roxbury Farm

The ideal equipment system for your farm is (a decision) you must make before you spend a nickel. Purchasing equipment narrows your options for future purchases. For a dairy farm, this might be the choice between making baleage or hay (or square or round bales). It is important to be realistic about the scale you will be operating at and allow for improvement.

Buying the right tractor depends a lot on what you want to pull or carry with it. Four wheel drive tractors can pull 30 to 50% more per HP than two wheel tractors. Your equipment dealer will be able to tell you how much power and or weight you need to pull a certain piece of equipment, which can vary with soil types. Many farmers fill their tires with CaCl to gain weight and increase their pulling power. Once you decide on the right size tractors, you determine the wheel spacing and you will operate your farm under the ideal row and wheel spacing that suit your particular crops. Check if the harvesting and cultivating tools of your choice are made to fit your system (i.e., can they be set up to cultivate and harvest your bed width and the row spacing of all your crops and fit on your tractors).

Incorporation of large amounts of organic matter often demands the use of larger tractors and tillers developed to do a good job. A spader does an excellent job in mixing cover crops into the topsoil with limited passes. Many small vegetable growers stay away from letting cover crops mature due to their inability to incorporate them. By making a change in your farming system, you might see that you do not need expensive tools to incorporate the organic material. One farmer allows his crop of rye and vetch to mature and leaves it on the surface for a full summer and winter. In the spring the rye and vetch have partly broken down through decomposition and only a light tool is needed for incorporation. The advantage of this system is the organic matter feeds the microorganisms where they are most active. The disadvantage is that there is no time for bare fallow period to decrease the weed pressure.

Labor

Labor is a very important consideration for scaling up your farm. Labor costs can quickly eat into gross sales on a vegetable farm of any size. Labor requires a whole new level of planning, financing, and communication. Yet, if you are scaling up your farm, you most likely will need to hire labor. It can be difficult to find labor and many farmers refrain from scaling up for this reason alone. Consider whether you enjoy working with people and feel like you have the management skills to take on employees. Check into your state’s labor laws before hiring anyone. If you intend on hiring labor, at the minimum you will need to pay workers compensation tax and the state’s minimum wage.

In a study about livelihoods of several different scales of market farms, the Center for Integrated Agricultural Systems found that vegetable farms over 12 acres often have crews of 10 or more people during the growing season. A 20-acre vegetable farm may require 12,500 or more total labor hours per year. The four large-scale organic operations in their study ranged from 462 to 613 total labor hours per acre and averaged 554. The farmers themselves accounted for between 17% and 45% of the total labor hours in these enterprises. Payroll expenses consumed between 19% and 41% of gross farm sales (average of 32%) (Hendrickson, 2005).

Apprentices vs. Hiring Farm Workers

Many farmers think that hiring apprentices or interns can help offset labor costs. This is often not the case. Apprentices and interns have less experience and take more time to train. Also, if you are hiring an apprentice or intern you are legally obligated to provide them with an educational experience. On the other hand, if you hire experienced farm workers, you may see your productivity go up. There also tend to be fewer interpersonal issues when you hire an employee versus an apprentice/ intern. Whether you are hiring farm workers or an apprentice or intern, it is important to take time to follow up on their credentials and make sure the employee is a right fit for your farm.

For help with planning labor, consult the ATTRA publication include Positive Practices in Farm Labor Management.

The University of Missouri publication titled Hiring and Managing Farm Labor provides helpful information on hiring, training, management, and legal considerations of employees.

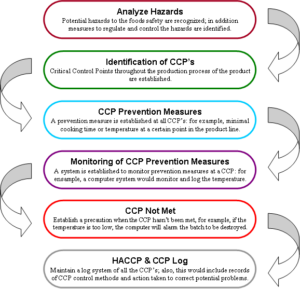

HACCP Seven Principles. Image: Josh Levy-Kramer, 2005, Creative Commons

Food-Safety Planning

The Food Safety Modernization Act (FSMA) is a national law that will require more stringent standards for small to mid-sized farms. Currently there is an exemption for small farmers, but if you sell to a grocery store or distributor, they may require that you follow the requirements of the FSMA.

GAP, HACCP, and Food Safety

It is important for a farm to be proactive about food safety. GAP stands for Good Agricultural Practices. It is a self-auditing process that farms can go through to insure that they are following basic food-safety protocols. Your farm can be audited independently or through the USDA Harmonized GAP program.

ATTRA has developed a great graphic publication on how to implement food-safety standards on your farm, An Illustrated Guide to Growing Safe Produce on Your Farm: Good Agricultural Practices.

Farms that practice on-farm processing, livestock farms, or farms that have a lot of post-harvest handling procedures (e.g., large-scale vegetable washing facilities) may need to go an extra step. HACCP stands for Hazard Analysis Critical Control Points. HACCP is an internationally recognized procedure that assesses the weak areas of your farm that may be cause for a food-safety concern. It is essentially an audit of your entire production and post-harvest handling systems. Once the weak areas are identified, then you can address them. For example if you identify an area on your farm where runoff from shelters for animals could come in contact with your vegetable fields, this would be considered a “critical control point.” Diverting the flow or moving the shelter would be an important action to remedy the situation. The following image illustrates the process of HACCP.

Marketing

Expanding your farm requires a well-thought-out marketing plan. It also requires product quality and consistency, especially for wholesale markets. It is important to consider whether or not you are able to produce a quality product consistently throughout the season. One of the best ways to make this determination is through excellent planning and record keeping. Also, it is very important to contact and secure marketing opportunities before investing in a farm expansion. This section will explore some common markets that growers pursue when expanding their farms.

Considerations for Selling Into Wholesale Markets

Excerpted from Wholesale Success by Family Farmed

- Buyers want larger quantities—many prefer pallets. Production should yield a consistent weekly supply.

- Producers must build relationships with wholesale buyers and stay in touch regularly to communicate issues such as timing, quantity, price, quality, etc.

- Field heat must be removed with proper cooling. The “cold chain” must be maintained from the field to the customer with refrigerated storage of most fruits and vegetables.

- Products must be sorted uniformly to match USDA grades. Food-safety procedures must be followed, including necessary recordkeeping.

Grocery Stores

Grocery stores vary widely in their volume and food-safety requirements. Independent grocery stores and food cooperatives can be more amenable to limited volume and lack of consistency. Larger chain grocery stores may have shelving fees and regional distribution models that might make it harder to break into supplying them. The best way to find out about grocery store requirements is to contact the produce manager.

See the ATTRA tipsheet Tips for Selling to Grocery Stores.

CSA

There are several very large farms that sell through a community supported agriculture (CSA) model. CSAs are complex in that you have to manage a lot of different crops as well as deal with your customers. It is important to have experience selling through a CSA before expanding to a larger scale. It is also important to consider your goals for expansion. Is your expansion goal to specialize and simplify the number and types of crops that you grow? If so, a CSA is probably not a good marketing option.

For more information, see the ATTRA tipsheet Tips for Selling through CSAs.

Restaurants

Selling to restaurants can be a great way to scale up the farm. This opportunity really depends on the restaurant and their purchasing volume, however. Some restaurants will want small quantities of very specialized products from farmers but buy larger quantity items from a wholesale distributor. Contact chefs that have expressed a desire to purchase local foods. Many local food organizations have events that connect producers with restaurant and other wholesale markets. Keep an eye out for these types of events locally.

For more information, see the ATTRA tipsheet Tips for Selling to Restaurants.

Schools and Other Institutional Buyers

Selling to institutions such as schools, hospitals, and government agencies can be a challenge because they often have tight budgets, are locked into contracts with certain distributors, and have limited cooking capacity. Recently, however, there has been growing interest on the part of hospitals and schools in sourcing local products. It is likely that food safety requirements will be greater in these settings, and producers will need higher liability insurance. If you intend to sell to institutions, it is also important to consider whether or not you are able to provide a consistent quantity and supply. Contact the food service manager at the institution you are interested in selling to, in order to find out their requirements.

For more information, see the ATTRA publication Tips for Selling to Institutional Markets.

Distributors

Produce distributors are businesses that aggregate product and resell it in small or large quantities to their customers. Distributors may range in size from an individual with a van to a company with a fleet of eighteen-wheelers. Distributors primarily purchase directly from farmers, although they may also buy from brokers or packing houses. Most distributors will expect producers to follow stringent food safety requirements and use an invoicing system.

For more information, see the ATTRA tipsheet Tips for Selling to Produce Distributors.

Aggregators and Food Hubs

If your operation is not quite large enough to reach wholesale volumes, you may need to aggregate your product with products from other growers. This can pose a challenge for product quality, consistency, and traceability. Aggregating can also have significant implications for food safety and marketing (Day-Farnsworth et al., 2009).

There are many innovations and solutions that have helped growers successfully aggregate their products to sell to larger markets. Food hubs coordinate the aggregation of products from multiple producers. Some food hubs can be Internet-based, or virtual. Others provide the physical infrastructure for packing and shipping quantities that most small-scale producers find difficult to manage on their own. In a study of scaling up to meet the demand for local foods at a wholesale level, researchers found the following innovations to be most successful:

-

-

- Pre-season planning among grower pools can help match supply to demand and give growers a better idea of what it costs to produce specific products.

- Buyers, growers, and distributors can collaboratively project product sales in advance of the season, and growers can plant according to these projections.

- Aggregators and distributors can provide buyers with product availability updates at least weekly during the growing season.

- Growers and entrepreneurs can pool their resources to improve their storage capacity, make transportation more efficient, and streamline logistics.

- Development of processing infrastructure can build markets for blemished produce that may not make the cut for fresh market sales but can serve as ingredients in processed foods (Day-Farnsworth et al., 2009).

-

For more information and models on aggregating, see the Good Food Network webinar on entering into an aggregation channel. Also see the ATTRA publications Food Hubs: A Producer Guide, and Tips for Selling to Aggregators/Grower Marketing Co-ops.

Not every marketing option is included in this section, but it includes markets that diversified growers typically access with the least risk.

For information on selling to wholesale distributors, terminal markets, packing houses, and produce brokers, see ATTRA’s tip sheets on these topics.

Insurance

As your farm size increases, so does your risk. For this reason, insurance becomes more important. This section discusses both crop and liability insurance and how expansion might affect your options.

Crop Insurance

The larger your farm, the more financial risk you take on. Two broad sources of financial risks for farmers are yield losses—caused by weather, pests, and diseases—and the often-high variability of the prices of crops and livestock. One way to prevent a significant loss in revenue is to buy crop insurance. Generally, the greater the diversity, or specialization, of the crops and livestock you grow, the more difficult it can be to obtain insurance that fully covers the value and risks of your production.

Fortunately, whole-farm revenue insurance is an alternative federally subsidized insurance option for highly diversified or specialty-crop farmers of varying scale. This insurance is called AGR-Lite, or Adjusted Gross Revenue insurance. It is currently only available in 38 states. Check this link for the states where it is available. Many diversified farms are resistant to purchasing insurance because they are intimidated by the process or they do not think it is worthwhile. Understanding whether AGR-Lite could be an option for your farm has been made easier by the development of an assessment tool called the AGR-Lite Wizard. This tool, developed with the support of USDA’s Risk Management Agency, allows you to check your eligibility for the product, lists the level-of-coverage choices available, estimates your premium cost, and estimates what payments you would receive if you sustained eligible losses.

Product Liability Insurance

Most grocery stores and distributors will require the producers they purchase from to have product liability insurance. Product liability insurance helps protect you should the food you produce cause harm to consumers. It also helps to protect consumers, should they get sick and have to shoulder large medical costs. It is wise, regardless of your market and farm size, to have product liability insurance, but wholesale markets may require additional coverage. Rates for product liability insurance vary by how much liability coverage you purchase and by your gross sales. Many stores and distributors will require a minimum amount of coverage—usually between $500,000 and $1 million.

The Drake University Agricultural Law Center has an extensive online toolbox that addresses many legal issues associated with direct marketing, including product liability insurance. It includes a series of check sheets and a forum to ask legal questions. Find The Legal Guide for Direct Farm Marketing here.

Conclusion

Scaling up can help you meet your farm goals and help reduce the complexity of your farm. If you decide to expand your farm, it is very important to consider how you will acquire land and equipment and manage labor. Consider the costs of these factors and how you intend to finance an expansion. Finally, before you plant that first seed, it is important to develop a marketing strategy.

Questions to ask yourself before you expand your farm

Think about the primary reasons why you want to expand your farm and what resources will be required to undergo an expansion. Use the spaces provided below to answer your questions.

What are your primary reasons for expanding the farm?

Re-visit your goals. Does this expansion align with your goals?

Will you need to purchase more land? If so, how much and how will this be financed?

Have you considered how you will sell your products once you expand? Write down your markets.

Scaling Up Your Vegetable Farm for Regional Markets

By Tammy Howard, NCAT Agriculture Specialist

Published June 2014

©NCAT

IP464

Slot 476

Version 061214

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development.

Related Publications

- Evaluating a Farming Enterprise

- Planning for Profit in Sustainable Farming

- Financing Your Farm: Guidance for Beginning Farmers

- Federal Working Lands Conservation Resources for Sustainable Farming and Ranching

- Tips for Farm Leases and Contracts: Creating Smart, Effective Documents

- Finding Land to Farm: Six Ways to Secure Farmland

- Positive Practices in Farm Labor Management

- Illustrated Guide to Growing Safe Produce on Your Farm: Good Agricultural Practices

- NCAT Marketing Tip Sheet Series

- Food Hubs: A Producer Guide