Meat Plants: Improving Profitability in Small and Very Small Operations

By Nick McCann, NCAT Agriculture Specialist

Abstract

Small and very small meat plants in the U.S. typically struggle with extensive overtime costs, high turnover, high stress, production overcapacity, a declining rural customer base, declining profitability, and an extensive need for capital investment. This publication highlights small changes that have been made at some meat plants to solve common problems and increase profit that don’t require significant capital expenditure. In addition to small, low-capital changes, this publication highlights a basic methodology that meat-plant managers can use to create their own solutions to individual plant problems.

Contents

Introduction

Basics

Rate and Margin

Key Opportunities in Meat-Plant Management

Conclusion

References

Further Resources

Introduction

Is your meat plant a high-stress environment? Is every day an emergency? Is overtime a fact of life? Do you have trouble keeping employees? Does your plant lack capacity, with only risky capital investment and expansion as viable alternatives for your business to address the issue? Such problems are common in small meat plants and have come to be accepted as normal by many owners and man- agers. This publication will discusses methods that have been used in small meat plants in the U.S. to identify excess capacity, reduce overtime, decrease employee turnover, and reduce the number of management “fires” that need to be put out. Readers will see that with small changes in scheduling, product mix, and how employees are used, it is possible to produce significant improvements in profitability. The first part of this publication will discuss the basic metrics for decision making. The second part will give a framework for managers to analyze and then improve their business’s performance. Finally, this publication will discuss some actions that have helped improve the profitability of small plants. While this publication does provide examples from real meat plants in the U.S., the point is not to give a set of answers for how every meat plant should work. Rather, it is to give a set of decision-making tools for managers to analyze their own situations and develop their own solutions to increase profitability.

Basics

“Show me how I will be measured, and I will show you how I will behave.” This familiar statement illustrates the important implications of measurement for capital-investment, prod- uct-mix, and employee-management decisions. Without proper measurement, key information used to make decisions in any of these areas can be misleading or arbitrary. As a first step, let’s answer a number of questions to outline a basic framework for making decisions.

What’s the Goal of Your Business?

Money may not be everything, but it is an important element of all businesses, small meat plants included. The goal of a business is to make money now without jeopardizing its ability to make money in the future. Simply put, actions that move the business in the direction of that goal are productive, and actions that don’t move the business in that direction are not.

It is greatly important, then, to define the measurements we need to determine whether we are moving toward our goal. These are our goal-oriented measurements (Goldratt and Cox, 1984):

- Net income. This is all the money left over after expenses.

- Return on investment. This is a relative measurement of income. For example, it might seem like a good thing to have a million-dollar income, but it’s not if you had to invest $1 trillion to make it.

- Cash flow. This is a two-sided measure of business success. If a business has a healthy cash flow, it is of secondary importance. But if you lack cash, on the other hand, it can be a disaster for your business.

These overall goal-oriented measurements are important, but they are not sufficiently connected to what’s happening on the meat-plant floor to be of use in day-to-day decision mak- ing. The following measurements can show the likely future impact of decisions or actions on the meat-plant floor in regard to net income, return on investments, and cash flow (Goldratt and Cox, 1984) (Goldratt and Fox, 1986):

- Throughput: Throughput is not production. It is the rate at which the business generates money through sales. Throughput can generally be calculated by subtracting unit-variable costs from sales. Unit-variable costs are costs that can be tied easily to each unit of production. However, unit-variable costs do not include labor in meat plants. For a locker processing a custom animal, the rate that money is generated through sales can be represented by this calculation: sales – (ingredients + offal removal + packaging). For an official animal, the rate can generally be represented this way: sales – (animal purchase + ingredients + offal removal + packaging).

- Inventory and investment: This is everything the system invests in to generate sales. Inventory generally includes money tied up in boxed meat, purchased live animals in pens (for inspected facilities), products waiting to be delivered or picked up by customers, products in retail coolers, and ingredients. Invest- ment will typically include money tied up in equipment and buildings.

• Operating expense: This is money the system spends turning inventory into throughput. Operating expenses typically include labor, utilities, and depreciation.

What Does This Mean for Decision-Making in My Small Meat Plant?

Consider this scenario: The owner/manager of a small custom meat plant in a rural area is thinking about buying a new sausage stuffer. This stuffer is nice. It stuffs faster with less labor, and it really impresses friends in the industry. The stuffer salesman has some impressive graphs and statistics on labor savings, savings in raw-material waste, and the payback period. Raw-material-waste savings are negligible, but there are huge savings in the labor category. However, the manager is still unsure about making the investment even with the impressive potential labor savings. How should the manager analyze the situation? Below is an example of how to look at throughput, inventory and investment, and operating expense to make a decision.

How Will the Decision Increase Throughput?

At this plant, the owner makes an especially delicious smoked product that is often in high demand from his custom-slaughter custom- ers. Because of this, many of the orders require smoking. Even though the new sausage stuffer would move faster, approximately half of the products out of the new stuffer would still go to the smokehouse. This would create a bottle- neck of orders waiting for the smokehouse. The customers often wait until the whole order is finished so they don’t have to make more than one trip to pick it up. The new stuffer would move much faster, but, because there would be a line of orders waiting for the smokehouse, the plant wouldn’t get orders out the door any quicker. That means throughput, the cash generated from sales, would not improve with a new stuffer. Remember, throughput is not throughput until you get paid.

How Will the Decision Decrease Inventory and Investment?

We can see that a faster sausage stuffer would not make the rest of the production process faster. It also would do nothing to decrease inventory because the orders would still be waiting for customers to pick them up. Additionally, payments on a loan for the stuffer would increase investment costs, thereby reducing cash flow, especially in light of the fact that through- put would not increase.

How Will the Decision Decrease Operating Expense?

The owner of this plant has no plans to let any- one go. The woman currently working the sausage stuffer is a part-time employee already, and she is often needed at the checkout counter of the plant, which doubles as a small-town grocery store. In effect, expenses will actually go up because of depreciation on the sausage stuffer. However, even if the manager could eliminate a full-time position or change an employee’s job to part time, would that be advisable? Think about the following questions:

- What is the likely future impact on employee behavior if new equipment replaces job positions or reduces them to part time?

- Would you get significant resistance from your employees for any business improvement because of the fear it would inspire more job cuts? Would that environment make your business money, or would it create more friction and problems in your plant?

- Will you find good employees who are willing to work part time?

- Would it be more likely that you would find part-time employees who have other priorities or are waiting for something better to come along?

These are all important questions for a meat- plant manager who thinks that new equipment and layoffs and/or lower wages are the answers to increasing profitability.

In the case of this plant, it was decided that a new sausage stuffer would not change throughput and probably wouldn’t change inventory, but it would surely increase investment and operating expense. This would serve to decrease return on investment and cash flow yet offer no increase in net income.

A typical sausage stuffer. Photo: Arion Thiboumery

In fact, a new stuffer, in this instance, would probably negatively affect net income as well as return on investment and cash flow. Because the goal of this owner was make more profit, the sausage stuffer was not purchased—despite the attractive graphs and payback-period information provided by the salesperson. The risk of spending money only to see negative effects on the bottom line became even more apparent in light of expected competition from a rebuilt plant nearby. Often, businesses measure their actions based on labor “savings” or greater “machine efficiency.” But do these measurements give you the information you need to make decisions? Ask yourself, How do I make decisions? Are my decisions getting me closer to my goal? Experience at small meat plants has shown that decisions increasing throughput—while simultaneously reducing or maintaining operating expenses and inventory and investment—will have positive effects on net income, return on investment, and cash flow.

Rate and Margin

However, having better measurements is only the first step in increasing business performance. There are ways to organize your plant’s produc- tion to promote even better performance. To begin to understand how to implement them, we first need to understand how the rate of pro- duction behaves. To illustrate this concept, let’s outline a hypothetical situation.

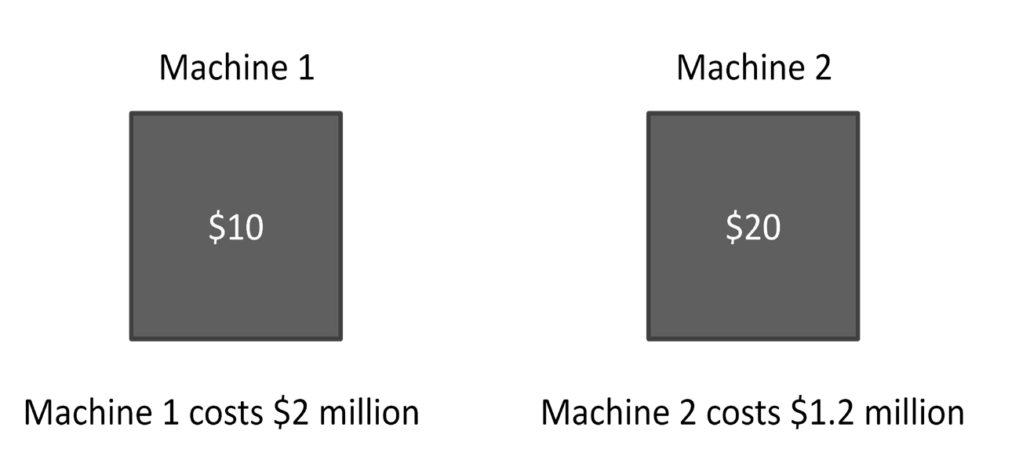

Figure 1: Two Money-Printing Machines

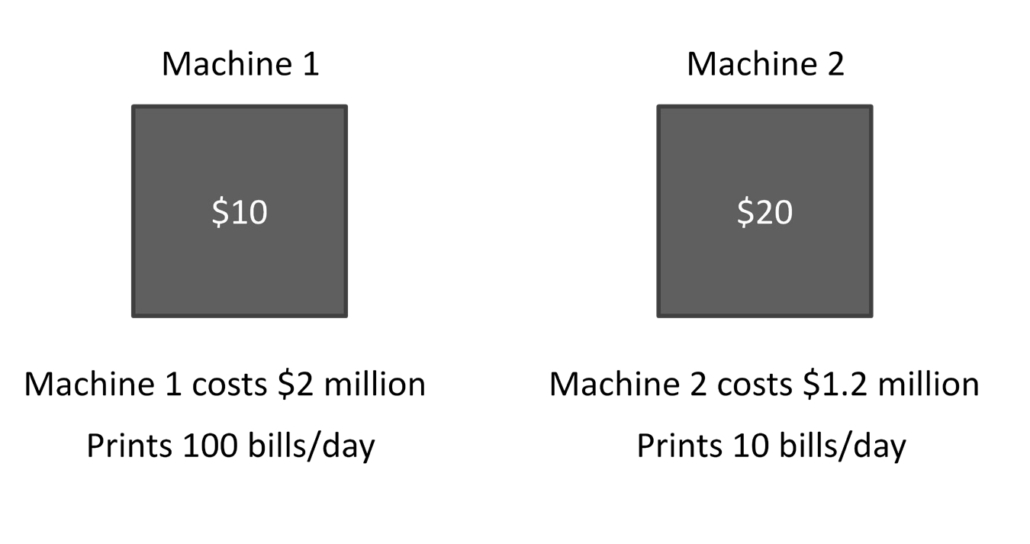

Figure 2: Two Money Printing Machines with Rate

The graphic above represents two money-printing machines. Machine 1 prints $10 bills and costs $2 million, while Machine 2 prints $20 bills and costs $1.2 million. At first glance, which machine looks more attractive? Machine 2 costs less, and it prints a bigger denomination per unit. Given that, it seems you’d have to be crazy to choose Machine 1. However, let’s add one more piece of information that really puts this choice in perspective:

Which machine would you choose now? Machine 1 might cost more and have a lower denomination, but it actually prints money faster. Machine 1 should now be looking much more attractive than Machine 2, despite its higher price. A meat plant has more than one station and machine, but, as we will discuss, no matter how large the plant and complicated the processes, decision making can be very simple.

How Can I Find the Rate at Which a Plant Operates?

The rate at which a plant operates is most often tied up in what is called the plant constraint.

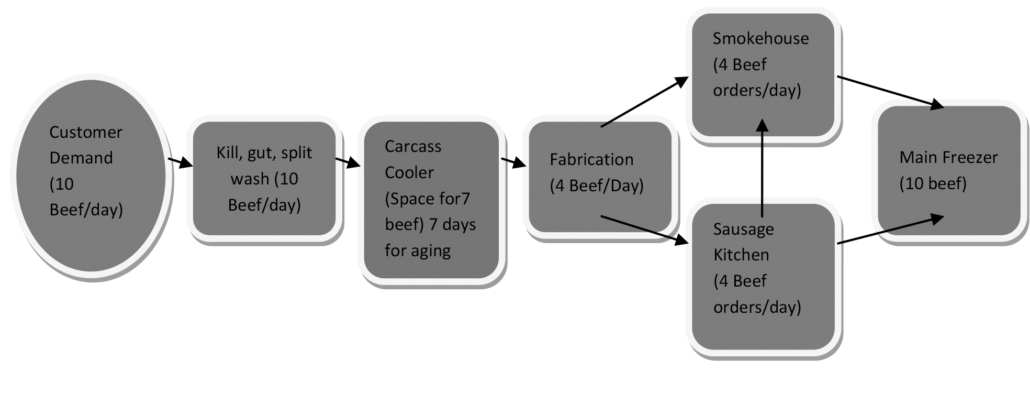

The plant constraint is simply this: anything that limits the plant’s ability to achieve more of its goal. A constraint could be an internal plant process such as your cutting table, or it could be market demand. Either way, the constraint in your system governs the amount of money that you make. Identifying and focusing on your plant’s constraint will help increase profits and general business performance. The graph below represents a simplified meat-plant process. This plant only kills beef and is used to illustrate the concept of a constraint.

Figure 3: A Generic Meat Plant Process

From Figure 3, we now can answer key questions about the plant’s ability to process beef:

- What is the constraint? The cooler. Why? The cooler can only accept and discharge one beef per day. In every other part of the plant, more than one beef can be processed per day. The cooler limits the amount of beef moving through the system.

- Should we buy a faster sausage stuffer for the sausage kitchen? No, any increase in capacity in the sausage kitchen would yield no improvement in the system. Remember, the cooler is already blocking the plant’s production ability. Improving the sausage stuffer would cost money with no improvement in profit.

- Should we buy a bigger smokehouse? No, any increase in smokehouse capacity would not yield an improvement in the system. Why? For the same reasons we wouldn’t buy a faster sausage stuffer.

- What is the maximum rate at which the plant can produce beef for sale? One beef per day. Why? That is the maximum rate at which the constraint can operate. The constraint governs the rate at which the plant can generate sales (throughput).

- When would the constraint become the customer demand? If the capacity of the cooler were expanded to be greater than customer demand for custom beef (more than 10 beef per day).

Beef hanging in a meat plant’s cooler. Photo: Arion Thiboumery

What Does This Mean for My Small Meat Plant?

The key is focus. Only by increasing processing capacity at your constraint will you improve the ability of your plant as a whole to process more (and thus make more money). Improvements in other areas will not increase profitability.

Improving throughput has a much bigger impact on the bottom line than cutting operating expense. Extension manufacturing professionals working with small meat plants found that improving throughput had roughly 2.7 times more positive impact on profitability than simple cost cutting (Willett, 2010).

The key to increasing throughput is to first find excess capacity and then capitalize on that excess capacity through increased sales. Business-pro- ductivity specialists Eli Goldratt and Jeff Cox outlined five focusing steps (1984) that can help you identify and capitalize on excess capacity in your plant:

- Identify the constraint(s)

- Exploit the constraint

- Subordinate the constraint

- Elevate the constraint

- If a constraint has been broken, repeat the process.

How Do I Identify the Constraint in My Meat Plant?

During the busy part of the year, ask yourself these questions:

- Where am I getting backed up?

- Where do my people need to work the most overtime?

- What process and/or policy, if I had the choice, could I change and thereby increase throughput?

The place or process that gives you the most headaches is generally a good point to start looking for your constraint. During the slow part of the year, it might be that you have excess capacity and the market is your constraint. Remember, the constraint is the limiting factor in your business, with respect to your goal. Ask yourself, “What is my limiting factor?”

How Do I Exploit the Constraint?

When you exploit the constraint, the aim is to maximize the throughput through this con- straint (and thus the system as a whole). Remember, throughput is not simply production; it is money in the bank. Because the constraint is the limiting factor in a meat plant, increasing the capacity of the constraint will increase through- put. One small custom U.S. meat plant has instituted a policy of keeping the cooler—the plant’s constraint—full during the busy season. When a beef is taken out of the cooler to be cut, another beef is harvested and put into the cooler. This means that the manager had to decide to begin slaughtering every day. However, even as the manager resolved to slaughter every day and keep the cooler full, there were still reservations:

- What happens when a customer is late?

- What happens when a customer doesn’t pick up an order?

- What about when an employee calls in sick?

One thing is for sure: something unexpected will happen. This plant outlined several solutions to cope with that inevitability:

- The plant kept a buffer of ready-to-slaughter animals in pens out behind the plant. Why? If a customer didn’t show up on time (or at all), the ready-to- slaughter animals were available. Even if an employee didn’t show up to do the slaughtering, the plant could rearrange the duties of other employees to keep the cooler full. The cooler (the constraint) was protected, despite the unreliability of customers and sick employees.

- The plant began delivering products for a fee and charging for late pickups. Why? Originally, there was a problem with the freezer filling up and stopping the production flow. A late-pick-up fee gave customers an incentive to pick up orders on time. Additionally, delivery has become a value-added service that some customers like, and it has helped to win more business.

- The plant lowered prices for retail sales during the slow season and increased advertising. Why? The owner had always thought of slow season as something that simply had to be dealt with. However, a better understanding of the plant’s system showed that the business could sell more exempt retail products through a sale. Even as it was charging less, the business made more profit by filling its excess capacity.

At first, the owner had thought the plant needed to make capital investments to expand capacity. However, she now realized that her plant actu- ally had excess capacity and could accept more business. This increased profit.

How Do I Subordinate the System to the Constraint?

When you subordinate the constraint, you set the pace of the system to match the pace of the constraint. The plant shouldn’t accept more animals than can realistically be processed by the constraint. For example, if two beef are coming out of the cooler, then only two beef can be accepted for slaughter and then moved into the cooler. Accepting more animals would just expand the production queue.

Special note. It is possible that some employees might be standing around idle some of the time. If the process isn’t the constraint, this is OK. If the process is the constraint, then you should work hard to make sure that this doesn’t happen. Remember, making all your people work 100% of the time doesn’t necessarily make you more money.

How Do I Elevate the Constraint?

Elevation of the constraint comes after you have fully exploited the constraint and subordinated the system to the constraint. Elevation usually requires that you increase the capacity of the constraint to generate throughput. Additionally, elevating the constraint in a meat plant can mean investing capital. If you know the limiting factor that governs the productivity of your plant, you also know where to focus investment in increased capacity. Remember that in our example meat plant, only an investment in the cooler would yield increased profitability.

If a Constraint Has Been Broken, Repeat the Process

If, through the preceding steps, you have been able to “break” a constraint—to overcome it so it is no longer the limiting factor in your process—a new constraint will form, and the analysis process must be repeated to find it.

Key Opportunities in Meat-Plant Management

Experience at small custom exempt and inspected meat plants has identified four related strategies, based on common constraints in the industry, that the plants have successfully used to improve their profitability.

Scheduling: Slaughter Every Day

This serves to smooth the flow through the plant and decrease the amount of overtime that you and your employees need to work. For plants with only official slaughter, it might not be feasible to slaughter every day because an inspector might not be present. However, if you have both custom and official slaughter, it is still possible to slaughter every day by timing official slaughter according to your inspector’s visits and filling extra slaughter slots with custom animals. Slaughtering only on certain days shocks your system, creates panic, and racks up overtime. Slaughter every day to spread the work out. Ask yourself, why do I slaughter only on certain days of the week? What do I need to do to slaughter every day?

Employee Placement: Keep It Stable

Are you constantly moving people around to put out management “fires” in your plant? Do you find that after you have solved one problem, another problem emerges? Do you then move people over to solve the next problem, with the cycle continuing itself? Keep your people focused on their jobs. Moving them around to cope with problems just makes the overall struggles bigger.

Product Mix: Should I Choose Beef, Hogs, Goats, Deer, or Poultry?

As our money-machine example showed, both rate and margin are important in making decisions. The same principle applies when you’re deciding whether to emphasize beef, hogs, goats, or chickens in your meat plant. One plant in Iowa can process hogs six times faster than beef. If this is true, beef must generate six times more profit per unit than hogs in order to be equal in profitability. Product mix, then, is an important part of increasing throughput to generate higher profits. Many plants hang beef for seven to 14 days, while hogs, deer, or goats require much less or even no time in the carcass cooler. Additionally, most small-plant managers generally find that hogs and deer are easier to fabricate. Think about getting more hogs or small ruminants into your plant to make more money. Think about which animals allow you to get paid faster. Should you be emphasizing one species over another?

Delivery: Consider It a Value-Added Opportunity to Increase Sales

One small custom plant in the U.S. was suffering from low sales and a declining population in the county where it’s located. In order to stimulate demand for the plant’s services, the owner began offering delivery of custom meat for a fee to friends and family locally and in regional cities. This was a value-added service that solved the problem of declining sales due to declining population because it opened another avenue for selling meat. Farmers found out about the service, and now sales have increased.

Conclusion

There are often significant opportunities to improve your business with little or no capital investment. Slaughtering every day, keeping employee placement stable, and adjusting the product mix are all changes that a plant man- ager has the power to influence. The results can be tremendous. One processor has improved her profit by at least 93% simply by deciding to slaughter every day, adding delivery to her sales strategy, and keeping her employees focused. She did all of this without significant capital investment. Ask yourself, “Is this possible for my meat plant?”

References

Goldratt, Eliyahu and Jeff Cox. 1984. The Goal: Excellence in Manufacturing. North River Press, Great Barrington, MA.

Goldratt, Eliyahu and Robert E. Fox. 1986. The Race. North River Press, Great Barrington, MA.

Willet, Michael. 2010. Successes and Opportunities in Process Management. Iowa Meat Packers Association Annual Conference, Ames, IA.

Further Resources

The Goal: Excellence in Manufacturing. 1984. Eliyahu Goldratt and Jeff Cox. North River Press, Great Barrington, MA.

The Race. 1986. Eliyahu Goldratt, and Robert Fox. North River Press, Great Barrington, MA.

Meat Plants: Improving Profitability in Small and Very Small Operations

By Nick McCann

NCAT Agriculture Marketing Specialist

Published March 2011

© NCAT

IP 385

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development. ATTRA.NCAT.ORG.