High Tunnels in Urban Agriculture

By Chris Lent, NCAT Agriculture Specialist

Abstract

This publication identifies the unique benefits of high tunnels to urban farmers. It covers the basics of siting and constructing a high tunnel, as well as some of the policy and zoning challenges urban growers face when planning to erect a tunnel. It also discusses high tunnel management, including soil fertility, irrigation, and disease and pest control. Finally, it includes resources on intensive crop production and other uses for high tunnels.

Contents

Introduction

High Tunnel Benefits for the Urban Grower

Installing a High Tunnel in the City

Urban High Tunnel Management

Conclusion

Case Study: Elijah’s Promise

References

Further Resources

Introduction

High tunnels have been helping farmers manage risks and increase profits for a long time. Now urban growers are using these simple structures to help them achieve these same goals, while facing unique challenges associated with urban farming. Tunnels are being used on rural and urban farms in many different ways, but they can offer special advantages and can be more profitable if they are being used close to densely populated urban and peri-urban areas (Butler and Bauer, 2013).

High tunnels, also referred to as hoop houses, are low cost, usually unheated, metal-tube structures covered with one or two layers of greenhouse plastic to create a protected environment for crops. High tunnel end walls are usually wood framing covered by plastic or plywood. The side walls are often designed to roll up or down with a simple hand or electric crank to help ventilate the tunnel for temperature and humidity control. The added layer of protection created by these structures, when installed correctly and managed well, can expand the growing season into the winter and allow for early harvests in the spring. When temperatures fall below freezing at night, the minimum temperature in a high tunnel can be 6° higher than outside, and if low tunnels are used over the growing beds inside a high tunnel, 9° can be gained (Wien, 2006). High tunnels can add at least four weeks to the beginning and end of the normal growing season, giving the urban grower a hand up in expanding and extending markets, growing more variety, and adding resilience to the farm.

High tunnels extend the season by protecting crops from harsh field conditions caused by wind, rain, and frost, and also can protect crops from pests and diseases that affect outside field crops. But unique conditions are created inside a high tunnel, which can lead to specific soil-fertility problems along with specific pests and disease problems (Blomgren et al., 2007). Because of this, high tunnels require an extra degree of management to ensure a quality crop and good production rates.

High Tunnel Benefits for the Urban Grower

Markets

One of the biggest benefits of growing in high tunnels for the commercial urban farmer is the opportunity to increase profitability. The favorable growing conditions inside a tunnel can increase the quality of the crop and overall crop production, so high tunnel growers have more potential to increase sales at a good price for their product.

Like most economic decisions on an urban farm, investing in a high tunnel should be looked at in terms of the markets that are available. If there is a winter farmers market nearby that does good business, a high tunnel for winter growing can be a profitable option. Tomatoes have been shown to be the most profitable warm weather crop to grow in high tunnels, but if there is no market for the fruit, production and quality won’t matter. If you are just considering getting into high tunnel production on your farm, you should look at the types of markets you can access and form a marketing plan to sell what you will grow before you build and plant into a high tunnel. For more information on developing a marketing plan, you can access the Marketing section of ATTRA’s Scaling Up for Regional Markets tutorial.

Markets are the biggest driver of whether a high tunnel can increase the profits of a farm. It’s in this regard that the urban or peri-urban farmer has a distinct advantage. Being in close proximity to larger populations of people can be a help in developing markets. Rural growers often choose to drive their crops to urban markets to get a better price and to sell more. Urban farmers are already near larger market bases, so although developing markets can still be a challenge for the urban farmer, she can save money on transport infrastructure and fuel. Urban farmers can look for niche markets by selling to ethnic communities that want a particular type of food. Another good marketing option for urban growers is restaurants with chefs who are working on a farm to table menu and want to buy from local producers. Building a relationship and trust with a restaurant, or any other market, is important, and having a consistent supply of products year round can be of great help. If buyers experience variations in supply from a local farmer, they have to turn to other suppliers. A high tunnel can be perfect for growing quality specialty crops in an intensive manner to supply these types of markets for a larger part of the year.

Efficient Use of Space

Most high tunnel growers try to make efficient use of their valuable, protected growing space. Urban growers usually use intensive planting methods with close plant spacing and quick crop succession to get the most out of the available space. The profitability and success of an urban farm depends on the efficient use of space. The relatively valuable protected space inside high tunnels lends itself to the efficiencies of intensive growing methods.

Quick-growing crops like salad greens and radishes can be grown in rapid succession, and as soon as a crop is harvested, another can often be planted in the same bed, perhaps that same day. Crop planning is the key to being able to take full advantage of succession planting. Commercial urban farmers use tools like spreadsheets for crop planning. This allows them to think through each crop planting date throughout the growing season and create a plan that acts as a planting guide for that year. A crop plan should include planting dates, crop type, location, and amount of row or bed feet to be planted. Once a detailed plan for each crop is complete, it can be used to develop a planting schedule, a transplant schedule, a greenhouse seeding schedule, and even a comprehensive seed order.

Because of the extended growing season inside a tunnel, more successions of cash crops can be added to a crop plan. This, coupled with the ability to work in the tunnel when weather would not permit outside work, makes the growing space in the tunnel even more valuable and productive.

Growing beds and the walking aisle in a high tunnel should be sized to fit the needs of the farmer and the crop being grown. Wider beds can increase the square footage of growing space, but may be harder to plant, weed, and harvest. Aisles can be narrowed to increase growing space, but again, work in the tunnel can be less efficient if there is not enough aisle space. Some high tunnel growers use aisles as narrow as 12 inches, but most growers find that size restrictive. Thirty-inch beds with 18-inch aisles seem to work well for many growers. At this size, the beds can be straddled easily and there is space enough to walk—and for tools and harvest containers—in the aisles. Each grower has to settle on what is the right size and layout of beds for her tunnel and cropping system. One word of caution about intensive planting in high tunnels is that plant spacing that is too close can limit air flow around plants and lead to increases in foliar disease. This is especially true in the humid growing conditions of a high tunnel, and some growers who have had disease issues in their tunnels have decided to increase plant spacing.

Soil Protection

Soil contamination is a concern for growing food in urban areas. Heavy metals like lead, arsenic, and cadmium are frequently found to have accumulated in urban soils, depending on the types of industry nearby and past use of a plot of land. Airborne contaminants blown in by the wind can contaminate or increase contamination levels in the soil where they land (Wuana and Okieimen, 2011). Urban growers often go to great trouble to remediate contaminated soils and use best practices to mitigate the risk of growing food in these soils. High tunnels can help protect urban soils from being contaminated by windblown soil particles that are bonded with heavy metals. The tunnels can also act as a barrier to Polycyclic Aromatic Hydrocarbons (PAHs), which are organic compounds formed under high heat or high pressure conditions (such as during the combustion of carbon fuels) and other airborne contaminants. In addition to creating excellent growing conditions for a cash crop, high tunnels can also help urban growers who are concerned about recontamination of their soils, and this adds another layer of increased risk management and another benefit to urban growers who use high tunnels. For more on soil contamination in urban soils, see the Urban Agriculture section of the ATTRA website.

“[High tunnels] offer a different component to traditional urban form. By witnessing the unique (to urban dwellers) appearance, community members and visitors will be curious about what happens inside. If the tunnels are integrated into other urban agricultural efforts, the hoop house becomes a symbol of community growing efforts” (Rutgers University, 2012).

Building Community

High tunnels on an urban farm can help build community and markets for the farm. The structure itself can attract attention in an urban setting. The process of constructing a tunnel is made easier with many hands, and this can bring people together and start to build community around the structure. Once installed, the structure can be a focal point of an urban farm and can be used to promote the farm’s ability to grow food for a larger part of the year. It offers a place for people to gather during farm tours and other special events. Many people love the perpetual spring conditions created by a high tunnel, and that can make an impression on a cold late-fall day. Urban growers who incorporate high tunnel production into their operation can use the structures to help grow loyalty to their farm from the surrounding community. Having a high tunnel can differentiate a farm from other urban growing efforts and highlight the legitimacy of the farm to the local community.

Installing a High Tunnel in the City

Siting

Choosing and properly preparing a site to install a high tunnel are some of the most important factors in how well the high tunnel will perform for years to come. Most urban farms have a limited amount of space and workable soil. Although intensive high tunnel growing methods will make the most use of limited space, the lack of land base on urban farms can make it hard to find an ideal place to install a tunnel. A level (less than 5% grade), well-drained, fertile soil is preferred for high tunnel production. Soil can be prepared after the high tunnel is installed, but starting with deep, well-drained, fertile soil will make the process easier during the first year.

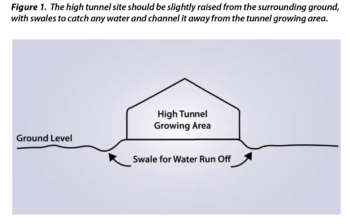

If the site is not well drained, it’s important to elevate the area of the tunnel slightly from the surrounding ground. This can be done with small excavating equipment or by hand if the area of the high tunnel is small enough. Soil can be taken from outside the perimeter of the high tunnel and placed where the interior of the high tunnel will be. This will create a small swale along the sides of the tunnel and a slightly raised plateau in the area that the high tunnel will cover. (See Figure 1.)

Another consideration for installing a high tunnel on an urban farm is shading. High tunnels are usually unheated structures that rely on the sun and solar heat gain to raise daily temperatures and allow for growing crops for an extended season. For that reason, it is imperative that a high tunnel is not shaded by other structures, buildings, or trees for the majority of the day. This is especially important if fall, winter, and spring growing will be a focus for your farm. A good rule of thumb is that if, at a minimum, the area is completely unshaded from 9:00 am until 3:00 pm year-round, the site will probably work well. If there is a question as to the level of shading at a certain site, it may be a good idea to have a solar site evaluation. Solar panel installers can conduct these evaluations using a Solar Pathfinder tool to determine the shading of a particular area.

Orientation

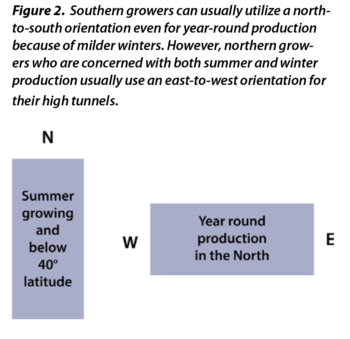

The orientation of a high tunnel refers to the direction the length of the tunnel runs. Most high tunnels that are installed to grow summer crops are oriented north-to-south to limit shading from bed to bed inside the high tunnel, and to allow for airflow from a predominately west wind when the sides of the high tunnel are rolled up. North of 40° latitude, an east-to-west orientation is preferred for cool-season growing, because it exposes a larger area of the high tunnel (the long southern-facing side) to the sun. This south-facing side of the high tunnel then acts as a big solar collector and allows the high tunnel to gain heat more quickly. (See Figure 2.)

Construction

It is not the purpose of this publication to describe the entire construction process of a high tunnel. In fact, the details of constructing a high tunnel will vary for different styles and brands of high tunnels. What is important is to choose a type and size of high tunnel that fits your operation and location and to choose a high tunnel company that offers good support to help you during the installation.

A Gothic tunnel with roll-down sides to protect plants from the wind. Photo: Chris Lent, NCAT

High tunnels come in two basic styles: Gothic and Quonset. These names refer to a difference in the shape of the high tunnel. A Gothic tunnel comes to a peak at the top with a slope down to a straight side. The Gothic shape is known to shed snow well and is popular in northern regions. The Quonset tunnel is shaped like a simple semi-circle, ending either at the ground or at the top of a straight side.

Level ground helps make high tunnel construction easier. However, since tunnels follow the slope of the ground, they can be installed on ground that has up to a 5% grade. It is important to have level ground from corner to corner across the end walls. This not only makes end-wall construction easier, but increases the strength and stability of the structure.

The logistics of setting up a tunnel on an urban farm can be challenging. The high tunnel components are usually delivered on a small flatbed truck. The pieces are not conducive to packing on pallets, so unloading the truck is usually done by hand. Have a good plan as to where you will place the components. If you don’t have the room to spread them out, stack the pieces with the components that you will need last in the construction on the bottom. Stack in reverse order, with the ground stakes, which you will need in the first part of construction, on top. If you don’t plan to build right away, the components should be out of the way of the farm’s day-to-day operations, but they should be located close to the final tunnel location for construction efficiency. Don’t store them inside the area where the tunnel will be, because you will only have to move them again when construction begins.

For more information on choosing the right type and size of high tunnel for your operation, see the Further Resources section of this publication.

Policy and Zoning

The policies, or lack thereof, concerning agricultural practices in your town or city and the zoning laws in your area will impact your ability to construct a high tunnel. High tunnels are not attached to a foundation and are usually considered non-permanent structures that could be moved, unlike typical greenhouse structures. This can be beneficial to urban growers who are leasing land, as there is flexibility in moving the high tunnel. In addition, because the structures are not considered permanent, it may be simpler to obtain a building permit, or a permit may not be needed at all.

Zoning codes for what urban agriculture practices are allowed vary from town to town and city to city. A first step is to visit your city’s or municipality’s website for information on zoning and permitting. There you can usually find zoning maps and determine whether your town has specific permitting procedures for agricultural structures. Even if your property is zoned for agricultural use, a permit to build a high tunnel on the property may still be required. Usually a variance or building permit is needed from the city planning board, the department of planning and development, or similar body in your town, to place a high tunnel on the land. Knowing the zoning code as it pertains to urban agriculture can also help you decide where to look for ground in your city if you don’t already have a property. When selecting land to farm, review the zoning code of the city in order to determine if the land is zoned for agricultural use, and if the zoning allows for the construction of a high tunnel.

For more information on zoning and policy issues related to urban agriculture, see the Further Resources section and the case study at the end of this publication.

Urban High Tunnel Management

Soil Fertility

The unique conditions created in a high tunnel can increase crop production and crop quality. These conditions can also affect soil fertility and health. First, the soils inside a high tunnel are dependent on irrigation water for all moisture, creating an irrigated, desert-like condition. In this system, water is constantly moving up and evaporating instead of being flushed downward by rain as in open field conditions. This evaporation can transport nutrient salts to the soil surface and cause salt buildup in the root zone, which can affect the growth of the crop (Hoskins, 2010).

Secondly, crops are usually grown intensively in a commercial high tunnel, which can put extra demands on soil fertility. Crops also grow more quickly in the higher average daily temperature, causing the plants to use nutrients more quickly. For these reasons, fertility of the soil needs to be monitored closely in a high tunnel. This is done by testing for major nutrients and micronutrients, nitrogen, soluble salts, and soil organic matter more frequently than in field production. It is not unusual for growers who use their tunnels for both winter and summer production to perform soil tests at least twice a year. If there is a specific nutrient deficiency or other problem that the grower is trying to fix, testing can be more frequent. Foliar testing to determine the nutrient uptake in the crop itself is also common for high tunnel growers who want to manage soil fertility closely. The idea is to not over-apply nutrients while supplying the crop with what it needs to produce a good harvest.

A standard soil test that measures the pH of the soil and levels of major nutrients is useful at first to bring major nutrients to optimum levels and into balance. Once a high tunnel is in production, however, it is useful to start testing for micronutrients and soil organic matter (SOM) levels, as well. These are additional measures with additional testing costs. After the first few years of production, additional soil testing for soluble salts levels is advisable, especially if manure-based compost is being added to the soil. High tunnel growers are starting to use a Saturated Media Extraction (SME) test to get a better idea of what nutrients are available for the crop. This test always includes a salt test and can help a grower hone an appropriate fertility plan for high tunnel crops. The University of Maine soil testing lab offers a high tunnel soil test package that uses the SME test. To learn more about this test and other soil testing labs that offer alternative soil testing, see the Further Resources section.

“With their intense management and heavy crop nutrient use, high tunnel production systems deplete soil organic matter more quickly than traditional field production systems.” (Naeve, 2010)

Another challenge in urban high tunnel production can be maintaining high levels of soil organic matter (SOM). The warm, moist conditions in a high tunnel, along with the higher temperatures in an urban setting, can cause increased biological activity in the soil. This can quicken mineralization, or the cycling of nutrients in SOM to plant-available forms. SOM impacts soil fertility by providing materials for soil microorganisms to break down into plant nutrients, and by providing surface area in the soil for nutrients to be stored until plants need them. It also adds to the tilth of the soil and helps with air and water infiltration, as well as increases the water holding capacity of the soil (Moebius-Clune et al., 2016). To increase organic matter, high tunnel growers can add compost to the soil. Vegetative-based compost (grass, leaves, and vegetable matter) is a better soil amendment for high tunnels because animal-manure composts can increase the likelihood of soluble salt buildup in the soil. This may not even be an issue, as most compost made in an urban setting is vegetative-based compost. When salts do build up, high tunnel growers will usually remove the plastic and let rainwater naturally flush the soil. Another good amendment to increase permanent organic matter in high tunnel soils is peat moss. Generally, organic growers try to reach or exceed 4% organic-matter content in their soils.

Irrigation

Because high tunnel soils are heavily irrigated, any problems with the water source can become exaggerated in the soil. Elements in the water supply can accumulate quickly in high tunnel soils, so managing the watering system becomes very important. High or low water pH or an excess of major nutrients or micronutrients, as well as contaminants, are all possible water problems. These are usually not issues if water is supplied by a municipal potable water source, but it would still be a good idea to monitor your irrigation-water supply with a test once a year for possible problems.

Farmer Highlight

Farmers in a drought-stricken section of Texas use landscape fabric over the soil in their high tunnels, with drip tape emitters only at each plant. The ground cover reduces evaporative water loss, and the strategically placed emitters allow for a very economical use of irrigation water. The d’Agrellas of PEAS Farm outside of the city of Conroe, Texas, use an average of five gallons of water a day in their 20-foot by 40-foot high tunnel that they purchased with the help of NRCS (Moseley, 2013). Other urban growers using the same setup would save on water costs and help stretch their water supplies if they are relying on water-collection systems for irrigation water.

Drip irrigation is a good option for urban high tunnel producers because it can reduce the amount of water needed and save money on the water bill. Drip irrigation also keeps crop foliage drier, helping growers avoid foliar diseases, which can be a problem in the high-humidity growing conditions of a high tunnel. Fertigation is the technique of fertilizing crops through an irrigation system. It is common for high tunnel growers to use fertigation to provide plant nutrients, and the fertigation systems are overwhelmingly designed to be used with drip irrigation. Drip irrigation tape can be installed under plastic mulch. Plastic mulch is often used to warm the soil and provide weed control in warm-weather high tunnel crops like tomatoes and cucumbers.

However, as effective as drip irrigation is, overhead irrigation can have its place in high tunnel production. Overhead watering is useful for germinating direct-seeded crops or for watering broadcast-seeded cover crops. Additionally, overhead systems that hang from the high tunnel crossties are easy to drain for freeze protection during winter production. Ideally, both types of irrigation systems can be installed, but this depends on farmer preference and budget considerations.

High Tunnel Water Collection

Some high tunnel manufacturers off er substantial gutter systems to collect water for irrigation. Photo: Chris Lent, NCAT

Rainwater runoff can be a concern in an urban setting. Stormwater is collected and concentrated on impermeable surfaces and can wash sediment and contaminants into local watersheds. By creating healthy, functioning soils, urban farms can help reduce this runoff. High tunnels can concentrate a lot of rainwater and should be designed as mentioned above to handle that water. Rainwater-collection systems can be used to capture the precipitation that falls on the high tunnel and use it for irrigation purposes on the farm. A simple gutter system can be installed on any high tunnel, using parts available from home-supply centers. Some high tunnel manufacturers sell gutters for their high tunnels. Either way, the water can be collected into a large tank and pumped into the irrigation system when needed. Iowa State University developed an excellent manual and accompanying video describing how to install water-collection systems.

Urban High Tunnel Pests and Diseases

Some of the unique conditions created in an urban setting can contribute to specific pest and disease problems for urban growers. For example, the fragmented habitats of insects in cities and towns can be more conducive to crop pests than to beneficial insects (Hunter, 2002), making biological pest control more difficult. Soft-bodied insects like aphids, thrips, and mites (common high tunnel pests) are able to move around and sample fragmented food sources more readily than hard-bodied insects (most beneficial insects are hard bodied). Fragmented habitat can make it hard to maintain beneficial insect populations, so pest populations that would normally be controlled by beneficial insects can expand quickly to feed on crops and spread disease.

The heat-island effect is a well-known occurrence in urban areas, in which lack of vegetation, a prevalence of heat-holding materials like concrete, and operation of motors and electronics can raise temperatures almost 10° above rural areas in the same region. Consequently, diseases and pests that prefer warmer temperatures can be more prominent on urban farms. High tunnel temperatures are higher than outside temperatures by an average of 7° to 10°, increasing the likelihood inside these structures of diseases and pests that like warm temperatures. Humidity levels are higher inside the tunnel as well, creating good conditions for pests and diseases that like warm, moist conditions. The warmer urban conditions also make it more likely that pests will overwinter in an urban high tunnel when they might not survive in a rural setting. However, one advantage of this warming effect in urban areas is that it can extend the growing season for cash crops. It also allows the urban grower to grow insectary crops for a longer part of the year, to attract beneficial insects.

Diseases and pests can quickly get out of control and beyond the point of effective intervention in any setting. However, the net result of fragmented habitat and the heat-island effect on urban high tunnel production is more frequent infestations that grow rapidly. Effective control of high tunnel pests always starts with scouting and properly assessing the type and amount of pests or diseases that might be taking hold in the crop. For urban high tunnel production, the thresholds for action should be lowered and as soon as a pest is identified, steps should be taken to control it. Physical barriers, humidity and temperature controls, hand picking, diverse cover cropping, beneficial insects and other biological controls, fertility management, planting of insectary crops, trap cropping, and pesticides are all tools that are available to help with pest and disease control. The first and most important step is properly identifying the problem. There are resources listed in the Further Resources section on how to scout for and identify common high tunnel pests and diseases, as well as the interventions that can best protect crops from damage.

Conclusion

Urban growers face unique production and marketing challenges, such as limited land base and consistent quality production. High tunnels can be a good way to help overcome some of those challenges. Extra time and labor go into managing high tunnels, but this is usually outweighed by the increases in crop quality and production amounts, and the ability for year-round production. These attributes can help any farm business, but urban growers can especially benefit from them because of their proximity to population bases and possible market outlets.

Case Study: Elijah’s Promise

The following case study follows a New Brunswick Community Gardening Coalition (NBCGC) project called Elijah’s Promise and its attempt to build a high tunnel in New Brunswick, New Jersey. It is an example of some of the complications that can occur with erecting a high tunnel in an urban setting. At the time of this case description, the city of New Brunswick did not have zoning codes specific to urban agriculture purposes. When no codes exist, a use variance is usually required by the city, and that can slow down and complicate a project.

Used by permission from Kathe Newman

Associate Professor of Urban Planning and Director, Ralph W. Voorhees Center for Civic Engagement, Edward J. Bloustein School of Planning and Public Policy

Rutgers University

33 Livingston Avenue

New Brunswick, NJ 08901

848-932-2799

knewman@rutgers.edu

The process of identifying a suitable lot to construct a high tunnel for Elijah’s Promise began during the Fall 2011 Community Development Food Studio. Vacant spaces in downtown New Brunswick were considered based on their physical characteristics such as size, slope and proximity to existing urban growing operations. The vacant lot at 15 Nielson Street, across from Elijah’s Promise’s Shiloh Community Garden, was deemed physically suitable for the installation of up to ten 18′ by 40′ high tunnels. Following the research completed by the Fall 2011 Studio, the Spring 2012 Studio began its efforts by exploring the regulatory and logistical steps required to construct a high tunnel system at 15 Nielson Street.

Our first step was to correspond with the City of New Brunswick Department of Planning and Development. We learned that Elijah’s Promise would be required to apply for site plan approval to construct a high tunnel on any privately owned lot in New Brunswick. Furthermore, we learned that because agriculture is not a principal permitted use in the City’s R-6 Multifamily District a “use variance” would be required from the Zoning Board of Adjustment. Application forms for site plans and variances are available at the city’s website. In reviewing these forms we learned that variance applications typically require the participation of professional consultants, such as land surveyors, engineers, architects, planners and attorneys. While many New Brunswick officials support Elijah’s Promise’s multifaceted efforts to improve the quality of life for local residents, the current site plan and variance application processes are not suited for constructing a high tunnel as a principal lot structure. If the City Zoning Code identified greenhouses as a permitted principal use, then Elijah’s Promise could submit a site plan application that met the bulk planning requirements for structure setback, size, height, etc. and not require a “use variance.” Submitting a site plan application that does not require variances can significantly limit the need for professional consultants and subsequently reduce costs associated with the application process. It should be noted that all site plan applications and construction permits require escrow fees to cover the cost of planning and construction review.

Our correspondence with Planning and Development also revealed the importance of ownership and Indemnification. Applicants seeking planning approvals and construction permits must illustrate that they are applying for site improvements as the property owner or on behalf of the property owner. The lot at 15 Nielson Street is owned by The Community Builders. If Elijah’s Promise decides to contract with professional consultants and apply for a “use variance” to construct a high tunnel at 15 Nielson Street, Elijah’s Promise will need to enter into an agreement with The Community Builders. This form of agreement typically identifies the responsible party for maintaining and operating the property, the extent of liability for each party, and the length of agreement.

In light of the challenges associated with constructing a high tunnel at 15 Nielson Street we met with Elijah’s Promise to revisit the objective and consider other locations. As mentioned above, the New Brunswick Zoning Code permits the construction of greenhouses as an accessory use in the City’s residential and commercial districts. But while installing a high tunnel over the existing raised beds at Shiloh Community Garden could significantly ease the approval and permitting process, we believe this falls short of the goal to expand urban agriculture in New Brunswick. The Fall 2011 survey of growing and growable sites also identified the lot of the New Brunswick Community Farmers Market as physically suitable for adding additional growing space. The property is owned by Rutgers University and therefore it is exempt from city approvals. (Rutgers University, 2012)

References

Blomgren, Ted, Tracy Frisch, and Steve Moore. 2007. High Tunnels: Using Low-Cost Technology to Increase Yields, Improve Quality and Extend the Season. Regional Farm and Food Project and Cornell University. University of Vermont Center for Sustainable Agriculture.

Butler, Bryan, and Lisa Bauer. 2013. High Tunnel Production: The Basics for Success and Three Case Studies on Profitability. University of Maryland Extension Factsheet FS-957.

Hoskins, Bruce. 2010. Managing Soils in High Tunnels Session. Farmer to Farmer Conference. Northport, Maine.

Hunter, Mark D. 2002. Landscape structure, habitat fragmentation, and the ecology of insects. Agricultural and Forest Entomology. Vol. 4. p. 159-166.

Moebius-Clune, B.N., D.J. Moebius-Clune, B.K. Gugino, O.J. Idowu, R.R. Schindelbeck, A.J. Ristow, H.M. van Es, J.E. Thies, H. A. Shayler, M. B. McBride, D.W. Wolfe, and G.S. Abawi. 2016. Comprehensive Assessment of Soil Health The Cornell Framework Manual, Edition 3.1. Cornell University, Geneva, NY.

Moseley, Beverly. 2013. Texas high tunnels boost production possibilities for urban farmers. NRCS, Texas.

Iowa High Tunnel Fruit and Vegetable Production Manual. Naeve, Linda. 2010. Iowa State University Extension, Ames, IA.

Rutgers University Edward J. Bloustein School of Planning and Public Policy. 2012. High Tunnels in New Brunswick: Community Food Security and Economic Development.

Wien, H. C. 2006. Use of Low Tunnels to Improve Plant Growth in High Tunnels.

Wuana, Raymond A., and Felix E. Okieimen. 2011. Heavy Metals in Contaminated Soils: A Review of Sources, Chemistry, Risks and Best Available Strategies for Remediation.

Further Resources

Publications

Water, Soil and Fertility Management in Organic High Tunnels. 2013. By John Biernbaum. Michigan State University.

This is a very concisely written 10-page paper on soil, water, and fertility management techniques in high tunnel production.

Fertilizing Crops in High Tunnels. 2010. By Keith R. Baldwin. NC A&T State University Cooperative Extension Program. Farm Bureau Bio-Ag Symposium.

This paper describes approaches to high tunnel fertility management. Pre-plant fertility, soil and foliar testing, application rate calculation, and fertigation techniques are covered. Both conventional and organic fertility approaches are covered.

High Tunnels: Using Low-Cost Technology to Increase Yields, Improve Quality and Extend the Season. 2007. By Ted Blomgren and Tracy Frisch. University of Vermont Center for Sustainable Agriculture.

This 77-page manual covers most aspects of high tunnel crop production management in depth. It has been and remains an invaluable resource for high tunnel producers.

Soil Testing Options for High Tunnel Production. 2013. By Bruce Hoskins. University of Maine.

This short paper describes soil-testing packages specifically developed by the author in conjunction with Vern Grubinger, a Vegetable and Berry Specialist with the University of Vermont Extension, and how to interpret those tests.

High Tunnel Hoop House Construction Guide. 2014. By Steve Upson. Samuel Roberts Noble Foundation. Ardmore, OK.

This is a 102-page pictorial guide on construction of all types of high tunnels and hoop houses. All construction details are covered as well as sighting, layout, material options, and equipment and tools that are needed.

The Hoophouse Handbook. 2003. Edited by Lynn Byczynski. Growing for Market.

Hoophouse Update. 2010. Edited by Lynn Byczynski. Growing for Market.

The Winter Harvest Handbook. 2009. By Eliot Coleman. Chelsea Green Publishing Co., White River Junction, VT.

High Tunnel Production Manual. 2008. By Penn State Center for Plasticulture. Pennsylvania State University, University Park, PA.

Online Resources

Urban Grower’s Manual. 2008. By Amanda Cather. The Food Project, Lincoln and Roxbury, Massachusetts.

Urban Guide to Farming in NY. 2013. Edited by Hannah Koski. Cornell Small Farms Program.

See item #23, Pest and Disease Management.

Hightunnels.org

An extensive listing of online resources for high tunnel growing.

Cornell University High Tunnels

High Tunnels in Urban Agriculture

By Chris Lent, NCAT Agricultural Specialist

Published October 2016

©NCAT

IP524

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development. ATTRA.NCAT.ORG.