Organic Small Grain Production Overview

By Susan Tallman, CCA, NCAT Agronomist

Published February 2011; Updated August 2025

By Gabriella Soto-Velez and Hakeem Holmes, NCAT Agriculture Specialists

Abstract

This publication gives a general overview of organic small grain production. It includes basic production principles, tips on transitioning to organic, ideas for designing crop rotations, and examples of rotations from various parts of the United States. It also suggests resources for further reading.

Contents

Introduction

Production Principles

Yield Differences Between Organic and Conventional Systems

Transition Out of CRP

Crop Rotation

Livestock Integration

Conclusion

References

Further Resources

Introduction

Today, wheat and rice remain cornerstones of global food security, with their cultivation deeply woven into the agricultural landscapes of numerous nations. China and India stand out as powerhouses in both wheat and rice production, their harvests significantly shaping global supplies. Beyond these staples, a diverse array of small grains, including oats, barley, and rye, contribute meaningfully to both human and animal diets. Although most people anticipate that global wheat production will remain robust, various factors influence the yields and availability of these grains in different regions. For instance, while the United States expects a slight dip in its wheat output despite increased planting, global oat production is showing promising growth. Meanwhile, barley and rye production present a slightly different picture, with projected minor decreases worldwide. This intricate interplay of production trends underscores the dynamic nature of global agriculture and the continuous efforts to meet the world’s demand for these essential commodities (USDA Foreign Agricultural Service, 2025).

Table 1. World Corn, Wheat, and Rice Production

| Crop | World Production (1,000 MT) | U.S. Production (MT) |

|---|---|---|

| Corn | 1,214,171 | 377,633 |

| Rice | 532,663 | 7,053 |

| Wheat | 797,227 | 53,650 |

The term small grains can have varying definitions, depending on the context. Typically, it refers to cereal crops with relatively small kernels compared to crops like corn. These commonly include wheat, oats, barley, and rye. In some contexts, the term may also encompass crops like sorghum, which is characterized by a smaller plant bearing relatively large kernels. Despite these differences, the defining characteristic is generally the kernel size. This publication provides an overview of organic production practices for small grains.

Although all the small grains are important and have a place in a crop rotation and in the human diet, wheat is the most significant in terms of amount produced and economic returns. Table 2 illustrates comparable small grain production in the U.S. and the world for the 2024 crop year.

Within the United States, the Great Plains states lead others in small grain production. Kansas, North Dakota, Washington, and Montana rank as the top wheat-producing states, respectively. In 2022, these four states combined produced a total of 848,412,543 bushels (23.1 MMT) of wheat (USDA NASS, 2022).

Even as wheat plays a significant role in the agricultural production of the U.S., the USDA estimates that only 1% of all total cropland in the U.S. is certified organic (USDA ERS, 2022). Of 41 million acres nationally in small grains production, only 513,142 acres are certified organic. As of 2021, Montana ranked as the U.S. state with the most organic grain acreage, with 76,782 certified organic acres (USDA NASS, 2022).

Table 2. Global Small Grain Production

| Crop | World Production (MT) | U.S. Production (MT) |

|---|---|---|

| Barley | 143,612 | 3,132 |

| Oats | 22,492 | 984 |

| Rye | 10,686 | 374 |

| Wheat | 797,227 | 53,650 |

A Brief Definition of “Organic”

Organic farming is a holistic system of agricultural production that emphasizes ecological sustainability, soil health, and biodiversity. Although people often describe organic farming by what it prohibits—namely, the use of synthetic fertilizers, pesticides, and genetically modified organisms (GMOs)—it is equally important to understand what it promotes. According to the USDA’s National Organic Program (NOP), “organic” is a production system that integrates cultural, biological, and mechanical practices that foster resource cycling, promote ecological balance, and conserve biodiversity. In essence, organic farming prioritizes building healthy, resilient systems over simply avoiding synthetic inputs.

For instance, under Title 7 of the Code of Federal Regulations (CFR) Section 205.204, organic producers are expected to use organic seeds and planting stock. However, producers may use non-organic (but untreated) seeds, although only when organic versions are not commercially available. This flexibility ensures practicality while still maintaining the integrity of the organic system (USDA, 2011).

To market crops legally as certified organic, farmers must follow organic practices for at least 36 months prior to their first harvest and undergo a rigorous certification process. This includes submitting an Organic System Plan (OSP) to a USDA-accredited certifying agency and passing an annual on-farm inspection. All certifiers follow the same national standards outlined in Title 7 CFR Part 205.

To learn more about how to create an OSP for your own operation, refer to the Guide for Organic Crop Producers published by ATTRA. Additionally, the Rodale Institute’s Transition to Certified Organic Agriculture course offers free online training and practical resources, including modules on organic no-till systems and system planning.

To locate a USDA-accredited certifier, visit the USDA Organic Integrity Database.

Certification costs, including fees for application and inspection, vary by acreage and certifying agency. However, producers can apply for reimbursement of up to 75% of certification costs (up to $750) through the Organic Certification Cost Share Program.

Demand for organic grains fluctuates according to buyers’ needs. In general, the value of sales for organic small grains continues to increase in the United States. According to the USDA NASS, sales of organic small grains increased by about 37% from 2016 to 2021. Although the opportunity for producing organic grains is significant, organic production is not without its challenges. Weed management, soil fertility, soil moisture, tillage, rotation design, and marketing present a unique set of obstacles for organic grain farmers. However, there are several reasons to consider producing organic small grains.

Table 3. Top 10 States for Organic Small Grain Acreage Harvested, 2022

| State | Total Organic Small Grain Acreage |

|---|---|

| Montana | 76,782 |

| Idaho | 58,774 |

| Wyoming | 57,881 |

| Oregon | 35,940 |

| Colorado | 30,985 |

| Utah | 25,083 |

| Iowa | 24,263 |

| Kansas | 23,642 |

| Washington | 18,361 |

| North Dakota | 16,964 |

Reasons to Consider Organic Grain Production

Organic grains consistently command higher prices in the market, compared to conventionally grown grains. This price premium can significantly boost a farmer’s income per bushel/ton, potentially offsetting any initial yield differences during the transition and beyond.

Globally, the demand for organic food, including grains, is steadily increasing. Consumers are increasingly aware of the potential health and environmental benefits of organic products and are willing to pay more for them. This growing demand creates a potential market for organic grain farmers.

While the initial transition to organic may involve some upfront costs (e.g., learning new techniques and certification costs), organic farming can significantly reduce reliance on expensive synthetic fertilizers, pesticides, and herbicides in the long run. Many government agricultural agencies and organizations offer programs and financial incentives to support farmers transitioning to and maintaining organic production. These may include cost-share programs for certification, technical assistance, research funding, and risk-management tools specifically designed for organic systems.

Refer to the ATTRA publication Understanding Organic Pricing and Costs of Production for a more detailed explanation of what influences organic pricing and production costs.

Production Principles

The key agronomic factors in growing organic small grains include building soil health, managing nutrients and water use, controlling pests, and designing a rotation.

Healthy soil is well aggregated, resembling cottage cheese or chocolate cake. Photo:

Lee Rinehart, NCAT

Soil Health: The Foundation of Organic Farming

Healthy soil is the cornerstone of any successful organic farming system. Soil organic matter plays a crucial role in supporting soil biology, improving structure, increasing water retention, and enhancing nutrient availability. Even though organic matter makes up a small percentage of most soils, its impact on soil productivity and resilience is significant.

Whether you’re aiming to improve fertility, integrate livestock into your system, or grow small grains, ATTRA has in-depth resources that can help you dive deeper into the role of soil biology and the effects of various farming practices:

- Soil Health Indicators and Tests helps you evaluate and monitor your soil’s biological, physical, and chemical health.

- Integrating Livestock and Crops helps you design holistic systems that include animals to build soil.

- Nutrient Management in Organic Small Grains helps small grain producers build fertility and optimize organic yields.

Agronomic Principles for Growing Organic Small Grains

- Maintain soil health by preserving organic material. Organic matter is always breaking down, especially in warm, wet conditions, so producers must consistently replenish it. Limit soil disturbance to prevent further breakdown and use strategies like leaving crop residues in the field and growing cover crops to build and protect soil organic matter.

- Analyze soil regularly to determine nutrient levels. Grain harvesting depletes essential soil nutrients, especially nitrogen and phosphorus. Rebuild fertility by incorporating organic matter (e.g., compost, residues, and cover crops). Because organic nutrient inputs can be costly, efficient use and planning are essential.

- Utilize legume cover crops to supply nitrogen. Obtain other vital nutrients from approved organic fertilizers, giving priority to those that are biologically derived and locally available.

- Prioritize biological nutrient sources like manure, legumes, compost, and cover crops.

- Minimize reliance on costly and less-readily-available mined fertilizers like rock phosphate.

- Incorporate livestock into the farming operation where possible. Animal manure adds organic matter and nutrients like phosphorus, enriching soil fertility. The trampling action of livestock can also improve soil structure by lightly pressing seeds into the soil and breaking up surface crusts. Additionally, livestock saliva, manure, and even shed hair contribute to increased soil biological activity, supporting a diverse and thriving soil microbiome.

- Conserve soil moisture in dry climates by managing cover crops. Maximize winter snow accumulation by leaving taller crop stubble after harvest.

- Reduce fallow periods to maintain ground cover, prevent erosion, and enhance soil biomass. Incorporate cover crops during fallow periods to boost organic matter, suppress weeds, and improve soil biology.

- Employ a combination of methods for weed control, including mechanical weed control, tillage, resistant crop varieties, adjusted planting density, and crop rotation. Cover crops in rotation can help control weed pressure. Address persistent perennial weeds before attempting organic grain production, potentially opting for pasture or hay production during the transition. For more information on mechanical weed control, check out the ATTRA blog Combcutting: An Innovative Approach for Reducing Broadleaf Weeds in Small Grains.

- Recognize that pest and disease pressures increase with higher humidity and temperatures. Organic farming in warm, humid regions presents greater challenges for pest management.

- Implement a diverse crop rotation. This practice is crucial for disrupting pest cycles and mitigating financial risks.

Investing in soil health leads to long-term productivity, improved resilience to climate stress, and better outcomes for the farm ecosystem as a whole. Good management practices are necessary to maximize organic-matter additions and decrease organic-matter depletion. Table 4 summarizes these practices.

Enhancing soil organic matter is fundamental to improving soil health and productivity in small grain systems. Sources of active organic matter include crop residue, cover crops, animal manure, and compost. In agricultural operations that do not incorporate livestock, crop residues and cover crops are typically the primary sources of organic inputs. Conversely, for integrated farming systems that include livestock, such as dairy operations, manure and compost are more readily available and serve as valuable amendments.

Determining Optimal Organic Matter Levels

The ideal soil organic matter content varies based on soil texture and climatic conditions. Fine-textured soils, rich in clay and silt, naturally possess higher organic matter levels compared to coarse-textured sandy soils. For instance, sandy soils may contain less than 1% organic matter, loamy soils approximately 2% to 3%, and clayey soils range from 4% to more than 5%. Therefore, management practices should aim to increase soil organic matter incrementally over time to achieve a stable equilibrium appropriate for the specific soil type and environment (Magdoff and Van Es, 2021).

Table 4: Effects of Different Management Practices on Organic Matter

| Management Practice | Gains Increase | Losses Decrease |

|---|---|---|

| Add materials from outside the field (manures, composts, etc.) | Yes | No |

| Better utilize crop residue | Yes | No |

| Include high-residue-producing crops in rotation | Yes | No |

| Include sod crops in rotation (grass/legume forages) | Yes | Yes |

| Grow cover crops | Yes | Yes |

| Reduce tillage intensity | Yes/No | Yes |

| Use conservation practices to reduce erosion | Yes/No | Yes |

Monitoring Soil Organic Matter

Regular soil testing is essential to track changes in soil organic matter levels. It is advisable to conduct soil analyses every few years and maintain detailed records of the results. Significant alterations in soil organic matter may take several years to manifest, and it often requires a decade or more to observe measurable changes (Collins et al., 1992).

Indicators of increased organic matter include improved aggregation as evidenced by visual observation, reduced soil crusting following heavy rainfall, a darker soil hue, and enhanced crop yields during periods of drought stress.

Sorghum planted in corn residue. Photo: Darron Gaus, NCAT

Managing Crop Residue

Crop residues are a primary source of organic matter in small grain systems. Residues from crops like wheat, oats, and rye typically have high carbon-to-nitrogen (C:N) ratios, around 80:1, leading to slower decomposition compared to more succulent broadleaf plants, such as clovers and vetch, that possess a lower C:N ratio (Beggeman, 2018).

When managing crop residues in organic systems, consider the following principles:

- Keep crop residue in the field: Leaving crop residues on the field surface helps prevent soil erosion, reduces soil water loss, and enhances soil organic matter. Removing residues can lead to increased erosion and loss of valuable organic material (Mondal and Chakraborty, 2022). Additionally, in temperate climates, leaving stubble in the field can help keep the soil warmer, which is important for crops during cold winters. Warmer soil helps crops survive and speeds up germination, leading to better growth. Research on the Canadian prairies has found that fields with crop residue or cover crops stay warmer in winter and freeze at shallower depths. This can protect roots from extreme cold and help crops get a strong start in the spring (Cárceles et al., 2022).

- Ensure uniform residue distribution during harvest: Utilize chaff spreaders during harvest to distribute straw evenly across the field, avoiding windrows. This uniform coverage promotes consistent microbial activity and residue decomposition.

In subtropical and tropical regions, crop residue management requires tailored approaches due to distinct climatic conditions:

- Utilize residues as mulch: Leaving residues on the soil surface as mulch helps maintain soil moisture, suppress weeds, and regulate soil temperature. This practice is particularly beneficial in warmer climates where rapid decomposition can reduce soil cover (Huang et al., 2022).

- Incorporate cover crops: Planting cover crops with lower C:N ratios, such as legumes, can accelerate residue decomposition and enhance soil fertility. Legumes, with their lower C:N ratios, decompose more rapidly, providing nitrogen to the soil.

- Avoid residue burning: Burning is sometimes practiced for rapid field clearing, but it leads to nutrient loss and air pollution. Alternative methods, such as mulching (Ruiz Diaz and Presley, 2021) or composting, are more sustainable and preserve soil health.

Implementing these residue-management strategies, adapted to specific climatic conditions, can significantly improve soil health and productivity in small grain systems.

Mixed cover crops. Photo: Lee Rinehart, NCAT

Using Cover Crops

When using cover crops to increase soil organic matter, it’s important to select species with a higher carbon-to-nitrogen (C:N) ratio (a higher concentration of carbon than nitrogen in plant tissue). Grasses such as cereal rye and triticale are excellent choices, as their fibrous residues break down more slowly and contribute more stable organic matter (humus) to the soil. These high C:N cover crops help build long-term soil structure and carbon reserves.

In contrast, broadleaf species like legumes decompose more quickly due to their lower C:N ratio, contributing less to long-term organic matter accumulation but providing quicker nutrient cycling, especially for nitrogen. While they are not typically used to build humus, broadleaf cover crops like buckwheat can play a complementary role in soil health. Buckwheat is a fast-growing crop known for its ability to scavenge and make phosphorus and other nutrients more available from the soil. Its quick biomass production and aggressive weed suppression make it ideal for short windows in rotations. Though it decomposes quickly and adds less stable organic matter, buckwheat is a valuable tool in organic systems for nutrient cycling and soil fertility management. Additionally, annual ryegrass (Lolium multiflorum) is a cool-season grass cover crop that plays an important role in phosphorus cycling. Its dense, fibrous root system improves soil structure and helps pull phosphorus from parts of the soil where it might otherwise be unavailable to plants. Research has shown that annual ryegrass can recover and recycle a significant amount of phosphorus—up to 42% of what the next crop might need—by breaking down its residues after termination (Hansen et al., 2022). This means ryegrass not only helps capture nutrients while it’s growing but also continues to benefit the soil and future crops as it decomposes. Its fast growth also makes it a great option for preventing erosion and holding onto nutrients during the cool season.

Small grain cover crop in almond orchard to be baled for hay. Photo: Rex Dufour, NCAT

Combining high C:N and low C:N cover crops in a rotation—or even in a mix—can maximize benefits by improving both nutrient availability and long-term soil health. For instance, cereal rye and hairy vetch or red clover are excellent combinations that provide high biomass and the C:N benefits of both species.

For an overview of using cover crops and their effect on soil organic matter, check out the ATTRA publications Overview of Cover Crops and Green Manures and Cover Crops for Hot and Humid Areas.

Animal Manure

The benefit of manure to soil organic matter varies based on the manure type and its specific composition. Factors such as the animal’s diet and the inclusion of bedding materials significantly influence manure quality. For example, solids like beef manure and poultry litter typically contain higher concentrations of organic matter, compared to more diluted slurry and liquid forms. To estimate the contribution of organic matter from manure, it’s common to consider that a portion of the manure’s organic matter will decompose within a year, with the remaining fraction contributing to soil organic matter (Johnson, 2022). For more information about how to use manure in your organic system, please refer to the ATTRA publication Manure in Organic Production Systems.

Compost

The organic-matter content of compost varies widely, typically ranging from 30% to 70%, depending on the materials used to make the compost. A laboratory analysis can determine the exact organic matter content of a specific compost batch. Due to its relatively high organic matter levels, compost can add a substantial amount of organic matter to the soil, similar to that of a high-carbon cover crop. However, sourcing enough compost can be challenging for large-scale organic grain farmers.

Rate of Organic Matter Decomposition

The rate at which organic matter decomposes is crucial for soil health. Rapid decomposition can lead to a quick release of nutrients, leaving minimal organic matter in the soil over time. Conversely, slow decomposition can result in excessive residue that immobilizes nutrients, a process where soil microbes tie up essential nutrients, particularly nitrogen, as they break down high-carbon materials like straw or wood chips. During immobilization, microbes consume available nitrogen to meet their own needs for breaking down carbon-rich residues, making that nitrogen temporarily unavailable to plants. This can lead to nutrient deficiencies in crops until microbial activity stabilizes and starts to release nutrients back into the soil. The goal is to achieve a consistent, steady rate of decomposition that balances nutrient availability with long-term organic matter buildup.

Conservation strips of native vegetation prevent soil and nutrient loss from organic grain fields and promote biodiversity. Photo: Nora Chovanec, Villicus Farm

Several factors influence the rate of active organic matter decomposition, including climate and tillage practices.

Climate

Climatic factors such as temperature and moisture influence soil organic matter levels. Generally, as annual precipitation increases, soil organic matter levels rise due to increased plant biomass and residue inputs. Conversely, higher average temperatures can accelerate organic matter decomposition, potentially leading to lower soil organic matter levels. This is because microbial activity, responsible for decomposing organic matter, is enhanced in warmer conditions (Magdoff and van Es, 2021). Although farmers cannot change their location, understanding the climatic influences where they operate is essential. In regions with higher decomposition rates, more frequent additions of organic matter may be necessary to maintain soil health.

Tillage Practices

Tillage significantly impacts organic matter decomposition. It disrupts soil structure, incorporates oxygen, and accelerates the breakdown of organic matter. Excessive tillage can lead to increased decomposition rates, reducing soil organic matter levels and increasing the risk of erosion. Reducing or eliminating tillage can help preserve soil organic matter by maintaining soil structure and reducing erosion risks. However, carefully managed tillage in low-precipitation areas is sometimes necessary to bury excess surface reside that is not decomposing. It’s important to use the tillage method that suits your crops, tools, and region to ensure minimal disturbance to the soil structure and soil biology.

This presents a challenge for organic grain production, which often relies on tillage for weed control. Balancing weed management with practices that preserve soil organic matter is crucial for sustainable production (Li et al., 2024).

Managing a rye/vetch cover crop mixture with a roller-crimper at Tuckaway Farm, Lee, New Hampshire. Photo: Andy Pressman, NCAT

The Roller-Crimper

The roller-crimper is a vital tool in no-till organic farming, designed to terminate cover crops without disturbing the soil. It consists of cylindrical drums, often filled with water to adjust weight, which roll over cover crops, crimping their stems to kill them naturally while creating a protective mulch layer. This mulch helps suppress weeds, conserve moisture, and improve soil health by reducing erosion and adding organic matter as it decomposes (Bergtold and Sailus., 2020).

Proper timing of termination is critical to ensure that the cover crop contributes effectively to nutrient cycling and supports the growth of the subsequent cash crop. Terminating too early may lead to regrowth or insufficient biomass for mulching, while waiting too long can result in woody residues with limited nutrient release. The ideal practice is to terminate cover crops at flowering or the early milk stage—when biomass production is maximized and nutrient content is still relatively high—to ensure adequate fertilization and smoother decomposition in synchrony with cash crop uptake, and to ensure that the cover crop does not regrow.

There are several key considerations for effective roller-crimper use:

- Timing of termination matters: The growth stage of the cover crop at rolling is one of the most important factors for success. Research has shown that grasses like cereal rye should be terminated between late flowering and the early milk stage, while broadleaf cover crops should be rolled at peak biomass (about 2/3 into their flowering stage or as the pods begin to set) (Southern Cover Crops Council, No date). Rolling too early can result in incomplete termination, allowing the crop to regrow, while rolling too late can lead to seed production, which may cause volunteer weeds in the next planting season (Bergtold and Sailus, 2020).

- Not all cover crops respond the same: Cover crops vary in how well they respond to rolling and crimping, making timing a critical factor for successful termination. Legumes and broadleaf crops are generally more challenging to kill, with species like vetch needing at least 80% of its flowers open for crimping to be effective. Some legumes, such as crimson clover and rapeseed, often require multiple passes to fully terminate them without herbicides. On the other hand, Austrian winter pea is one of the easiest legumes to terminate, as its tender stems crimp readily.

- Synchronize mixes: When using cover crop mixes, it’s essential to choose species that mature at similar times to avoid uneven termination. If a grain reaches maturity too soon, while a legume is still flowering, the grain may set seed before rolling, and this reduces control effectiveness. To ensure the best results, select cover crop varieties with synchronized growth stages by working with seed suppliers (Southern Cover Crops Council, No date a).

- Cover crop biomass is key: A roller-crimper works best when there is sufficient plant biomass to form a thick, weed-suppressing mulch layer. For example, a rye cover crop should ideally produce at least 5,000 pounds per acre of biomass before termination. Insufficient biomass can lead to poor weed control and faster decomposition, reducing the benefits of rolling (Bergtold and Sailus, 2020).

- Equipment setup and weight adjustment make a difference: The effectiveness of a roller-crimper depends on applying the right amount of pressure. If it’s too light, the cover crop may not be fully crimped and will regrow. If the pressure is too heavy, stems can be severed, which also leads to regrowth. Adding or removing water from the drum allows farmers to customize its weight based on field conditions and cover crop type (Panday et al., 2024).

- Mounting position can affect success: Research suggests that attaching the roller-crimper to the front of the tractor helps crimp the cover crop before it’s compressed by the tires, leading to more uniform termination. However, some farmers have had success using rear-mounted rollers for certain crops, like legumes. Choosing the right mounting position depends on the type of cover crop and field conditions (Bergtold and Sailus, 2020).

Organic farmers interested in integrating roller-crimping into their no-till systems should consider the following:

- Experiment on a small scale to determine the best timing and weight settings.

- Choose cover crops that are proven to terminate well with crimping.

- Work with local agricultural Extension services or conservation districts to access regional trial results.

- Consult organizations like the Rodale Institute for research and training on best practices.

By understanding timing, crop selection, and equipment adjustments, farmers can successfully use roller-crimpers to reduce tillage, improve soil health, and create resilient organic cropping systems. However, it’s important to recognize that roller-crimping is a nuanced practice that requires experience. Successful organic farmers often have years of cover crop management under their belts, with firsthand knowledge of how different species behave, the optimal stage for termination, and how to integrate them effectively with cash crops.

When selecting a roller-crimper, consider factors such as equipment compatibility, field conditions, and specific farming practices to ensure optimal performance. (The Further Resources section of this publication provides contact information for several roller-crimper suppliers.) Farmers can consult manufacturers and agricultural Extension services to find the best solution for their particular fields. Proper timing and equipment setup are essential to achieving a clean kill and avoiding issues like regrowth or poor seedbed conditions.

Harvest Ridge Organics, Lewiston, Idaho. Photo, Kirsten Strough for USDA

Additional Equipment for Cover Crop Management

Many farmers utilize tools such as stalk choppers, roller harrows, cultipackers, bed rollers, and land rollers—either factory-made or custom-modified—to achieve effective cover crop termination in no-till systems. Another method, swathing, involves cutting the cover crop and laying it down in windrows to dry. This technique is particularly effective in systems that integrate livestock, as the swathed cover crop can be a high-quality forage for grazing or baling for later use. Swathing offers flexibility in managing cover crops for both soil health and livestock feed, making it a practical choice for diversified operations.

Unlike conservation agriculture, which typically emphasizes keeping the soil covered with living plants or residues year-round and minimizing soil disturbance, swathing intentionally cuts the cover crop, removing some biomass from the field. While this may slightly reduce the amount of organic matter returned to the soil compared to roller-crimping or leaving residue in place, the trade-off is the added benefit of integrating livestock nutrition into the system. When managed carefully, swathing can still support soil health goals by reducing weed pressure, maintaining surface cover, and contributing nutrients through manure deposition from grazing animals.

Yield Differences Between Organic and Conventional Systems

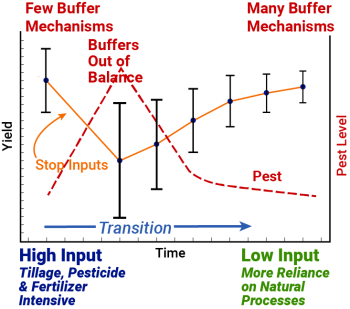

It takes time for an ecosystem to adjust to different farming techniques. In a conventional system, there are few buffers and many inputs. (A buffer would be any biological factor that minimizes adverse conditions, such as beneficial insects, microbial activity, etc.) During the transition period, the farmer reduces off-farm inputs (pesticides and fertilizers), but the buffers are not fully developed yet. The system is unbalanced. As the rotation is established and the natural buffers increase, the system levels out and yields return to levels similar to those before the conversion.

Figure 1: Potential drop in yield during the transition period. Notice that, over time, organic yields do return to near-conventional levels, with less variability than before. Graph: Gilmore, 2009

People commonly believe that small grains, such as wheat, barley, and oats, yield less in organic systems than in conventional ones. While this observation holds true in many cases, a study by Le Campion et al. (2020) highlights that the comparison isn’t so straightforward. Yields in both organic and conventional systems are shaped by a range of factors, including region, climate, soil fertility, and management intensity, and there is considerable variation within each system.

In the United States, conventional grain production can range from high-input systems that use synthetic fertilizers and pesticides intensively, to more extensive systems with fewer inputs, particularly in drier regions. Similarly, organic farms may differ widely in nutrient management, depending on whether they have access to manure, rely on compost, or depend on cover crops to build soil fertility. In most organic systems, nitrogen availability is a primary limiting factor in achieving high yields, especially for nitrogen-hungry crops like small grains.

Across a wide range of trials, Le Campion and colleagues found that organic grain yields ranged from 44% to 96% of their conventional counterparts. Organic systems were more competitive in regions with low rainfall and naturally lower yield potential, while conventional systems outperformed in high-input, favorable environments.

While yield remains a critical factor for farmers making their living from small grain production, other dimensions of sustainability are also gaining attention, especially in the face of a changing climate. A 2022 study published by Azarbad in Frontiers in Microbiology points out that organic practices, which avoid synthetic inputs and build fertility through natural sources like plant residues and manure, tend to support more diverse and resilient soil microbial communities. These microbial populations play a key role in soil health and may help buffer crops against the adverse effects of climate stress, such as drought or nutrient loss.

Taken together, these studies suggest that although organic systems may not always match conventional yields, their potential to build long-term soil resilience and microbial activity could offer critical advantages under increasingly unpredictable climate conditions. Yield is only one part of the equation; farmers may also benefit from considering how management practices affect the biological foundation of their soils.

Ask other organic growers in your region for specific yield information.

Table 5: Organic Small Grain Yield

| Crop | Organic Acres Harvested | Organic Production in BU | BU/Acres |

|---|---|---|---|

| Barley | 70,204 | 3,986,655 | 57.79 |

| Oats | 53,477 | 3,932,406 | 73.53 |

| Wheat | 376,682 | 12,497,632 | 33.18 |

Table 6: Conventional Small Grain Yield

| Crop | Acres Harvested | Production in BU | BU/Acres |

|---|---|---|---|

| Barley | 2,430,308 | 163,059,374 | 67.09 |

| Oats | 914,059 | 60,558,354 | 66.25 |

| Wheat | 37,211,994 | 1,707,074,481 | 45.87 |

Transition out of CRP

Converting CRP (Conservation Reserve Program) land to organic production can be relatively straightforward from a certification standpoint but challenging from a production perspective. Because CRP land has typically been idle for more than a decade and planted in native grasses, it often meets the USDA Organic Program’s requirement that no synthetic fertilizers, pesticides, or GMOs have been applied in the past 36 months. As long as this can be verified through documentation and confirmed during the annual organic inspection, the land may be certified organic immediately. However, bringing it into productive organic crop rotation requires thoughtful management and patience.

One of the biggest hurdles is soil fertility. Years of undisturbed growth lead to a high carbon-to-nitrogen ratio in the buildup of dead plant material and root systems. When this land is first tilled, microbial activity surges to break down the carbon-rich residue. But with this greater activity, microbes consume all available nitrogen in a process called nutrient immobilization, meaning nitrogen is temporarily locked up and unavailable to plants. This often leaves soils nitrogen deficient. To restore balance, many organic farmers till converted land for a full season, then plant a nitrogen-fixing green manure crop, which is tilled in at mid-bloom the following year. With this strategy, it can take up to 18 months to be ready to plant a winter-seeded cash crop. Regular soil testing during this period is essential, and early crops like barley, which is less demanding than wheat, are often used to ease the transition. For deeper insight into utilizing cover crops to convert CRP land, refer to the ATTRA publication No-Till Case Study, Bauer Farm: Cover Crop Cocktails on Former CRP Land.

Weed pressure is another common issue. Once the soil is disturbed, dormant weed seeds buried for years can germinate rapidly. To get ahead of this, intensive cultivation is usually necessary for the first one to two years. Green manure crops should be terminated before weed seeds set, ideally at mid-bloom, and follow-up shallow tillage can help target each new wave of seedlings. Many farmers begin their rotation with a spring forage like oats and peas, which can help suppress early weed growth while contributing organic matter to the soil.

Transitioning to Organic in Stages

Because the transition time can be a challenge, successful organic farmers often recommend transitioning in stages. Rather than converting the entire farm at once, divide it into sections and convert one portion at a time over the course of three to five years.

Producing both conventional and organic on the same farm is known as “parallel production,” and presents its own challenges. The main challenge is to keep accurate records to prove that the conventional production practices have not carried over to the organic land. For example, organic production requires cleaning implements when moving from one type of field to the next and maintaining adequate buffer space between fields. In addition, organic regulations require cleaning storage facilities with organic-approved methods and labeling bins clearly to avoid any confusion.

Resources for Transitioning to Organic Production

Canadian Organic Growers (COG) has an excellent book titled Gaining Ground that profiles 80 Canadian farmers and their transition experiences. In addition, COG also publishes the Organic Field Crop Handbook, an excellent resource for organic grain farmers. Contact COG at cog.ca, or call 888-375-7383.

The USDA Natural Resources Conservation Service (NRCS) may provide some cost-share for transitioning to organic through the EQIP program. Check with your state NRCS office for more information.

Crop Rotation

Designing an effective crop rotation tailored to a farm’s unique conditions and goals is a cornerstone of successful organic farming. The National Organic Program (NOP) mandates crop rotation for organic certification, specifying that rotations must achieve the following:

- Maintain or improve soil organic matter content

- Provide for pest management in annual and perennial crops

- Manage deficient or excess plant nutrients

- Provide erosion control

Key Considerations for Rotation Design

Soil Fertility and Organic Matter

- Include legumes like clover or alfalfa to fix nitrogen biologically, reducing dependence on external nitrogen sources.

- Plant grasses and other cover crops to build soil organic matter, improving soil structure and water retention.

Pest and Disease Management

- Rotate crops from different plant families to break pest and disease cycles. For example, adding buckwheat to your rotation not only creates shading that outcompetes weeds, but the nectar from the blossoms attracts beneficial insects like lady beetles and predatory wasps (SARE, 2007).

Weed Suppression

- Use cover crops and staggered planting dates to outcompete weeds. For example, rye can suppress weed-seed germination through its allelopathic effects.

Soil Structure and Erosion Control

- Plant deep-rooted crops (e.g., alfalfa) to loosen compacted soils and improve aeration.

- Maintain cover on the soil year-round to reduce erosion from wind and water.

Biodiversity and Resilience

- Diversify crop types to promote increases in the following:

-

- Beneficial insects

- Soil microbial activity

- Pollination and nutrient cycling

- Resilience to drought, pests, and other stressors

Livestock Integration

- Allow livestock to graze cover crops, turning forage into fertility through manure. Livestock help close the nutrient loop, improving both soil structure and nutrient availability (USDA, 2025).

By applying these principles, farmers can design crop rotations that support organic certification while improving long-term soil health, productivity, and farm resilience.

Want to dive deeper? Check out ATTRA’s tipsheet: Crop Rotation in Organic Farming Systems

Livestock Integration

Sheep grazing on corn. Photo: Linda Coffey, NCAT

As noted in previous sections, integrating livestock into an organic small grain system can significantly enhance soil fertility through the strategic use of manure and grazing. While the full design and management of a livestock-integrated system is beyond the scope of this paper, it remains an important consideration when planning for the long-term sustainability of organic grain production.

Livestock can play a vital role in maintaining the health and resilience of the farm ecosystem. Their manure contributes valuable nutrients and organic matter to the soil, supporting microbial activity and improving nutrient cycling. Grazing animals can help reduce pest and weed pressures—targeting pests like the wheat stem sawfly and suppressing invasive weeds such as field bindweed—while also utilizing cover crops as forage, adding another layer of functionality to the crop rotation.

However, it’s important to manage livestock integration carefully to avoid potential downsides. For instance, weed pressure can increase if animals are not consuming the appropriate forage or are selectively grazing preferred species, allowing less-palatable weeds to proliferate.

Additionally, while animal trampling can improve soil structure by stimulating biological activity and helping to incorporate organic matter, excessive trampling due to high stocking densities or wet conditions can lead to soil compaction, which negatively impacts water infiltration, root development, and overall crop performance.

To prevent these issues, it’s critical to follow recommended stocking rates based on the carrying capacity of the land and to adjust grazing intensity based on weather and soil conditions. Furthermore, adequate rest periods between livestock grazing and sowing the next small grain crop are essential. This rest period allows time for manure to break down, pathogens to dissipate, and soil structure to recover—ensuring optimal seedbed conditions and compliance with organic certification standards regarding manure application and crop harvest intervals.

When thoughtfully implemented, livestock integration can enhance fertility, diversify the farm enterprise, and improve the ecological function of organic small grain systems.

To explore the benefits and considerations of combining animals and crops, ATTRA’s publication Integrating Livestock and Crops: Improving Soil, Solving Problems, Increasing Income offers valuable insights and practical strategies.

See also the ATTRA publication Nutrient Management in Organic Small Grains for more information on using manure for grain-crop fertility.

Conclusion

There are many compelling reasons to grow organic small grains, such as decreased pesticide use, market prices higher than those for conventional grains, and more. However, it’s important to follow good agronomic practices in order to maintain soil health and adequate organic matter. Give attention to soil nutrient levels and rotation design. Minimize tillage and consider integrating livestock when possible.

Transitioning to organic production can be a challenge. The learning curve can be steep the first few years, and price premiums are not available until certification is achieved, usually in the third year of organic production. Plan cash flow accordingly and transition in phases to allow for the adjustment time before yields and markets are established.

Become involved with local organic organizations. Connect with other farmers and listen to their stories of success and failure. Nothing can substitute for the voice of experience in helping to raise organic small grains successfully.

References

Azarbad, Hamed. 2022. Conventional vs. organic agriculture–which one promotes better yields and microbial resilience in rapidly changing climates? Frontiers in Microbiology. Vol.13. p. 903500.

Beggeman, Sonja. 2018. Understand Carbon-to-Nitrogen Ratios Before Buying Cover Crop Seed. Ohio State University Extension.

Bergtold, Jason, and Marty Sailus (eds.). 2020. Conservation Tillage Systems in the Southeast. SARE Handbook Series 15. Sustainable Agriculture Research and Education (SARE).

Cárceles Rodríguez, Belén, Víctor Hugo Durán-Zuazo, Miguel Soriano Rodríguez, Iván F. García-Tejero, Baltasar Gálvez Ruiz, and Simón Cuadros Tavira. 2022. Conservation agriculture as a sustainable system for soil health: A review. Soil Systems. Vol. 6, No. 4. p. 87.

Collins, H.P., P.E. Rasmussen, and C.L. Douglas, Jr. 1992. Crop rotation and residue management effects on soil carbon and microbial dynamics. Soil Science Society of America Journal. Vol. 56. p.783-788.

Gilmour, J. 2009. Preparing for the 2009 International Certified Crop Adviser Exam. International Plant Nutrition Institute. 175 p.

Hansen, V., D. Müller-Stöver B. Gómez-Muñoz, A. Oberson, and J. Magid. 2022. Differences in cover crop contributions to phosphorus uptake by ryegrass in two soils with low and moderate P status. Geoderma. Vol. 426. p. 116075.

Huang, Bin, Zaijian Yuan, Mingguo Zheng, Yishan Liao, Kim Loi Nguyen, Thi Hong Nguyen, Samran Sombatpanit, and Dingqiang Li. 2022. Soil and water conservation techniques in tropical and subtropical Asia: A Review. Sustainability. Vol. 14, No. 9. p. 5035.

Johnson, Leslie. 2022. Not all manure is created equal. University of Nebraska-Lincoln Water. Oct. 3.

Kane, D.A., M.A. Bradford, E. Fuller, E.E. Oldfield, and S.A. Wood. 2021. Soil organic matter protects US maize yields and lowers crop insurance payouts under drought. Environmental Research Letters, Vol.16, No. 4. p. 044018.

Le Campion, Antonin, François-Xavier Oury, Emmanuel Heumez, and Bernard Rolland. 2020. Conventional versus organic farming systems: dissecting comparisons to improve cereal organic breeding strategies. Organic Agriculture. Vol. 10. p. 63–74.

Li, Yu-Mei, Yu-ming Wang, Guang-wei Qiu, Hong-jiu Yu, Feng-man Liu, Gen-lin Wang, and Yan Duan. 2024. Conservation tillage facilitates the accumulation of soil organic carbon fractions by affecting the microbial community in an eolian sandy soil. Frontiers in Microbiology. Vol. 15. p. 1394179.

Magdoff, Fred, and Harold VanEs. 2021. Building Soils for Better Crops, Fourth Edition. Sustainable Agriculture Research and Education.

Mondal, Surajit, and Debashis Chakraborty. 2022. Global meta-analysis suggests that no-tillage favourably changes soil structure and porosity. Geoderma. Vol. 405. p. 115443.

Panday, Dinesh, Reza K. Afshar, and Arash Ghalehgolabbehbahani. 2024. Cover Crop Roller-Crimping to Manage Weed Pressure in Regenerative Organic CBD-Hemp Production. Rodale Institute.

Ruiz Diaz, Dorivar, and Deann Presley. 2021. Crop residue decomposition and nutrient release rates. Kansas State University Agronomy eUpdate, No. 807.

Southern Cover Crops Council. No date a. Termination With Rolling and Crimping.

Southern Cover Crops Council. No date b. When should I terminate my cover crop? In: Cover Crop Resource Guide: Row Crops – Mountains, Ridge & Valley, Piedmont – Terminating Cover Crops.

Sustainable Agriculture Research and Education (SARE). 2007. Managing Cover Crops Profitably. 3rd ed. Buckwheat. SARE Outreach.

United States Department of Agriculture (USDA). 2011. National Organic Program (NOP) Regulations. USDA Agricultural Marketing Service.

USDA Foreign Agricultural Service (FAS). 2025. Data and Analysis.

USDA National Agricultural Statistics Service (NASS). 2022. Corn, Grain – Production, Measured in Bu – United States. Quickstats, U.S. Department of Agriculture.

USDA Natural Resources Conservation Service (NRCS). 2024. Soil Health. United States Department of Agriculture.

United States Department of Agriculture (USDA). 2024. Understanding Soil Health and the Role of Organic Matter. USDA NRCS Soil Health Division.

Zentner, R.P., C.A. Campbell, V.O. Biederbeck, F. Selles, R. Lemke, P.G. Jefferson, and Y. Gan. 2004. Long-term assessment of management of an annual legume green manure crop for fallow replacement in the Brown soil zone. Canadian Journal of Plant Science. Vol. 84. p. 11–22.

Further Resources

Books

Building Soils for Better Crops, Fourth Edition. 2021. By Fred Magdoff and Harold VanEs.

Sustainable Agriculture Research and Education.

An excellent resource for an in-depth discussion of organic matter and soil health.

Managing Cover Crops Profitably, 3rd Edition. 2007. By SARE Outreach. Sustainable Agriculture Research and Education.

A great resource for anyone looking for more information on cover crops.

Websites

Cover Crop Rotation. University of Manitoba.

This project looks at several types of cover crops in rotations to determine the viability and benefits that this practice may have on soils in the Prairies.

Crop Diversity Calculator. By Dr. Dwayne Beck. Dakota Lakes Research Station.

In this tool, crops are broken into several basic categories: warm-season crops, cool-season crops, grasses, and broadleaves. The diversity score increases as crops from each of these categories are grown in rotation.

Organic Grain Resource and Information Network (OGRAIN), University of Wisconsin-Madison

OGRAIN provides resources, research, events, and a community network for organic grain production in Wisconsin. Online offerings include fact sheets and case studies.

The Grain Place Foundation is dedicated to research and education in regenerative and organic farming practices, with a focus on long-term, sustainable systems. The site includes information on their demonstration farm, educational events, and research initiatives.

Iowa State University Long-Term Agroecological Research (LTAR)

This project examines the long-term effects of organic and conventional farming systems on soil health, crop yields, and environmental impacts. Results help guide best practices for sustainable agriculture in the Midwest.

Marbleseed – Organic Field Crops Resources

Marbleseed provides educational resources, research, and practical guides for organic field crop production. Materials include fact sheets, webinars, and farmer stories focused on sustainable practices in the Upper Midwest.

Rodale Institute – Crop-Livestock Integration

Rodale Institute’s Crop-Livestock Integration program explores how combining crops and livestock in one system can improve soil health, increase biodiversity, and enhance farm resilience. The site features research findings, guides, and farmer case studies.

Soil Health Indicators and Tests. ATTRA publication. November 2020.

For further reading on soil biology.

Suppliers

Several manufacturers in the United States offer roller-crimpers, essential tools for terminating cover crops in conservation tillage systems. Inclusion in this list does not constitute an endorsement of any particular product by NCAT. Here are some notable options:

I & J Manufacturing

Gap, Pennsylvania

717-442-9451

Offers front-mounted Cover-Crop Rollers in standard widths of 8 feet. 10.5 feet, and 15.5 feet, with custom sizes up to 60 feet. Features chevron-pattern blades and fillable drums for adjustable weight.

Kirby Manufacturing

Merced, California

209-722-9331

Offers Roller-Crimpers designed to flatten and terminate cover crops efficiently, featuring V-shaped blades and fillable roller tanks for added weight control. Built for high-durability crimping, ideal for large-scale no-till operations.

Rite Way Mfg. Co. Ltd.

Imperial, Saskatchewan, Canada

306-962-3645

Offers the Crush-Rite Crimper Roller, designed for organic no-till and weed suppression without chemicals. Features a heavy-duty, welded drum design for durability and variable widths for different field conditions.

Organic Small Grain Production Overview

By Susan Tallman, CCA, NCAT Agronomist

Published February 2011

©NCAT

Updated August 2025

By Gabriella Soto-Velez and Hakeem Holmes, NCAT Agriculture Specialists

IP408

This work is supported by ‘Preparing a Resilient Future: Beginning Farmer and Rancher Training for Organic Field Crop and Livestock Producers in the Northern Great Plains,’ project award no. 2021-70033-35698, from the U.S. Department of Agriculture’s National Institute of Food and Agriculture.