Small-Scale Wind Energy on the Farm

Farms and ranches, such as this one in southwest Minnesota, can use wind-generated electricity to reduce utility bills. Photo: Warren Gretz, NREL

By Cathy Svejkovsky, NCAT Energy Specialist; Updated by David Ryan, PE, NCAT Energy Engineer

Wind-generated electricity is attracting the interest of farmers, ranchers, and other landowners across the country. People find wind energy attractive for a variety of reasons, including its lower impact on the environment than other fuels and its potential economic benefits. In some situations, wind-generated electricity can help farmers and ranchers reduce their energy costs. This publication introduces small-scale wind energy to help farmers and ranchers decide whether wind energy is the right option for them.

This publication draws heavily on Small Wind Electric Systems: A U.S. Consumer’s Guide (DOE/GO-102005-2095), produced by the National Renewable Energy Laboratory (NREL). Material from that publication is reprinted and adapted here with permission from NREL.

Contents

Introduction

Why Should I Choose Wind?

How Do Wind Turbines Work?

Is Wind Energy Practical?

Is There Enough Wind at My Site?

Zoning Issues

Do I Want to Interconnect to the Utility?

Can I Sell Excess Electricity?

What Size Wind Turbine Do I Need?

How Much Energy Will My System Generate?

Basic Parts of a Small Wind Electric System

What do Wind Systems Cost?

Financial Incentives

References

Further Resources

Related Publications

Introduction

Wind energy systems convert the power of the wind to electric power. The machine that does the conversion is called a wind turbine (it is also sometimes called a windmill). Wind energy systems are the fastest-growing technology in the energy sector: in the last 10 years, wind energy growth has averaged over 25% per year worldwide (World Wind Energy Association, 2012). Small wind electric systems can make an important contribution to our nation’s energy needs. Similar to the trend of wind power in general worldwide, small wind energy systems are being installed in ever-greater numbers, with an estimated 35% growth rate (World Wind Energy Association, 2012).

Many rural areas have sufficient wind speeds to make wind energy an attractive alternative, and farms and ranches can often install a small-scale wind energy system without a significant impact on their ability to plant crops and graze livestock. Most farms and ranches have enough open land (generally an acre or more) to be able to use a wind turbine to provide a significant portion of their electricity from wind power.

What Is “Small-Scale” Wind?

Most of the wind-powered electricity in the world is generated by large scale, utility-interconnected power plants. The size of wind turbines in these wind plants has increased from 12-meter rotor diameter (20- to 30-kilowatt capacity) machines in the 1980s to 126-meter rotor diameter (4- to 6-megawatt) machines nowadays. Modern “small-scale” wind turbines are usually considered to be less than 50-kilowatt capacity, although some people consider 300-kilowatt wind turbines “small.” The definition is arbitrary, but for the purposes of this publication, a system that can be “net metered” and supply energy to a house, farm, or irrigation system can be considered “small.” See the text box on page 8 for more about net metering.

Why Should I Choose Wind?

Wind energy can be a cost-effective small-scale renewable energy system. Depending on the wind resource and the electricity consumption of a farm, a small wind energy system can lower electric bills, help avoid the high costs of extending utility power lines to remote locations, prevent power interruptions, and provide a non-polluting source of electricity.

How Do Wind Turbines Work?

Wind is created by the unequal heating of the Earth’s surface by the sun. Cold and warm areas make pressure differences in the atmosphere, and air moves from higher-pressure areas to lower pressure areas, creating winds. Wind turbines convert the kinetic energy in wind into mechanical power that runs a generator to produce electricity. Wind turbine blades are aerodynamically designed to capture as much energy as possible from the wind. The wind turns the blades, spinning a shaft connected to a generator that makes electricity.

Is Wind Energy Practical for Me?

A small wind energy system may provide a practical and economical source of electricity if:

- Your Property has a good wind resource

- You have at least one acre of land in a rural area

- Your local zoning codes or covenants allow wind turbines

- You have high electric energy (kWh) rates

- Your property is in a remote location that does not have easy access to utility lines

- You commonly experience utility power outages

- You are comfortable with long-term investments

It’s important to examine your reasons for wanting to purchase a wind energy system. If your reasons are purely economic, you could be disappointed, since wind energy systems can have long payback periods. If you are also interested in benefits such as environmental protection, independence, reliability, or energy security, you may find the cost and payback period perfectly acceptable. Make sure you fully understand the results you can expect, as well as potential obstacles, such as zoning laws, generation capacity, maintenance requirements, and warranty coverage.

Is There Enough Wind at My Site?

Does the wind blow hard and consistently enough at your site to make a small wind turbine system economically worthwhile? That is a key question and one that is rarely easily answered. The wind resource can vary significantly over an area of just a few miles because of local terrain influences on the wind flow. Yet, there are steps you can take that can help answer this question.

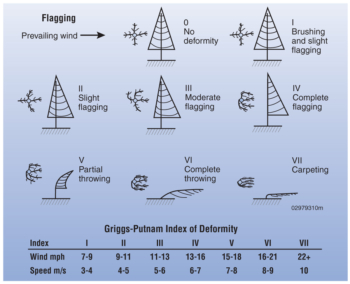

One useful, indirect way to measure the wind resource is by observing vegetation. Trees, especially conifers or evergreens, can be permanently deformed by strong winds. This deformity, known as “flagging,” can be used to estimate the average wind speed for an area. For more information on flagging, consult A Siting Handbook for Small Wind Energy Conversion Systems, by H. Wegley, J. Ramsdell, M. Orgill, and R. Drake. Sites with moderate to complete flagging may be reasonably good candidates for an economical wind turbine, and it may be worth the time and money to look for historical wind data for those areas.

Figure 1. Flagging, the effect of strong winds on area vegetation, can help determine area wind speeds. Source: Windustry

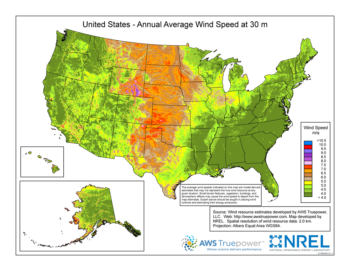

A wind resource map can help in estimating the wind resource in a region. State wind resource maps, tools, and data can be found on NREL’s website. These maps provide wind speed estimates at 30 meters height, which are useful for identifying small wind turbine opportunities.

Additional wind resource maps, showing region specific data, appear in NREL’s Wind Energy Resource Atlas of the United States. Note that wind maps provide only broad estimates–wind speed at a potential wind turbine site cannot be determined solely based on the maps. The maps are based primarily on weather satellite data and computer models. For site-specific wind resource data, you will need to install a weather station that includes a data logger. Small weather stations costing a few hundred dollars will provide a good idea of the character of the wind at a potential turbine location.

In general, the highest average wind speeds in the United States are found along seacoasts, on ridgelines, and in the Great Plains; however, many areas have wind resources strong enough to power a small wind turbine economically. The wind resource estimates on the map shown in Figure 2 generally apply to terrain features that are well exposed to the wind, such as plains, hilltops, and ridge crests. Another way to estimate the wind resource is to get average wind speed information from a nearby airport. The National Climatic Data Center collects data from U.S. airports and

makes wind data summaries available for purchase. Summaries of wind data from almost 1,000 U.S. airports also are included in Wind Energy Resource Atlas of the United States.

First Things First: Make Your Farm Buildings as Energy-Efficient as Possible

Before choosing a wind system for your farm or ranch, reduce your energy consumption as much as possible. Energy conservation is almost always more cost-effective than renewable energy systems and could reduce the size of wind energy system needed. From wall insulation to light bulbs, there are many ways to make farm buildings more energy-efficient.

- Reduce heating and cooling needs by as much as 30% by investing just a few hundred dollars in proper insulation and weatherization products.

- Save money and increase comfort by properly maintaining and upgrading heating, ventilation, and air-conditioning systems.

- Install double-paned, gas-filled windows with low-emissivity (low-e) coatings to reduce heat loss in cold climates and spectrally selective coatings to reduce heat gain in warm climates.

- Replace lights in high-use areas with energy-efficient fluorescent lighting. Replacing incandescent light bulbs with compact fluorescent light bulbs, for example, can save two-thirds of the cost of energy spent running those lights.

- When shopping for products such as lighting, windows, and heating and cooling systems, look for the ENERGY STAR label. ENERGY STAR products have been identified by the U.S. Environmental Protection Agency and U.S. Department of Energy as being the most energy-efficient products in their classes.

Use caution, however, because local terrain and other factors may cause the wind speed recorded at an airport to be different from other nearby locations. Also, airport wind speeds are generally measured at heights of only about 20 to 33 feet (6 to 10 meters) above ground. Average wind speeds increase with height and may be 15% to

25% greater at a typical small wind turbine hub height of 80 feet (24 meters) than those measured at airport anemometer heights.

Figure 2: U.S. Wind Map. Source: NREL

Direct monitoring by a wind resource measurement system at a site provides the clearest picture of the available resource. A good overall guide on this subject is the Wind Resource Assessment Handbook. Wind measurement systems are available for as little as $150 for low-cost residential weather stations with data-logging capability, but professional wind assessment equipment can cost $8,500. This expense may or may not be justified, depending on the exact nature of the proposed small wind system. The measuring equipment must be set high enough to avoid turbulence created by trees, buildings, and other obstructions. The most useful readings are those taken at the height of the wind turbine rotor (“hub-height”). If there is a small wind turbine system already in the area, you may be able to obtain information on the annual output of the system or wind speeds at its location.

Measuring Wind Resource

Home-scale weather stations can be purchased from a number of suppliers. These weather stations contain data-logging capacity and can interface with a home computer. You can use the data that a weather station provides to estimate the energy production of a particular wind turbine, or wind turbine suppliers can use it to estimate the energy production from the machine they have for sale. Finally, if you want to have an independent evaluation of the wind at your site at a reasonable cost, you can call the National Center for Appropriate Technology (see Further Resources section). Most residential-style weather stations collect data at only two meters above the ground. It is best to collect data from a higher mounting height, at least 10 meters (33 feet). Getting to that height means investing in a suitable-size pipe and supporting structure. Correlate 10-meter data with local airport data to get an idea of what wind speeds at your location have been over the long term.

| Manufacturer | Description | Ballpark Price |

|---|---|---|

| Oregon Scientific | WMR-200 | $400 |

| WMR-88 | $150 | |

| Davis Instruments | Vantage Pro2 | $900 |

| Rainwise | MK-III Computer Package | $1,500 |

| Onsite Computer Corp. | Hobo H21-001 with sensors | $1,500 |

| Professional wind data gathering systems | ||

| NRG Systems | 34-meter tower kit | $8,500 |

Using Wind Data

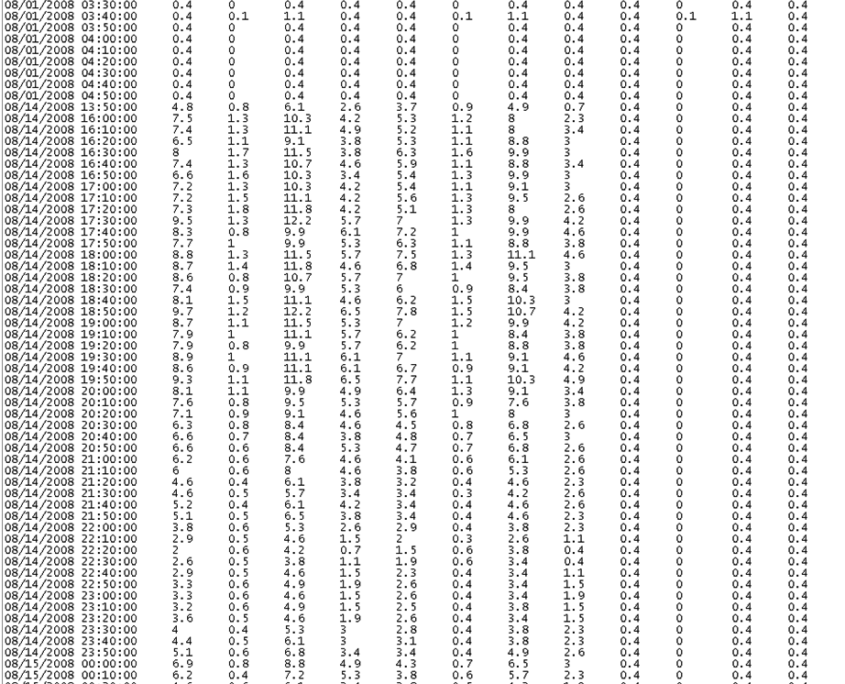

To analyze wind data, collect a time-series of wind data values. Normally these are 10- or 15-minute interval values. The data may be viewed in a text file, but it is more useful if it is opened in a spreadsheet or database application. NRG Systems provides a free software package to help analyze wind data (collected with their data logger), and there are other software packages available, such as Windographer, that can help in analyzing wind data. If you prefer a professional analysis, NCAT can review wind data at a reasonable cost.

The software (or a spreadsheet or database application) can produce two graphs that are helpful to see if your site is suitable for a wind turbine: a frequency diagram and a wind rose. The frequency diagram is a summary of the amount of time the wind blows at each certain wind speed over the time period the data was collected. The wind rose is an indicator of how much of the time the wind is blowing from each direction.

Table 2: Raw Wind Data Example. Source NCAT

Zoning Issues

Before investing in a wind energy system, be sure to research potential obstacles. Some jurisdictions, for example, restrict the height of structures permitted in residentially zoned areas, although variances might be allowed. Most zoning ordinances have a height limit of 35 feet. Find out about the zoning restrictions in your area by calling the local building inspector, permitting authority, or planning board. At a minimum, contact the county commission to ask what, if any, county requirements exist. They can tell you if you will need to obtain a building permit and provide a list of requirements. In addition to zoning issues, neighbors might object to a wind machine that blocks their view, or they might be concerned about noise. Most zoning and aesthetic concerns can be addressed by supplying objective data. For more information about permitting, see Permitting Small Wind Turbines: A Handbook.

Do I Want to Interconnect to the Utility?

If the load you want to serve with a wind turbine is already connected to the electric utility (“grid connected”), it is far more economical and convenient to use a grid-connected wind turbine. If the site has problems with electric outages, batteries can provide an uninterruptable power supply while the system still enjoys the benefits of grid supplied power. For a load that is remote from the utility grid—a stock-watering system, for example— a wind turbine and batteries can provide electric power without connecting to the grid.

Stand-Alone Systems

Stand-alone systems (systems not connected to the utility grid) often utilize batteries to store excess power for use when the wind is calm. They need a charge controller to keep the batteries from overcharging. Deep-cycle batteries, such as those used for golf carts, can discharge and recharge 80% of their capacity hundreds of times, which makes them a good option for remote renewable energy systems. Automotive batteries are built to deliver a large amount of power for a short period of time and are not made to discharge most of the energy they are storing. These shallow-cycle batteries should not be used in renewable energy systems because of their short life in deep-cycling operations.

Small wind turbines generate direct current (DC) electricity. In very small systems, DC appliances operate directly off the batteries. Standard appliances that use conventional household alternating current (AC) require an inverter to convert DC electricity from the batteries to AC. Although the inverter slightly lowers the overall efficiency of the system, it allows a home or farm building to be wired for AC, a definite plus with lenders, electrical code officials, and future buyers.

For safety, batteries should be isolated from living areas and electronics because they contain corrosive and explosive substances. Lead-acid batteries also require protection from temperature extremes. Batteries should be enclosed in a box that is vented to the outside.

There are practical limitations to the size of batteries. For power requirements greater than around 10 kW that need a reliable power supply, a generator that burns a fuel for backup is usually a better choice than batteries. There are virtually unlimited combinations of wind, solar electric, battery, and generator that may be used to provide power and energy for any use on the farm. In a nutshell, if you want to be “off grid,” you can; you are limited only by your pocketbook.

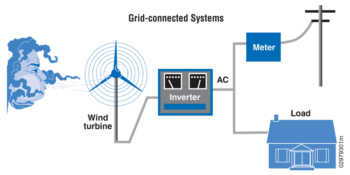

Grid-Connected Systems

Small wind energy systems connected to the electricity distribution system are called grid-connected systems. Grid-connected systems require a power-conditioning unit (inverter), which makes the turbine output electrically compatible with the utility grid. Usually, batteries are not needed. A grid-connected wind turbine can reduce your consumption of utility-supplied electricity for lighting, appliances, and electric heat. If the turbine cannot deliver the amount of energy you need, the utility makes up the difference. When the wind system produces more electricity than the household requires, the excess is sent or sold to the utility. Grid-connected systems can be practical if the following conditions exist:

- You live in an area with average annual wind speed of at least 10 mph (4.5 m/s).

- Utility-supplied electricity is expensive in your area (about 10 to 15 cents per kilowatt-hour).

- The utility’s requirements for connecting your system to its grid are not prohibitively expensive.

- There are good incentives for the sale of excess electricity or for the purchase of wind turbines.

Can I Sell My Excess Electricity to the Utility?

Federal regulations (specifically, the Public Utility Regulatory Policies Act of 1978, or PURPA) require utilities to connect with and purchase power from small wind energy systems. However, you must contact your utility before connecting to its distribution lines to address any power quality and safety concerns. Be aware that some utilities are more welcoming of interconnection than others. It is important to contact your

utility early on in your planning process to learn about its interconnection policies and expected costs. The American Wind Energy Association is a good source for information on utility interconnection requirements.

Figure 5. A grid-connected wind turbine can reduce consumption of utility-supplied electricity. Source: U.S. Department of Energy

What Size Wind Turbine Do I Need?

If you are grid-connected, the size of wind turbine to install depends on the rate that the utility will credit you for the energy produced, as well as other factors that will vary from utility to utility. BEFORE spending any money, ask your utility what their rules are for interconnecting and getting paid for excess energy your wind turbine may produce. Be sure you understand all of the utility costs and what the utility will pay or credit you.

For grid-connected applications, look at your electric billing history to get an idea of average energy consumption. Ask your utility for two years of history and average them. If the load you want to serve is charged a demand charge, your energy rate will be lower, and this will affect the payback period of the wind turbine (wind turbines

do not affect the demand charge, only the energy charge). Bear in mind that energy conservation is usually far less expensive than any generation system, so before investing in a wind turbine, be certain that you are being as efficient in your electric energy use as possible. Efficiency pays off in two ways: first, it decreases your electric bill, and second, it allows you to get by with a smaller, less expensive wind turbine. Figures 6 and 7 show a sample two-year electric energy consumption and demand history.

Net Metering

Generators interconnected to the utility can be net-metered. This means that the generator is connected at the customer’s breaker panel (on the customer side of the electric meter), and if the power generated is greater than the load, the power runs in reverse through the meter and runs it backwards, subtracting the generation from the consumption registered by the meter. The basic idea of net metering is that the energy you generate is simply “netted out” from the energy you use. There are a number of methods to measure energy in net-metered systems. The simplest way is just to have a single energy (kWh) meter that can rotate in either direction. The customer is billed for the net energy used in a given billing period. If you generate more energy than you use in a billing period you may be paid for it, you may be given credit for it that you can carry forward, or you may lose it. Each utility has its own way of administrating net metering, so contact your utility to understand how it does net metering before buying any equipment.

If we average consumption for the Figure 6 example, we get 64 kWh per day average energy use. To furnish all of the energy used in this example, we would need to get a wind turbine capable of producing an average of 64 kWh per day. This example facility happens to be demand metered also, so it is charged monthly for the maximum power used in any 15-minute interval during the month (see Figure 7).

If you are not going to be connected to the grid, you must understand that you will have to provide both the electric power and the electric energy for whatever your off-grid generation system will serve–you are the electric utility! Proper system design is critical to be sure electricity is available for your loads when it is needed, be it for a remote stock-watering system (1 to 3 kW, maybe with batteries, maybe without batteries), or for your home and farm out buildings (10 to 20 kW, maybe with batteries, maybe with a backup generator). In general, for serving off-grid loads greater than about 20 kW, a hybrid system using both a wind turbine and a fueled generator is advisable. Hybrid diesel-wind systems can be built to serve facilities of several megawatts of load. If our example facility was to be served by an off-grid electric system, the system would have to be able to provide 13 kW of electric power at any time and also would have to provide the average of 64 kWh of electric energy per day.

Making a Load and Energy-Use List for Off-Grid System Sizing

Make a complete listing of all the electric loads you want to be able to run, and then estimate how much time each load will run in a day. This “laundry list” of electric loads is very important, so take your time! There are online versions of this type of chart.

| Amperage1 | Voltage | Wattage2 | Phases3 | Hours per day4 | Power Req’d KW | Daily Energy kWh | |

| Equipment | |||||||

| Refrigerator | 120 | 460 | 1 | 6 | .46 | 2.76 | |

| Water heater5 | 240 | 9000 | 1 | 1.5 | 9 | 13.5 | |

| 60-watt incandescent light bulb | 120 | 60 | 1 | 4 | .06 | .24 | |

| 20-watt compact fluorescent light bulb | 120 | 20 | 1 | 4 | .02 | .08 | |

| Cold/hot water dispenser | 6.2 | 120 | 744 | 1 | 6 | 0.744 | 4.464 |

| Electric Clock | |||||||

| Total | 10.287 | 21.116 |

- The nameplate amperage is the most current the device will ever draw per its design. This amperage will give you a slightly high number for the wattage.

- If the wattage of the equipment is not on the nameplate, multiply the Voltage by the Amperage to calculate wattage.

- For three-phase loads, multiply the Voltage by the Amperage then multiply that result by 1.73 to calculate wattage. Generally, all residential loads in the U.S. will be single-phase

- Some equipment “cycles” on and off when it is working normally. you have to estimate how many hours the equipment runs taking this into account, or, you can plug the appliance into a “Kill-A-Watt” or other energy monitor to measure its energy use in a day.

- Some appliances may have more than one electric load. For example, an electric water heater typically has two 4,500-watt heating elements. You have to account for the TOTAL load that might come on at ANY time in this form.

How Much Energy Will My System Generate?

This 1-kW wind turbine from World Power Technology, Inc. is used for pumping water for 120 head of cattle at a ranch in Texas. Photo: World Power Technology

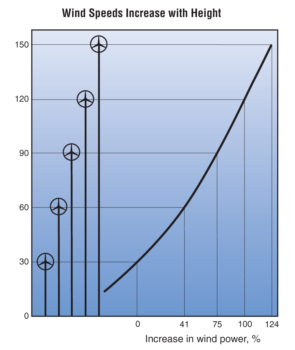

As mentioned above, most U.S. manufacturers rate their turbines by the amount of power they can safely produce at a particular wind speed. Even a small increase in wind speed results in a large increase in power. That is why a taller tower will increase the productivity of any wind turbine by giving it access to higher wind speeds, as shown in Figure 9.

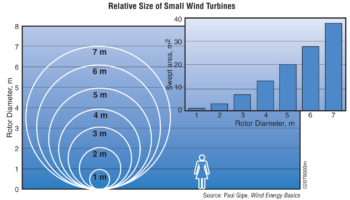

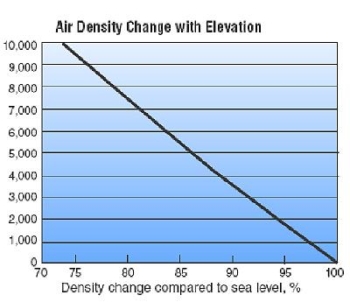

The larger the rotor, the more energy a wind turbine can capture, as shown in Figure 10. Air density changes slightly with air temperature and with elevation. The ratings for wind turbines are based on standard conditions of 59° F (15° C) at sea level. A density correction should be made for higher elevations as shown in Figure 11. A correction for temperature is typically not needed for predicting the long-term performance of a wind turbine.

The best measure of wind turbine performance is annual energy output. The difference between power and energy is that power (kilowatts [kW]) is the rate at which electric energy is consumed, while energy (kilowatt-hours [kWh]) is the quantity consumed. An estimate of the annual energy output from a particular wind turbine, in kWh/year, is the best way to determine whether the turbine and tower will produce enough electric energy to meet your needs.

Wind turbine manufacturers or dealers can help estimate the expected energy production. They will use a calculation based on the particular wind turbine power curve, the average annual wind speed at the site, the height of the tower, the elevation, and (if available) the frequency distribution of the wind—an estimate of the number of hours that the wind will blow at each speed during an average year. Contact a wind turbine manufacturer or dealer for assistance with this calculation. An example of an energy production calculation is shown below.

To get a preliminary estimate of the performance of a particular wind turbine, use the formula:

Figure 9. Increase in wind power vs. tower height

AEO = 0.01328 D2 V3

Where:

AEO = Annual energy output, kWh/year

D = Rotor diameter, feet

V = Annual average wind speed, mph

Wind Powering America’s Small Wind Economic Model is a spreadsheet tool that can help you analyze the economics of a small wind electric system and decide whether wind energy will work for you. The tool asks for information about how you’re going to finance the system, the characteristics of your site, and the properties of the system you’re considering. It then provides a simple payback estimate in years.

Example Calculation of Production Based upon Power Curve and Frequency Diagram

Now that you know the loads and energy requirements, you can figure out the wind turbine size needed to generate that much energy. Wind turbine manufacturers provide the expected annual energy output of their turbines as a function of annual average wind speed. This is called “Annual Energy Production” and it is an estimate based on the average wind speed and assuming a “typical Rayleigh wind frequency distribution,” and so should be viewed with a bit of skepticism. It is better to get a “power curve” for the wind turbine and combine this information with the frequency information from actual wind measurements. The power curve shows how much power the machine will produce at a certain wind speed.

Figure 10. Increase in turbine power vs. rotor diameter. Source: Small Wind Electric Systems – A U.S. Consumer’s Guide, U.S. Department of Energy

Looking back at our example facility that used 64 kWh per day, we can see that this wind turbine is too big. The turbine will generate an estimated 40,100 kWh per year at the lowest average wind speed on the table, but our facility uses only 23,360 kWh per year. We need to look for a smaller wind turbine.

The Endurance S-343 wind turbine will generate an estimated 23,400 kWh at an annual average wind speed of 8.5 meters per second (18.7 mph), so if we have a very windy spot this wind turbine will come close to meeting the energy needs of our example facility. Now we use the wind speed frequency diagram (Figure 4) for our site to see if we have enough wind. First, we create a table showing the percentage of the time the wind blows a certain speed, and then enter the power the turbine will make at that wind speed. From these two numbers we can calculate the energy the machine will make at each wind speed, multiplied by the time at that speed. We add them all up, and we get the annual production at our site at the sensor height (in this case, 40 meters or 130 feet). In our example, we get a total of 17,772 kWh per year.

Figure 11: Air Density Change with Elevation. Source: Small Wind Electric Systems – A U.S. Consumer’s Guide, U.S. Department of Energy

If the wind data was collected at a height different from the hub height of the wind turbine, then the data must be corrected so that it represents wind speeds that will be experienced by the turbine. It is common to have data from a lower height than the turbine height. We can use the following relationship to calculate the wind speed at some height based on the measured wind speed at the location:The wind shear can be expressed as

v / v° = (h / h°)α

where

v = the velocity at height h (m/s)

v° = the velocity at height h° (m/s)

α = the wind shear exponent

The wind shear exponent varies with the terrain.Using a spreadsheet helps to calculate the wind speed at the turbine height.

What are the Basic Parts of a Small Wind Electric System?

Home-scale wind energy systems are generally comprised of a rotor, a generator or alternator mounted on a frame, a tail, a tower, wiring, and the “balance of system” components (controllers, inverters, and/or batteries). Through the spinning blades, the rotor captures the kinetic energy of the wind and converts it into rotary motion to drive the generator.

Wind Turbine

Most turbines manufactured today are horizontal-axis, upwind machines (the rotor faces the wind) with two or three blades, which are usually made of a composite material such as fiberglass. These machines are designed so that turbines rotate around a horizontal axis. The rotor may be upwind of the tower or it may be downwind of the tower. Small wind turbines usually have passive yaw, which means that the rotor is perpendicular to the wind naturally; upwind machines use a tail to keep the rotor facing the wind and downwind machines naturally stay perpendicular to the wind. Wind turbines larger than about 25 kW generally have active yaw, where the machine has wind direction sensors controlling yaw motors that keep the rotor facing the wind.

The amount of power a turbine will produce is determined primarily by the diameter of its rotor. The diameter of the rotor defines its “swept area,” or the quantity of wind intercepted by the turbine. The turbine’s frame is the structure onto which the rotor, generator, and tail are attached. The tail keeps the turbine facing into the wind.

The amount of power a turbine will produce is determined primarily by the diameter of its rotor. The diameter of the rotor defines its “swept area,” or the quantity of wind intercepted by the turbine. The turbine’s frame is the structure onto which the rotor, generator, and tail are attached. The tail keeps the turbine facing into the wind.

| Terrain | Wind Shear Exponent – α – |

| Open Water | 0.1 |

| Smooth, level, grass-covered | 0.15 |

| Row crops | 0.2 |

| Low bushes with a few trees | 0.2 |

| Heavy trees | 0.25 |

| Several buildings | 0.25 |

| Hilly, mountainous terrain | 0.25 |

Tower

Because wind speeds increase with height, the turbine is mounted on a tower. In general, the higher the tower, the more energy the wind system can produce. The tower also raises the turbine above the air turbulence caused by obstructions such as hills, buildings, and trees. As a general rule of thumb, the bottom of the rotor blades should be at least 30 feet (9 meters) above any obstacle that is within 300 feet (90 meters) of the tower. Relatively small investments in increased tower height can yield very high rates of return in energy production. For instance, raising a 10-kW generator

from a 60-foot tower height to a 100-foot tower increases system cost by about 10%, but can increase energy production by 29%.

Bergey XL-1 horizontal-axis upwind machine. Photo: NREL www.nrel.gov/data/pix/Jpegs/11238.jpg

Mounting turbines on rooftops is not recommended. All wind turbines vibrate and transmit the vibration to the structure on which they are mounted. This can lead to noise and structural problems with the building. Furthermore, because the rooftop is not very high above the ground and is likely to be surrounded by other buildings and trees, a rooftop-mounted wind turbine can be exposed to excessive turbulence that will shorten its life.

Balance of System

The parts needed in addition to the turbine and the tower, or the balance-of-system parts, will depend on the application. Most manufacturers can provide a system package that includes all the parts needed for a particular application. For example, the parts required for a water-pumping

system will be much different than those needed for a residential application. The balance-of-system parts required will also depend on whether the system is grid-connected, stand-alone (independent of the utility grid), or part of a hybrid

system (a power system that uses more than one source of energy—wind and photovoltaics, for example). For a residential grid-connected application,

the balance-of-system parts may include a controller, storage batteries, a power-conditioning unit (inverter), and wiring.

What Do Wind Systems Cost?

According to the National Renewable Energy Laboratory, small wind energy systems cost from $3,000 to $5,000 for every kilowatt of generating capacity, depending on size. Smaller wind systems are more costly per kilowatt of installed capacity. Wind energy becomes more cost-effective as the size of the turbine increases. Although small turbines cost less in initial outlay, they are proportionally more expensive per unit of energy produced.

Types of Towers

Monopole tower. Photo Windustry.org

Source: Windustry.org

There are three basic types of towers suitable for farm-sized turbines:

Monopole

This type of tower is generally the least expensive. It is a tilt-up-style tower and is generally installed using a gin-pole and winch. Monopoles generally have four guy wires for support. Maintenance on the turbine is performed by tilting the tower down. The height of this type of tower is limited by the weight of the machine, and 10-kW machines are generally the largest that can be placed on such towers. Tilt-up towers require space for guy wires and for tipping the tower up and down.Guyed-lattice wind turbine. Photo: Windustry.org

Guyed lattice

Guyed-lattice towers are generally more expensive than monopole designs but can support larger turbines at higher heights. Towers are generally installed using a gin-pole and winch. Guyed-lattice towers also come with the advantage of either being able to tip down or being relatively easy to climb for regular maintenance (climbing, if done with appropriate safety precautions, gear, and training, is much safer than tilting a tower down and up every time maintenance is required). Guyed-lattice towers require much space for tipping up and down the tower and for the guy wires. Check with turbine manufactures to see what tower options they recommend for various turbine models.Lattice wind turbine. Photo: Windustry.org

Lattice

Lattice towers, in most cases, are required for machines larger than 20 kW in size. The installation of these towers is generally more complicated than that of a guyed-lattice tower because a crane is needed to lift the tower and turbine into place. Maintenance is performed by climbing the tower. If major work is required on a machine, a crane may be required to remove the turbine from the tower. Check with manufacturers to determine what tower options they recommend with different turbine models.

A 10-kW system, for example, can cost$47,000 to $60,000 installed. Rebates, tax credits, and other incentives can reduce these costs. Well-sited small wind turbines can usually pay for themselves within 15 years, about half their serviceable lifetimes, if the right incentives are applied, says AWEA.

Although wind energy systems involve a significant initial investment, accounting for a lifetime of reduced or avoided utility costs can make them competitive with conventional energy sources. The length of the payback period—the time before the savings resulting from the system equal the cost of the system itself—depends on the specific system, the wind resource at the site, electric costs in the area, and how the wind system is used.

Can I Install a Wind Energy System Myself?

“Most dealers offer either complete turnkey (ready-to-operate) installations or the option to purchase direct from the factory and install the system yourself. The first option offers more customer support from the company. Self-installation offers significant savings and a hands-on understanding of the turbine. Prospective owners can discuss the options available with manufacturers to decide which method best suits their budget and technical skills.” –American Wind Energy Association

Financial Incentives

Small wind turbines can provide supplemental power for farms and ranches, as on this farm in western Kansas. Excess power is fed back into the utility grid. Photo: Warren Gretz, NREL/PIX09615

Financial incentives can make wind energy more affordable for farmers and ranchers. Find out what incentives exist at both state and federal levels from the Database of State Incentives for Renewable Energy (DSIRE) at www.dsireusa.org.

Wind energy can be an attractive alternative for farms and ranches across the country, offering numerous benefits, including reduced energy costs, reduced environmental impact, and increased energy independence. However, as with all renewable energy systems, there are also challenges involved with these systems. Conduct a careful analysis of energy needs and wind resource potential, as well as system economics, benefits, and potential obstacles, to see if wind is a good choice for your farm or ranch.

References

Arkansas Energy Office. 2008. Consumer’s Guide to Renewable Energy in Arkansas.

Environmental and Energy Study Institute. 2012. Fact Sheet: Small Scale Wind Power for Homes, Farms and Communities.

U.S. Department of Energy. 2005. Small Wind Electric Systems: A U.S. Consumer’s Guide.

NorthWestern Energy. 2007. The Consumer’s Guide to Small Wind and Solar Photovoltaic Generation.

U.S. Department of Energy, Wind & Hydropower Technologies Program. 2012. Small Wind Electric Systems 2012.

World Wind Energy Association. 2012. Small Wind World Report.

Further Resources

American Wind Energy Association

National Center for Appropriate Technology (NCAT)

National Renewable Energy Laboratory

National Wind Coordinating Collaborative

U.S. Department of Energy Wind Energy Technologies Program

Small-Scale Wind Energy on the Farm

By Cathy Svejkovsky, NCAT Energy Specialist

Published August 2007

Updated November 2012

By David Ryan, PE, NCAT Energy Engineer

© NCAT

IP311

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development. ATTRA.NCAT.ORG.