Solar-Powered Livestock Watering Systems

By Mike Morris, NCAT Agricultural Specialist and Vicki Lynne, NCAT Energy Specialist; Updated by By Chris Lent, NCAT Agricultural Specialist

Solar-powered livestock watering systems such as this one are becoming increasingly popular, especially in remote areas. Photo: NCAT

Contents

Introduction

Cost

Solar Pumping Technology—What You Need to Know

Designing and Installing Systems

Frost-Free System Design

Project Descriptions

Further Resources

Abstract

Because of falling prices, long life, and low maintenance requirements, solar is rapidly becoming the first choice for pumping water in remote locations. This publication gives an introduction to solar-powered livestock-watering systems, including discussions of cost, components, and terminology, as well as some suggestions for designing and installing these systems. The strengths and weaknesses of solar pumping are compared to the main options for pumping in remote locations: mechanical windmills, wind turbines, and portable generators powered by gas, propane, or diesel fuel. Design considerations for freeze protection in water-pumping systems are also discussed. Descriptions of four successful projects and a brief resource list are included.

Introduction

Remote or off-grid power sources—including solar panels, mechanical windmills, wind turbines, and portable generators—can pump water for livestock in locations where electricity from power lines is unavailable. By encouraging animals to move away from ponds and streams, these systems give livestock greater access to forage. They also reduce livestock pressure on stream banks, preventing nutrient loading, damage to streamside vegetation, erosion, and pollution.

Solar pumping replaced a gas powered generator on the Tomlinson Ranch near Gold Creek, MT. Photo: NCAT

Solar pumping works anywhere the sun shines, and most parts of the United States have plenty of sunlight to run these systems. Solar pumping is a natural match for summer grazing applications, since it produces the greatest volumes of water in sunny weather and during long summer days—exactly when animals need water the most. With proper precautions, solar pumping systems can be used during the winter months too, even though shorter daylight hours will cause reduced water output.

Why should you consider installing a solar-powered livestock watering system on your farm or ranch? These factors may affect your decision:

-

-

- Distance from power lines and the cost of a line extension

- Operation and maintenance costs of a solar system compared to the alternatives, such as a mechanical windmill or a gasoline, propane, or diesel-powered generator

- The uncertainty of future electricity, propane, gasoline, and diesel prices

- Environmental benefits such as riparian protection, energy independence, and demonstrating non-fossil energy alternatives

-

Cost

In 2012, the typical cost for a small to medium-sized solar pumping system suitable for stock watering is $2,000 to $6,000. This does not include installation costs or well drilling. Retail prices for solar panels have dropped dramatically, falling by around two- thirds between 2008 and 2012.

More good news for consumers is that solar pumping systems are eligible for a 30% federal Business Energy Investment Tax Credit. There is no maximum credit amount, and a similar 30% tax credit is available to homeowners. These incentives have been in place since 2005 and are scheduled to last until December 31, 2016. Agricultural producers are also eligible to apply for grants or loans from the competitive Rural Energy for America Program (REAP), administered by USDA Rural Development. Grants are up to 25% of eligible project costs. For more information, visit www.rurdev.usda.gov or contact your state USDA Rural Development office.

Note that conditions and exclusions apply to both the Business Energy Investment Tax Credit and the REAP program. The information above is accurate as of 2012, but rules may change for both of these programs. For current incentives, check with your solar dealer or visit the Database of State Incentives for Renewable Energy (DSIRE).

Even with big price decreases and readily available financial incentives, solar panels are by no means a cheap way to generate electricity. After all, consider the fact that a 100-watt solar panel costing hundreds of dollars generates only enough power to light a 100-watt light bulb. Solar pumping systems are designed to run on low power, usually just a fraction of a horsepower. The four solar pumping systems described at the end of this publication range from 128 to 420 watts, or 0.2 to 0.6 horsepower. If you are familiar with irrigation pumps ranging from several to 100 horsepower or more, you’ll need to scale down your expectations.

Many solar panels on the market today (in 2012) cost under $2.00 per watt, and a set of panels for a small to medium-sized system should cost well under $1,000. However, keep in mind that prices for pumps, racking, wire, controllers, and other components have not dropped. In the case of pumps (discussed at length below), quality has arguably improved, but so have prices.

Solar pumping is well-suited to low-head and low-volume situations. Where large volumes and deep wells are involved, solar pumping becomes prohibitively expensive because it requires specialized, expensive pumps and extremely large solar arrays. Likewise, most pressurized irrigation systems require far too much power to be run economically with solar panels, although solar pumping can be an excellent choice for small drip-irrigation systems.

Although solar electricity is not cheap, there are many situations where solar-powered pumping systems can be justified based on economic reasons alone. When you factor in installation, fuel, and maintenance costs over the life of the project, you may find that solar is the most attractive option.

If power lines are readily available, they will generally provide the cheapest source of electricity. For many who decide to install a solar pumping system, a major consideration is the cost of utility-line extensions. Line extensions commonly cost $10,000 to $50,000 or more per mile. One very rough rule of thumb is that remote pumping (whether solar-, wind-, or generator-powered) is worth considering whenever the distance from the utility grid exceeds about one-half mile.

How do you choose between solar power, a mechanical windmill, a wind-electric system, and a gas-, propane-, or diesel-powered generator? No two pumping situations are alike, but here are a few guidelines:

Solar-powered systems have a relatively high initial cost compared to low–quality, generator-powered systems, but they are long-lasting and require little maintenance. Solar watering systems have few moving parts, and the components in these systems have proven to be very reliable when installed properly. Warranties on solar panels are usually 20 years or more.

Gas- or propane-powered generators sometimes have a lower initial cost than solar power, although the cost of fuel must also be included. Low-end gas-powered generators require frequent maintenance and have a design life of only about 1,500 hours, making them a costly and labor-intensive option in the long run. On the other hand, better-quality generators have many strong points. A high-quality, self-starting propane-powered generator operates unattended, runs day and night, is easy to install, should last many years, and is especially well-suited to situations involving deep wells and high volumes of water. Warranties are typically two to three years.

Although they cost about twice as much as comparable gas-powered generators, diesel-powered generators will often have a lower initial cost than wind- or solar-powered systems. In low-head and low-volume situations, a solar-powered system very often will produce cheaper water over the life of the system than a diesel-powered generator. On the other hand, where large volumes of water are required, a diesel-powered system may be the best available option. Warranties on diesel generators range from one to three years.

Mechanical windmills or windpumps—along-familiar sight in rural America—have a gearbox that converts the circular motion of the blades into up-and-down strokes of a pump cylinder. In a good location—one with average wind speeds above seven miles per hour—a wind-powered pump may produce cheaper water than a solar-powered pump. However, windmills often have a higher initial cost than comparable solar or generator-based pumping systems. A new windmill from Aermotor, a well-known company, will cost anywhere from $2,000 to $13,000, not including tower or installation costs. In general with windmills, you should expect much higher maintenance requirements than you would get with a solar-powered system. Warranties are typically five to seven years.

Wind turbines include a generator that converts the circular motion of the blades into electrical current. These systems may be used alone or in combination with PV panels to power a pump. A small wind turbine rated at 500 watts can be purchased for as little as $650 and will power a small to medium-sized pumping system at a site with excellent wind speeds. However, you’ll need a tall tower (80-plus feet in most locations) to take full advantage of the wind, adding considerably to the cost of the system. Likewise, you may be tempted to add a small wind turbine to an existing solar array, creating a more powerful hybrid system. But unless you have outstanding wind speeds (averaging at least seven miles per hour), you’re probably better off simply adding solar panels to the system and increasing water storage capacity to meet your needs.

There is a night-and-day difference between the maintenance requirements of solar and wind-powered systems. Solar-powered systems typically operate nearly maintenance-free for years. On the other hand, wind turbines and windmills have somewhat demanding installation and maintenance requirements, and catastrophic failure is not uncommon. See the ATTRA publication Small-Scale Wind Energy on the Farm for more information.

The bottom line is that solar stacks up very well against the available alternatives, if you are looking to pump water in a remote location. If you are replacing a windmill, there is no question that you should seriously consider solar. In fact, solar-powered systems appear to be steadily replacing mechanical windmills and are well on their way to becoming the first choice for pumping water in remote locations.

All of these generalizations should be taken with a grain of salt. New equipment is coming on the market all the time, every option has its advantages, and it bears repeating that every pumping and stock-watering situation is site-specific.

Solar Pumping Technology—What You Need to Know

Before talking to a dealer, it’s a good idea to know some basic terminology:

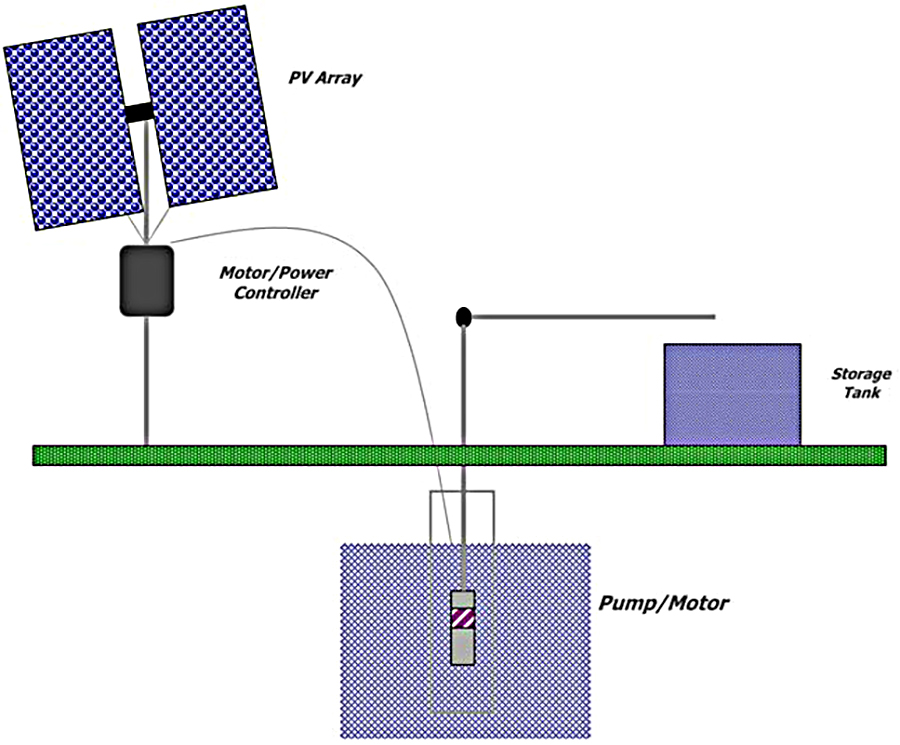

Figure 1. A typical solar-powered stock watering system includes a solar array, pump, storage tank and controller. Graphic: NCAT

Solar Modules. Solar electric systems are sometimes called photovoltaic, or PV, systems. The word “photovoltaic” is often abbreviated “PV.” Solar panels, or modules, generate direct current (DC) electricity. A group of modules is called an array. Modern solar panels are designed to withstand golf-ball-sized hail and usually come with 20-year (or longer) warranties. Most water-pumping systems will need two to six panels. The size and number of panels is determined by the voltage requirements of the pump. The size and type of pump, in turn, is determined by the amount of water needed and the height and distance the water needs to be pumped.

Mounting Structures. There are two ways to mount solar modules: on a fixed structure or on a tracking structure. Fixed mounts are less expensive than trackers and tolerate high winds better. They should ideally be oriented to face true south (not magnetic south), and the tilt angle also needs to be adjusted. The usual recommendation is to adjust the tilt angle to latitude minus 15 degrees for summer use, latitude plus 15 degrees for winter use, and equal to latitude for year-round operation. For example, if you were located at 40 degrees latitude, you would set the tilt angle at 25 degrees in the summer and 55 degrees in the winter, or else leave the tilt angle at 40 degrees year-round.

A tracking array follows the sun across the sky. A tracker will add at least $600 to $1,200 to the cost of a system, but in some cases this is a good investment since trackers can increase water volume by 25 percent or more in the summertime, compared to a fixed array. Trackers are either passive, meaning that they use no electricity, or active, meaning that they require a motor to move them. Active systems are more expensive and that extra cost can usually only be justified for a larger array. For the smaller-sized arrays involved with most solar pumping systems, a passive tracker is the most cost-effective option. Liquid stored in a passive tracker is warmed by sunlight and flows through tubing to the opposite side of the tracker. The weight of the fluid causes the tracker to tilt the panels toward the sun.

The effectiveness of a tracker is somewhat site-specific. Generally, the more sun hours available at a location, the more you’ll benefit from a tracking system. In a poor location receiving less than four hours of sun per day on average, a tracking system may not have much impact on the volume of water pumped. Also keep in mind that trackers add complexity to a system and make the system more susceptible to wind damage than a fixed array. Finally, it should also be pointed out that trackers have become less popular as solar panels have dropped in price. You may find that it’s easier and more cost-effective to simply add another panel or two, rather than install a tracker. An experienced dealer/installer can help you decide whether a tracker would be right at your location.

Once the panels are fastened to a mounting structure, the whole structure can be mounted on a trailer to make it portable. Towing the trailer from one pasture to another makes it possible to follow animals through a rotation and pump water from the nearest well, stream, or pond. In some systems, the pump moves along with the trailer from one pasture to the next. In other cases, a stationary pump is installed in each pasture, and only the panels and electronic components (i.e., the power supply) are moved.

A few words of caution about portable systems: If the pump is mobile, it will be susceptible to freezing in cold weather. So during periods of cold weather, you’ll need to be diligent about draining water from the pump and lines every time the pump is used. Also check your warranty. Hauling components around on a trailer may cause damage that would not be covered under a warranty. Although solar-electric systems are reasonably sturdy and robust, frames can bend, wires can rip loose, and glass can crack or break. Some farms with mobile units remove the modular array, the most fragile component, and place it in soft packing material when they move it from one pumping site to another. Trackers can be used on mobile systems, but they make removing the panels for transport more complicated because of the extra connections involved in tracker installation.

Pumps. Solar panels produce direct current (DC) power, and DC pumps typically use one-third to one-half the power of alternating current (AC) pumps. For this reasons, DC pumps are used far more often than AC pumps in solar-powered systems. However, the German companies Grundfos and Lorentz have both developed pumps that can run on either AC or DC power. This allows a backup AC generator to be used, without an AC-to-DC converter, when there are periods of little sun.

All pumps can be classed as either submersible or surface, and as either displacement or centrifugal.

Submersible pumps, placed down a well or sump, are very commonly used in small stock-watering applications. Among other advantages, they are not exposed to freezing temperatures, do not need special protection from the elements, and do not require priming. Surface pumps, located at or near the water surface, are used primarily for moving water through a pipeline. Some surface pumps can develop high heads and are suitable for moving water long distances or to high elevations.

Displacement pumps use diaphragms, vanes, or pistons to seal water in a chamber and force it through a discharge outlet—similar to the way your heart pumps blood. On the other hand, centrifugal pumps rely on centrifugal force. A spinning impeller adds energy to the water and pushes it into the discharge outlet, similar to the way water sprays off a spinning bicycle tire.

Displacement pumps operate at slower speeds than centrifugal pumps. They generally move less water but are more powerful—like driving a car in low gear—and are often used in deep well and high head situations. On the other hand, if there is a lot of water to move (high flow) without much increase in elevation (low head), usually a centrifugal pump is chosen for the job. Centrifugal pumps are generally high speed pumps that need to spin an impeller very quickly in order to produce any pressure at all. In partial sun, as the impeller slows down, a centrifugal pump often loses its ability to move water, while a displacement pump will keep pumping, albeit at a slower rate.

The screw-like rotor seen on this dissection of a helical rotor pump is what gives this pump its name. Photo: Grundfos

One type of submersible displacement pump, the helical rotary pump, has recently become popular on the solar water-pumping scene. The helical rotary pump uses screw-like rotors to pressurize and pump water. Helical rotor pumps are a good choice for a deep-well application, and they are well-suited for pumping low volumes of water at a high head. These pumps can also handle some particles in the water without being damaged. For this reason, some installers prefer helical rotor pumps for surface-water pumping from streams and ponds, where water clarity can be an issue.

Choosing the right pump for your system can be complicated. For an in-depth comparison of solar water pump performance, see the Further Resources section at the end of this publication, under “Determining the Optimum Solar Water Pumping System for Domestic Use, Livestock Watering or Irrigation.” Currently, many professional installers are relying heavily on Grundfos SQFlex (SQF series) pumps for both deep-well applications and surface-water pumping because of this pump’s reputation for reliability, low maintenance, ability to run on either AC or DC current, and the advantages of the helical rotary design. These pumps cost around $2,000 to $3,000, and Lorentz has a series of helical rotary submersible solar pumps in the same price range. SunRotor sells a helical rotary pump starting at around $1,300.

Depending on your situation, however, a less-expensive pump might be adequate. For example, Shurflo and Sunpump both offer submersible high-head pumps that cost $700 to $2,000. Some of these are diaphragm pumps and others are multi-stage centrifugal pumps. When diaphragm pumps are used heavily, manufacturers recommend replacing the internal parts every two years. However, there are anecdotal reports of some of these pumps going five or six years without a problem. Full rebuild kits for the Sunpump submersible solar pumps cost around $400.

Storage. Batteries are usually not recommended for solar-powered livestock watering systems because they reduce the overall efficiency of the system and add to the maintenance and cost. Instead of storing electricity in batteries, it’s generally simpler and more economical to install three to 10 days’ worth of water storage tanks. Storing water is almost always cheaper and simpler than storing electricity. Adding batteries to a system may make sense, however, in any of three situations: 1) The storage tank is not elevated enough to use gravity flow; 2) there is not enough storage tank capacity and water needs to be pumped at night or in cloudy weather; and 3) continual water flow is needed as part of a freeze-protected system.

Pump controller. The pump controller varies voltage to optimize the amount of water pumped in less-than-ideal light conditions. It also protects the pump from high or low voltage that would damage the pump. Some controllers allow you to tie in a power source other than the solar panels, such as a wind turbine or a generator.

Inverter. An AC pump requires an inverter—an electronic component that converts DC electricity from the solar panels or a battery bank into AC electricity to operate the pump. Inverters are at best about 93% efficiency, so the PV array needs to be sized to account for this power loss.

Other equipment. A float switch turns the pump on and off when filling the stock tank. It’s similar to the float in a toilet tank but is wired to the pump controller. Low-water cut-off electrodes protect the pump from low-water conditions in the well.

Designing and Installing Systems

The average consumer is likely to be intimidated by the prospect of sizing and designing a solar pumping system, and most people need help from a qualified solar dealer. In general, dealers are eager to help. Many will provide a no-cost proposal based on a few simple questions you can answer over the phone. If the price seems too high, you can easily get bids from other dealers.

In order to size and design a system correctly, the dealer will want to know:

-

-

- How much water you need

- When you need the water

- Whether your water source is a stream, pond, spring, or well

- Water available in gallons per minute (gpm)

- Well depth

- The distance from the top of the water source to the ground level and storage tank

- The size and type of piping you plan to use (a dealer can make recommendations)

- How far the water needs to be pumped

- Water-quality problems (e.g., silt or high mineral content) that may damage the pump

- How much volume is available in storage tanks and how the tanks are arranged

-

A dealer can help you size and design a system that will meet your specific needs. Photo: NCAT

Based on these factors, the dealer will recommend a system, putting together a list of suitable components. This is one area where the dealer’s experience and familiarity with systems is essential. A dealer can also save you time and aggravation by providing the correct hardware: clips, screws, nuts, bolts, washers, cable (cut to correct lengths), and assorted wiring and connectors. The customer usually provides peripheral items, such as water piping and fittings, tanks, mounting structure support post, concrete, and grounding materials.

If the location will allow the storage tanks to be higher than the stock tanks, gravity can be used to supply water to the stock tanks. Keep in mind, when gravity-feeding water to a stock tank, that some float valves need a certain amount of pressure to work properly. Make sure the elevation of the storage tank is sufficient to supply that pressure. If a gravity system is not possible, a booster pump with a battery bank can be used to pump water from the storage tank to where it’s needed. Another option is a large, pressurized storage tank that acts just like the pressure tank in most domestic well-water systems. Pressure builds up in the tank as it fills and is then used to push water to the stock tanks.

The most common complaint about solar pumping systems is that flow volumes are disappointing. There’s often a period of adjustment and tweaking when systems are first installed. When you are sizing the system, you don’t want to throw money away on a vastly oversized system, but you need the system to be big enough to handle the highest water-use situations throughout the year, allowing for periods of cloudy weather when your system will pump little or no water. This can be a balancing act, but oversizing the system just a bit (perhaps 20%) will help ensure that you don’t need to invest in a backup system for those times of highest water use.

Installing a solar pumping system is generally something the landowner can do. A few words of caution are necessary, however. Installing one of these systems is a complex task, combining elements of electrical work, plumbing, and heavy construction (often including earthmoving, concrete-pouring, and welding). Written instructions are not always as complete as they should be. A backhoe or tractor with a front-end loader is almost a necessity for some larger projects.

Frost-Free System Design

Using a solar watering system in the winter presents some challenges. The problems of lower light conditions and shorter days can usually be handled by adding more solar panels. The larger challenge, though, is keeping pipes, valves, water tanks, and troughs from freezing. You’ll have no way to power the high-wattage (often 1,500 plus) AC electric resistance heaters that are commonly used to keep water from freezing. And during the night—when temperatures are at their lowest—solar panels generate no power at all.

You have several options to prevent freezing, including using heat from the earth or sun, insulating components, and continuously circulating water. By following a few basic design principles from the outset, you can build a system that will most likely function in cold weather for many years without a problem. When you install the system, you’ll need to reduce the chances of freeze-up of components that may be in contact with water. You’ll need to bury piping below the frost line. If the system includes a well, install a pitless adapter. Any above-ground sections of piping should be insulated and arranged so they drain at night as well as when it’s cloudy and no water is being pumped. Frost-free hydrants may not work in this situation. If the handle is left up and the solar-pumped water stops running—either because it’s night or because it’s cloudy—the hydrant will freeze.

Suggestions for Keeping Water Open

There are several ways to keep watering tanks open and keep storage tanks from freezing. For starters, you can take advantage of geothermal heat by burying the bottom of the tank. And there are many commercial cold-weather watering tanks on the market (see the Further Resources section at the end of this publication). Each livestock-watering situation is unique, so you’ll need to tailor a solution to your site, weather, and terrain. Below are some ideas, and you can find more design information in the Further Resources section under “Remote Winter Watering Systems for Beef Cattle.”

1) Pump water into a large, enclosed storage tank at a higher elevation. You should insulate the tank in some way, bury it, or mound dirt up around it. If any part of the tank is exposed, paint it black to absorb the sun’s heat during the day. From the storage tank, run a buried line to supply the watering tanks by gravity. You can direct this flowing water around the inside perimeter of the watering tank, where ice tends to form first. You can allow water to trickle continuously, overflowing the tank onto a drain field. Or you may prefer to use a thermostatically controlled float valve that opens when temperatures drop below a certain point. (Note that these valves may require some minimum pressure to operate correctly.)

2) If a storage tank is not an option, you can fill the watering tank directly during the day and make a small hole in the tank so it will drain slowly at night, keeping water moving. Remember that whenever water is being lost, you are decreasing the efficiency of the system. Also, there are no guarantees that the sun will come out the next day to refill the tank. So if your system is set up to drain every night, a backup power source may be worth considering.

3) You can use large heavy-equipment tires as watering tanks. These help keep water open since they are black and absorb heat from sun during the day. They are also flexible enough not to crack if freezing occurs. These tires are often available for free and they are very tough and can take abuse from animals. NRCS drawings and installation designs for a heavy-equipment-tire stock tank can be found here.

4) Much of the heat loss from a watering tank occurs at the surface of the water. You can reduce this heat loss considerably by placing an insulated cover over a large part of the surface area of the tank. Provide openings around the edge where animals can drink. You can also insulate the sides of watering tanks with insulation, sawdust, or wood chips. Partially burying a watering tank, or berming it with earth, takes advantage of the earth’s warmth to prevent freezing.

5) Another way to make use of the earth’s warmth is to install a culvert under the tank with a sealed bottom. You can circulate water from the culvert into the tank with a separate small-wattage solar-powered pump. This system requires a battery bank to allow for night use. You’ll need to put the batteries in a non-freezing area, such as on a platform above the water level in the culvert. A number of companies offer systems of this kind and are listed in the Further Resources section at the end of this publication. To save battery power, a motion sensor can be added to this type of system, causing the water to circulate only when a thirsty cow approaches the tank.

6) You can use a special in-tank propane heater to keep water from freezing. Trojan Specialty Products in Dodge City, Kansas, is one company that sells two types of these water heaters. www.trojan livestock.com

7) Innovative producers have experimented with building solar-heated air collectors or water collectors on their tanks. For some examples and inspiration, visit Build It Solar. Another possibility is to install a small air pump (like those used in aquariums) to circulate water within the stock tank. Note that this approach would require a battery bank for night use.

Project Descriptions

John Hopkins of Forks Farm installed a solar pumping system to open up more acreage to grazing on his farm near Bloomsburg, PA. Photo: Chris Lent, NCAT

Forks Farm, Forks, Pennsylvania

John Hopkins and his wife Todd raise pastured poultry, beef, lamb, and pigs on their farm along Huntington Creek. They installed a two-panel, 300-watt solar water system to open up 25 acres to seasonal grazing that previously had no water supply. They developed a spring-fed, shallow, eight-foot well for the project and used a Grundfos 6-SQF-2 pump. The system is capable of pumping 1,100 gallons a day in the summer season. The system cost $6,850 installed, not including the excavation of a trench to bury the water line.

Ballard Ranch, Lavina, Montana

A tracking PV array replaced an old and unreliable windmill onthe Ballard Ranch near Lavina, MT. Photo: NCAT

When their old water-pumping windmill finally died, Jim and Adele Ballard installed a solar pumping system to replace it. The new system pumps water from a 65-foot-deep well to a pair of stock tanks holding about 4,000 gallons. Four 80-watt PV modules on a tracking rack power a submersible piston pump that delivers a maximum flow rate of 5.5 gpm, enough to water 100 cow/calf pairs. The system produces average flows of 2,000 to 3,000 gallons per day during the summer months. Solar component costs in 2001 were $5,500.

This solar pumping system on the Hirsch Ranch near Deer Lodge, MT, is protecting stream banks along Racetrack Creek, an important trout spawning stream. Photo: NCAT

Hirsch Ranch, Racetrack, Montana

Rick and Pam Hirsch installed a solar pumping system on a 10-foot-deep, backhoe-dug well on their property to water 36 cow/calf pairs. The pumping system uses two 64-watt PV modules, a passive tracking rack, and a submersible diaphragm pump equipped with a sand shroud and low-water cut-off electrodes to protect the pump. The system is designed to produce flows of 2,600 to 2,800 gallons per day during the summer months. Solar component costs in 2001 were $2,400.

A trailer-mounted PV system is improving range management and water quality along Painted Robe Creek near Lavina, MT. Photo: NCAT

Painted Robe Watershed Group, Lavina, Montana

The Painted Robe Watershed Group has been developing off-stream sources of drinking water for cattle along Painted Robe Creek, a tributary to the Musselshell River with water-quality problems. The group received a trailer-mounted solar pumping system from the Montana Department of Environmental Quality. It was first installed on the Leo Schraudner Ranch to water 150 cattle at the site of a 60-foot-deep well. Seven 60-watt panels on a fixed, trailer-mounted rack use an inverter to convert solar-produced DC to the AC electricity needed by the submersible centrifugal pump. Water is pumped into two 1,100-gallon tanks. The system is designed to produce average flows of 2,880 to 4,000 gallons per day during the summer months. Solar component costs in 2001 were $10,650.

Further Resources

Solar equipment dealers and manufacturers are a good source of information. To locate solar equipment dealers and installers who have experience with solar pumping, go to NCAT’s Directory of Energy Alternatives. You will find a clickable map that allows you to locate dealers and installers in your area.

For information about incentives:

Visit the Database of State Incentives for Renewable Energy. Click on your state.

Manufacturers of cold-weather stock-watering systems:

Publications

Watering Systems for Serious Graziers. 2006. By USDA Natural Resources Conservation Service.

This 40-page guide covers topics on livestock water needs, water sources, delivery systems, tanks, protection watering areas, tank location, installing pipes and spring water development.

Pumps and Watering Systems for Managed Beef Grazing, Second Edition. 2007. By Donald Pfost, James Gerrish, Maurice Davis, and Mark Kennedy. University of Missouri Extension, Columbia, MO.

This eight-page guide covers water-quantity requirements for different grazing animals, distribution systems, pipe and stock tank sizing, and choice of pumps.

Determining the Optimum Solar Water Pumping System for Domestic Use, Livestock Watering, or Irrigation. 2009. By Brian D. Vick and R. Nolan Clark. USDA Agricultural Research Service, Bushland, TX.

This nine-page report shows results from tests performed on solar pumps under various conditions. It discusses options for remote water pumping, types and performance of PV modules, and types and performance of various solar pumps.

Remote Winter Watering Systems for Beef Cattle. 2006. By Manitoba Agriculture Food and Rural Initiatives, Agriculture and Agri-Food Canada, and Manitoba Forage Council.

This brief guide discusses four low-tech designs for cold-weather watering systems.

Solar Water Pumping Basics. 2012. By Chris Callahan and Ben Waterman. 2012. University of Vermont Extension New Farmer Project.

This article discusses the principals of water pumping, including how to determine water flow and pressure requirements. If offers a four-step process for designing a solar water-pumping system. This is a good article for those interested in more information on designing their own system for irrigation or livestock watering.

Design of Small Photovoltaic (PV) Solar-Powered Water Pumping Systems. 2010. Teresa D. Morales and John Busch. USDA Natural Resources Conservation Service, Portland, OR. NRCS Technical Note No. 28.

This 71-page technical note discusses solar design, including the components of solar pumping systems. PV panels, controllers, and pumps are covered, as well as mounting considerations. An in-depth, 12-step design process follows for those interested in designing their own system.

Solar-Powered Livestock Watering Systems

By Mike Morris and Vicki Lynne

NCAT Energy Specialists

© NCAT

IP217

Slot 220

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development. ATTRA.NCAT.ORG.