Dairy Goats: Sustainable Production

By Linda Coffey, Margo Hale, and Paul Williams, NCAT Agriculture Specialists

Abstract

This publication is intended for those interested in starting a commercial goat dairy. It discusses the five major considerations to be addressed in planning for dairy goat production: labor, sales and marketing, processing, regulations, and budgeting and economics. It includes production information specific to dairy goats, including choosing breeds and selecting stock.

This is a companion piece to ATTRA’s Goats: Sustainable Production Overview. The Overview should be read first, since it contains production information for goats in general, including grazing management, fencing, reproduction, nutrition, diseases and parasites, and resources.

Introduction

In 1994, world-wide production of goat milk was approximately 10.5 million tons. In the United States at that time, there were approximately one million dairy goats producing 600,000 tons of milk, about 300 known dairy goat businesses, and at least 35 known commercial goat-cheese makers. These cheese makers produced about 640 tons of U.S. goat cheeses, while at least another 650 tons of goat cheese were imported that year from France alone. (Haenlein, 1996)

Dairy goats are enjoyable animals, easy to handle and haul, and relatively inexpensive to purchase, feed, and house. Dairy goat production, especially pasture-based production, offers the opportunity for profitable and sustainable diversity on a small farm. For example, a vegetable farm can use goats to clean up residue and fertilize the land, while producing milk for the family or for raising kids, calves, pigs, or other livestock. Goats will browse and help keep pastures from being overrun with woody species.

In some locations, Grade A dairies may have a market for fluid milk. Goat milk can often be enjoyed by people who are allergic to cows’ milk, and infants of all species generally thrive on goat milk. Value-added products such as cheese and yogurt made from goat milk are finding a growing acceptance in the dairy market, with sales of goat cheese increasing more than 16% in 2000. (Specialty Cheese Market, 2001)

However, producing dairy animals and dairy products requires a great commitment of time and energy and consistent attention to detail. Proper nutrition and milking procedures, skillful kid raising, and good general health care are essential for success. In addition, costs must be kept under control. Most important of all is marketing; a viable business requires a healthy demand for the product or products produced and a price that allows a profit.

Because commercial production is so much more challenging than keeping a few dairy goats, this publication will first address the major issues of labor, marketing, processing, regulations, and budgeting. The production notes— including selecting stock, feeding, breeding, and milking— compose the second major section. Finally, budgets and a list of further resources are also provided.

Getting Started

Things to be considered before entering a commercial dairy goat business include the availability of labor, the marketing outlook, processing options, regulations, budgeting, and economics.

Labor

Labor is a major concern. Do you enjoy goats enough to spend mornings and evenings, seven days a week, week after week, feeding, milking, and cleaning up? Do you have the support of your family in this? Many dairy producers have faced frustration and burnout after trying unsuccessfully to hire competent help. If your family is not willing to help with the business, you should probably consider a less demanding enterprise.

Estimates vary regarding the labor demands of a goat dairy. Dr. Robert Appleman believes that a 100-doe dairy selling fluid milk to a processor will require about 1.5 full-time workers. (Appleman, 1989) Appleman’s calculations:

- Milking: 25 does/person/hr (305 days)

- Set-up and clean-up: 40 min. daily

- Manure handling and bedding: 25 min. daily

- Feeding hay and grain: 30 min. daily

- Heat detection: 30 min./day for 6 months

- Breeding: 20 min. x 2 breedings

- Miscellaneous: .5 min. daily per doe

Some of the above figures are per doe, while others are per herd. Total labor per doe in Appleman’s budget is 34.7 hours per year, 70% of which is spent milking (Appleman, 1989).

In contrast, a Pennsylvania State University budget estimated labor as 22 hours per doe per year to run a 100-doe facility while a Rutgers Cooperative Extension budget considered 13.6 hours per doe per year to be sufficient for a 100-doe herd. With so much variation in estimates, you may want to visit a producer who has a dairy the size you intend to operate, work beside the farmer for a week or so if possible, and ask what that farmer thinks is realistic. Facilities and efficiency of milking, feeding, and cleaning can account for a lot of the difference, and that should be kept in mind as you plan your dairy farm. Also, note that these figures do NOT include any value-added processing or marketing time; if on-farm processing is part of your business, labor costs will be significantly higher.

Marketing

If labor is available, the next concern is marketing. What product or products do you hope to sell? Is there an unmet demand for that product in your area? If so, what price can you realistically expect to receive? Can you make a profit if you sell at that price?

In the case of fluid milk, a prospective producer must first locate a reliable buyer. Judy Kapture, long-time producer and columnist for the Dairy Goat Journal, issues a strong warning to the farmer planning to start a goat dairy.

You are certainly wise to be cautious. I can tell far too many stories about people who used all their money to set up their farm as a goat dairy, and then never did sell any milk. Or their milk market fizzled out within a year… Get in touch with them (the buyer) to find out if they actually are planning to buy more milk. Learn the details—how much milk do they want from a farm, what do they pay for milk, is winter production a necessity, what do they charge for hauling, etc.

Then talk with some of the people who are shipping milk to them now. You want to find out if they feel the pay for the milk is good enough to make the goatkeeping effort worthwhile. (Remember that feed and other costs vary greatly and a “good milk price” in one area may be too low for another.) You may get some surprises when you ask this question… Be cautious about new startups. Sometimes they have a lot of enthusiasm but no idea how difficult it will be to market their milk or cheese or other product in the quantities they need… Are there patrons shipping milk to the buyer now? Talk to them, all of them. Are they getting paid? Is the buyer taking all the milk he promised he would?… How good is the market for what they are planning to sell? (Kapture, 2001)

In many areas of the United States, there are no processors. In some areas, a processor is available but already has enough milk producers on contract. Therefore, it is vital to be sure you have a market for your milk. If you are unable to sell to a processor, it may be feasible to sell to individuals raising baby animals, or to market the milk through your own livestock (raising calves, for example, and selling them for meat). In some areas it is possible to sell milk directly to individuals for human consumption, but in MANY states that is ILLEGAL. To find out what is legal in your state, contact the agency responsible for dairy regulations. The American Dairy Goat Association (ADGA) lists the contact information for state agencies on its website.

Marketing to individuals will require much more time and effort and will be harder to initiate. For example, a milk truck going to a commercial dairy may pick up 200 gallons of milk every other day. If there is no milk truck, how much milk can you sell each week? If the answer doesn’t equal “all of it,” what will you do with the rest? The available market is a major factor in determining your scale of operation (herd size).

Processing

Some producers choose not to deal with a milk buyer and hope to increase their farm profits by processing the milk themselves. Diversifying the products you sell may offer more income and financial stability. Those products might include fluid milk, milk-fed pork, goat cheese of one or more varieties, yogurt, fudge, goatskins, meat, or goat-milk soap or lotions.

Cheese is a good alternative to selling milk, particularly if you like direct marketing. It is legal to use raw milk in making cheese if the cheese is aged at least 60 days before sale (Dairy Practices Council, 1994). Fresh cheese must be made with pasteurized milk. Cheesemaking classes will prove helpful, and much practice, experimentation, and sampling will be necessary before you are ready to market farmstead cheese. You must abide by regulations (talk to your inspector about what is involved). Cheese-making resources are discussed in The Small Dairy Resource Book (see Further Resources), and Caprine Supply and Hoegger Supply Company (see Further Resources) offer several books about cheesemaking.

Edible products will require a Grade A dairy, commercial kitchen, and licenses (contact your state agency for more details), while soap making does not. Soap is non-perishable, easy to ship, and does not require much milk. These advantages make soap an appealing option for small farm enterprises.

Any further processing (beyond selling bulk fluid milk) will create extra demands on the farmers, since they must somehow tend not only to the dairying but also to the processing, packaging, marketing, delivery, and paperwork (Dunaway, 2000). Also, while diversifying products may add stability (not all the eggs in one basket), each new product will require more equipment, labor, storage space, production knowledge and skill, and outlets and time for marketing. Unless there is a large labor force available, too much diversification will be unsustainable. Dr. Tatiana Stanton points out the following.

If you try to produce a whole line of products, it can make really big marketing demands on you if you are not going to sell them to the same buyer. For example, if you are a small producer and are going to sell fudge, soap, and cheese all to the same local food co-op or over the Web, that is one thing. You are going to have to do a lot more marketing if your cheese is going to cheese shops or restaurants, and your fudge and soap to gift shops. You may find in such a case that it is a terrible decision to expand your line. (Stanton , 2002)

Brit and Fleming Pfann, owners of Celebrity Dairy in North Carolina, have said, “Marketing takes a huge amount of time, and as we’ve gotten more involved in cheese-making and in selling the cheese, we’ve found that we have very little time to spend with the animals” (Pfann, 2002). Other farmers have echoed that observation, and this is disappointing to those who enjoy the goats far more than processing or marketing. If you yourself do not want to be involved in marketing, then you will need a partner who is capable, reliable, and enthusiastic.

Your customers can be local individuals, restaurants, farmers market patrons, grocery stores, or even mail-order and Web customers. Harvey Considine cautions against pricing products too cheaply.

In a competitive market such as goat cheese, one must be constantly aware of what the competition is charging, but even then everyone must know their own costs of production. If you do not cover those costs you will not be long in business. Keep in mind that other factors than competition can justify price… My counsel always is to produce a high-quality product consistently and charge what you must to make your venture profitable. (Considine, 1999)

There are successful farmstead cheesemakers, and their stories may inspire you. Their experiences should help prospective producers think through the demands of the occupation and decide whether family support and available labor will be adequate to meet the challenges. Some thoughts shared by Brit and Fleming Pfann of Celebrity Dairy in North Carolina illustrate the demands of farmstead cheesemaking.

- Sustained long hours of work (all year)

- Great breadth of skills (dairy animals, cheesemaking, marketing)

- Significant capital investment

- …and may return a modest annual income.

Another North Carolina goat dairy is the Goat Lady Dairy; like Celebrity Dairy, it produces delicious farmstead cheese and has other enterprises to diversify the farm income. Goat Lady Dairy also offers a class in farmstead cheesemaking.

Split Creek Farm, South Carolina

Evin J. Evans and Patricia BellSplit Creek Farm, in Anderson, South Carolina, is a great example of a farm that started out small and grew to be a large operation. Evin Evans and Patricia Bell’s goal was to be self-sufficient, and that required gradual growth.

Split Creek Farm started with three goats and a few acres. Over the years Evans and Bell added to their herd and their pastures, fences, and barns. The herd, mostly Nubians, peaked at 750 goats; the farm’s goat population now averages approximately 275, with about half of those being milked.

Split Creek became a commercial Grade A Dairy in 1985 and started a small-scale cheese operation three years later. They increased their production as the demand for goat cheese grew, and by 1990 Split Creek had progressed from the original 4-gallon vat batches to the current 150-gallon vat batches. Split Creek currently sells raw milk, award-winning cheeses and fudge, soap, gift baskets, and folk art at a retail shop on the farm. Split Creek Farm’s primary concerns are herd health and the ultimate quality of the dairy products they sell. In keeping with their commitment to sell natural products, Evans and Bell do not use hormones to enhance breeding or milk production, and herbicides and pesticides are not used on their pastures.

Evans and Bell, with assistance from two full-time and two part-time employees, care for the goats and produce and sell the products. They have worked long and hard for what they have accomplished, and they are proud of the quality of their goats and their goat milk products.

Regulations

Grade A Requirements

The U.S. Food and Drug Administration drafted the Pasteurized Milk Ordinance (PMO), which states that only pasteurized milk can be sold as Grade A. Enforcement of this ordinance is under the jurisdiction of state departments of health or agriculture (Zeng and Escobar, 1995), and local requirements may vary. The American Dairy Goat Association provides contact information for the authority in each state, and it is important to contact your state inspector early in the process of setting up your commercial goat dairy. State inspectors will be able to make helpful suggestions and can assist you in planning and procuring USDA-approved equipment. Many producers have commented that their state inspectors helped them avoid expensive mistakes.

The Langston University publication Grade A Dairy Goat Farm Requirements discusses the requirements for a Grade A dairy. These include a milking barn or parlor with a floor made of concrete or other impervious material for easy cleaning and walls and dust-tight ceilings that are smooth, painted, or finished and in good repair. Sufficient ventilation is needed to eliminate condensation, minimize odor, and provide comfort for the milker. Adequate lighting is required, as well as a storage cabinet for medications. Wooden milking stands are not acceptable. (Zeng and Escobar, 1995)

A separate milk room is required for cooling and storing goat milk, to minimize the risk of contamination from the milking barn. The structure must be in good repair and easy to clean. The floor should slope evenly to a drain, and wash-sinks, hot water, and on-site toilets are required. Milking lines and other equipment should be of stainless steel or other smooth, non-absorbent material. Milk storage tanks must have an efficient cooling system. Fresh, warm milk coming out of pipelines or milking buckets must be cooled to 45 degrees F within two hours. The water supply must comply with the Clean Water Act requirements, as enforced by the EPA, and a dairy waste management system must be in place. Grade A dairies are inspected at least twice a year, and milk samples are collected periodically.

Scrapie Eradication Program

Scrapie is a fatal, degenerative disease affecting the central nervous system of sheep (and goats, very rarely), one of the class of diseases known as transmissible spongiform encephalopathies (TSEs). Other examples of TSEs include BSE in cattle and Chronic Wasting Disease (CWD) in deer and elk. There is no evidence that scrapie can spread to humans, but BSE, a TSE similar to scrapie, has been implicated in variant Jacob-Cruchfeld disease, and therefore there is a concern about its potential to spread to humans. Negative public perceptions and the loss of export opportunities have encouraged the efforts to eradicate scrapie from the U.S. The incidence of scrapie in goats is extremely low, so it is highly unlikely that your herd will be affected. Nevertheless, goat producers (and sheep producers) are required to participate in the Scrapie Eradication Program. Details about this program are available by contacting your state veterinarian or by visiting the National Eradicative Scrapie Initiative website. You must first contact your state veterinarian to request a premises identification number. For additional information or for help in obtaining a premises ID number, call 866-USDA-TAG (toll-free). You will then receive free eartags with your premises ID printed on them, and you must tag any breeding animals over the age of 18 months before they leave your farm. Dairy goat producers may use tattoos instead of ear tags, and the state veterinarian can assist by assigning a premises ID that consists of your state abbreviation and the ADGA tattoo sequence assigned to the farm. In addition, any breeding goat (or sheep) that crosses state lines (for shows or to be sold, for example) must be accompanied by an official Certificate of Veterinary Inspection (health certificate) issued by an accredited veterinarian. Registered goats may be transported across state lines using registration tattoos as identification, provided they are accompanied by their negative certificate registration or a health certificate listing the tattoo number.

Raw Milk Sales

Many natural foods consumers want raw milk. Many experts do not consider selling raw goat milk an option at all, due to legal issues and health concerns. Attorney Neil Hamilton discusses raw milk sales in his book The Legal Guide for Direct Farm Marketing (see Resources: Books). Hamilton recommends contacting your state department of agriculture for information on regulations.

The sale of unpasteurized milk is the subject of regulation because of concerns over the transmission of diseases. In some states, such as Iowa, the sale of raw milk—even in small quantities—is strictly prohibited by state regulation and the state officials take a rather rigorous approach on the issue. In other states, officials have a more permissive attitude toward the sale of raw milk, allowing small-scale personal sales to occur even if not specifically allowed by law. In some states dairy farmers are allowed to make limited sales of raw milk directly to consumers as long as the sales meet the requirements established by law or regulation. The requirements usually relate to how the milk is sold, the quantity involved and compliance with state sanitation requirements for the dairy operation. (Hamilton, 1999)

Even if raw milk sales are legal in your state, you will want to consider carefully the risks of selling raw milk to customers. Many serious diseases can be transmitted to humans who drink raw milk, including brucellosis, tuberculosis, caseous lymphadenitis, leptospirosis, Q Fever, staphylococcal food poisoning, and others (Smith, 1994). Even if you are sure your milk is pure, that the goats are healthy, that the milk has been handled with faultless cleanliness and carefully cooled, and even if you regularly drink the milk with no ill effects, once the milk leaves your farm it may be carelessly handled and become unsafe to drink. This is especially hazardous if the person drinking the milk has a weakened immune system or is very old or very young. Get the advice of your state department of health before you agree to sell raw milk to individuals.

Budgeting

Before beginning a commercial goat dairy, you must study the economic feasibility of the enterprise. There are many sample budgets available, but each must be customized to fit an individual farm. Investigate feed costs in your area as well as the selling price of milk. Costs of building or converting barns, fences, and watering systems are key considerations. Initial investment in livestock and in milking systems will be a large expense. Commercial dairy producers Stephen and Beverly Phillips of Port Madison Farm near Seattle, Washington, offer the following insights based on their experience.

“It takes capital to expand into a commercial-sized dairy,” Stephen says. “You must have the money to grow or keep the off-farm job or both. Sweat equity alone cannot do the job.”

“A good plan, written down, is important to measure your progress. Otherwise, you get so close to the proverbial trees that you do not realize that you have made progress.”

“When making improvements, it is important to plan for the size you may need in four or five years.”

“And like most goat dairies, you need to beware of burnout.”

Beverly sums up her advice by emphasizing, “Don’t quit your day job too soon.” (Thompson, 1997)

Bee Tolman, operator of the Tolman Sheep Dairy Farm, offered further advice to prospective dairy farmers at the 2002 8th Great Lakes Dairy Sheep Symposium.

“Do a complete business plan before you do anything else. Include all financial statements in detail. Don’t miss the details—they will be your undoing. And be conservative. I was advised by a goat dairy farmer (who has since folded) to add 30% to all budgeted costs. I didn’t. I now know that if I had, my plan would have been far more accurate.” (Tolman, 2002)

As Ms. Tolman points out, it is wise to talk to farmers who are currently in the business to ensure that your plan and your budget are realistic. Begin your calculations by taking the following steps.

- Do market research. Is there a market? What is the current price for your product, whether fluid milk for processing, bottled milk, milk-fed livestock, cheese, or soap? Is there a strong demand for your product?

- Estimate production level. How many does are you planning to milk? How productive will they be, on average? (Does in a large herd typically produce less than does in a hobby herd; ask several commercial producers what their herd average is, and be sure to select does for your herd that can produce enough milk to be profitable.) Be as realistic about production and marketing as you possibly can.

- Investigate costs. What does feed cost in your area? How much feed will you need in order to produce the amount of milk you plan to produce and sell? What about buildings, equipment, fencing, hay? You will need to come up with marketing and hauling costs, health costs, costs of utilities, supplies, breeding, and labor. Initial cost of breeding stock, cost of raising replacements, and an extra “cushion” for unexpected expenses must also be considered. Remember that under-capitalization can doom even a good business venture.

- Consider labor NEEDED and available. Plan for peak seasons such as kidding and breeding, as well as any labor needed for processing and marketing.

- Compile a business plan. Your lending agency will tell you what other figures are needed; your local Cooperative Extension agent may be helpful. See also the Further Resources section for help with business plans.

Break-even milk production above total operating costs is 1,263 pounds/head at the $24.00 price of milk.

Break-even milk price/cwt. above total operating costs is $15.16 using a production of 2,000 pounds/head.

*Break-even price and production are calculated to cover total operating costs only while keeping revenues from kid and cull sales constant.

This table was developed using figures from the Dairy Goat Budget developed by the Department of Agricultural Economics, Oklahoma State University and included in the Economics section of this publication. (Sahs, 2003)

The Minnesota Extension Service published a very interesting look at the economics of the dairy goat business in 1989. Robert D. Appleman, the author, explored costs and returns from a 10-doe hobby dairy and a 100-doe commercial dairy. His budget (Economics of the Dairy Goat Business — HG-80-3606) can be ordered by contacting order@dc.mes.umn.edu. He also did some fascinating calculations, such as looking at the impact of a change in cost of one input on the cost of producing 100 pounds of milk, the influence of marketing registered kids, or of marketing kid bucks, the labor required, and several other interesting scenarios. It is well worth reading the full article, and figuring today’s costs for your area instead of Minnesota’s 1989 costs. Even though the article is out of date, Appleman’s conclusions offer food for thought, and are summarized below.

- The cost of producing 100 pounds of goat’s milk may vary from $22 to more than $37. To return a profit, then, a gallon of milk may have to sell for $3.20 or more.

- The greatest contributor to the high cost of producing goat’s milk is labor. Every effort should be made to minimize this input. The greatest opportunity to accomplish this is to mechanize the milking process.

- Marketing costs can be prohibitive.

- Unless one has a good market for excess, it is not advisable to keep young stock beyond that needed to maintain the doe herd productivity.

- If milk can be sold at a price of $12/cwt or more, milk-fed kids sold at 25 pounds for 80 cents per pound are not profitable.

- There is an economy to size, especially when combined with considerable sale of breeding stock.

- Emphasize high production per doe. Maintaining dry does (non-breeding does that will have a long dry-period) can quickly eliminate any profit potential. (Appleman, 1989)

Oklahoma State University Extension Specialist Roger Sahs works on goat farm budgets for dairy goat and meat goat enterprises (see Table 2). He recommends that farm managers take the time to work out an enterprise budget.

“…[an enterprise budget] would be an essential tool in evaluating whether such an alternative would be to the manager’s financial advantage. Farm management skills and knowledge are a very integral aspect of success with commercial dairies. The ability to bear losses from business risk, a large capital base, and well trained labor are also important considerations.” (Sahs, 2003)

Spend time working on budgets before committing the capital to a commercial enterprise. Show your budget to a commercial producer to check whether your figures on costs, receipts, and expected production are realistic; then consider whether your expected return is sufficient compensation for your efforts. Doing your homework before taking the plunge will save you much heartache and expense. Several other sample budgets are included in this publication in the Further Resources section.

Production Notes

Selecting Stock

Once you have figured out what products you will sell, have the business plan and budget figured out, and are sure there is enough qualified labor and available capital to sustain the business, you are in position to select goats for the dairy. All the preliminary work will help you to prioritize and budget the purchases of stock and equipment, and to have an idea of what type of goats you need. For instance, commercial producers of fluid milk will want animals that produce a lot of milk; depending on the milk buyer’s priorities, butterfat and protein percentages may also be important. A cheesemaker will be more interested in total protein yield. Those who plan to sell breeding stock will want to consider production records, conformation, and pedigree (including records of related animals). Those who are marketing milk through kids may prefer a dual-purpose animal, such as the Nubian, that will bear meatier kids. A person purchasing a family milker will want to milk the doe to see how easily she milks out, taste the milk for flavor, and observe her disposition. An animal that is perfect for one use may not be the best choice for another.

All buyers will need to find healthy goats that produce the quantity and quality of milk needed for their business. That is the essential part. However, many producers will first choose a breed that is personally appealing, then find breeders and visit farms to select goats for the dairy. Therefore, we will first discuss breeds, then address finding a breeder, evaluating health, and production records.

Choosing a Breed

Breed choice will depend on how you will use the milk, the availability of the breed in or near your area, and personal preference. Since there are differences in milk composition (% butterfat, % protein) and the quantity produced, some breeds will (on average) be more suitable for some farms than others. However, individuals WITHIN breeds vary more than individuals BETWEEN breeds. For instance, while on average, Saanens produce more milk than Nubians (see Table 3), some Nubians will produce more milk than some Saanens (as illustrated in the “range” column of the table). Though Nubians may produce less milk than Saanens, the composition of Nubian milk makes it more suitable for cheesemaking. Therefore, it is important to select individuals that possess the characteristics you need. Production records are the best way to know this. (Production records will be discussed later in this publication.)

Selecting a breed that is fairly common in your area may make it easier to acquire (and to sell) breeding stock, provided the other producers have goals and management systems similar to yours.

Personal preference plays a major role in selecting a breed. Dairy farmers must spend hours with their animals, so get animals that you enjoy seeing, that will function on your farm, and that have dispositions that suit you. This is an individual choice, best made after observing individuals of various breeds and working with them, if possible. General descriptions of the breeds are given below. Further information about the breeds and contacts for the breed clubs are available from the ADGA website. Descriptions and pictures of the breeds may be found on the Oklahoma State University website.

In the United States, there are six full-size dairy breeds available. They are Saanen, Alpine, Toggenburg, and Oberhasli—the Swiss breeds—and Nubian and LaMancha.

Some producers raise crosses of these breeds; these crosses are referred to as “experimentals.” The Swiss breeds have similar body and ear shapes and similar milk composition.

Saanens tend to be larger than the other Swiss breeds, and are generally heavy milkers with slightly lower butterfat percentages. They are white goats with erect ears and are known for being gentle and productive milkers with long lactations. Saanens are sometimes called “the Holsteins of goats.” Saanens may sunburn and must have some shade available during hot weather.

Toggenburgs are recognized by their color pattern, since they are always brown with white legs, white stripes down the side of the face, and other white markings. They are medium sized, sturdy, and hardy. On average, their milk is lower in butterfat and in protein percentages than the other breeds.

Alpines come in a whole range of colors and color patterns and are slightly smaller than Saanens. Like the Saanens and Toggenburgs, the Alpines originated in the cool climate of the Swiss Alps. Alpines are popular in commercial herds, and there are more Alpines on production test than any other breed (as of 2002).

The Oberhasli is a Swiss dairy goat of medium size. Its color is chamoisee (bay, with deep-red bay preferred, accented with black markings). Oberhaslis are not as numerous in the United States as the other breeds, and fewer Oberhaslis are enrolled in DHI production testing. Therefore, it may be difficult to locate stock, especially production-tested stock.

Nubians are known for their floppy ears and for producing milk that is highest in butterfat. They do not produce as much milk as the other breeds, and are considered a dual-purpose goat since they tend to be meatier than other breeds. Nubians are sometimes referred to as the “Jerseys of the goat world” and are the most common breed in the United States. Some producers think they are not well suited to a commercial dairy because of their active and energetic disposition. Others appreciate the Nubian’s contribution to the bulk tank, especially if the milk is intended for cheese, yogurt, or ice cream.

LaManchas were developed in the United States, and these goats are also easily identified by their distinctive ears. LaManchas have very tiny ears, and sometimes appear to have no outer ear at all. LaManchas are smaller than the other dairy breeds, but they are very good producers of sweet, creamy milk. Breeders of LaManchas claim that these goats are docile and sweet-tempered. They can be any color.

Based on 2002 ADGA DHIR Individual Doe Records

Averages compiled by the ADGA Production Testing Committee

Visiting a Breeder

Visiting other producers can help you select a breed or breeds. Locating a good breeder is key to getting your business off to a good start. To find breeders in your area, you can check with your local Extension service. The American Dairy Goat Association publishes a directory of breeders every year, including contact information and a list of breeds raised by each member. It is well-organized and is free to members.

You may want to visit three or four breeders before making a purchase; this gives you the opportunity to compare how the animals are raised, fed, and housed, and to assess the overall health of the herd. Ask lots of questions (see the section below for some suggested questions).

You should try to find a breeder who:

- Is willing to provide health certificates

- Is part of the Dairy Herd Improvement Association (DHIA)

- Allows free access to all production and breeding records

- Manages a farm that has well-cared for animals and land

Evaluating health

ALL buyers of dairy goats should insist on healthy goats. There are three main ways to gather information about the health of a dairy goat.

- visual appraisal

- interview the owner or herd veterinarian

- request that certain tests be performed, such as

- mastitis test (by milk culture or California Mastitis Test)

- blood tests to check for CAE, TB, brucellosis, etc.

- fecal tests to screen for internal parasites

Ideally, all three methods (visual, interview, and testing) should be used.

First, examine the whole herd, looking for

- Shiny coats

- Lively manner

- Easy movement (no limping, no swollen joints or misshapen udders)

- No abscesses

- Proper body condition (not fat or excessively thin)

- Firm, pelleted manure

- Well-shaped udders and teats (symmetrical udders)

A herd that meets all these visual criteria gives evidence of being healthy and well-managed.

Second, interview the herd owner or veterinarian.

- What diseases have been problems in this herd?

- What criteria do you use for selection or culling?

- What diseases are tested for routinely?

- What is the vaccination and parasite management protocol?

- Are replacement kids raised using pasteurized milk, to reduce the incidence of milk-borne diseases such as CAE, Johne’s, mycoplasma, and others?

- How long do does stay productive in this herd?

- How long is the average lactation in this herd?

- What is the average production level of this herd? (Ask to see records.)

Third, ask that tests be run on the does you are considering. These tests will increase the cost of the animal, and you should be prepared to absorb at least some of that cost. Some tests may not be necessary; if the veterinarian certifies that there are no suspected cases of Johne’s, for instance, and you observe that all animals appear healthy, you may choose to forgo the Johne’s test. Check with your veterinarian about which diseases are occurring in your area, and get his or her recommendations on which diseases are worth testing for.

Buying healthy stock initially will save you much money, time, and disappointment in the long run. Diseases shorten the productive life of the animal and reduce the chances of a profitable farm; therefore, it is wise to spend effort and money in the beginning to secure healthy animals. See the Health section of this publication and of the ATTRA publication Goats: Sustainable Production Overview for more information about some diseases to be aware of.

Production Records

Having verified that the stock is healthy, the next concern is their productivity. Keeping your needs (that is, the needs of your dairy products customers) in mind, investigate the productive potential of each animal. Production records from the Dairy Herd Improvement Association (DHIA) of the individual and of its relatives offer the best insurance that you are purchasing a productive animal. Type classification, also known as linear appraisal (an objective score given by a trained judge, who provides a professional appraisal of an animal’s conformation), may be available and offers another tool for selecting animals with desirable traits. Pedigree records are also very useful, since they give information about the genetic makeup of the animal. For a complete description of these tools and how to use them, as well as a wealth of information about what to look for in a good dairy goat, see Dairy Goat Judging Techniques, by Harvey Considine.

When examining production records, keep in mind that production is naturally much lower during the first lactation. Examine the records to see overall production in pounds, length of lactation, and butterfat and protein percentages (if those are important to your operation). Bear in mind that your own management will be a major factor in the doe’s production on your farm; production records only verify that a goat has the genetic potential to produce milk. To learn more about production records, type evaluation (linear appraisal), and the DHI program, visit the American Dairy Goat Association website.

DHI records are useful when purchasing goats, but are even more useful as a management tool after purchase. In some areas, the cost is as low as $2.00/month/goat. From the information you can:

- Measure real productivity

- Track persistency through the lactation

- Evaluate the effect of a feed change

- Select your best producers and cull the lowest ones

- Identify potential mastitis problems

- Improve the profitability of your herd

Producers who are on DHI test say that it costs nothing, because it returns such valuable information that it more than pays for itself. Eliminating unproductive individuals will improve the sustainability of your farm; records are the best tool in this effort. For more information about production testing and to locate a DHI in your area, talk to local producers, contact your local Extension agent, or visit the Animal Improvement Programs Laboratory (AIPL) website. (The AIPL site contains production, type, and pedigree records compiled by ADGA and DHI, as well as other information.) The American Dairy Goat Association also provides information about production testing and type evaluation.

Finally, when selecting stock, keep in mind that the most important part of the herd is the buck. As the sire of your next generation, the buck is “half of your herd,” and choosing an excellent buck is the quickest way to improve the herd. Again, production records (on the dam, daughters, and on any other relatives) are the best way to assess the usefulness of the buck. Linear appraisal will also be helpful, if available. The sire you select should come from good bloodlines and be healthy and fertile. Your veterinarian can perform a breeding soundness evaluation before purchase. If that option is not available, at least check the scrotal circumference of the prospective sire (it should be at least 20 cm.), to get an indication of sperm-producing potential. It is not a guarantee of fertility, however. Please refer to Goats: Sustainable Production Overview for more details on selecting a buck and evaluating breeding stock.

Choosing healthy stock with good genetics is an important step in setting up a sustainable farm. However, in order to live up to their potential, the animals must be well managed and correctly fed. In order to make a profit with dairy goats, this must be accomplished economically.

Redwood Hill Farm, California

Jennifer Bice(The following was adapted from an article by Jennifer Bice in the Dairy Goat Journal, September/October 2003. Ms. Bice is the owner of Redwood Hill Farm. The complete article, including a diary kept by Redwood Hill’s farm manager, can be found on page 57-60 of that issue.)

Redwood Hill Farm Grade A Goat Dairy is located in Sebastopol, Sonoma Country, California. Sebastopol is near the coast, about 50 miles north of San Francisco. Redwood Hill Farm is a “farmstead operation” because in addition to producing a unique line of artisanal goat-milk cheeses and goat-milk yogurt in five flavors, the farm manages its own herd of 400 dairy goats (Alpine, LaMancha, Nubian and Saanen).

The farm was started in the 1960s by Kenneth and Cynthia Bice and their 10 children. Active in 4-H with many different animal species, the family quickly made dairy goats their favorites. Jennifer Bice and her husband, Steven Schack, took over the family farm in 1978 and expanded the business and product line. Steven died in 1999, and Jennifer knew that continuing the business would be the best way to honor his memory.

With a herd of 400 registered dairy goats, a Grade A dairy, and a processing plant, Redwood Hill Farm employs 12 people, as well as 5 work exchange students from other countries. These students stay for 12 to 18 months. They come from agricultural college programs in their own countries to live, work, and learn in the United States. While the students don’t always have direct dairy goat experience, they learn quickly and are highly motivated. Currently Redwood Hill Farm has students from Bulgaria, Hungary, Turkey, Honduras, and France.

Redwood Hill Farm is now building a larger processing plant to meet the demand for its goat milk products. From award-winning animals (including ADGA National Champions in four breeds) to gold medal awards for their cheese and yogurt at product competitions, Redwood Hill Farm strives to be the best. That, along with providing a good life for its employees and the dairy goats themselves, is a big part of the Redwood Hill Farm mission.

This story was written for the introduction to the Commercial Dairy Diary feature in the Dairy Goat Journal, September/October 2003. For a copy of this article/issue or other issues, go here.

Feeding

To review the information contained in the Overview, goats are ruminants, and their health and productivity depend on the rumen function. Microorganisms in the rumen digest fiber, carbohydrates, and protein and supply the animal with nutrients. Without those microorganisms, the goat will die. Therefore, it is of paramount importance that the animal is fed appropriately to keep the ruminal organisms healthy.

The rumen microorganisms are “healthiest” when goats are eating good-quality forages, such as vegetative pasture. To get the best milk production from your goats, you must provide excellent quality forages. A pasture that contains many kinds of plants, including browse plants such as blackberries, multiflora roses, willows, or Russian olive, is ideal. Cool-season annuals such as ryegrass will provide a lush, high protein forage in the early spring before many other grasses are tall enough to graze. In the winter, a good mixed-grass hay (cut at an early stage of maturity) is ideal. Goats will eat a wide variety of plants, including weeds. They are selective eaters that will seek the most nutritious plants while grazing, browsing, or eating hay. They are also wasteful eaters, and therefore it is wise to help them use their feed more efficiently by controlling their grazing and by feeding them only a little more hay than they will clean up. There is a trade-off here; if you allow goats to be very selective, they will waste more feed, but they will produce more milk. If you are too strict with their forage allowance, you will save money on feed but lose income from milk. Experience and experimentation with your own herd and farm will help you find that happy medium. Check with your local Extension and NRCS agents for information about what forage plants do well in your area. Information about the grazing habits of goats is provided in the ATTRA publication Goats: Sustainable Production Overview. Some studies about pastures for dairy goats are discussed below.

Steve Hart and B. R. Min at Langston University are doing research on grazing-based dairy goat production systems (see Further Resources). Dr. Hart points out that the “goal of pasture management is to supply high quality pasture starting at the beginning of lactation and maintain high quality forage in sufficient quantities throughout lactation.” This is very difficult and requires the establishment of several types of forage. At Langston (in Oklahoma), they grazed cool season annuals such as wheat, rye, or oats, perennials such as orchardgrass, Berseem clover interseeded with wheat, and warm season grasses such as crabgrass, sudangrass, millet, Johnsongrass, and cowpeas. While it is important to have an assortment of forages available, it is also crucial to maintain those forages in a vegetative state, because that is when their protein levels and digestibility are highest.

At the same time, it is very important to control grazing so goats do not graze too close to the ground, since that will hurt the plants’ ability to regrow and will expose the animals to more parasite larvae. Removing goats from the pasture when they have grazed the grasses down to about 3 to 4″ will greatly reduce parasite problems. Another practice that will help is to graze cattle after the goats to pick up larvae and “clean” the pasture. Tilling or making hay after grazing will also help. More information about internal parasites is provided in the ATTRA publication Managing Internal Parasites in Sheep and Goats.

In 2001, producers Kristan Doolan and George van Vlaanderen of Does’ Leap Farm in Vermont conducted a Northeast SARE project comparing the production of dairy goats that either grazed pasture or browsed in a wooded area (see Further Resources). In that experiment, the goats that browsed produced more milk and had longer lactations. The investigators concluded that browse is at least as nutritious as pasture, and that the shade in the browse areas helped keep the does cooler, which also helped production. The full article was published in The Dairy Ruminant Newsletter and then re-printed in CreamLine, Winter 2002 issue.

Darrell Baker also used SARE funding to explore the potential for using irrigated pasture at his dairy in Tucumcari, New Mexico. Over a two-year period, Mr. Baker made observations and kept financial and production records. He concluded that irrigated pasture provided a very environmentally friendly way to produce milk, and that dairy goats were a profitable way to use irrigated pasture. His observations are of interest, and we offer the following excerpt from his final report.

…I also noticed that the goats have an incredible sensitivity to pasture quality. I was expecting this to some degree, but not to the degree that it showed up. Because I could measure milk production on a daily basis, the sensitivity was much more noticeable with the goats than if I had been running steers… There was also a noticeable correlation between paddock moves, length of stay, and milk production. During the first three days in a fresh paddock, milk production would rise then fall during the next three days from 5 to 10 percent. Another move to a fresh paddock would cause a 2 to 11 percent rise, then as the stay lengthened, milk production would start dropping again even though there was still a large amount of forage left in the paddock. This leads me to believe that I need more and smaller paddocks, more moves, and more goats to fully utilize the forage available while keeping pasture production up. (Baker, 1998)

As mentioned previously, Drs. Hart and Min at Langston University have been conducting research on grazing dairy goats. As part of this work, goats were fed four different rations:

- A — Control: Kept in the barn, fed alfalfa hay and a high level of grain

(2/3 lb. of grain for every pound of milk over 3.3 lbs.) - B — Grazed and fed 2/3 lb. of grain for every pound of milk over 3.3 lbs

- C — Grazed and fed 1/3 lb. of grain for every pound of milk over 3.3 lbs

- D — Grazed, no supplemental grain

Researchers found that body condition of the does greatly influenced milk production, with thinner does being less productive during the lactation. Internal parasite problems also had a negative effect on production. Milk production responded to grain, increasing by 1.7 pounds for every added pound of supplemental feed. However, in the second year of the study, when the does were kidded in better body condition, does fed no supplemental grain produced 7.74 lb. milk/day, while those in the barn produced 8.91 lb/day, and the does fed a small amount of grain (1/3 lb. for each pound of milk over 3.3 lb/day) produced 9.17 lb/day.

Considering the cost of grain and alfalfa hay, it seems likely that the goats on pasture were much more economical to feed and produced comparable quantities of milk. This has implications for those considering organic dairies and for others who want to reduce feed costs. Hart notes that butterfat percentages were lower in the second year for goats that were not supplemented. He also notes that having high-quality forage available in adequate amounts is the key to feeding dairy goats on pasture.

As stated earlier, rumen microorganisms are “healthiest” and milk production is highest when goats are eating high-quality forage. However, it is difficult (if not impossible) to provide good-quality pasture year round. Also, dairy goats have a high requirement for nutrients because they are producing milk at a high level. Therefore, supplementation with concentrates will usually be necessary.

Care is needed when feeding concentrates (grain) to balance the energy needs of the goat and to protect the ruminal organisms. With this in mind, there are some general rules for feeding dairy goats.

- Graze goats on the highest-quality forage available, and be sure there is a plentiful supply of good pasture or good-quality hay.

- Lactating dairy goats need about 5 pounds of feed per day (dry matter basis) per 100 pounds of goat, with at least half of this being forage. Some goats will eat even more during peak lactation (up to 6% of body weight on a dry matter basis).

- Goats require 12 to 14% protein in their diets (the higher amount is for growing kids or high-producing does).

- Limit the feeding of grains so that the pH of the rumen stays in a favorable range.

- Increase grain levels very slowly (.2 lb every 3 or 4 days, to a maximum of no more than 50% of the diet). (Hart, 2004)

- Feed cracked rather than ground grains to encourage rumination and thus salivation, which helps to buffer rumen acids and maintain favorable rumen pH.

- If you must feed high-concentrate diets (for example, to an extremely high-producing doe during peak lactation), divide grain into several small feedings and offer sodium bicarbonate to help buffer the rumen.

- If diets are not high enough in roughage, it may be necessary to feed a buffer (such as sodium bicarbonate) at 4% of the concentrate ration in order to maintain butterfat production. (Smith, 1994)

- It is always important to monitor the feed consumption of your herd. If they are not cleaning up their grain, grain should be reduced and better quality forage offered.

Because of the lactation curve, individual requirements change over the course of the year. Producers generally adjust the amount of supplementary feed, rather than change the ration composition. Care must be taken to avoid sudden changes in diet, and careful observation is needed to monitor body condition and milk production so that supplementary feed may be increased or decreased when necessary. Over-feeding is wasteful and counter-productive, as it may result in does that are too fat, have birthing problems, and do not milk well. On the other hand, under-feeding in late gestation will place the doe at risk for metabolic diseases (pregnancy toxemia) and may also reduce production through the lactation period. The safest bet seems to be to allow the pregnant doe plenty of good-quality forage — and be sure the doe is indeed eating plenty of it. Allow 4 pounds of forage (dry matter basis) per 100 pounds live weight of the doe.

Does that consume a lot of forage during late pregnancy will continue to eat ample forage after kidding, will be less susceptible to digestive disorders, and will yield more milk at the same concentrate level. One French study looked at the effects of the ration during late pregnancy and early lactation. One group of Alpine goats was fed a well-balanced diet, including alfalfa hay (as much as they wanted) and a limited amount of grain during late pregnancy, with a slow increase in grain during early lactation. Another group was fed a restricted amount of hay, a large quantity of grain during late pregnancy, and a quickly increasing amount of grain after kidding. Each of the goats fed ample amounts of hay produced about 148 pounds more milk on average during the first 12 weeks of lactation than the goats fed a restricted amount of hay, a large quantity of grain during late pregnancy, and a fast increase in the amount of grain fed after kidding. (Morand-Fehr, 1978)

Hart’s research at Langston University (see Further Resources) has also been exploring the effect of level of grain supplementation on milk production. See the Langston website for more information.

Guidelines for Supplementing Lactating Does

Start the doe on grain a month before kidding and have her consuming about 1.5 lbs of grain by the time she kids. This allows the rumen organisms to slowly adapt.

After kidding, increase grain slowly to about 3 lbs/day by 4 weeks post-kidding.

After peak lactation, feed according to milk production. Feed 1/2 lb of grain for every pound of milk over 3 lbs milk/day, along with good quality forage. For example, a goat producing 8 pounds a day would get all the good forage she could eat plus 2 ½ pounds of grain, split into two feedings (5 lb. milk over 3 lb. x ½ lb feed/lb milKB].

Never feed more than 4 pounds of grain to a doe per day. (Hart, 2004, and Smith, 1994)

While the focus of this section is on feeding lactating does, you should remember that the care and feeding of kids and replacement animals is equally important. Kids kept for replacements should be fed lots of good quality forage so that they can reach 75% of their mature body weight in about 8 months. Breeding does to freshen as yearlings will increase their lifetime production. To increase your understanding of the kid’s digestive system and how to feed young animals, refer to Nutrition of the Young Goat: Birth to Breeding, and these Feeding and Nutrition resources. Another resource with information on kid rearing is the Dairy Goat Production Guide, by Harris and Springer, University of Florida. This guide includes a good general overview of raising dairy goats.

Milking

Goat milk production is usually seasonal in the U.S., with most dairy goats being bred in the fall and kidding in the spring. However, year round production is required by some markets, and it is possible by staggering kidding. This is done by breeding does out of season, which requires extra management. Milk production will be less in the does producing out of season compared to does freshening in the spring. Therefore, producers will need to get a premium milk price to offset the lower production in the off season.

Goats usually lactate for eight to 10 months and produce about 750 quarts of milk during that time. (Considine, 1996) This is approximately 1500 pounds (“a pint’s a pound,” roughly, so a quart is two pounds) and is not sufficient production to sustain a viable commercial operation, according to Tatiana Stanton of Cornell University. (Stanton, 2003) She estimates a commercial fluid milk operation needs more than 2000 pounds of milk production per head in order to be profitable. Again, this reinforces the value of production records so that the profitable animals can be identified, while unproductive (and therefore unprofitable) goats can be culled.

Milking must be done on a routine schedule. Most farmers milk twice a day at 12 hour intervals. Milking can also be done three times a day. There will be an increase in milk yield, but often the increased yield is not worth the extra time and labor involved in milking three times a day. There has also been research on milking goats once a day. Milking once a day decreases milk yields, especially in early lactation. Milk from goats milked once a day contained higher percentages of total solids, yet total solid yield was less than does milked twice a day. (Salama, 2003)

You should milk young, healthy animals first, and oldest animals last. This decreases the spread of infections and disease. Calm, low-stress handling of the does at milking time will aid in reaching optimum milk production. You should strip the teats before milking to observe any abnormalities in the milk. Some of the abnormalities that may be seen are clots or little butter-like chunks in the milk or stringy milk. Both are evidence of mastitis. Each doe will take two minutes to milk out (Mowlen, 1992). During milking time it is a good idea to inspect the does for any signs of injury or disease.

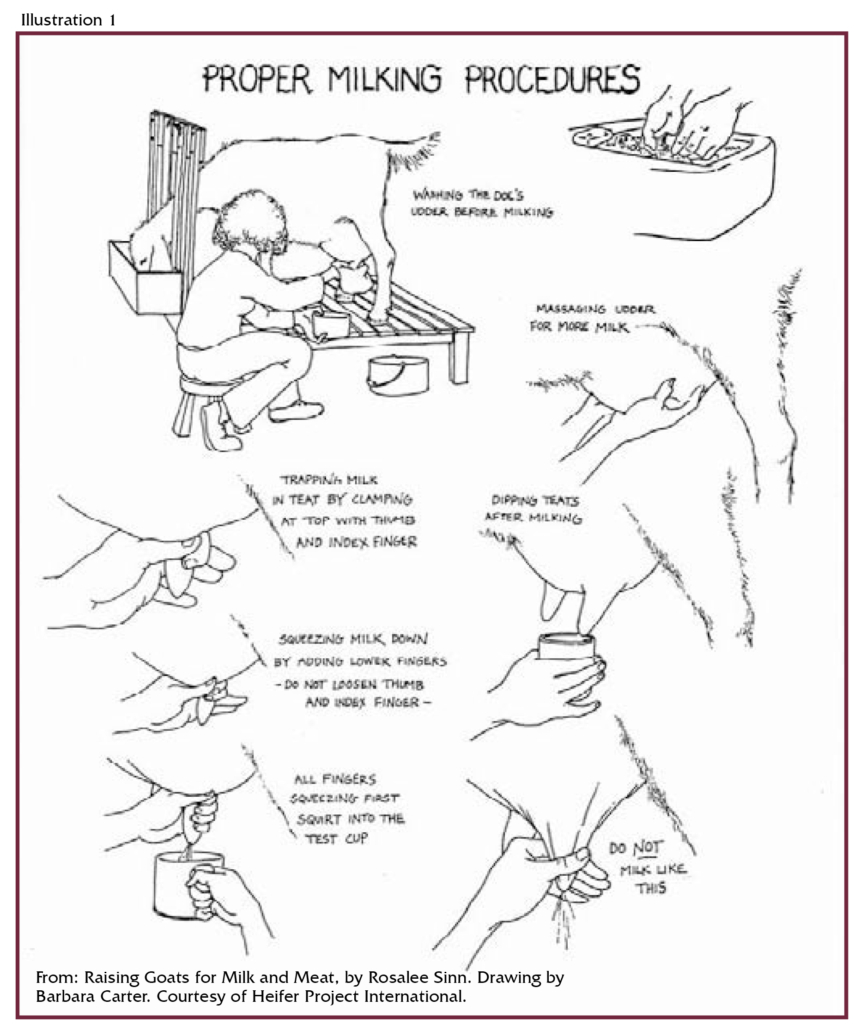

Hand milking is efficient for herds of up to a dozen or so goats. Many hand-milkers use a seamless, stainless steel pail with a hood or cover to keep out debris. Many producers find that milking is a good time to feed the doe grain. This keeps the doe occupied and standing still during milking. Using a milking stand provides several benefits. It keeps the doe tied and standing still and also puts the doe at a comfortable height for the milker. See the hand-milking sketch for an example of a milking stand (Illustration 1).

From Raising Goats for Milk and Meat, by Rosalee Sinn. Drawing by Barbara Carter. Courtesy of Heifer Project International

A platform can also be used when hand milking or when using a milking machine. The platform should be 15 to 18 inches high and constructed so each animal has adequate space to be tied. Allow 3½ feet in length for each doe and 18 inches in width. Does will mount the platform by steps or a ramp. It is vital that the ramp/steps be made so that the goats will not slip. Slipping just once can make does reluctant to go up to the platform.

For herds larger than 15 or 20 goats, it is often more economical and practical to machine milk. Milking machines for small-scale operations are available from Caprine Supply and Hoegger Supply Company, among others. Farms with more than 50 goats will require a large and efficient milking parlor, designed for convenience and in compliance with regulations. When herd size justifies a parlor, there are several designs to choose from. Milking can be done from the front, back, or side of the doe, and milk can go directly into the bulk tank or first go into recorder jars that let you monitor individual production.

Proper sanitation, proper vacuum levels, and proper milking machine maintenance will also reduce the risk of mastitis. Monitor your equipment to make sure that it is functioning properly. Fluctuation of the vacuum in the milking machine can cause backwash, which allows intramammary transmission of bacteria. Also, a doe with teats that are the wrong shape or size can cause vacuum problems. To minimize this risk, milk young, healthy udders first, and then milk abnormal does last.

Whatever the parlor design, it is crucial that your parlor is set up so animals move in and out quickly. If the parlor is set up inefficiently, milking time will increase dramatically. Visit several farms to see possible layouts and talk to current producers about the advantages and disadvantages of their designs. Because parlors will be used twice daily for many years and require a major financial investment, it is important that they be carefully planned.

Regardless of the milking set-up and method, you must maintain sanitary practices, from cleaning the teats before milking to handling the milk. Teat sanitation is probably the most critical step in milking. Milking time, milk quality, and risk of mastitis (see Health section) all depend on how teats are cleaned.

There are several different methods of cleaning the teats before milking. You can spray the teats with water using a low-pressure nozzle. The water should be warm and may contain a sanitizer. The teats must then be dried, usually using paper towels. The problem with spraying is that too much water gets on the udder, and dirty water ends up on the teats and in the teatcups. This leads to contaminated milk and an increase in mastitis. For these reasons, spraying with a low-pressure nozzle is not recommended unless the teats are very dirty (which should not occur if sanitation is adequate). There are premoistened towels (similar to baby wipes) that are available to clean the teats. These towels are easy to use and work well on teats that are not very dirty. The drawback to these towels is that they are expensive.

Pre-dipping is another way to clean teats before milking. Most experts consider it the best sanitizing procedure to reduce mastitis. (Levesque, 2004) The whole teat should be covered with disinfectant (some producers use the same disinfectant for pre- and post-dipping, and others choose a less expensive predip) that is then left on the teat for 15 to 30 seconds. The teat is then wiped dry. This is important for teat stimulation and to make sure all of the disinfectant is removed before milking. The teats can be dried with individual paper towels (never use the same towel on more than one doe) or cloth towels (individual as well). Cloth towels dry and stimulate better than paper towels and in the long run are cheaper. (Levesque, 2004) If using cloth towels, you must properly sanitize them between milkings, by using hot water and bleach and drying them in a clothes dryer.

Whatever method is used for cleaning the teats, it must be done thoroughly and consistently. You must also realize that no disinfectant will be efficient on very dirty teats. Some teats may have to be washed and then disinfected. Once you have the teat clean, disinfected, and dry, do not touch it again before milking or you will put bacteria back on it. After milking, the teats must be dipped in disinfectant called teat dip (usually iodine). The teat canal is relaxed and dilated after milking, which makes it more vulnerable to bacteria. That is why disinfecting after milking is crucial in preventing mastitis.

Sanitary practices must also be used when handling the milk. After milking, strain the milk with a disposable filter, and then cool the milk immediately. Ice-water baths work well for small scale operations. A bulk tank cooler is necessary for larger operations, and it must chill the milk to 45 degrees F within two hours.

All milking equipment must be thoroughly cleaned and sanitized after using. Milk residue must be removed, and all milk contact surfaces must be cleaned thoroughly to remove bacteria. Milk residue should be immediately rinsed out with warm (100-115° F) water. The utensils should be cleaned with soap and a scrub brush, immediately rinsed, and hung on a rack so that they are dry prior to the next milking. Utensils must be sanitized with a chlorine solution immediately prior to milking.

Strict sanitation is necessary to prevent diseases and is critical for food safety. It requires time and money, but it is time and money well spent. It is cheaper to prevent disease and contamination than to treat it. A good reference for producers considering a commercial dairy is the Small Ruminant Guidelines from the Dairy Practices Council. These Guidelines include a wealth of technical information about the details of setting up a milking parlor, producing quality milk and farmstead cheese, proper handling of wastewater, and much more. The Guidelines are sold separately or as a set. For a commercial dairy operation this is an invaluable tool.

Does are bred to freshen once a year and are usually allowed a two to three month nonlactating (dry) period before the next parturition. This allows the mammary system time to repair and regenerate for the next lactation. The greater a doe’s production, the longer the dry period should be, because she has used more nutrients than an average-producing doe. She will need more time to replenish losses and store reserves. Does that are not given a normal dry period usually produce only 65 to 75% as much milk in the subsequent lactation as does given a dry period. (Harris and Springer, 1996) It is important for does to be dried off in good body condition and have a minimum of an eight week dry period. When drying off a doe you should reduce the quantity and quality of her diet. Grain should be reduced or removed, and she should be given a lower quality of hay. Changing the doe’s routine will assist in reducing milk flow. You must continue to monitor drying-off does, because it is common for mastitis to develop during this time.

Health

The ATTRA publication Goats: Sustainable Production Overview contains information about health issues that are important for all goats, including internal parasites, Caprine arthritis encephalitis, abortion, footrot, caseous lymphadenitis, contagious ecthyma, and fly control. This publication provides discussion about three additional diseases of particular interest to dairy goat producers: mastitis, Johne’s disease, and ketosis.

Mastitis

Mastitis is an inflammation of the mammary gland. It is usually caused by the bacterium staphylococcus or streptococcus, but it can also be caused by other bacteria, such as mycoplasm, e. coli, and pseudomonas, or by improper milking machine operation. Symptoms include pain, heat, redness, swelling, and a hard udder. Mastitis causes a reduction in production and in profitability. Does will not always show physical symptoms of mastitis. A decrease in milk production and an increase of somatic cell counts are good indicators of mastitis. Somatic cell counts rise in late lactation, so a rise in SCC is not always an indicator of infection. Milk samples can be cultured to determine the organism causing mastitis (strep, staph, or mycoplasma). Mycoplasma is cultured differently from staph and strep, so you must request the milk test for mycoplasma; it will not show up on the staph/strep test. Streptococcus infections are responsive to antibiotics and are fairly easy to eradicate. Staphylococcus infections do not respond well to antibiotic treatment. Mycoplasma is less common than staph. and strep., but it is highly contagious and is usually the culprit in herds experiencing outbreaks of clinical mastitis that resist therapy. Mycoplasma can be transmitted to the kid through the milk. Raising kids on pasteurized milk will reduce the incidence of mycoplasma in the herd. Once a doe is infected with mycoplasma, she will be a lifelong carrier and will shed the organism in her milk and feces. There is no effective treatment for mycoplasmal mastitis, but it can be controlled. You must identify infected animals by culturing milk samples and then segregate or cull infected animals. The California Mastitis Test (CMT) is another tool for detecting mastitis. The CMT is cheap and easy, but is not very sensitive for goats. The CMT is more useful for ruling out mastitis than for diagnosing it in goats. (Smith, 1994)

Other causes of mastitis may include injury, malnutrition, or a contaminated or malfunctioning milking system. The first line of defense against mastitis is healthy teat skin. The cause of teat injury must be quickly identified and eliminated. Mastitis is also linked to diets deficient in vitamins A and E, selenium, and copper. Fluctuations in the milking vacuum, improperly designed and improperly functioning milking equipment can also lead to mastitis.

To Implement a Mastitis Control Program

- Examine udders twice daily at milking for abnormal secretions of milk (e.g., lumps or stringy milk) and hot, swollen udders. Treat early if mastitis is detected.

- Wash (with a minimum of water) and dry teats before milking. Remove the milking machine promptly when milk flow has ceased.

- Use a recommended teat dip following each milking to decrease entry into the udder of mastitis-causing organisms.

- Dry treat (infuse teat with antibiotics) at drying off to kill bacteria in the udder.

- If milking by machine, have equipment checked periodically to be sure that it is functioning properly.

- Employ strict sanitation practices so that mastitis is not spread from one goat to another, including using individual towels for cleaning the teats and disinfecting the milking machine after milking a goat with mastitis.

- Treat all cases of mastitis promptly and properly with antibiotics. Record all treatments and note the withdrawal times for milk and slaughter. If retreatment is necessary, use a different antibiotic, as bacteria vary in their resistance to different antibiotics. In problem cases, have your veterinarian culture a milk sample to determine the most effective treatment. (Pennington, no date)

Johne’s Disease

Johne’s Disease is a contagious, chronic, usually fatal bacterial infection of the intestinal tract. This disease primarily occurs in ruminants, with different serotypes of the bacteria infecting cattle and goats. Johne’s can be difficult to detect because an animal can be infected for months and not show signs. Clinical cases of Johne’s rarely occur before one year of age and are most commonly seen in two- and three-year old goats. (Smith, 1994) By the time a clinical case is detected in a herd, there will usually be several sub-clinical carriers of the disease (animals not showing signs). Carriers of the disease shed the bacteria, which can survive in the environment for more than a year.

Weight loss while maintaining a good appetite is the best indicator of Johne’s Disease in goats. Cattle have diarrhea when infected, but this is not usually a clinical sign in infected goats. There is no known treatment for Johne’s, but there are several tests that can be used to detect the disease. Many diagnostic labs offer ELISA and AGID tests to detect and confirm cases of Johne’s. Fecal testing and tissue sampling can also be used to detect the disease. Johne’s is not considered a major problem for goat producers, but it is a disease that can cause problems if introduced into a herd.

Ketosis

Ketosis is a term for a metabolic condition whereby the animal cannot or will not consume enough energy to meet its needs. Goats are at risk for ketosis during late pregnancy (pregnancy toxemia) and during early lactation (lactational ketosis).

Pregnancy toxemia can be caused by either underfeeding or overfeeding in early pregnancy. For instance, a doe that is carrying more than one kid and is not fed enough energy will be ketotic. An over-fed doe will have less capacity to eat because the full uterus plus internal fat stores take up too much space, thus limiting the amount of feed the doe can hold. Also, feeding too much grain (or corn silage) in late pregnancy will cause the doe to develop acidosis; this puts the doe off feed and may contribute to pregnancy toxemia.

Similarly, rapidly increased energy demands during early lactation cause high-producing dairy goats to lose weight and condition, as they can not eat enough to meet their needs. A gradual increase in the amount of grain offered (.2 lb every 3 days) (Smith, 1994) will meet enough of the energy needs to protect against ketosis, but will not trigger acidosis.

Treatment of ketosis involves improving the diet by offering better quality roughage and slowly increasing concentrates. Propylene glycol is also given to increase blood sugar levels, but overdoses can be fatal; Mary Smith of Cornell University recommends 60 ml given two or three times daily. (Smith, 1994) In cases where the disease has progressed and the doe is unable to eat or to get up, consult your veterinarian. If the doe is within one week of her due date, inducing the doe to kid or performing a C-section may save either the kids or the doe.

Treatment of mild acidosis (when the doe is off feed because of over-eating grain) involves offering the best quality hay and withholding grain to allow the rumen to recover. Plenty of water, oral antacids, and oral tetracycline may help. Severe acidosis may kill the doe; the goat will be off feed, the rumen ceases to function, and the animal may groan, grind teeth, have constipation followed by diarrhea, and go down. This is a very serious condition; consult your veterinarian immediately if you suspect the goat has over-eaten grain.

Again, prevention is best; increase concentrates very slowly, and do not feed finely ground grain (cracked is preferable). Protect the rumen organisms by feeding several small feedings rather than one large feeding, and offer forage first. (Smith, 1994) Steve Hart recommends that you start a doe on grain a month before kidding and gradually work up to 1.5 pounds of grain (in two feedings) by kidding time; then gradually increase (.2 lb. change every 3 or 4 days) until you are feeding .5 pounds of grain for every pound of milk over 3 lbs./day, always providing good quality forage or hay. Never feed more than 4 pounds of grain per day, and use cracked corn rather than ground to reduce the incidence of acidosis. (Hart, 2004)

See ATTRA’s Goats: Sustainable Production Overview for information about other significant health problems, including CAE, CL, internal parasites, abortion, soremouth, and footrot. Further information about disease prevention and treatment can be found by consulting your veterinarian and by exploring the resources listed at the end of this publication.

Remember that for all diseases, prevention is better than treatment. Paying attention to your animals and to selection, nutrition, and sanitation will increase the health and productivity of your herd.

Conclusion

The decision to start a dairy goat operation is not easy. You probably will not become rich, but if you like goats, have the markets and an understanding of them, and have the time to build a business, this can be a rewarding enterprise.

There is much more to learn about dairy goat production, and the Further Resources section will help you to find more information. Your best source of information is another farmer; talk to as many as you can, and learn from their experience.

“Sustainability” is proven with time, and the following story illustrates some of the necessary ingredients for a sustainable dairy goat business. Our thanks to the author/farmer, Debbie Taylor, for sharing her story.

Blufftop Farm, Arkansas

Debbie and Randy TaylorBy Debbie Taylor, 2004

Blufftop Farm is located in Pope County, Arkansas, in the foothills of the Ozark mountains. The soil is sandy and shallow. Most of our farm is used to grow timber of many species.

We (my husband Randy and I) began raising goats in 1974 as a hobby and for milk for ourselves. We began with a grade doe, a purebred Nubian doe, and a purebred Nubian buck. We had been married two years and lived on a farm owned by his family, who lived out of the state. I was a city slicker who had always wanted to live on a farm; he had a little farming experience, mostly with grain. The hobby persisted and grew, and gradually more breeds were added. We began showing the goats and went on DHIR test. Eventually there was too much milk, and commercial production was investigated.

Throughout this time we had a few jobs, Randy went to college, and our logging business evolved. We purchased our own land and built fences, barns, shops, and our house in 1985, the dairy in 1986. Though I do not work in the log woods anymore, I do the bookwork for our company. Randy does not help with the daily goat-related chores but helps fix everything that needs fixing and operates the hay baler. Our daughter, Jessica, helps with the goat operation. I was a licensed American Dairy Goat Association judge for 15 years, but it is too hard to do all that traveling and do a good job with the operations at home.

Currently, we milk 72 head. The milk is marketed to the only plant currently operating in our state (Jackson-Mitchell, Yellville, Arkansas). A tanker picks it up at the farm weekly. The milk is processed, evaporated, and canned.

We sell most of the doe kids and quite a few of the bucks, mostly to other breeders who want goats for showing or family milk, and we export some goats. Having the herd on DHIR test, appraising them yearly, and showing some, has helped sales of kids. We like having registered stock, and though it requires a lot more planning and paperwork, kid sales are an important part of the income.