Equipment and Tools for Small-Scale Intensive Crop Production

Farm machinery. Photo: Andy Pressman, NCAT

By Andy Pressman and Omar Rodriguez, NCAT Agriculture Specialists

Abstract

This publication focuses on equipment and tools for intensive crop production on a small-scale commercial farm. It details equipment and hand tools for soil preparation, planting, weed management, and harvesting. The use of appropriate equipment and tools, both in terms of size and practicality, can increase production efficiency and profits while minimizing disturbance to soil and to plant health. Lists of further resources and tool and equipment suppliers are included.

Contents

Introduction: Selecting Appropriate Tools

Soil Preparation

Seeding and Planting

Weed Control

Harvest

Summary

References

Further Resources

Appendix

Introduction: Selecting Appropriate Tools

Most farmers can tell you how important it is to have good tools and equipment to increase efficiency and production. They can also tell you about the impact equipment can have on farm expenses, assets, and other financials. Scale of production plays a fundamental role in all current and future farm operations; it is a critical consideration in decision-making related to effective use of labor and in making sure the tools and equipment used can do the work that is needed. It is common to see tractors and equipment more than 50 years old being used today on smaller-scale farms. Many farmers who operate at this scale also rely on imported tools and machinery designed for more intensive cropping systems. The farm-equipment market in the United States often leaves smaller-scale farms to rely on older equipment that requires frequent maintenance and repairs to keep running. However, the current interest in small-scale intensive crop production in the United States has generated a resurgence of the small-scale farm machine industry and provided opportunities for farmer-to-farmer knowledge sharing on tool and equipment design and local fabrication of hand tools.

“Any intelligent fool can make things bigger, more complex… It takes a touch of genius – and a lot of courage – to move in the opposite direction.”

— E.F. Schumacher

Equipment and tools are necessary for plant propagation, soil preparation, planting, pest and weed control, irrigation, harvesting, postharvest handling, storage, and distribution. Sustainable agriculture can be a labor-intensive business; by selecting the appropriate tool for the task at hand, farmers can increase profits by increasing crop yields, improving crop quality, and reducing expenses. There are several factors to consider when choosing appropriate agricultural equipment and tools:

- Does the tool or equipment support your whole-farm plan?

- Is the tool or equipment appropriate to your farm’s location and growing condition?

- How does the tool or implement impact soil health, production, and marketing?

- Is it safe to use and appropriate to your skill and comfort level and to that of other farmworkers?

- Is it appropriate in scale now and for future growth?

- Is it easy to maintain and repair? How accessible are parts?

How a farm operates and maintains its equipment can have a significant impact on that farm’s bottom line. In addition to the initial purchase price and costs to operate and maintain the equipment, there are many associated costs that need to be considered. These can relate to taxes, fees for tool and equipment storage, insurance costs, and more. A partial budget is a tool that can help determine the return on investment when purchasing equipment. The University of Kentucky Cooperative Extension Service publication titled Understanding Equipment Costs on the Small Commercial Vegetable Farm (2020) offers additional methods to help small vegetable farms plan for the costs of operating, maintaining, and replacing equipment.

When a piece of equipment is needed on the farm, it is important to consider all options that may achieve the desired outcome. Maybe buying outright or leasing is the right choice, but there are often several other options that can be considered, as well. Many farmers purchase equipment jointly, especially when the equipment is specialized and not used often. Farm-tool lending libraries and equipment rental programs are offered in many areas, often through organizations such as county conservation districts. Utilizing these programs can be cost-effective, as rates are often determined by the job, acreage, or time spent using the equipment. Options to custom hire out the job or barter with a neighboring farmer may also be worth exploring. In some situations, the farmer may be able to change management practices in order to achieve a suitable solution.

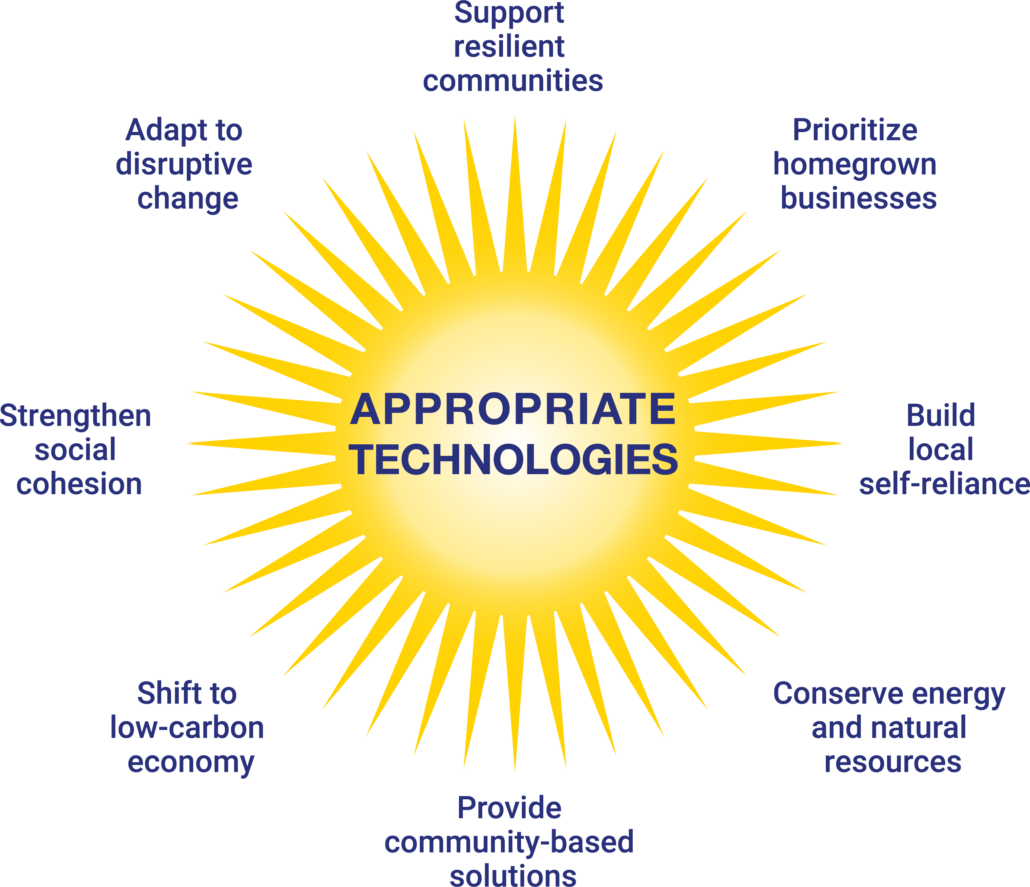

Appropriate Technologies

There are a number of characteristics that define agricultural tools as an appropriate technology:

- They should be safe to use and allow for efficient work.

- They should fit local conditions.

- They should be inexpensive to make, use, and maintain.

- They should be made from local materials.

- They should not deplete natural resources.

- They should promote fulfilling jobs and workplaces.

Open Source/Open System Tools & EquipmentFarmers have always been innovators and tinkerers, be it out of necessity, for profit, or simply for fun. Many farmers are also open to sharing information, especially when it comes to building, modifying, and utilizing specialty tools and equipment that will increase on-farm efficiencies and a farm’s bottom line.

The Culticycle, an open-source pedal powered tractor for cultivation and seeding, built from readily available lawn tractor, ATV, and bicycle parts. Photo: Farm Hack

Farm Hack is a community of collaborators interested in developing and sharing open-source tools for resilient agriculture. Farm Hack exists as a platform for community-based sharing and collaborative research. Join the Farm Hack community to access all the open-source tool designs

The Oggún tractor, developed by CleBer, LLC, is designed on an open system (non-proprietary) platform. This allows for each tractor to be designed at a scale that can lower costs and empower farmers to troubleshoot, configure, and adapt equipment as they deem necessary. And, by creating an open system design, CleBer’s Universal Power Platform (UPP) can be used for a range of small-scale equipment beyond tractors. Get more information on the Oggún tractor and CleBer’s open system design platform here.

More information on open-source tool designs is included in the Further Resources section of this publication.

Hand Tools

There are three components to consider when selecting hand tools for commercial crop production: how the tool fits the hand and body, how the tool fits the need, and the quality or durability of the tool. Ergonomics refers to how a tool is best designed for comfort, efficiency, safety, and productivity. The more ergonomically designed a tool is, the easier it will be on the human body. The length of a handle, the type of handle grip, the weight of the tool, and the angle of the tool head to the handle all affect the ergonomics of a tool.

The more durable a tool is, the longer it will last without sustaining significant damage or wear. Durability can be measured in the strength of the handle and tool head. The harder the steel used for the tool head, the better it will hold an edge—which in turn improves efficiency and reduces wear. Thus, it is important to keep a sharpening tool close by, and one that best serves that particular type of steel. Filing in the forward direction with something like a mill file with a bastard cut works to keep softer steels sharp, while sharpening stones perform well on harder steel blades, including stainless and spring steel. How the tool head and handle are joined together also affects the durability of the tool and determines whether parts can be replaced.

The Further Resources section of this publication contains a list of suppliers that specialize in various tool types, including tools ergonomically optimized for women and left-handed people, tools made from recycled materials, and many more.

Mechanized Equipment

In recent years, there has been a great amount of innovation in mechanized equipment for small farms. This includes machines specifically designed for seeding, bed preparation, harvesting, and much more. When selected appropriately, these tools can be great labor-saving investments that contribute to overall efficiency, productivity, and profit. Mechanization is often linked to an expansion in production, from a human-powered and labor-intensive scale to an increase in acreage and number of markets, but it can also be used to increase efficiency within current production systems. For example, tools can be used to farm more intensively on a given parcel by allowing for closer plant spacings, more efficient weed control, more precise bed preparation, and more efficient nutrient cycling for long-term resilience.

Drill-powered Iconoclast tool available from Neversink Farm. Photo: Andy Pressman, NCAT

Capitalization costs for purchasing mechanized equipment can have a significant impact on a farm’s budget and monthly cash flow. With planning, new farmers can design their systems to function now and for future growth. This will help in preparing to scale up and use mechanized equipment. Careful recordkeeping allows for an understanding of how mechanized equipment can reduce labor costs. It can also portray the return on investment while offering a pathway for managing financial risks, especially when debt (from a bank loan) is being considered for purchasing farm equipment.

Several tools are now on the market that run on battery power. This includes tools for soil preparation, cultivation, pest control, and harvesting. Although battery-powered tools, such as those powered by hand drills, have been available for many years, there are newer options being used on farms, such as chain saws and string trimmers. The batteries for these tools tend to be costly, though when they are selected carefully, interchangeable batteries allow for different tools to be powered by the same type of battery. Battery-powered tools don’t produce exhaust, are quieter, and are easier to maintain than tools that run on fuel.

Walk-Behind Tractors

A walk-behind tractor, or two-wheel tractor, can be an effective—even essential—tool for small-scale farming. At 3.5 to 16 horsepower, these two-wheeled power sources can handle the mowing, tillage, and cultivation needs for a farm up to a few acres. Their versatility allows them to be used in high tunnels, while also allowing them to be used in combination with a four-wheeled tractor to manage crop production on more acreage. Walk-behind tractors tend to be affordable for smaller scales of production, easy and safe to operate, and less costly to maintain. They can be equipped with a wide range of implements, including PTO-driven tillers, rotary plows, power harrows, and mowers. Other implements that can be pulled or powered by a walk-behind tractor include discs, roller-crimpers, seeders, and toolbars with various cultivation set-ups. Many of these implements are designed for 30-inch bed widths and can be used in combination with other hand tools for managing intensive crop plantings.

BCS tractor and implements. Photo: Strafford County (NH) Conservation District

Tractors, PTOs, and Toolbars

One horsepower is equal to the force required to raise 33,000 pounds one foot in one minute.

Tractors provide the power to push and pull farm machinery and move materials, when equipped with a front-end loader, forks, or hay bale spear. There are many considerations to be evaluated when selecting a tractor, including the type of operation, scale, terrain, physical layout of the production area, soil conditions, and implements that will be mounted to it. Small-scale farms do not often need large quantities of horsepower and can frequently get the job done with less than 30 horsepower. Additional considerations in tractor use include the skill level of the farmer or farm worker to safely operate the tractor and to maintain it.

A three-point hitch with toolbar. Photo: Andy Pressman,

NCAT

In 1939, Ford Motor Company came out with the three-point hitch on its Model N tractors. Prior to this time, the brand of most implements had to match the brand of the tractor, because each manufacturer had its own way of hitching its implements to its own tractors. The three-point hitch allows for implements to be easily attached to a tractor and lets the tractor carry the weight of the implement. Although single and double hitches served in a similar capacity, the three-point hitch also allows for the implement to be lifted by the tractor’s hydraulic system. As a result, the depth of the implement can be controlled; therefore, the load on the tractor is also controlled. The three-point hitch became standardized in the 1960s, making different manufacturers’ tractors and implements compatible.

PTO shield. Photo: NYCAMH

A toolbar can also be attached to a tractor to serve as a tool carrier. Toolbars are most often utilized for cultivation purposes, and they can be set up with multiple tools that can work in conjunction with one another. A shank is used to attach a tool, such as a sweep or shovel, to the toolbar. Depending on how much action, or mobility, is needed by the tool, different types of shanks can be used. For example, C-shanks vibrate slightly, S-shanks vibrate aggressively, and straight shanks are firm.

Starting in 1947, manufacturers began adding a built-in transmission device known as a power take-off (PTO) to tractors. The PTO allows the tractor to be driven while powering an implement. PTOs are a main feature on tractors today, including several walk-behind tractor brands. For most tractor implements, the PTO runs at 540 rpm, which equates to the PTO shaft rotating nine times per second. PTO entanglements are all too common on farms and investing in a PTO shield can prevent accidents caused by the PTO.

| Table 1. Decision Making: On-Farm Investments | ||||||||||||

| Decision Made By: Jack and Jill Hiller | Date: 01 / 26 / 2019 | |||||||||||

| Proposed Action & Objective: | Scaling up the market garden to commercial enterprise, finding an efficient approach to managing it | |||||||||||

| Is there a specific problem? | Tenacious perennial weeds; cheat grass; low organic matter | |||||||||||

| Are there alternative options being compared? | 1. Invest $$$$ in a BCS two-wheeled tractor and implements to allow for weed control and organic matter incorporations via shallow tillage 2. Invest $$ in imported compost and manage the system as no-dig; smother weeds and maintain by hand |

|||||||||||

| Mark Pass (P) or Fail (F) for each alternate where applicable. List any additional issues or points raised. |

P | F | P | F | Notes / Further information needed | |||||||

| Cause and effect test: Does this action appear to address the root cause of the problem? Have we discovered the root cause of the problem yet? | F | P | OM for intensive vegetable production requires inputs. Tillage spreads weeds. | |||||||||

| Weak link test – social: What are the possible reactions and effects of this action? How can I / we enhance any positive effects or address any negative impacts? | ~ | ~ | ~ | OM enhanced more by no-till than by tillage. | ||||||||

| Weak link test – biological: Does this action address the weakest point in the lifecycle of this organism, whether enhancing or diminishing its impacts? | F | P | Tillage controls weeds short term but damages soil structure; awakens weed seed | |||||||||

| Weak link test – financial: Does this action address the weakest link in the chain of production (resource conversion, product conversion, marketing)? | F | P | No-till feeds the soil while reducing labor. | |||||||||

| Marginal reaction test: Comparing two or more actions: Which option provides the greatest return (in terms of my/our holistic goal, for the time, money, and effort spent)? | F | P | Compost = lower investment for greater return | |||||||||

| Gross profit analysis test: Comparing two or more enterprises: Which contributes most to covering the overhead of the business? | ~ | ~ | P | BCS would be efficient (low labor) but continued use necessary | ||||||||

| Energy / money source & use test: Is the money or energy to be used sourced in a manner that is consistent with my/our holistic goal? Will the energy or money lead toward my/our holistic goal? | Note to self – it seems possible to close nutrient cycles and create future compost needs on site. With this in mind, the ongoing cost would be mostly labor. | |||||||||||

| Energy | Money | |||||||||||

| Source | 1. Oil 2. Labor | From sales of CSA shares | F | P | ||||||||

| Use | ||||||||||||

| Sustainability test: Will this action lead toward or away from the future resource base described in my / our holistic goal? | F | P | Leads to requiring oil, repairs, and maintenance over time | |||||||||

| Justification test: I/we can honestly say these tests have been used objectively, and not merely to justify a specific desired outcome. | BCS would work well, but no-dig has more benefits across more aspects of our context and at a lower cost | |||||||||||

| Society and culture test: Gut check – Considering all of the testing outcomes and my/our holistic goal, what is the feeling about the proposed action now? | F | P | No-dig feels more in line with where I’d like to be in five years. | |||||||||

| Monitoring: What social, financial, and ecological indicators can be tracked to discover (as quickly as possible) whether this action is progressing in the right direction? 1. Record total human hours for weeding, installing & total for the market garden; 2. Monitor compost application rates over four years | ||||||||||||

Source: Adapted from Regenerative Agriculture, by Richard Perkins

To Invest or Not to Invest

Efficient processes are often essential components of a successful farm. Whether talking about crop planning, bed preparation and turnover, management of pests, disease, and fertilization, or harvest and post-harvest, there are clear benefits to a streamlined and carefully designed plan. Selecting the appropriate suite of tools for a farm is an essential process that will have an impact on all the farm duties listed above. A well-selected combination of tools will allow a farmer to substitute human labor hours for a mechanical advantage. Combining real-time accounting information and a way to rank potential investments greatly reduces the possibility of making a poor choice. Whether a farmer chooses to create a simple back-of-the-envelope calculation that includes categories like cost, condition of purchase (new/used/rent), and urgency of need, or whether they use a more elaborate tool like the example included below, a well-thought-out investment is more likely to reflect the actual needs and expectations of the farmer.

Table 1 comes from the world of whole-farm planning, which is a holistic approach to establishing a short and long-term vision for the farm that examines values, capacity, and goals in creating a farm plan. Notice that the questions posed in the table go beyond cost and benefit to include a side-by-side comparison of two alternative options for addressing a farm need, as well as an examination of vision, goals, and future monitoring. Following the whole-farm plan methodology can help farmers adapt their goals and actions to align their needs and preferences for success in the long term. Eventually, the process of whole-farm planning will lead to the development of business, retirement, transition, estate, and investment plans.

Click here for a downloadable Excel version of Table 1.

For information on sizing tractors, see What Size Farm Tractor Do I Need? in the Further Resources section.

Soil Preparation

Preparing the soil for seeding and planting crops is a multi-step process. Depending on the soil condition and the kinds of crops to be planted, farmers can decide which tool or piece of equipment to use, the depth to which the soil needs to be prepared, and when the soil should be worked. Soil preparation disrupts soil structure and soil life; thus, maintaining and enhancing the life of the soil is the farmer’s responsibility. Selection and use of the right tools and practices to prepare the soil plays a crucial role in this regard. In some instances, farmers can get exceptional crop quality and yields with minimal soil disturbance through such practices as no-till farming or preparing raised garden beds through the technique of double-digging, in which the soil is loosened to a depth of as much as 24 inches.

Breaking the soil for commercial crop production usually requires the art of plowing or tilling the soil. The goal of soil preparation is to minimize soil damage while creating a smooth, deeply loosened seed bed with as little residue and as few weed seeds as possible in the top three to six inches. Tools serve to loosen and aerate the soil, break up residues and weeds, incorporate organic matter and soil amendments, and shape the planting bed. A well-prepared bed will be easy to seed or transplant into, have good water drainage, and be easy to cultivate. Soil amendments and organic matter can be incorporated into the soil as it is being prepared for seeding or planting.

Although draft-animal power does find a place on small farms, this publication does not include a discussion on equipment for draft power. However, many of the implements described in this publication were originally designed for draft animals and can be used with either draft or tractor power. Refer to ATTRA’s Draft Animal Power for Farming for information on the use of draft animals.

Equipment for Soil Preparation

Selecting the right piece of equipment for tillage depends on the type of soil that is desired. Tillage can be broken down into primary and secondary stages. Primary tillage aggressively loosens the soil and breaks up residues at a deep depth. Secondary tillage pulverizes and smooths the top several inches of soil. Equipment should be selected based on the type of tillage desired and how the equipment works, given the specific characteristics of the soil. The tools’ ability to perform correctly also depends on the horsepower of the tractor. Soils that are heavy, compacted, or have significant amounts of residues, for example, may require greater horsepower. In some cases, like in systems that are heavily degraded or that are compromised with a hardpan, a one-time heavy equipment rental or management option may be necessary. The horsepower required to pull a subsoiler to break up a hardpan may be much greater than what is required throughout the rest of the year, often needing around 25 to 30 horsepower per shank.

Hand Tools for Soil Preparation

Hand tools can thoroughly prepare a small amount of land for planting. Spades and digging forks are designed to thrust vertically into the soil rather than at an angle. They are preferable to a shovel because the blade of a shovel is often shorter than the blade of a spade; in addition, the curve of a shovel blade makes it difficult to deeply penetrate the soil. Short-handled spades and forks with a D- or T-shaped handle allow for more efficient use of energy when digging deeply and when moving soil.

A digging fork (left) with a T-handle and a spade with a D-handle. Photo: Andy Pressman, NCAT

After the soil has been forked or spaded, a garden rake can be used to break up larger clods and remove residues and stones that, left alone, could interfere with planting, cultivation, and overall plant health. Rakes can also be used to level a bed and open furrows for seeding. They can be used with the head facing either up or down and by using a push-pull motion. The handle of a rake can also be held parallel to the body so that the head can be used to lightly tamp down the soil after seeding. The seedbed rake is designed with longer tines that can be used to mark out specific rows for planting.

The broadfork, or U-bar, is used for tillage. Due to its minimal soil disturbance and no inversion of soil layers, some farmers include this tool in their regular operations for reduced or no-till production. It consists of two handles, one on each side of the fork, and teeth that are spaced about four inches apart. The teeth are designed and spaced so that as the handles of the broadfork are pulled toward the operator, the tines break the soil and lift it, without the broadfork itself being lifted. Once the soil is loosened, the broadfork is moved back about six inches, and the procedure is repeated down the bed. Some farmers find the broadfork useful for harvesting crops such as scallions and potatoes, as well.

Bed rollers can be used as a last step in preparing beds, to create a uniform planting surface. Depending on the desired condition of the bed, weight can be added to provide a more compressed surface. Additionally, bed rollers are compatible with dibblers for preparing transplant holes at regular intervals or placing row markers for follow-up with hand seeding or push seeders.

Primary Tillage Equipment

Primary tilling is performed by different types of plows, discs, rototillers, and spading machines. The moldboard plow is one of the oldest implements used for soil preparation. It consists of one or more curved pieces of metal, called bottoms, attached to a frame. The bottoms are pulled through the soil to cut it and then invert it, either partially or wholly. One- to four-bottom plows are common for small-scale production, and each bottom requires approximately 10 to 15 horsepower from the tractor. Plows come in various shapes and sizes, which determine the depth of the cut and how the plow moves the soil. Disc coulters can be added to the front of the plow to pre-cut the soil so that the bottom penetrates more effectively.

Chisel plows, or field cultivators, have curved shanks (also known as chisels) with sweeps or other tips attached to them. They are used for loosening the soil without inverting it, thus leaving residues on the soil surface. They are often used to break up hardpans and heavy soils and can be run across a bed before planting root crops. Root penetration can also be improved with a subsoiler. Subsoilers have straighter and longer shanks than chisel plows, usually about 18 inches; each shank needs about 25 horsepower to penetrate 16 to 18 inches or so. Subsoilers are also used to break up compacted soils and improve drainage and aeration by penetrating deeper than a chisel plow into the soil.

Discs can be used for both primary and secondary tillage. Discs are ground-driven implements that cut and mix the soil. They come in several different shapes and sizes and can be arranged in different rows and at different angles. Discs perform best on soils that don’t have a lot of residues and on soils that are not so wet that they will clog or so dry that the discs don’t cut. Heavy discs can be used for primary tillage and adding additional weight to the disc can help it cut further and incorporate better. Lighter discs can be used for secondary tillage after the soil has been plowed.

Rotary tillers can also be used for primary and secondary tillage up to around eight inches deep. Rotary tillers are instrumental in small-scale vegetable production, because they can produce fine seedbeds at varying widths. They are suitable to use with walk-behind tractors that have as little as five horsepower and four-wheel tractors up to 100 horsepower. Rotary tillers have a rotating shaft with several attached tines that mix the soil at various depths. While most tillers on the market use a forward rotation to mix the soil, reverse-tine tillers use reverse action to pull the tiller into the ground, burying larger soil clods underneath smaller clods, often leaving a finer seedbed with less compaction.

Rototilling is an effective way to prepare a seedbed; however, there are drawbacks when the tool is overused. Continuous rototilling can create a hard layer of soil, or plow pan, underneath the tilled soil and increase organic matter decomposition. It can also lead to soils that can quickly erode. Reducing the rototiller’s revolutions per minute or increasing the tractor’s ground speed can be less harmful to the soil than normal rototilling (Wiswall, 2009). Power harrows, or rotary harrows, are designed to gently move the soil “horizontally” up to a few inches in depth. The soil is not inverted nor over-pulverized, which allows for multiple uses during the season without jeopardizing soil structure or forming a hardpan.

A Celli spading machine at Pennypack Farm and Education Center in Horsham, Pennsylvania. Photo: Andy Pressman, NCAT

Spading machines are an alternative to using a rotary tiller. Common in Europe, spading machines loosen the soil and incorporate residues without turning the soil. Spaders are either rotary or reciprocating, and the spades on both types move more slowly than a rotary tiller through the soil. This action works the soil more effectively without causing compaction. Depending on the condition of the soil, a fine seedbed can be accomplished in a single pass without secondary tillage.

Secondary Tillage Equipment

Depending on how rough or crusted the soil is and how much plant residue remains, using secondary tillage equipment can further refine and level the soil before seeding or planting. Harrowing is used for shallow tillage and is most often practiced after plowing. Harrows can be used to break down the furrow slices caused by the plow, reduce clods, smooth out the soil surface, and kill young weeds. The types of harrows include light disc harrows, chain-link harrows, spring-tooth harrows, and spike-tooth harrows. If sod has been plowed under, the disc harrow will not bring lumps of sod up to the soil surface—unlike the spring-tooth or spike-tooth harrow. Although spike-tooth harrows do not pulverize the soil as well as other types of harrows, they can sometimes be used to cover broadcast seed.

Field cultivators consist of a toolbar with different implements mounted on it. They are heavier than harrows and are used when the soil is too rough, is too compacted, or has too much residue for a harrow. The toolbar usually has C-shanks or S-shanks with sweeps, tines, chains, or rollers attached to the bottom.

Bed Shaping

There are several advantages to forming raised beds, including warmer soils and better drainage. In addition, raised beds make it easier to steer a tractor and implement for planting and cultivating. Bed shaping is usually done by pushing loose soil into ridges with a hilling disc or other implement and then forming and pressing the soil into a bed. There are many different styles of bed shapers. Some can lay drip tape and plastic mulch and apply fertilizers. Many designs are made right on the farm.

Seeding and Planting

Farmers must take several factors into consideration when choosing how best to establish a crop for production. Local soil and growing conditions, market considerations, and crop type affect whether a crop should be direct-seeded or transplanted. Decisions made around crop establishment will affect performance; thus, the selection of appropriate tools for a particular farming operation can help greatly in saving time and labor, while also increasing the health, viable yield, speed to maturity, and quality of a crop.

Equipment for Direct Seeding

Direct seeding requires contact between the seed and the soil, so that the crop can establish itself once it germinates. Spin seeders are used for broadcasting cover-crop seeds at a set, desired rate. They can be handheld or tractor-mounted. Light harrowing, raking, irrigating, or adequate rainfall will help ensure good seed-to-soil contact.

SPIN farmer Wally Satzewich of Wally’s Urban Market Garden in Saskatoon, Saskatchewan, using an Earthway seeder. Photo: Courtesy of SPIN-Farming

Other types of seeders should be used for crops that need to be planted in the soil at a uniform spacing and depth. These include precision seeders, pinpoint seeders, stick- or jab-type seeders, and drills. Precision seeders can be manually pushed or tractor mounted to dispense individual seeds in a furrow. Seeds can be singulated through several different mechanisms, including cups, belts, vacuums, plates, and rollers. For small-scale farms, Glaser, Earthway, and Jang are brand names of precision push seeders that use plates or rollers. The Stanhay uses belts, and the Nibex uses cups. Both of these are available as walk-behind push seeders or toolbar-mounted seeders (Volk, 2009). Some seeders function as standalone units capable of seeding up to six rows of seed, while other single-row seeders offer attachments that can connect seeders together for seeding multiple rows, attach seeders to a wheel hoe, or mount seeders with a fertilizer attachment.

Pinpoint seeders are designed to be manually pulled and perform well for greenhouse planting. Medium- to large-sized seeds can be hand planted through a stick- or jab-type seeder that can also plant through plastic mulch. Seed drills also are available for manual or tractor-mounted seeding. Discs can be set for the size of the seed, but thinning may be necessary to achieve proper spacing between plants. Planet Jr. is a classic name associated with vegetable drills. Drills can also be used for planting grains and cover crops.

Desirable Features of a Hand-Pushed Precision Seeder

In his book The New Organic Grower, Eliot Coleman suggests several characteristics to look for in a hand-pushed precision seeder:

- It is easy to push in a straight line.

- It gives precise seed placement.

- It allows accurate depth adjustments.

- It is easy to fill and empty.

- It is flexible and adaptable.

- It has a visible seed level and seed drop.

- It includes a dependable row marker.

Equipment for Transplanting

Setting out transplants helps to extend the growing season and harvest period. Many farmers transplant crops by hand using a trowel, a dibbler, or a jab-style planter, but mechanical transplanters can speed up the planting process by offering more accuracy and less labor. Mechanical transplanters require one person to drive the tractor while a crew of one or more people drops transplants into the soil. Many farmers have designed simple sled-type transplanters that allow the crew to sit or lie down while they transplant by hand. Commercial transplanters have a shoe, coulter, or some other device to open the planting furrow. They also have a closing wheel that packs the seedlings, which are held on trays, in place once they are planted. Water-wheel transplanters inject water into the hole after the plant is set. Other types of transplanters include the gripper, the carousel, the spade, and the no-till.

A Rainflo water-wheel transplanter at Pennypack Farm and Education Center in Horsham, Pennsylvania. Photo: Andy Pressman, NCAT

Until recently there have been plenty of options for mechanized transplanting equipment for farmers at every scale, except those at the lower end of the spectrum—namely, the market gardeners. Now, the paper-pot transplanter and other similar products fill that niche for the small-scale farmer who is looking to increase efficiency. The hand-pulled transplanter relies on a sled and chain of pots that are pulled across a pre-prepared seedbed to plant and bury seedlings. A well-prepared seedbed is important for ease of planting, and, in the right context, this type of transplanter can greatly reduce transplanting times. One company claims that with its equipment, a single person can plant a 100-foot bed with 264 plants in minutes.

Conservation Tillage Equipment

Conservation tillage refers to several strategies and techniques for establishing crops in a previous crop’s residues, which are purposely left on the soil surface. The principal benefits of conservation tillage are improved water conservation and the reduction of soil erosion. Additional benefits include reduced fuel consumption, reduced compaction, planting and harvesting flexibility, reduced labor requirements, and improved soil tilth. Ridge till and no-till are the most common types of conservation tillage systems.

Ridge tillage uses specialized planters and cultivators to maintain permanent ridges, on which crops are grown. After harvest, the crop residue is left until planting time. The planter places the seed in the top of the ridge after pushing residue out of the way and slicing off the surface of the ridge top. Ridges are re-formed during the last cultivation of the crop with a ridge-tillage cultivator that removes weeds while building up the ridge.

As the name implies, tillage is not used in establishing a seedbed in no-till systems. Instead, crops are simply planted into the previous year’s crop residue or into cover crop residue. Farmers producing on smaller scales are utilizing several different hand tools and mulching techniques for no-till vegetable production, while no-till drills and transplanters can benefit farmers growing on a mechanized scale. No-till drills are equipped with coulters that slice the soil, allowing a double-disc opener to place the seed at a proper depth. The slot is then closed with a spring press wheel. No-till waterwheel transplanters are commonly used for vegetable transplants. The transplanter uses coulters that allow no-till planting into bare soil or terminated cover crops. A spiked wheel creates a hole and fills it with water, then workers riding on the transplanter place plants.

Weed Control

Weeds compete with crops for light, water, and nutrients, and they can affect a farm’s economic bottom line. Weeds can reduce crop yields through competition with cash crops, promote pests and disease, and even be problematic in the harvesting process. As a result, there is a large cost associated with controlling weeds. Minimizing weed growth both in the short term and the long term should be considered when designing a cropping system. Careful planning to limit weeds’ competition with cash crops and to reduce the amount of time, fuel, and other resources spent on controlling weeds can be vital to a farm’s economic viability.

There are several techniques for effectively controlling weeds, including chemical and cultural approaches, as well as the use of cultivation tools. Many of the control techniques can be integrated together to be more effective. All the techniques focus on either preventing weed seeds from germinating (pre-emergence) or suppressing established weeds (post-emergence).

A weed-management strategy includes several factors:

- Timing weed-control operations

- Selecting the most appropriate tools for cultivating

- Forming planting beds and crop-row spacing to match the cultivation tool and its configuration

- Incorporating other cropping practices such as cover crops, crop rotation, irrigation, fertilization, and pest management

Cultural Practices

Cultural practices include cover cropping, the use of stale seedbeds, mulching, tarping, and mowing. The practice of using a stale seedbed targets weed seeds within the top one to two inches of soil and is usually performed mid to late season. This technique allows the weed seeds to germinate, but the young weeds are then killed through practices such as flaming or scraping just below the soil surface. This prevents new seeds from coming up to the surface.

Mowing weeds can stress the weed plants so that they are unable to flower and set viable seed. Mowing around crops also can limit weeds’ ability to compete.

Mulching can create a physical barrier to limit weed growth. Organic mulches, such as straw, can also reduce the soil temperature, which may slow down the growth of weeds. Plastic and biodegradable “plastic” mulches are used with heat-loving plants and promote an earlier harvest by raising the soil temperature. Plastic mulches come in a variety of colors that affect the soil temperature differently. Although black plastic mulch doesn’t provide much heat to the soil, it effectively suppresses weeds. A plastic-mulch layer is an implement that can quickly lay plastic in a straight, flat, and tight manner over a bed. Depending on the unit, plastic-mulch layers can level the soil surface, shape beds, lay plastic over hoops or raised beds, and even lay drip tape under the mulch, all in one pass. Plastic-mulch lifters can be used to assist in pulling up the plastic mulch at the end of each season.

The use of plastic tarps can raise soil temperatures to levels that kill or debilitate many soil pathogens, insects, nematodes, weed seeds, and seedlings. Solarization refers to the use of clear plastic mulch on moist soils during the hottest parts of the year to harness the sun’s energy to reduce the number of insects, diseases, nematodes, and weeds in the soil. Solarization can also improve soil tilth and release nitrogen in the form of ammonium and nitrates, as well as calcium, magnesium, and potassium (Guerena, 2022). Adding organic amendments to the solarization process creates anerobic conditions that break down the carbon sources, creating a toxic environment for pests and diseases. This is known as biosolarization. Tarping, or occultation, is the process of using impermeable tarps for weed control. This is a more common practice in places that receive less sunlight. Weed seed germination is stimulated, but weeds then die after emergence due to lack of light. Tarps can also be used to warm up the soil in the early spring, speed up decomposition of crop residues, conserve soil moisture, and minimize nutrient leaching.

Terrateck manual plastic-mulch layer. Photo: Andy Pressman, NCAT

Cover crops can be planted to suppress weeds. Cover crops such as rye, oats, buckwheat, and sorghum-sudangrass can be planted during certain times of the year to smother weeds through competition or by creating a mulch layer. Some crops, such as rye, contain allelopathic chemicals that prevent weed seeds from germinating. Selecting which cover crop(s) to use depends on the goal for the cover crop, as well as how it will be managed or terminated. For cover crops that don’t winter kill, mowing will likely be necessary before incorporating the crop into the soil. Unlike sickle bar or rotary-type mowers that leave a lot of the cut biomass intact, flail mowers cut the cover crop material into fine biomass that is evenly distributed. Meanwhile, the roller-crimper is a cutting-edge implement that is being used to kill cover crops in no-till plantings. It consists of a metal drum with protruding blunt metal blades arranged in a pattern, designed to roll over a cover crop and crimp the plants so that they die, creating a mulch layer. Crops can then be planted or transplanted directly through the mulch.

Hand-Tool Cultivation

The primary tool used in hand cultivation is the hoe. For many farmers, hoeing may seem like back-breaking and labor-intensive work. This may well be the case, especially when using the standard hoe with a 90-degree angled blade and a 54- to 57-inch handle for weeding. These hoes are designed for such tasks as digging, chopping, and hilling soil, and they are inadequate for cultivating smaller weeds that have germinated in intensively planted beds. Understanding when to hoe and how to use different hoes will allow for easy cultivation of weeds.

The eye-hoe, or chopping hoe, is one of the oldest and most traditional tools in the world. The eye-hoe is designed with a heavy head for chopping larger weeds and roots and for moving soil. They are swung similarly to an axe, with the weight of the head doing the work.

Upright hoes allow for smaller weeds to be sliced just below the soil surface. Their blades can fit in narrow spaces and are relatively lightweight. Their handles tend to be longer, between 66 and 74 inches, which allows for a farther reach and for hand positioning that lets the user’s back stay straight. Examples of upright hoes are the narrow collinear hoe and the swan-neck or half-moon hoe.

The narrow collinear hoe has a thin metal blade, usually 3¾ inches or 7 inches long, placed at a 70-degree angle to the handle. The blade runs parallel to the soil surface and is used in a pulling motion, with the user standing sideways. The swan-neck hoe also is used in a pulling or sweeping motion, and the blade is a bit heavier and wider than the blade of the collinear hoe. The push hoe is designed with the front of the blade sharpened and lying flat on the ground so that it can “scuffle” across the soil surface in a pushing motion. The diamond hoe is sharpened on both the front and back of the blade, allowing it to cut in both a pushing and a pulling motion. The blade of a stirrup hoe is not fixed like the diamond hoe’s, which allows it to dig deeper into the soil as it cuts in both directions. In addition, the stirrups, or sides of the blade, make it possible for users to see how close they are cutting to the cash crop.

From left to right, a collinear hoe, a swan-neck hoe, a stirrup hoe, a “regular” hoe, and an eye-hoe. Photo: Andy Pressman, NCAT

Wheel hoes are one of the most efficient tools for weed cultivation on small land bases. The ability to attach different cultivation implements, such as stirrup hoes, chisels, and sweeps, onto a wheeled frame allows the user to stay upright while pushing and pulling the tool. Wheel hoes have either one or two wheels. Although the double-wheeled version is less common, it allows for cultivation on both sides of a crop row at the same time. Wheels come in different diameters, usually from nine to 24 inches, with the smaller-wheeled models being easier to direct and less tiring and cumbersome to use (Coleman, 1995).

Terrateck wheel hoe with attachments. Photo: Andy Pressman, NCAT

As with the toolbar for tractor-mounted cultivators, wheel hoes can also serve as tool carriers, as newer-type wheel hoes can be fitted with accessories that mimic larger-scale implements. For example, the French-manufactured wheel hoe from Terrateck can be positioned for in-row and between-row cultivation with setups using collinear hoe blades, various discs and blades, tine cultivators, and finger weeders. Tine weeders have also been adapted for manual cultivation by attaching flex tines to long tool handles.

Mechanical Cultivation

For many farms, an increase in production efficiency begins with a cultivating tractor. Farmall, Allis Chalmers, Ford, Case, Oliver, Kubota, and John Deere are some common brand names of cultivating tractors, and many models are designed for accuracy that allows the driver to steer close to the crops while cultivating. Guidance accuracy was incorporated into the design of many models by using belly-mounted toolbars and by offsetting the motor to give the driver a clear line of sight. Having the toolbar belly mounted also compensates for the lateral direction of the toolbar while steering. In other words, the toolbar moves slightly in the same direction the tractor is being steered. With rear-mounted implements, on the other hand, the toolbar moves slightly in the opposite direction of the tractor as it turns.

Many cultivating tractors were manufactured during the late 1940s and early 1950s and are still common on small-scale vegetable farms. The Allis Chalmers Model G, for example, was built between 1948 and 1955, and, unlike other cultivating tractors, its motor was placed behind the driver to provide even further guidance when cultivating. Newer makes with this type of design include Oggún, Tuff-Bilt, and Tilmore tractors. While some cultivating tractors were designed to be low to the ground for precision cultivation between young or low-growing crops, other tractors, such as the Landini, were built with a high clearance to cultivate between larger crops throughout the growing season.

An Allis Chalmers G converted to electric at Fair Share

Farm, Kearney, Missouri. Photo: Rex Dufour, NCATHuguenot Street Farm in New Paltz, New York, received funding from the USDA-SARE program to develop detailed instructions on converting an Allis Chalmers Model G into an electric vehicle. There are numerous instructions and videos available online, including the original plans, here.

There is a broad range of tractor-drawn and PTO-driven implements for weed cultivation. In addition to reducing weed populations and herbicide use, many of the implements function to loosen, aerate, and till the soil, as well as to incorporate soil amendments into it. Implements for cultivation are designed for both post- and pre-emerging weeds and include sweeps, discs, torsion hoes, brush hoes, spider wheels, finger weeders, S-tines, basket weeders, rolling cultivators, and other specialized cultivating devices. Some of the more common implements are described below. For a detailed explanation of weed-management tools, see Steel in the Field in the Further Resources section.

Cultivation Equipment for Pre- and Post-Emergence Weed Control

Controlling weeds before they germinate involves cultivating just below the soil surface. Pre-emergence cultivation can be done prior to or in between plantings or shortly after a crop has been planted. Clean fallow is a term used to describe repeated cultivation before or between plantings and is used to kill annual weeds, reduce weed-seed banks in the soil, and remove perennial weed growth (Grubinger, 1999). Once a crop has been planted, and even germinated, a technique known as blind cultivation is used in and between rows. Blind cultivation targets small weeds that have been up for a week or less and does not prevent large-seeded crops that have been sown deeply from germinating.

Disc harrows are one of the most versatile cultivation tools for clean fallowing. The blades of the disc loosen and mix the soil through a lifting action, which then leaves the soil level. Tandem disc blades are usually 16 to 18 inches in diameter and are set about seven inches apart, while offset disc harrows have discs 20 to 24 inches in diameter and are set nine inches apart (Schwenke, 1991). Offset disc harrows are often used in orchards because they can be set up to stir the soil close to trees. Some perennial weeds, particularly those that spread through rhizomes, are better dealt with by equipment that can dig the rhizomes up to the soil surface, where they can dry out and die. Spring-tooth harrows or field cultivators equipped with sweeps or shovels work well for uprooting perennial weeds.

Tine weeders and rotary hoes are two implements commonly used for blind cultivation. Tine weeders, also known as flex-tine weeders, consist of many small metal tines that are pulled through the soil at a fast speed, causing the tines to vibrate and remove the weeds from the soil. Timing is key, because the tines scratch the cash crop as well as the weeds growing between the rows. The depth of the tines can be controlled by gauge wheels or by using a three-point hitch. Rotary hoes often are used for blind cultivation in corn and beans and for breaking up the surface of crusted soils (Grubinger, 1999). Rotary hoes are ground-driven and consist of several spider wheels with “spoons” or tips that rotate and remove weeds.

Cultivation Equipment for Post-Emergence Weed Control

Tools for post-emergent weed cultivation are designed to be used for specific crop stages. As a crop grows and gains strength, more aggressive tools that throw soil can be used, such as sweeps, basket weeders, Spyders™, hilling discs, finger weeders, row-crop cultivators, and rolling cultivators. Implements such as wiggle hoes and brush weeders are designed for cultivating smaller crops between rows.

The sweep is one of the most basic tools used for cultivation. Sweeps are V-shaped blades on a shank that is attached to a toolbar. Depending on the style of sweep, the blade faces forward and slices, drags, or buries the weeds while throwing soil into the rows. The toolbar can be rear mounted, front mounted, or belly mounted to the tractor. Sweeps are usually set to a depth of one inch below the soil surface, and the depth of the sweeps can be adjusted to accommodate differences in elevation within a bed. Running a sweep too deeply can disturb plant roots and throw more soil. However, sweeps set at a deeper depth can also be used for hilling-up crops such as Irish potatoes, sweet corn, and broccoli (Schonbeck, 2010). Shovels are narrower than sweeps and throw less soil.

A basket weeder belly mounted to an Allis Chalmers G at Pennypack Farm and Education Center in Horsham, Pennsylvania. Photo: Andy Pressman, NCAT

Basket weeders consist of two rows of metal baskets that roll across the soil surface at different speeds. The first row is ground driven, which also drives a chain to power the rotation of the second row. This increases the rotation speed of the baskets in the second row, so that they cultivate weeds that survive the cultivation of the first-row baskets. The baskets scuff the soil surface without moving the soil. Basket weeders are belly mounted, can be driven at moderate speeds, and are ideal for cultivating various greens, such as lettuce. Buddingh basket weeders are designed for cultivating two- to eight-row beds.

The Spyder is a ground-driven wheel with offset teeth angled to either throw soil toward or away from the row. Torsion weeders and spring-hoes can be mounted to the Spyder to take care of weeds missed by the teeth of the Spyder.

Hilling discs are used to pull soil away from small crops or to hill (throw soil toward) larger crops, such as potatoes and sweet corn.

Finger weeders are metal, cone-shaped wheels mounted to the belly of a tractor. Protruding from the wheels are rubber-coated metal fingers that cultivate around the stems of plants. The wheels are ground driven and cultivate closely in rows.

Rolling cultivators contain gangs of wheels with tines angled to either throw or hill soil into the rows. The gangs swivel as they slice through the soil, digging up weeds. A fertilizer attachment can be used at the same time as a rolling cultivator for side-dressing crops (Grubinger, 1999).

A row-crop cultivator is a metal frame with several shanks and cultivators attached. The shanks can be set for specific crop rows and throw the soil as the frame is pulled by a tractor. Shields can be mounted to protect the more delicate plants.

Wiggle hoes are steered from the back of the implement as it is pulled by a tractor. They consist of half sweeps that face either to the left or the right and are attached to a shank. Wiggle hoes can be steered by the driver close to the crops, but this requires wide crop spacing.

Soil steamer. Photo: Andy Pressman, NCAT

The European brush weeder sweeps weeds out of the soil. The brushes fit between narrow rows of crops, which are protected by a shield. As with the wiggle hoe, a brush weeder is steered from the back of the implement by a driver.

Flame weeders use propane burners that create a flame of intense heat to control small weeds. Flame weeding is often used to kill weeds in the stale-seedbed technique, particularly for intensive plantings of greens and herbs, because it does not disrupt or throw the soil. There are different scales of flame weeders, from handheld or backpack flamers to tractor-mounted implements.

Soil steaming is an emerging technology that is being utilized to manage disease, weeds, and pests in fields and in high tunnels. The goal of soil steaming is to pasteurize the soil, not to sterilize it, by reaching temperatures between 140 and 180°C for an extended period. This is accomplished by using a boiler unit that fills a tarp laid over an area with steam or by directly injecting the steam into the soil. While soil steaming offers a solution for managing many pests, diseases, and weeds, more research is needed before conclusions can be drawn about the depth and breadth of the effects of soil steaming on soil biology.

Soil steaming at Picadilly Farm, Winchester, New Hampshire. Photos: Andy Pressman, NCAT

Harvest

Of course, like any operation, context is key, and every farm will benefit from careful planning and the design of workflows that make for a more efficient and less redundant process. Farmers should always ask themselves: How does this piece of equipment work with my management style and scale of production?

Let’s take an example of a simple yet often-overlooked and useful piece of equipment: storage boxes. How many different brands and shapes have you accumulated over the years? How much time do you spend looking for lids to match the correct box? As they say, the devil is in the details, and small time sucks like these can accumulate drastically when summed across an operation. Storage boxes that have incorporated lids that can also be nested inside one another or stacked when filled may be a good solution worth considering.

For those taking part in direct sales, who need to keep their produce cool, the typical and most common route has been to purchase a refrigerated vehicle. While this is a good option and one of the more reliable ways to transport delicate produce across longer distances, there is a more cost-effective choice. Well-made and lightweight insulated boxes made from recyclable materials may be a suitable substitute for many wanting to transport products from an on-farm refrigerator to the buyer or market.

There are so many harvest tools and implements out there, many of which are well known at the larger scales of production. A few that work for small- and mid-scale farms are harvest baskets, aprons, and bags, as well as knives, garden carts, and snips. To borrow the suggestions made by Daniel Mays (2020) in his book The No-Till Organic Vegetable Farm, when it comes to knives, there are many to choose from, but some farmers have found that a single multipurpose knife with a serrated edge should be carried by each farmworker and is best for general harvest needs. For crops that require a more delicate touch and that may have brittle or delicate stems (eggplant, peppers, flowers, tomatoes, etc.) a snip with long, straight blades should do the trick. People harvesting crops that can be harvested while standing (tomatoes, snap peas, other trellised crops, tree fruit, etc.) can benefit from the use of fruit-picking bags, which help with picking speed and ergonomics. When it’s time to transport from the field to the wash/pack station, a garden cart serves as a good bulk transporter for heavy produce or produce that has been accumulated at the end of the row.

There are also a couple of recent notable innovations that some will find particularly useful. Single-row potato diggers and tuber-digging ploughs can be attached to a small tractor or a two-wheeled tractor. These open the potential for economically viable potato production at smaller scales, particularly when thinking about more desirable and tastier cultivars.

Additionally, greens harvesters have been a great innovation for the small farm producing salad mixes or “cut and come again” greens. Many small farmers were priced out of salad mix production when innovations were made for larger growers that saved on labor costs; the small farm just couldn’t compete. Now, with several options for the small and mid-scale farmer, including the “Quick-cut-greens harvester” and similar scaled-up options, farmers don’t have to crawl around on hands and knees cutting each plant by hand; an entire bed can be harvested in a fraction of the time.

Foggy Meadow Farm – Benson, Vermont

Paul Horton and Sally Beckwith of Foggy Meadow Farm produce naturally grown vegetables and herbs on 4½ acres in Benson, Vermont. Foggy Meadow is a year-round operation that direct markets its crops through farmers markets and restaurants. From its start in 2004, Foggy Meadow has invested in small-scale equipment and tools, which has resulted in the farm being able to continue producing at this scale and remain economically viable.

Horton and Beckwith believe every farm should develop a reputation for growing certain crops. Foggy Meadow is known for its high-quality greens and carrots. Although most crops on the farm are transplanted, the farmers at Foggy Meadow direct-seed 1,000 row feet of salad mix and 10,000 row feet of carrots each week from March through September to ensure a continuous supply. Greens are grown in two 15-foot by 96-foot high tunnels during the spring and winter months, and tomatoes take root in these tunnels during the summer. The high tunnels are moved once or twice a year to new soil to help protect plants from soil salinity issues, pests, and disease.

Foggy Meadow Farm, Benson, Vermont. Photo: Courtesy of Sally Beckwith

Field crops are grown in ¾-acre sections. This amounts to having six to seven sections, which allows Horton and Beckwith to plan for extensive crop rotations. As spring crops come out of the ground, some land becomes a stale seedbed, while other parcels are cover cropped or sheet mulched for use the following spring.

The farm uses a 70-horsepower John Deere tractor for field tillage and bed preparation. Beds are prepared for planting using a combination of a five-shank chisel plow and a 70-inch rototiller. This creates beds for up to three crop rows, which are marked out in the bed using pins on a basket weeder. The Buddingh basket weeder is attached to a Farmall Cub—one of four tractors used for cultivation. There are two Farmall Super Cs, one with sweeps and hilling discs, and the other with shovels that are matched with the rows in each bed. In addition, a Farmall A tractor is set up with a 6-foot disc and harrow for planting cover crops. Having tractors set up with only one implement reduces the time and stress involved with switching implements on a single tractor. As Foggy Meadow Farm looks to produce more crops for winter markets, Horton is interested in purchasing another cultivating tractor with a toolbar set up for single-row crops.

Summary

Choosing the right tool or piece of equipment can greatly affect production efficiency and the economic bottom line for the small-scale farmer. Investing in well-designed hand tools of good quality enhances the farmer’s ability to maximize production on an intensive scale. Using tractors and implements designed for small-scale intensive crop production can increase crop quality and yields while reducing labor inputs. Such factors as soil type and crop selection play an important role in the utilization of farm equipment.

References

Coleman, Eliot. 1995. The New Organic Grower. Chelsea Green Publishing, White River Junction, VT.

Grubinger, Vernon. 1999. Sustainable Vegetable Production from Start-Up to Market. Natural Resource, Agriculture, and Engineering Service, Ithaca, NY.

Guerena, Martin. 2022. Soil Solarization and Biosolarization. National Center for Appropriate Technology ATTRA Publication.

Mays, Daniel. 2020. The No-Till Organic Vegetable Farm. Storey Publishing, North Adams, MA.

Perkins, Richard. 2019. Regenerative Agriculture.

Schonbeck, Mark. 2010. Design the Cropping System and Select Tools for Effective Weed Control. eXtension.

Schwenke, Karl. 1991. Successful Small-Scale Farming: An Organic Approach. Storey Publishing, North Adams, MA.

Volk, Josh. 2009. Tools that Make Direct Seeding Easier. Growing for Market.

Wiswall, Richard. 2009. The Organic Farmer’s Business Handbook. Chelsea Green Publishing, White River Junction, VT.

Further Resources

Books and Publications

Build Your Own Farm Tools. 2021. By Josh Volk. Storey Publishing, North Adams, MA. 207p.

Offers small-scale farmers an in-depth guide to building customized equipment that will save time and money and introduce much-needed efficiencies to their operations.

Grower to Grower: Creating a Livelihood on a Fresh Market Vegetable Farm. 2005. By John Hendrickson. Center for Integrated Agricultural Systems. University of Wisconsin, Madison, WI.

Report that offers Wisconsin case studies to provide a basis for comparisons between farms on how to make farming a quality livelihood.

Growing for Market

P.O. Box 75

Skowhegan, ME 04976

800-307-8949

Subscription journal with news, advice, and resources for market farmers. Articles are written by market farmers and regularly include information on equipment and tools for market farms.

How to Use Implements on Your Small-Scale Farm. 2005. By Rick Kubik. Motorbooks International, Minneapolis, MN. 120p.

Describes how to use implements in detail, including their function, how they are attached and removed from tractors, when to use them, and basic maintenance and repair.

Managing Weeds on Your Farm: A Guide to Ecological Strategies. 2022. By C.L. Mohler, J.R. Teasdale, and A. DiTommaso. SARE Handbook Series 16. SARE, College Park, MD. 416p.

Provides in-depth information about dozens of agricultural weeds and the best ways to manage them.

Sample Costs to Produce and Harvest Strawberries. 2016. By M. P. Bolda, L. Tourte, J. Murdock, and D.A. Summer. University of California Agriculture and Natural Resources, Cooperative Extension and Agricultural Issues Center, UC Davis Department of Agricultural and Resource Economics.

Offers sample budget for labor, materials, equipment, and custom services to produce and harvest strawberries in the Central Coast Region.

Steel in the Field – A Farmer’s Guide to Weed Management Tools. 1997. Edited by Greg Bowman. A publication of the Sustainable Agriculture Network (SAN), Beltsville, MD. 128p.

Highlights 22 farms and how mechanical weed control works in their sustainable cropping systems.

The Market Gardener. 2014. By Jean-Martin Fortier. New Society Publishers, Gabriola Island, BC, Canada. 221p.

A compendium of proven horticultural techniques and innovative growing methods.

Understanding Equipment Costs on the Small Commercial Vegetable Farm. 2020. By M. Ernst., A. Butler, and T. Woods. University of Kentucky Center for Crop Diversification CCD-FS-18. University of Kentucky, Lexington, KY. 13p.

A free publication that describes equipment commonly used in small-scale vegetable production and details the methods for calculating farm machinery costs per hour of use.

What Size Farm Tractor Do I Need? 2007. By Paul E. Sumner and E. Jay Williams. University of Georgia Cooperative Extension Pub. No. ENG07-003. University of Georgia, Athens, GA. 8p.

Provides information and data to help determine the right-size tractor for a farm.

Videos

Vegetable Farmers and Their Sustainable Tillage Practices [DVD]. By V. Grubinger. 2007. University of Vermont Extension.

Eleven farmers and researchers in three northeastern states describe their sustainable tillage practices and tools, from mulches to ridge till to spaders.

Vegetable Farmers and Their Weed-Control Machines [DVD]. By V. Grubinger and M.J. Else. 1996. University of Vermont Extension.

Nine farmers from three northeastern states describe their tools for weed management, from cultivation to flaming.

Websites

Farm Tractor Manuals

Company offers a full line of parts, service / repair, and owners / operators farm tractor manuals for almost every make or model of farm tractor.

New York Center for Agricultural Medicine and Health

The mission of NYCMH is “Enhancing agricultural and rural health by preventing and treating occupational injury and illness.” NYCAMH provides services and education related to farm safety and farmer mental health.

TractorData.com

For 20 years, TractorData.com has been providing tractor specifications to farmers, homeowners, and the machinery industry.

University of Vermont’s Ground Work Tractor Resource Hub

The Ground Work Tractor Resource Hub brings together information and resources regarding basic tractor use and operation, basic tractor maintenance, tractor safety, tractor purchase decision-making, and farm mechanization strategies.

Yesterday’s Tractor Company

Website with active forums, photos, and extensive information about pre-1985 farm equipment.

Suppliers

This is not a complete list and is to be used for educational purposes only. The ATTRA Sustainable Agriculture Program is operated by the National Center for Appropriate Technology under a cooperative agreement with the Rural Business-Cooperative Service, U.S. Department of Agriculture. These organizations do not recommend or endorse products, companies, or individuals.

A.M. Leonard, Inc.

241 Fox Drive

Piqua, OH 45356

800-543-8955

info@amleo.com

Offers quality horticulture tools and equipment for nursery, landscape, and agriculture customers.

BCS America

14151 Fir Street

Oregon City, OR 97045

800-543-1040

info@bcsamerica.com

BCS America offers two-wheel tractors and a wide selection of implements for BCS two-wheel tractors.

Brookdale Fruit Farm

38 Broad Street

Hollis, NH 03049

603-465-2240

tractortrv@aol.com

Supplier of irrigation equipment and an assortment of equipment, including no-till vegetable seeders and transplanters.

Buckeye Tractor Co.

P.O. Box 97, 11313 Slabtown Rd

Columbus Grove, Ohio 45830

800-526-6791

buckeyetractor@bright.net

Manufacturer of specialty agricultural equipment.

Carts and Tools

7171 NE Highway 20

Corvallis, OR 97330

541-286-3161

Manufacture and sales of small battery-powered tillers and wheel hoes.

Carts Vermont

210 Pierce Road

St Johnsbury, VT 05819

800-732-7417

customerservice@cartsvermont.com

A variety of yard carts built with the durability for outdoor, continued use.

Clampco Fertilizer Applicators

3400 Rancho Vista Ct

Gilroy, CA 95020

408-706-0016

info@clampcoapplicators.com

Applicators designed for use with dry organic fertilizers.

Curly’s Ag

1349 Old Rosevale Road

Rosevale, QLD 4340

Australia: 0449 268 131

info@curly’sag.com

Tools and equipment designed and manufactured for efficient and productive sustainable bio-intensive farming.

Dailey’s Farm & Walk-Behind Tractors

141 Marvin Whitehead Rd.

Hohenwald, TN 38462

931-295-9009

Retails BCS, Yagmur, and Grillo walk-behind tractors, as well as hand tools and seeders. The company also has locations in Georgia and Indiana.

Easy Digging

1400 Forum Blvd. #585

Columbia, MO 65203

573-823-3539

contact@easydigging.com

Sells a variety of heavy-duty tools for gardening, landscaping, construction, and small-scale agriculture.

Earth Tools

1525 Kays Branch Road

Owenton, KY 40359

502-84-3988

officemanager.earthtools@gmail.com

Offers BCS and Grillo walking tractors, compatible implements, and a full line of hand-forged and professional garden tools.

Farmers Friend

99 Broome Lane

Centerville, TN 37033

931-583-0397

support@farmersfriendllc.com

Dedicated to equipping, educating, and inspiring growers to change the world through regenerative agriculture.

Ferrari Tractor C.I.E.

P.O. Box 1045

Gridley, CA 95948

530-846-6401

sales@ferrari-tractors.com

Dealer of new and used equipment for the small farm, with expertise in carrying European-made two- and four-wheel compact tractors and implements.

Flame Engineering, Inc.

P.O. Box 577

LaCrosse, KS 67548

800-255-2469

dragonmaster@flameengineering.com

Developer of flame weeders, including the Red Dragon® Agricultural Flamers.

Four Season Tools

9615 Grandview Road

Kansas City, MO 64137

816-444-7330

Dealer of small farm tools for seeding, harvest, weed management, and more.

Gempler’s

P.O. Box 5175

Janesville, WI 53547-5175

800-382-8473

customerservice@gemplers.com

Farm supply company.

Green Heron Tools

P.O. Box 71

New Tripoli, PA 18066

610-844-5232

info@greenherontools.com

Maker of high-quality hand tools and equipment specifically designed for women farmers.

Grindstone Farm

780 County Route 28, Tinker Tavern Road

Pulaski, NY 13142

customerservice@grindstonefarm.com

Organic farm and manufacturer of root-crop washer.

Growers & Co.

3535 Boul. Ste-Anne B.300

Quebec, Qc, Canada, G1E 3L6

418-524-4443

info@growers.co

Handcrafted products that address the need for reliable, functional, and durable market gardening tools and clothing. Founded by Jean-Martin Fortier.

FlameWeeders.com

1711 Mud Lick Rd.

Glenville, WV 26351

304-462-7606

info@flameweeders.com

Flame weeders designed for market gardeners.

Gulland Forge Broadforks

Siler City, NC

502-682-8529

gullandbroadfork@me.com

Designer and fabricator of high-quality forged broadforks.

Harmony Farm Supply and Nursery

P.O. Box 460

Graton, CA 95444

707-823-9125

info@harmonyfarm.com

Offers a full range of tools and supplies for the small-scale farm.

Hida Tool & Hardware Company, Inc.

1333 San Pablo Avenue

Berkeley, CA 94702

800-443-5512

hidatool@hidatool.com

Specializes in Japanese handcrafted weeders, hoes, sickles, and cutting implements.

Hillside Cultivator

911 Disston View Drive

Lititz, Pennsylvania 17543

717-626-6194

sales@hillsidecultivator.com

Manufacturer and dealer of cultivation equipment for fruits and vegetables.

HISCO Professional Tools

4320 North Cooper Ave.

Oklahoma City, OK 73118

405-524-2700

customerservice@hisco-okc.com

Professional-grade tools with reinforced fiberglass handles.

Hoss Tools

P.O. Box 429

Norman Park, GA 31771

888-672-5536

Custserv@hosstools.com

Carries a complete line of high-quality garden tools, gardening supplies, vegetable seeds, and cover crop seeds.

Howland Tools

25 Elm Street

Shelburne Falls, MA 01370

413-776-1948

info@howlandtools.com

Source for premium-quality hand tools made in the USA and imported from Europe. Howland stocks hand-crafted farm and garden tools from SHW, Falci, DeWit, Ashfield Tools, Hoss Wheel Hoes, Council Tools Axes, and more.

I&J

10 S New Holland Rd

Suite 2

Gordonville, PA 17529

717-442-9451

info@croproller.com

Manufacturer of roller crimpers for cover crops and durable, workable, and economical horse-drawn farm equipment.

Johnny’s Selected Seeds

955 Benton Avenue

Winslow, ME 04901

877-564-6697

communications@johnnyseeds.com

Offers a complete line of tools for the gardener or commercial grower, including flame weeders, wheel hoes, seeders, and hand tools.

Kennco Manufacturing, Inc.

1105 3rd Street NE

Ruskin, FL 33570

800-645-2591

sales@kenncomfg.com

Since 1973, Kennco Manufacturing has been designing raised bed shapers and plastic layers and developing farm equipment for small farm growers.

Kult Kress

717-984-8979

info@kult-kress.com

Manufacturer of efficient cultivation equipment including the Kress Finger Weeder and Kress Robovator.

Lee Valley Tools

P.O. Box 1780

Ogdensburg, NY 13669

800-267-8735

customerservice@leevalley.com

Offers an extensive inventory of gardening tools.

Market Farm Implement

257 Fawn Hollow Road

Friedens, PA 15541

814-443-1931

Specializes in vegetable-crop machinery from tillage to harvest.

Meadow Creature

P.O. Box 2112

Vashon, WA 98070

360-329-2250

sales@meadowcreature.com

Manufactures the Meadow Creature® Broadforks, the Avalon Cider Press, grub hoes, and other metal fabricated products.

Mechanical Transplanter Company

1150 Central Avenue

Holland, MI 49423

800-757-5268

mtc@mechanicaltransplanter.com

Offers a full range of manual and tractor-mounted equipment for tillage, planting, and cultivation.

Morgan County Seeds

18761 Kelsay Road

Barnett, MO 65011

573-378-2655

errolahlers@reagan.com

A seed and supply store for home gardens, organic growing, greenhouse operations, and commercial vegetable growing.

Neversink Farm

635 Claryville Road

Claryville, NY 12725

neversinkcustomerservice@gmail.com

Offers a variety of tools for weeding and bed preparation.

Organic Growers Supply (FEDCO)

P.O. Box 520

Waterville, ME 04903

207-873-7333

Cooperative supplier of hand tools, orchard supplies, irrigation, and seed-starting supplies for the organic grower.

OESCO, INC (Orchard Equipment & Supply Company)

8 Ashfield Road

Conway, MA 01341

800-634-5557

info@oescoinc.com

In continuous operation since 1954, supplying growers, gardeners and green industry professionals with professional grade machinery, tools, parts, and service.

Peaceful Valley Farm and Garden Supply

125 Clydesdale Court

Grass Valley, CA

888-784-1722

helpdesk@groworganic.com

Offers a full line of hand tools, growing supplies, irrigation and season-extension supplies, organic soil amendments, seed, and pest and weed controls.

Purple Mountain Organics

7120 Carroll Avenue

Tacoma Park, MD 20912

877-538-9901

Offers a full line of high-quality tools and equipment for the small farm, including hand tools, walking tractors, compact tractors, and implements.

Rain-flo Irrigation

929 Reading Rd.

East Earl, Pennsylvania 17519

717-445-3000

Purveyor of vegetable planting equipment, vegetable growing products, T-Tape drip tape for drip irrigation, plastic mulch, portable water pumps, diesel powered water pumps, and overhead crop irrigation.

Rebel Garden Tools

223B W. Walnut St.

Lancaster, PA 17603

717-288-7058

susquehanna.apothecary@gmail.com

Highly ergonomic forged tools; owned by Susquehanna Sustainable Enterprises.

Red Pig Tools

12040 SE Revenue Road

Boring, OR 97009

503-663-9404

redpigtools@frontier.com

Maker of forged-steel hand tools, including left-handed tools.

Ronnie Baugh Tractors

P.O. Box 58007

Raleigh, NC 27658

256-655-8792