More Than a Cover Crop: Developing a Farm-to-hospital Supply Chain for Yellow Peas

Sara Williams Flewelling, Aurora Mills and Farm, Linneus, Maine. Photo: Aurora Mills and Farm

By Lee Rinehart, NCAT Agriculture Specialist

Abstract

This publication provides a case study of the process, and insight into the opportunities, challenges, and steps undertaken, to turn locally grown yellow pea into a value-added product, build the supply chain, and get it integrated on hospital menus in the New England region. This case study provides a powerful roadmap for ways to build a truly values-aligned supply chain that supports people and the planet, with enormous potential for scaling and replication.

Contents

Introduction

Healthy Food, Regional Food Systems, and the Carbon Footprint

Why Yellow Peas?

A Pea’s Journey, From the Field to the Plate

A Primer on Growing Yellow Peas

Summary and Recommendations

End Note

References

Further Resources

Introduction

Healthy food cannot be defined by nutritional quality alone. It is the result of an entire food system that conserves and renews natural ecosystems, advances social justice and animal welfare, builds community wealth, and fulfills the food and nutrition needs of all eaters now and into the future (Riordan, 2022). In 2020, a pioneering new project was conceived with the goal of improving access to healthy food consistent with these attributes, while building resilience within New England’s regional food supply. This publication provides a case study of the process, and insight into the opportunities, challenges, and steps undertaken, to turn yellow pea into a value-added product, build the supply chain, and get it integrated on hospital menus. This case study provides a powerful roadmap for ways to build a truly values-aligned supply chain that supports people and planet, with enormous potential for scaling and replication.

The Food System, Currently

Our current food system thrives within a dominant social paradigm that is informed by a fundamental belief in progress, growth, prosperity, technology, and property rights (Beus and Dunlap, 1990). These values have fostered a capital-intensive, highly centralized economic system reliant on fossil fuels and global supply chains that has resulted in striking growth worldwide, especially in highly developed countries. But the industrial food system that has grown from this development poses enormous environmental and human-health risks through reliance on synthetic pesticides, fossil-fuel-based fertilizers, antibiotics, and hormones. Given its fundamental premise of technological efficiency and profit, many question whether this system can be relied upon to foster human and ecological health. We know that with dietary changes, reduced food waste, and sustainable agroecological farming systems a growing global population can feed itself in a way that supports food sovereignty and human and environmental health (Willett et al., 2019).

Industrial agriculture has succeeded in getting high volumes of food to global markets but is generating negative outcomes, including widespread degradation of land, water, and ecosystems; high GHG emissions; biodiversity losses; persistent hunger; the rapid rise of obesity and diet-related diseases; and livelihood stresses for farmers around the world (IPES-Food, 2016). Photo: Markus Spiske, Unsplash

Smallholders are the main or sole food providers to more than 70% of the world’s people, producing this food with less than 25% of the resources used in global agriculture (ETC Group, 2017). Photo: NCAT

We live in a world where food is industrially produced in monocultures far from where it is consumed and shipped hundreds, or even thousands, of miles to its destination. This is accomplished within a comprehensive land-use, manufacturing, and distribution system predicated on uniformity, efficiency, and scale to achieve profitability within defined margins. This system, for all its growth and prosperity for a few, has consolidated decision-making into a handful of people and corporations and has made it difficult for local and regional democratic action to foster a sustainable, equitable, and healthy food system. To shift the balance from this industrialized system, we must look to the local autonomous action of farmers, food hubs and aggregators, food processors and businesses, community organizations, and institutions. In an economy structurally in opposition to equity, opportunity, and food democracy, community groups are, through cooperative action all along the supply chain, building a just, equitable, sustainable food system that prioritizes human and environmental health. This case study is the story of one project that is finding a way to make that happen.

Connecting Soil Health to Human Health

From 2020 to 2023, the national nonprofit organization Health Care Without Harm demonstrated that it is possible to build a values-aligned food supply chain. Together with a farmer in Maine, a food processor in Boston, and a food hub in Rhode Island, they developed a pilot project to supply hospitals in Boston and beyond with a healthy, plant-based protein product through the Building and Promoting Institutional Markets for High‐Protein Specialty Crops project. Funded through a USDA Specialty Crop Block Grant, the pilot project demonstrated how transforming a cover crop into a cash crop can be a catalyst for fundamental systems change. The project incentivized farms to plant a cover crop that promotes sustainable farming practices and soil health and provides hospitals with a healthy, nutrient-dense, food option for patients, staff, and visitors, while creating quality, urban food-manufacturing jobs.

Plant-based protein – A style of cooking and eating that emphasizes and celebrates, but is not limited to, foods from plant sources—fruits and vegetables, whole grains, legumes, nuts and seeds, plant oils, herbs, and spices— and reflects evidence-based principles of health and sustainability.

– Culinary Institute of America

The Building and Promoting Institutional Markets for High‐Protein Specialty Crops project encompassed four U.S. regions, with supply-chain development work in the Pacific Northwest, California, Colorado, and New England. Working groups in each region developed partnerships with growers, processors, manufacturers, and institutional purchasers to spur demand for regionally grown plant-based protein through product development and technical assistance for growers and institutional buyers. In all, the food value chain in the Northeast consisted of:

- Aurora Mills and Farm, Maine (farm and seed miller)

- Johnson & Wales University, Massachusetts (product formulation)

- CommonWealth Kitchen, Massachusetts (product manufacturing)

- Farm Fresh Rhode Island, Rhode Island (product distribution)

- Brigham and Women’s Hospital/Sodexo, Massachusetts (purchaser)

- Beth Israel Deaconess Medical Center/Sodexo, Massachusetts (purchaser)

Early on, Health Care Without Harm led the effort to test the market to see what food choices currently exist and find ways to bring plant-based proteins into the hospitals’ food service systems. One common item on the hospital menus was a chickpea falafel. The product team had conversations and chose to develop a similar product made instead with a locally sourced protein. The team chose the yellow pea, as it is a cover crop that grows well across the New England region and, despite its soil health-inducing properties, lacks a strong market for human consumption. The yellow pea has a very high protein content and is used in rotation by many farmers as a cover crop to maintain soil cover and water conservation and improve overall soil health between cash-crop seasons. What resulted from the product development phase was a yellow-pea falafel that could easily be substituted for chickpea falafel.

The mission of Health Care Without Harm is to transform health care worldwide so that it reduces its environmental footprint, becomes a community anchor for sustainability, and a leader in the global movement for environmental health and justice. Health Care Without Harm engages hospital food service directors to promote values-based food purchasing standards and food-environment improvement in cafeterias and patient meals, and provides community food access support, food supply chain and product development, and public-policy awareness.

The hospitals involved in the project expressed enthusiasm for the yellow pea falafel, due to established institutional commitments to purchase local, sustainably produced food. This commitment is manifested by their involvement in such efforts as the Cool Food Pledge, a pledge through the World Resources Institute that outlines a commitment that, as a collective, they will reduce supply-chain emissions associated with food purchasing by 25% by 2030. Data is submitted annually for evaluation on how each member is progressing towards this goal. The information is used to assess how to continue to reduce greenhouse gas emissions, primarily through food waste reduction and transition to plant-based proteins. The yellow-pea falafel delivers a win-win for the hospitals, staff, and patients and the farmers and food producers in the region.

Tempeh: A sleeping giant ready to be woken up

Sarah Speare. Photo: Tootie’s Tempe

… so says Sarah Speare, CEO of Tootie’s Tempe in Biddeford, Maine, and a member of the Northeast plant-based protein project producer cohort. She co-founded the business in 2019 as a worker-owned cooperative, guided by her values to empower workers with distributed decision-making and profit sharing, and in which success is manifested by the health and well-being of people, animals, and the planet. For Sarah, the worker cooperative is a solution to a broken economic system. “The coop idea was developed to address inequity in business, and it is encouraging to see interest in coops and unions, and in sustainable resilient businesses, instead of exit strategies and top salaries paid to upper management in corporations,” notes Sarah. “It aligns community values for decision-making and opens doors regionally for distributors and consumer-owned coops.”

Tempeh is a fermented food product usually made with soybeans, vinegar, and starter culture. It is high in protein and can be made of almost anything pulse or bean-like, such as rice, peas, or beans. Sarah focused on traditional tempeh made from soybeans sourced from regional organic farms and is currently working on a good production practice for using yellow pea. Other options—heirlooms that can significantly increase crop diversity on farms, as well as healthy food options—include cattle beans and marfax. These Old-World varieties are adapted to New England, but at their current low scale are relatively high-cost items. For these, Sarah considers the possibility of craft batches to test the market.

Many farmers in New England grow soybeans, and though much of that goes into animal feed, it is also excellent food for people. “Soy is being maligned in popular press, perhaps because of processed foods” (Speare and Lent, 2022). Some people experience digestive problems or estrogen-level fluctuations from eating soybeans. Whether this is something inherent in soy, or due to variation in how bodies react to phytochemicals, or even a result of food processing, is less understood. But for food eaters and farmers in the Northeast, including soybean in a diverse crop rotation has both ecological and financial benefits, especially if the product is marketed through a regional food value chain.

Sarah produces tempeh through a two-day process. The beans are split and dehulled, soaked, cooked, and dried in a centrifuge. Then they are cultured with mycelium to ferment. On the second day, the tempeh is cooled, cut, and packaged into a shelf-stable product that is high in protein and fiber. The product can be used in recipes as a protein substitute for meat in dishes including tempeh meatballs, kabobs, chili, shepherd’s pie, and tacos, just to name a few.

Sarah envisions a regional food system not especially reliant on a single processing plant, but rather a network of franchised local producers. There are certainly challenges here: competitive pricing, qualifications of food manufacturing workers, and equipment suppliers top the list. There is also a lack of infrastructure and financial support for local supply chains. And there is a need for more farmers to grow pulses. This is an opportunity for a champion entrepreneur to take ownership of the concept and pull together stakeholders, much the same way the plant-based protein project did with hospitals in Boston. Sarah sees the champion as a steward to bring everyone together to share their collective needs and challenges and build relationships for common issues, such as acquiring large-scale grants or communicating about crop-growing concerns. A successful working group has qualities of entrepreneurship, grit, and versatility, and a has a true passion for innovation and food sovereignty.

Healthy Food, Regional Food Systems, and the Carbon Footprint

When an ecosystem is ignored, exploited, or destroyed, it has effects all along the food chain. Photo: NCAT

Webster defines health as “a condition in which someone or something is thriving or doing well.” Well-being, therefore, is a state that can be applied to people, animals, and the land. In other words, to ecologies. The ecology of the regional food system begins with the soil. The myriad microbiological life in the soil mineralizes nutrients and makes them available for plants to grow and produce leaves, stems, seeds, and fruit. A farmer plants a seed with intention, within an agroecosystem designed to sustain the life of the plant, and relies on the intricate relationships in the soil, combined with sunlight and water, to produce a crop. She cares for the crop during its growth and reproduction, harvests the seed, and carefully maintains its high quality through storage and packaging, until it makes its way to the next phases in this ecology – the food manufacturer, the distributor, and finally the food purchaser.

The ecology of the regional food system begins with healthy soil. Photo: NCAT

Hospitals have strict criteria for serving meals. In creating a menu, they must factor in cost, nutrition, and taste. Additionally, many hospital administrators, particularly in nonprofit institutions, have requirements to complete a periodic community health-needs assessment, when they look at how they perform on different indicators such as climate and community health. This has led to hospitals becoming increasingly interested in reducing their carbon footprint, and one strategy to do this is purchasing plant-based products and sourcing locally.

In recent years, farmers and food producers have connected with community organizations, nonprofits, and food hubs and distributors to provide food to regional institutions like hospitals and schools, and we’ve seen market demand grow for produce and value-added products. But throughout this transition, beans/peas/pulses have been less of a focus.

Yellow pea (Pisum sativum) was chosen for this project because it has attributes as an excellent cover crop, is very similar to soybeans in its planting and harvest agronomy, has a high protein content, and aligns with hospitals’ values and commitments to source food locally and sustainably. These characteristics fit well with the idea of provisioning institutions with a food product that: 1) is produced in a manner that is beneficial to soils and water; 2) captures carbon in the soil, therefore helping to mitigate the deleterious effects of a shifting climate; 3) is low in fat and high in protein, making it a healthy choice for health-care institutions; and 4) is local, meaning it can be grown easily by regional farmers and processed by local food manufacturers or kitchens and distributed by regional food hubs.

Yellow pea. Photo: North Dakota State University

Why Yellow Peas?

The yellow pea, a variety of field pea, is a pulse crop, a member of the legume family. Pulses are harvested as dry beans or peas, though some may be harvested fresh for human consumption. The word “pulse” comes from the Latin word “puls,” meaning a thick soup, potage, or broth (Keshavarz et al., 2020). Pulse crops commonly grown in the United States include chickpeas, pinto and black beans, lentils, cowpeas, and dry peas. In addition to being grown as cash crops, pulse crops are often used as cover crops for building soil health and providing fertility to subsequent crops in rotation. Some of the benefits of cover crops, especially legumes, in the crop rotation include the following:

- Soil health benefits – for example, cover crops may increase soil organic carbon and available nutrients, foster soil aggregation, and enhance nutrient cycling (Koudahe et al., 2022)

- Nitrogen fixation and nutrient carryover for cash crops – for example, field peas produce 90 to 150 pounds of nitrogen per acre, which can provide most, if not all, the nitrogen needed for the next crop in the rotation

- Water use efficiency – for example, cover crops can be terminated prior to spring planting if moisture is limited, or cash crops can be planted green into cover crops in wetter years, making planting conditions much better for the cash crop

- Disease and pest reduction by breaking pest life cycles – for example, Septoria leaf spot problems on cash crops are reduced when Austrian winter pea is planted in fall after snap beans and ahead of collards and mustard greens (Clark, 2007)

Legume cover crops, including yellow pea, provide quantifiable benefits to farmers, including ecological services and financial returns from reduced use of fertilizers. And, when viable markets and value chains exist, cover crops can reduce farm financial risk when used as a dual cash/cover crop.

Field peas as a cover crop produce high biomass, providing carbon to the soil and capturing nitrogen for use in subsequent crops. They can produce large amounts of dry matter per acre, and the residue breaks down for easy incorporation into the soil. This allows for rapid nutrient uptake by subsequent crops. Peas yield up to 150 pounds of nitrogen per acre, and they can out-compete weeds in the spring. In Virginia field trials in 2010-2011 and 2011-2012, no-till corn plots with cover crops were studied without irrigation or fertilizer. Field pea had a winter dry-matter biomass of 964 pounds per acre, a winter nitrogen uptake of 35 pounds per acre, a spring dry-matter biomass of 1,105 pounds per acre, and a spring nitrogen uptake of 72 pounds per acre, which, with the biomass produced, provided fertility to subsequent corn crops (Fleming and Thomason, 2020; Clark, 2007). As well, a 2022 meta-study on cover crops showed the amount of nitrogen fertilizer required for cash crops following legume cover crops was substantially reduced or eliminated, compared to crops grown without cover crops. It was also noted that pea cover crops could provide 17 to 37% of the nitrogen recommendation for corn and a 27% increase in soil organic carbon (Koudahe et al., 2022).

It is widely thought, and with increasing evidence, that cover crops (especially multispecies cover crops) increase soil microbial community abundance, which has a direct impact on soil fertility and nitrogen carryover, as depicted in the above paragraphs. In another study, soil bacteria and fungi increased and showed more species diversity, as well as a greater number of predatory insects and spiders, increasing by 7 to 31% with cover crops, compared to no cover crop. Also, the fungal fraction in the soil showed greater increases than bacteria, bringing the soil to a more favorable fungal-to-bacterial ratio. Soil microbial tests in the experiments showed higher soil-microbial activity and nitrogen release where field peas were grown, as well as 50% faster soil water infiltration rates with field peas in the rotation (Stepanović, 2017; Muhammad et al., 2021).

Finally, a meta study by Louisiana State University in 2020 determined that, for soybean production, cover crops significantly affected income. Soybeans without a cover crop yielded 48.3 bushels per acre with a return of $91.70 per acre, while the cover-cropped soybeans yielded 50.9 bushels per acre with a return of $112.20 per acre (Adusumilli and Wang, 2020).

Importantly for hospitals, and in addition to providing ecological and financial benefits to farmers, pulses are very good food. For thousands of years, pulses have been a common source of plant-based proteins, amino acids, antioxidants, fiber, and essential nutrients like iron, potassium, and folate. They are characteristically low-fat and free of cholesterol, sodium, and gluten, and may help reduce the risk of obesity, heart disease, diabetes, and certain types of cancer (MDA, no date). This makes pulses an excellent healthy food choice for hospitals.

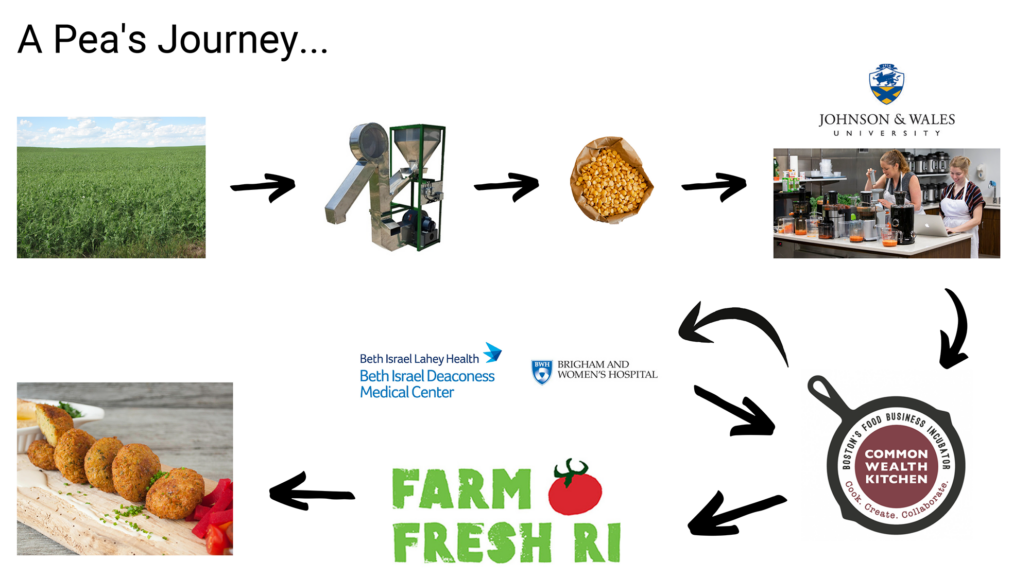

A Pea’s Journey, from the Field to the Plate

The pea started at Aurora Mills and Farm and was dried, cleaned, and bagged. From there it was shipped to Johnson and Wales in Boston for recipe formulation. Commonwealth Kitchen developed the manufacturing procedure and refi ned the process. Taste testing was accomplished with hospital staff and chefs, and then Farm Fresh Rhode Island took over as distributor. Finally, a pea falafel was on the plate in two hospitals. Source: Lee Rinehart, NCAT

For this project, we begin our journey in Aroostook County, Maine, at Aurora Mills and Farm. Sara Williams Flewelling and her family run their regenerative organic farm operation with a diversified crop rotation, growing cereals, soybeans, and 1/2 to 1/3 of their land base in legume covers, planted alone or in a mix. They have been operating this sustainable, biodynamic crop rotation system for the last 20 years. The farm has a long history of growing peas and is a longtime seed producer for Fedco Seeds in Maine, as well as producing and sourcing grain and pulses from local farmers for brewers (notably, their oats go into the recipe for brewing Allagash white, a Belgian-style wheat beer brewed in Portland, Maine) and for use in university commissaries.

Aurora Mills and Farm, Where the Journey Began

Sara and her father, Matt Williams. Photo: Aurora Mills and Farm

Flewelling’s father was an Extension agent for the University of Maine back in the 1990s. In 1998, he started the farm and, with his connections in Extension and his practical experience as a farmer, became known as one of the grandfathers of local grain in Maine. The legacy is continued as Flewelling sees her farming ethos to be one of remembering the old ways. In 2013, together with her husband (an agronomist working with Maine potato farmers), she came back to the farm, where she has been building community, jobs, and inspiration through alternative markets.

Her family were always early adopters and she recognized, from her father, that collaboration is very important. So, it was natural that she would use her farming and milling infrastructure and connections to perform as a yellow-pea supplier in the Building and Promoting Institutional Markets for High‐Protein Specialty Crops project.

As in many regions of the country, there is a large demand for soybeans in Maine but, outside of cover crop applications, there is not a large demand for yellow peas. And, because peas can come off the field early, there is ample time after a pea crop to establish a late-summer cover crop, like buckwheat, or a winter cover, like annual rye. So, yellow peas fit well within Flewelling’s cropping season. The missing piece was confronting the need to develop a market for peas. This would possibly increase pea cover crop acres and add value to farming operations by adding a cash enterprise that would increase farm profitability.

The opportunity came for Aurora Mills and Farm when they were approached by Health Care Without Harm to participate in the plant-based protein project. They were already growing peas, so, through online meetings with Health Care Without Harm and the National Center for Appropriate Technology, the logistics were set up to begin sending samples in small batches through a new supply chain for product development. By the time the recipe was developed and hospitals were placing the falafel on their menus, Flewelling had shipped a ton of yellow peas to CommonWealth Kitchen.

Flewelling uses a Canadian AAC Lacombe variety that is a “top-yielding, medium-maturity, medium-sized yellow pea variety with excellent resistance to powdery mildew.” This variety fits within this project as it “strikes an excellent balance between the small-seeded varieties commonly grown, and the robust seed size coveted by niche pulse food markets” (Alliance Seed, No date).

Photo: Aurora Mills and Farm

The peas were planted in May, after oats, and followed by winter rye, which is typically harvested the next August for rye flour and marketed to bakers and brewers. A common grain head was used to take the peas off in the summer, and, due to harvest challenges such as rainfall and humidity, Flewelling needed an infrastructure for drying. At harvest, the peas were at about 15 to 16% moisture, and they were dried to below 14%, recognizing that if dried too much the peas tend to shatter, reducing the quality of the crop. Endres and Kandel (2021) from NDSU Agriculture provide detailed information on drying peas in Field Pea Production. See Further Resources.

Peas should be cleaned free of weed seeds, stones, or foreign material before storage (Endres and Kandel, 2021). Flewelling uses a dual cleaning process, with a preliminary cleaning line for removing foreign materials and sizing according to density and pea width. This is followed by an optical color sorter that takes the seed purity from 95% pure before optical cleaner to about 99% after.

After drying and cleaning, some of the peas were stone milled and sifted into flour for various uses in baking, and the rest were packed in 50-pound bags and sent to Boston to continue their journey along this fledgling value chain.

The First Stop: Johnson & Wales University

The first step in the food manufacturing process was product formulation. As with any new food product, it takes time, innovation, and trial and error to turn a raw product into a nutritious, palatable food. It started with an idea, where Health Care Without Harm led the effort to identify a food product that would fit within hospital guidelines. They began with an item currently on the menu, a falafel. Johnson & Wales University was contracted by Health Care Without Harm to develop a recipe that was within nutritional guidelines and accounted for cost, taste, preparation requirements and use, and frozen storage. And, importantly, the product formulation and process had to be scalable from a benchtop, hand-made recipe to one that could be produced in large volumes. For this, the final recipe was translated into percentages to allow kitchens to easily prepare the falafel at any scale they needed. In addition, the developers recognized that some kitchens may have issues sourcing fresh seasonings, so they used dry herbs in different variations and were able to replicate the falafel without changing flavors. But what was most difficult was determining an appropriate serving size, developing a recipe that was baked (the original falafel was fried), and keeping the fat content low. Johnson & Wales used the resource of their food innovation center to address these concerns and deliver an exceptional product.

Johnson & Wales started with 20 pounds of peas from Aurora Mills and Farm and soaked them overnight. They had to determine how easy, or difficult, this product was to work with. Many variations on a recipe were tried at first. They finally settled on what Stacy Mirabello, an associate professor with Johnson & Wales University, calls an original “gold standard,” or a prototype formulation to which all other variations may be compared (Mirabello, 2022). She developed a falafel with combinations of fresh cilantro, parsley, garlic, onion, cumin, coriander, olive oil, and lemon and offered taste testings at CommonWealth Kitchen. Ten people, including hospital chefs, food service directors, Health Care Without Harm personnel, and staff from the National Center for Appropriate Technology participated in the taste test and made recommendations, and the process started again.

Johnson & Wales was the right choice for product formulation for several reasons, which easily translate into characteristics that others may consider if trying to replicate this kind of project. They were local to the project and possessed the technical capacity to pull it off. Community-based foodways are developed on relationships and reciprocity, and Johnson & Wales’s ethos of sustainability and justice made them a great fit. They have noticed a trend over the past few years of community groups, institutions, and businesses making commitments to reduce their carbon footprint. There is a market for sustainability and locally grown, healthy food in universities and hospitals. “People are more aware of what they are putting in their body, especially young people,” notes Mirabello. “People in their 30s to 40s are in a grab-and-go culture, and the standard American diet is a goliath we are up against.” Local foodways, like the plant-based protein project, point to a better way.

Chef Sean Sherman. Photo: JWU

Modern commercial agriculture is very good at pushing yield on foods that are nutritionally deficient. “We can be rethinking things completely. There’s a lot of food needs out there… and of course, there are more people today, but if we really looked at the food needs of particular regions based not on privilege but on just population and how to get food out there, there are solutions.”

– Chef Sean Sherman, quoted in the JWU News article: “The Future Is Indigenous” (Feldman, 2023). The JWU 2023 Cultural Life event was not a part of the Building and Promoting Institutional Markets for High‐Protein Specialty Crops project.

CommonWealth Kitchen: Building a Sustainable Food Economy Grounded in Racial, Social, and Economic Justice

For Jen Faigel, co-founder and Executive Director of CommonWealth Kitchen (CWK), collaborating with Healthcare Without Harm to support this project was a natural fit. CWK operates Greater Boston’s nonprofit food business incubator and small business development center. Their work focuses on helping diverse food entrepreneurs build successful businesses to build wealth, create jobs, improve culturally relevant food access, and to build a food economy where everyone can participate and prosper. Core to CWK’s work is forging values-aligned industry partnerships to secure market access and drive reliable sales for member businesses. This work has included getting diverse member-company products and its own value-added farm products integrated into college and hospital cafeteria menus and stocked in campus retail locations, as well as taking over operation of a college food court to provide turnkey retail space for immigrant-owned food companies. To complement this market-access work, CWK operates its own small-batch manufacturing operation, providing outsourced processing to help emerging food businesses scale, as well as offering value-added processing and product development for farms and institutions.

For Jen Faigel, co-founder and Executive Director of CommonWealth Kitchen (CWK), collaborating with Healthcare Without Harm to support this project was a natural fit. CWK operates Greater Boston’s nonprofit food business incubator and small business development center. Their work focuses on helping diverse food entrepreneurs build successful businesses to build wealth, create jobs, improve culturally relevant food access, and to build a food economy where everyone can participate and prosper. Core to CWK’s work is forging values-aligned industry partnerships to secure market access and drive reliable sales for member businesses. This work has included getting diverse member-company products and its own value-added farm products integrated into college and hospital cafeteria menus and stocked in campus retail locations, as well as taking over operation of a college food court to provide turnkey retail space for immigrant-owned food companies. To complement this market-access work, CWK operates its own small-batch manufacturing operation, providing outsourced processing to help emerging food businesses scale, as well as offering value-added processing and product development for farms and institutions.

Sara Williams Flewelling and Jen Faigel at the end

of project meeting, Saco, Maine, March 2023. Photo: Health Care Without Harm

Small-batch manufacturing gets a lot of interest from scale-appropriate food producers and farmers, but not many companies are at the right scale, and have the right attitude, to take this on. CommonWealth Kitchen fills this need and works mainly with farms for processing surplus crops on demand. “It’s a big deal,” says Faigel, “because to turn a crop into a product for sale, you need a recipe, USDA approval, appropriate packaging, a label” (Faigel, 2022). That’s something CommonWealth is set up to do.

Faigel continues, “So what if we develop a dozen master recipes and price them out, then go to farms and say, here is the deal. Give us 100 pounds of peppers and we will make sauce. We will buy all the ingredients and do the processing and develop a custom logo, and charge on the yield at the end. Now the farmer has a shelf-stable product they can take to markets or even into institutional accounts” (Faigel, 2022).

This example illustrates how CommonWealth Kitchen can develop custom products and commercialize for a regional scale. It means they can be incredibly nimble and innovative for a project like the plant-based protein pea falafel. When they received the recipe from Johnson & Wales, Faigel consulted with Mirabello on variations and worked to scale it up for institutional buying. The original recipe had a good nutritional profile, but the recipe needed to be fine-tuned to work with CWK’s automated portioning and shaping equipment and to improve the crumbly texture and mouth feel. The ultimate solution involved replacing most of the dry herbs with fresh herbs, adjusting the ratio of whole peas to pea flour, and adding a dash of olive oil to balance taste and texture with ease of production, while meeting the nutritional requirements. During that scaling process, there was also back-and-forth with Aurora Mills to make sure there was consistency on the raw ingredients coming from the mill. Once the recipe was set, the team still had to review and get approval on portion size, packaging method, case size, preparation, and storage instructions, and finalize the nutritional panels to have a finished product ready for distribution.

CommonWealth entered this partnership to deepen ongoing, reliable sales channels, and partnerships for its member companies, while providing a reliable source of revenue to support its own operations. And, of course, CWK wanted to bring an alternate, sustainably produced product to market that could support farmers, improve soil health to help mitigate the impacts of climate change, strengthen regional food supply chains, and demonstrate an alternative to our centralized, industrialized food system.

At the current scale, to meet the hospitals’ budget requirements, the distributors’ mark-ups, and farm and milling costs, the field falafel project does not cover all CWK’s production costs. However, with proper scale, CWK sees a path to improve production efficiency, streamline ordering and inventory, and demonstrate a financially viable product that works for all the supply-chain partners while providing eaters a delicious, nutritious, vegan field falafel. This approach has enormous potential to transform other products and processes and move more of our food to a values-based regional, sustainable supply chain.

So, moving forward is a matter of scale. What is the right scale for the food producer, as well as the farmer, to be profitable while offering a valuable and affordable product to institutions? This is the ongoing work Faigel engages in with her staff at CommonWealth Kitchen in moving to more regional food systems and away from centralized processing.

This is what a sustainable food economy looks like. So, what is the best way to develop this value chain in other regions? Maybe a cooperative? The end users (food buyers) need to change how they do procurement, and they have constraints to overcome, as we will see later in this case study. It’s really a balancing act, because all actors in the value chain have needs, but farmers have the least wherewithal to manage risk. So, asking the hard questions of “where does risk and return sit” and “how do we incentivize adoption” is critical.

A cheaper falafel can be obtained from a large food distributor, but that’s not the point. A local food system like this one engages farmers, a set of buyers who will use the product, a manufacturer to process it, and a distribution system. Faigel wants to ensure that profits go mostly toward the farmers, so she sees a need for one actor in the value chain to assume the risk at the beginning of the project to get farmers on board, then, at a minimum, the kitchen has to cover their costs. Additional scaling and product development can hopefully lead to profits that extend further through the value chain.

Interlude: Product Sampling

During the development process, Johnson & Wales, CommonWealth Kitchen, and food-service staff from Brigham and Women’s Hospital and Beth Israel Deaconess Medical Center got together to sample the falafel. This was more than just an opportunity to taste the new product and give feedback on the recipe, though this was also critically important. According to Chef Frank Neugebauer, who served as the Culinary Operations Manager with Beth Israel Deaconess Medical Center, it was an opportunity to get chefs and food service directors together and get buy-in on the new product (Neugebauer, 2022). Chefs and food service directors at hospitals are busy. They have nutritional and financial constraints they must deal with as they provide good food to hospital staff and patients on a daily basis. But, as we will see in this case study, many are fully committed to serving healthy, local foods, especially if they are sustainably grown.

Chef Frank notes that finesse is needed in this process and getting the chefs on board is key. Multiple taste testings are a way to do this, as this allows project members to get to know each other, perhaps have the farmer tell the story (putting a face on the product), and provide feedback to the food manufacturer on taste, texture, and the eating experience. He also suggests that, before a chef commits, he would like to see the product again several times. This is where the finesse comes in because, as we have found in this project, getting chefs on board is just as much about relationship building and trust as it is about providing a superior product that they will be excited to place on the menu.

Photo: Farm Fresh Rhode Island

The Next Stop, Distribution – Farm Fresh Rhode Island

Imagine a New England abundant with diverse family farms and fertile soils and with locally and honestly produced foods and flavors at the heart of every table (FFRI, no date). This is the mission of Farm Fresh Rhode Island. Their approach, in addition to being a regional food hub, is working with farmers markets and farm to school programs. Wellbeing is at the heart of their vision.

Nikki Ayers, the Fund Development Manager for Farm Fresh Rhode Island, was approached by Health Care Without Harm to serve as a distributor in the pea-falafel value chain. Farm Fresh Rhode Island came with a package deal, as they also had, in addition to a pea falafel, precut vegetables to deliver, and their buyers needed distribution. This tied in easily with Ayres’s other organizational goals. Since she has no sales team (they are a distributor and connector), the partnership with Health Care Without Harm was fortuitous, as it brought them buyers. Everything Farm Fresh Rhode Island receives is direct from suppliers. Most goods are shipped directly, and this keeps the supply chain very short, with shortened food miles, and reduces the amount of time a product is in a truck or on the road. And, what’s more, Ayers notes that a shorter supply chain influences pricing, as the product doesn’t go through very many steps on the way to the buyer. This results in fewer markups. For pricing, she works with CommonWealth Kitchen, deciding what’s too much or too little and looking for wiggle room that works for them both.

To review, the yellow peas were milled at Aurora Mills and Farm in Maine and sent to Boston, where Johnson & Wales wrote the recipe and CommonWealth Kitchen manufactured the falafel product. This is where Nikki came into the picture. Farm Fresh Rhode Island picked the product up from CommonWealth Kitchen in 15-pound cases and sent them to their Rhode Island facility to stage for distribution to hospitals.

This New England food chain makes things easier because all the players are close together geographically. Proximity among the partners strengthens the regional food system by allowing distributors like Farm Fresh Rhode Island to visit other food hubs, collect goods and products, and send full food trucks back to Rhode Island after deliveries.

How could a food system like this become the norm? Ayers notes their commitment to the 50 by 60 Vision, a University of New Hampshire-organized effort to transform the New England food system by sourcing 50% of New England food from local producers by 2060. “The only way to do this is through regional food systems,” says Ayers. “We can’t do it alone. We bring products and produce in from the New England region, and so connect the dots between food hubs” (Ayers, 2022). This necessitates fruitful relationships between food hubs in the whole region, allowing them greater ability to distribute locally.

Image: Farm Fresh Rhode Island

Value-added products are a huge way to incentivize regional buying. Since there is not a lot of food manufacturing in Rhode Island, Farm Fresh Rhode Island buys from food hubs and manufacturers in places like western Massachusetts and sells products that are niche in their area to other food hubs in their network. This diversifies their offerings and provides market access to local producers.

What made this system work for Ayers, and what may be a key consideration for future projects, is making sure you have an approved vendor for hospital food service, which Farm Fresh Rhode Island is. It is absolutely critical to incentivize this for a regional food chain to work because unless you are on the approved hospital vendor list—in our case, Sodexo—no sales will happen. Other factors include a clean Good Manufacturing Practice audit, food safety compliance, and liability insurance, but the value comes back in dividends once the distributor-buyer relationship is solidified. These are the attributes that Farm Fresh Rhode Island brought into this partnership, and they are one reason why the project is successful.

A Pea Becomes a Falafel on Hospital Menus

Community-based and academic hospitals both have a desire to be sustainable and climate friendly. As mentioned, increasing plant-forward purchasing and taking the Cool Food Pledge are indicators of their commitment. Area food service managers are fulfilling these commitments by increasing their purchase of products from local vendors, farmers, and fishers.

“We need more regenerative farming,” says Brigham and Women’s Food Services Area General Manager Susan Langill. “Much of what we consume is detrimental to Earth, but plant-based foods as championed by initiatives like Future 50 Food support regenerative agriculture and good nutrition” (Langill, 2022). More plant-based foods need to be on the menu to achieve the goal of a 25% reduction of the hospital food service greenhouse-gas footprint.

“We need more regenerative farming,” says Brigham and Women’s Food Services Area General Manager Susan Langill. “Much of what we consume is detrimental to Earth, but plant-based foods as championed by initiatives like Future 50 Food support regenerative agriculture and good nutrition” (Langill, 2022). More plant-based foods need to be on the menu to achieve the goal of a 25% reduction of the hospital food service greenhouse-gas footprint.

Future 50 Foods, an effort between World Wildlife Federation and Knorr Foods, is a business and nonprofit program designed to stimulate a shift toward plant-based foods that have a lower environmental impact than animal-based foods (Shaver, 2019). Sodexo, as food services provider at Brigham and Women’s and Beth Israel Deaconess, has signed on to the Future 50 Food initiative, and Farm Fresh Rhode Island, the distributor in this project, is an approved Sodexo vendor. The 2019 Future 50 Foods report recommends a greater variety of vegetables to increase intake of vitamins, minerals, and antioxidants; use of plant-based sources of protein to replace meat, poultry, and fish; and more nutrient-rich sources of carbohydrates (Shaver, 2019).

However, a mere protein transition will not in itself transform the food system. Diversified agroecological production systems, local and regional food chains and markets, and the development of local food pathways can all increase access to healthy and sustainable diets (IPES-Food, 2022). The food chain should respond holistically to myriad structural challenges by encouraging behavioral shifts that address issues well beyond the singular focus on greenhouse gasses, such as biodiversity loss, chemical pollution, land degradation, livelihood stresses, hunger, and micronutrient deficiencies (IPES-Food, 2022). Fortunately, the demand signals from regional hospitals have begun to close the loop on this project, suggesting that a sustainable food value chain is within our grasp.

A viable local food pathway is not so easy to adopt because of dominant supply-chain logistics. Cost is a huge factor. Hospitals, especially nonprofit hospitals, operate on a narrow margin. Medicare payments are stagnant, while supply and labor costs rise, and hospital administrators seek ways to cut costs to remain viable. Now, within this economic landscape, is the pressure to pay more for local food. “It’s challenging, but not mutually exclusive,” says Langill. “There is a sincere desire to support local foods.”

Her challenge is to keep the price point for food affordable for hospitals. Then, there is the patient menu, which has its own nutritional constraints and operates on an even narrower margin. The patient menu is strictly a cost to the hospital, with no means to recoup higher costs with higher charges (i.e., meals are not charged to the patient). Many local items come at a higher cost than their nationally mass-produced counterparts; even more so when you factor in supply-chain logistics. Less costly, large distributors prefer to only stock high-volume, high-turnover items, thus adding another layer of cost for transportation logistics. Hospital food services are pressured to purchase foods for the patient menu at a lower cost.

As a work group, the hospital directors, FFRI, and CommonWealth Kitchen needed to find creative ways to do things differently around pricing. Each member suggested a maximum tolerance of what they would be able to pay for a product, then determined a balance with lower-cost items in the cafeteria where they could make up the margin (like coffee and soda). With this kind of arrangement, they noticed that increased profit from other offerings would support this initiative.

Alongside price considerations is distribution. “Sodexo has goals around locally sourced food and was very receptive to figuring out how to get this product to our plates,” notes Avery Palardy, Beth Israel Deaconess Medical Center’s Sustainability Program Manager. They have some restrictions on contracts, but Farm Fresh Rhode Island, an authorized vendor contractor, was instrumental to ensuring the success of this project.

Now, the pea falafel is a standard offering on the menu at the participating hospitals. At Brigham and Women’s Faulkner Hospital, a falafel wrap with tzatziki is offered daily at the Garden Café Grill Station and featured as a patient menu special as a yellow-pea falafel with sweet potato hash, harissa vinaigrette, and plantain chips. They also have combined two local products for a patient special of yellow-pea fritters over basmati rice with meal mantra sauce.

Pea falafel gyro at Brigham and Women’s Hospital.

Photo: Susan Langill

At Beth Israel Deaconess Medical Center, the pea falafel is on the salad bar (the easiest way to get it quickly on the menu) for two weeks within a five-week rotation and has since been integrated as an item on the grill for a yellow-pea falafel wrap. Though the product is currently used in one hospital out of a 14-hospital system, Sodexo has a vision to scale it across the Beth Israel Lahey Health system as a standard menu item.

The bottom line, accurately stated by Molly Riordan of Health Care Without Harm, is that as committed as we are to resilient regional food systems and to the environment, we must acknowledge that the business case is front-of-mind. To be successful, hospitals, distributors, and farmers need to know their risks and intentions are being addressed. In this project, shared vision, collaboration, and communication are what delivered our pea from the field to the plate.

A Primer on Growing Yellow Peas

Yellow peas are an open-pollinated, cool-season, annual cover-crop legume that can be planted from the humid South to the cool North. Field peas, like yellow pea, have been grown as a cover crop for years, and many farmers are aware of the benefits of having them in a rotation. Once planted, and when they have begun to spread, peas have an incredible ability to smother weeds. Their high biomass, especially when combined with a small grain, fosters soil aggregation by feeding large amounts of carbon to soil microorganisms, resulting in increased nutrient cycling and subsequent water-holding ability and air exchange in the soil.

In addition to the soil fertility benefits of yellow peas is their ability to provide nutrients to subsequent cash crops. The nitrogen carryover for peas can be around 1 to 1.25 pounds of nitrogen per acre to the soil for each bushel that is produced (Martens and Martens, no date). This translates into 60 to 120 pounds per acre in nitrogen carryover, which can significantly reduce the need for nitrogen fertilizer. And, because yellow pea is a legume, it fixes its own nitrogen and only needs phosphorus and potash, as with any other common legume that is grown commercially. If the reduction of nitrogen fertilizer isn’t enough, a yellow-pea cover crop may reduce financial risk and has, as this publication shows, the potential to serve as a dual crop, both for soil cover and for cash.

Yellow pea lends itself easily to an early spring planting. The soil should be above soil 40°F and is best planted with a drill or planter at a depth of one to two inches. Seeding rates for a monocrop are at least 150 pounds per acre, with higher rates possible for higher yields. Care should be taken to ensure mature plants don’t lodge prior to harvest. If it’s planted with a small grain, University of Maine research suggests keeping the pea fraction of the mix to 10 to 20% to prevent lodging (Molloy and Mallory, 2013). Pea and small-grain seeds differ in size and weight. See the table below for details on various mixes, based on the percentage of pea seed in the mix.

| Seeding rates for polyculture plantings for various pea varieties with a small grain | |||||||

| Seeding rate (#/sq.ft.) | Seedling rate (lbs/acre) | ||||||

| Varieties | Percentage of pea seed in the mix (%) | Pea | Cereal | Mixture total | Pea | Cereal | Mixture total |

| DS Admiral/Conlon | 10 | 3 | 28 | 31 | 66 | 104 | 170 |

| DS Admiral/Newdale | 10 | 3 | 28 | 31 | 66 | 142 | 208 |

| DS Admiral/Kawartha | 10 | 3 | 28 | 31 | 66 | 122 | 188 |

| DS Admiral/Conlon | 19 | 6 | 23 | 29 | 123 | 86 | 209 |

| DS Admiral/Newdale | 19 | 6 | 23 | 29 | 123 | 119 | 242 |

| DS Admiral/Kawartha | 19 | 6 | 23 | 29 | 123 | 102 | 225 |

| DS Admiral/Colt | 21 | 4 | 14 | 18 | 82 | 43 | 125 |

| Source: Molloy and Mallory, 2023 | |||||||

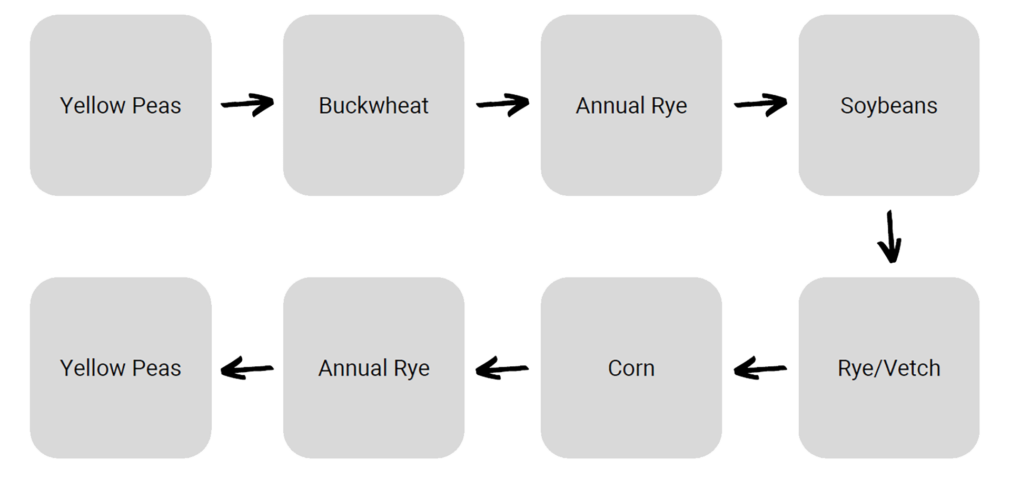

Yellow Pea in Crop Rotations

Because of its seasonal characteristics, yellow pea can work well in common summer crop rotations. Sara Williams Flewelling plants yellow pea in May following oats, harvests in the summer, and follows the pea crop with annual rye, which is harvested the following August to make rye grain and flour for brewers and bakers (Flewelling, 2022). In the mid-Atlantic, yellow pea may help diversify a typical corn-soybean-wheat rotation (Groff, 2022).

Example four-year crop rotation including yellow pea. Image: Lee Rinehart, NCAT

Yellow pea performs better when there is less chance of rain and humidity during harvest. Steve Groff, a cover crop agronomist in Pennsylvania, notes that there is a reason why yellow peas are grown primarily in regions like Oregon and Canada. In northern regions, it’s typically dry over the summer, providing higher pea quality and ease of harvest. The crop can be swathed and laid for drying then combined more effectively. In more humid areas, you can’t do that because of humid weather and rain, which is a big limitation, causing potential lodging and susceptibility to fungal disease (Groff, 2022).

A common-head combine taking the crop directly off is best in regions susceptible to summer rains. Pea stems break down more easily than soybeans; therefore, less power is required, especially after the pods are ripe. Mary-Howell Martens, an organic grower, grain processor, and co-owner of Lakeview Organic Grains in Penn Yan, New York, recommends when setting up the combine to open the concaves, speed up the cylinder, and turn up the air for better collection and delivery of the seed to the hopper (Martens and Martens, no date).

Endres and Kandel (2021) recommend ensuring correct combine settings to maintain seed quality. The reel speed should be slow to minimize seed shatter and the combine should be operated at low cylinder speeds, from 350 to 600 rpm, to minimize seed cracking and splitting. As harvest seed moisture decreases, the cylinder speed should be reduced (Endres and Kandel, 2021).

Equipment for harvesting grains and pulses can be a barrier for farmers who do not currently operate a grain enterprise. Vegetable producers, especially, are usually not set up with the right equipment to harvest peas mechanically, and, if you don’t have a neighbor who can harvest for you, the cost of buying a combine can be prohibitive. One item to consider is the Allis-Chalmers All-Crop Harvester. This equipment was made from the 1930s to the 1960s and, though no longer being manufactured, used harvesters are relatively cheap and parts are still being made (see AllCropHarvester.com). The tool can be pulled with a 54-horsepower tractor to harvest beans, peas, and grains, and may be ideal for startup when trying out a new enterprise on smaller acreage. The Small Farmer’s Journal has detailed instructions on set-up and operation available online.

All Crop Harvester. Image: Small Farmer’s Journal

Detailed information on pea production, including harvest systems, drying, cleaning, and storage, can be found in Endres and Kandel’s (2021) Field Pea Production, published by North Dakota State University Extension. Also see the Further Resources section for several other production guides from around the country.

Yellow peas can grow well in the Northeast, mid-Atlantic, Southeast, and western states, but farmers often can’t compete with the commodity market on price, due especially to the scale of production in Canada and the northwestern United States. This necessitates the development of an innovative marketing plan to provide a premium to the farmer and open the way for the cover crop to become an added value stream for the farm. And, in addition to peas, farmers may investigate other value streams that may open the way for cover crops to become a value-added enterprise.

Cover Crop Options for Niche Markets

Canola is high in oil and has uses for biodiesel or biolubricants, as well as animal feed. It provides a high-biomass cover crop and works well in rotation with cereal grains, in place of a wheat-soybean double crop. Cowpeas, a warm-season crop like soybeans, is spring planted, fast growing, and provides high biomass. Its taproot breaks up plow pans and compacted soil, and it can be used as a forage crop, as well. It is a high-protein pea that can be marketed fresh or dry for flour or meal. Farmers may also consider growing barley for brewers or even cover-crop seed, such as red clover, hairy vetch, and winter peas, much like Aurora Mills and Farm in Maine, which established contracts with a regional seed company for seed production. Again, where there are no established markets, an innovative marketing plan, like the yellow-pea pilot project described in this case study, could help develop a supply chain though the cooperation of farmers, local food manufacturers, and food hubs and regional distributors.

Summary and Recommendations

Our pilot project endeavored to showcase how all the players in this small food chain overcame the institutional, structural, and behavioral barriers to bringing sustainably grown local food to hospitals in the Northeast. One of the main barriers we identified was that local producers alone can’t meet hospital demand. It takes collaboration and coming to terms with an equitable price. It means establishing a viable distribution network that is efficient and responsive to local changing conditions. And, the product needs to be scalable.

Lessons Learned

Food-product development takes a long time. It takes visioning, planning, relationship building, compromise, and determination. Because of this, a sustainable food-system development project needs an entrepreneur, a champion, someone with the energy to drive the project forward. This champion should be a resource for buyers, a lead generator, and do all the groundwork in value-chain development. In this instance, Health Care Without Harm served that role. Hospitals are complex in structures, procedures, finances, and relationships. But, given their community presence and voice, they can be a connector. Health Care Without Harm was able to leverage the economic power of the network with a shared goal of supporting healing and health and link that to the food system.

It also takes willing partners. All players must be intentional, placed-based, and cognizant of varied interests and constraints. The success of this project is a result of the partners becoming allies with farmers to create a human-centered, intentional, and durable value chain. For that to be sustained, the champion needs to build and foster connections within an entrepreneurial community, a value chain of institutions and food hubs and farmers that has a vision of what the food system can be.

The initial result of our project is, according to Riordan of Health Care Without Harm, geographically limited in the impact it can have, given current partners, the ability to produce, and the constraints on how hospitals can purchase food. There may be a plateau, and it is a question that we want to continue to probe. Do we want to create similar products by enlarging the region? Or develop systems in other regions or distribute nationally? “I don’t think we have landed on an answer, but we have demonstrated it is possible to make these connections and develop a product that fits everyone’s needs,” Riordan adds. “So, who are the actors in other regions and what is the impact we want to see?” Each locality will have to come up with their own answers to these questions. But this project, we hope, has shed light on some of the questions to ask.

Certainly, hospitals have limits on what they can do with their food budgets. Farmers, as well, have a lot of things to think about when considering selling into an institutional market on this scale. Chief among them is the capacity to clean and process pulses. For our project, an optical cleaner was the pinch point at the farm level, due to its expense and the technical assistance that was needed in getting it set up. It cannot be overstated how much of a barrier this can be to farmers and processors. We recommend that future projects take this into consideration at the outset and develop partnerships for farmers to aggregate pulse crops with others in the area for cleaning and milling and eventual shipping further into the value chain. Finding the right milling partner is crucial. Without an engaged and committed processor onboard, the farmer must become the expert and teach the contractor how to do it. Unless the farmer is an established miller, like Aurora Mills and Farm, this may place too heavy a burden on the farmer.

It is crucial, at the very start, to get together a team of farmers, food manufacturers, distributors, and institutional buyers and do a feasibility study. Map out the marketing environment and get buy-in from everyone in the proposed value chain. A cooperative development organization may be a key player at the beginning and can support the development of the value chain through facilitation and feasibility studies to identify barriers and opportunities in processing, pricing, and distribution. Other key support can be obtained through business planning and start-up funding. And, importantly, establishing cooperative support for farmers for growing, processing, and shipping.

End Note

Interest in plant-based proteins predates this project. For many years, Health Care Without Harm has advocated for better protein alternatives to encourage hospitals to change their meat purchasing toward diversified farming systems, diversified and healthy diets, animal welfare, and better land stewardship. The philosophy remains, but recently the societal conversation has shifted to more plant-based protein. This framing isn’t negative but reflects a trend toward better land practices that reduce our impact on ecosystems and climate. We want to emphasize that the issue isn’t whether plant protein is better than meat protein, but how and where each is produced. We align with the International Panel of Experts on Sustainable Food Systems in advocating for meaningful food-system reform pathways that “shift the focus from ‘protein transition’ to sustainable food system transition and sustainable food policies, prioritize reform pathways that deliver on all aspects of sustainability, and reclaim public resources from ‘big protein’ by realigning innovation pathways with the public good” (IPES-Food, 2022).

References

Adusumilli, Naveen and Hua Wang. 2020. Cover Crop Economics: Analysis from Studies Across Louisiana. LSU Ag Center.

Alliance Seed. No date. AAC Lacombe.

Ayers, Nikki. 2022. Fund Development Manager, Farm Fresh Rhode Island. Personal communication.

Beus, Curtis E. and Riley E. Dunlap. 1990. Conventional Versus Alternative Agriculture: The Paradigmatic Roots of the Debate. Rural Sociology. Vol. 55, No. 4. p. 590 – 616.

Clark, Andy (ed). 2007. Managing Cover Crops Profitably, 3rd Edition. Sustainable Agriculture Research and Education (SARE).

Endres, Gregory and Hans Kandel. 2021. Field Pea Production. North Dakota State University Extension.

ETC Group. 2017. Who Will Feed Us? The Peasant Food Web vs. The Industrial Food Chain.

FFRI. No date. Mission Statement, Farm Fresh Rhode Island.

Faigel, Jen. 2022. CommonWealth Kitchen. Personal communication.

Feldman, Andrea. 2023. Chef Sean Sherman at JWU: The Future Is Indigenous. Johnson & Wales University News. February 22.

Fleming, Cathy and Wade Thomason. 2020. Cover Crop Performance Evaluation in Field and Controlled Studies. Dept. of Crop & Soil Environmental Sciences, Virginia Tech.

Flewelling, Sara Williams. 2022. Aurora Mills and Farm. Personal communication.

Groff, Steve. 2022. Cover Crop Coaching. Personal communication.

HCWH. No date. Healthy food and communities. Health Care Without Harm.

IPES-Food. 2016. From uniformity to diversity: a paradigm shift from industrial agriculture to diversified agroecological systems. International Panel of Experts on Sustainable Food Systems.

IPES-Food. 2022. The politics of protein: examining claims about livestock, fish, ‘alternative proteins’ and Sustainability.

Keshavarz, Reza, Chelsea Didinger, Ann Duncan, and Henry Thompson. 2020. Pulse Crops and their Key Role as Staple Foods in Healthful Eating Patterns. Colorado State University Extension.

Koudahe, Komlan, Samuel C. Allen, and Koffi Djaman. 2022. Critical review of the impact of cover crops on soil properties. International Soil and Water Conservation Research. Vol. 10. p. 343-354.

Langill, Susan. 2022. Brigham and Women’s Hospital Food Services Area General Manager. Personal communication.

Martens, Mary-Howell and Klaas Martens. No date. Managing Field Peas Organically. Lakeview Organic Grains.

MDA. No date. Pulse Crop Programs. Montana Department of Agriculture.

Mirabello, Stacy. 2022. Johnson & Wales University, College of Food Innovation & Technology. Personal communication.

Molloy, Tom and Ellen Mallory. 2013. Field Pea Demonstration Trial 2013 Results. University of Maine Cooperative Extension.

Muhammad, Ihsan, Jun Wang, Upendra M. Sainju, Shaohong Zhang, Fazhu Zhao, and Ahmad Khan. 2021. Cover cropping enhances soil microbial biomass and affects microbial community structure: A meta-analysis. Geoderma. Vol. 381.

Neugebauer, Frank. 2022. Chef, Beth Israel Deaconess Medical Center. Personal communication.

Riordan, Molly. 2022. Soil Health and Health Care. Presentation at the Pasa Sustainable Agriculture Conference. Health Care Without Harm and National Center for Appropriate Technology.

Shaver, Dorothy. 2019. Future 50 Foods Report. Knorr and World Wildlife Federation, in partnership with Dr. Adam Drewnowski, Director of The Center for Public Health Nutrition at the University of Washington.

Small Farmer’s Journal. 2010. Allis-Chalmers “60” All Crop Harvester. Vol. 34, No. 4.

Speare, Sarah and Chris Lent. 2022. Episode 273. Tootie’s Tempeh: Bringing Organic Plant-Based Proteins to Local Consumers and Institutions. ATTRA Voices from the Field Podcast. National Center for Appropriate Technology.

Stepanović, Strahinja. 2017. Field Pea Production: Rotational Costs and Benefits. University of Nebraska.

Willett, Walter et al. 2019. Food in the Anthropocene: the EAT–Lancet Commission on healthy diets from sustainable food systems. The Lancet Commissions. Vol. 393, Issue 10170. p. 447-492.

Further Resources

Food Value Chains

Farm to Healthcare Tipsheet: Procuring Local Food, Improving Health, National Center for Appropriate Technology, ATTRA Program

Healthy Food In Health Care, Health Care Without Harm

Healthy Food and Communities, Health Care Without Harm

Cool Food Pledge, Practice Greenhealth

Food Service Toolkit, Farm to Institution New England

Local Food Directories: Food Hub Directory, USDA Agricultural Marketing Service

How To Start a Cooperative, USDA Rural Development

Food Hubs & Values-Based Supply Chains, UC Davis Sustainable Agriculture Research & Education Program

Community Kitchens: Key Elements of Success, UW-Madison Center for Integrated Agricultural Systems

Growing Field Peas

Aurora Mills and Farm, Linneus, Maine

Organic Pulses Production, Economics, and Marketing, National Center for Appropriate Technology, ATTRA Program

Pisum sativum L. (dry pea), New Crop Resource Online Program, Purdue University

Dry Field Pea, Alternative Field Crops Manual, University of Wisconsin and University of Minnesota

Field Peas, Managing Cover Crops Profitably, 3rd Edition, SARE

Field Peas, Cover Crop Guide for NY Growers, Cornell

Grains, Pulses & Oilseeds, University of Maine Cooperative Extension

Growing Dry Pea in Montana, Montana State University

Field Pea Production, North Dakota State University

Production Resources, Saskatchewan Pulse Growers

Production Guides, Northern Pulse Growers Association

Harvesting Tips, Northern Pulse Growers Association

Allis-Chalmers “60” All Crop Harvester, Small Farmer’s Journal

Processing Field Peas

Processing Information and Technical Manual, USA Pulses

Pulses in Food Manufacturing, Legume Chef

Pulse Processing Technology, Pulse Canada

More Than a Cover Crop: Developing a Farm-to-hospital Supply Chain for Yellow Peas

By Lee Rinehart, NCAT Sustainable Agriculture Specialist

Published June 2023

© NCAT

IP640

Slot 679

Version 060123

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development. This publication was also made possible in part with funding from the Specialty Crop Block Grant Program, as administered by Health Care Without Harm, grant # AM19SCMPVA0003. ATTRA.NCAT.ORG.

Special thanks to Molly Riordan (Health Care Without Harm), Jen Faigel (CommonWealth Kitchen), Susan Langill (Brigham and Women’s Hospital), Avery Palardy (Beth Israel Deaconess Medical Center), Mark Tucker (Sodexo), and Chris Lent and Mike Lewis (NCAT) for providing technical review of this publication.