High Tunnel Grapes: Temperature and Soil Management

By Luke Freeman, NCAT Agriculture Specialist; Dr. Elena Garcia, University of Arkansas Division of Agriculture, Agriculture Experiment Station; and Dr. Amanda McWhirt, University of Arkansas Division of Ag, Cooperative Extension Service

Abstract

This publication is the third in a series on high tunnel grape production, based on research led by Dr. Elena Garcia at the University of Arkansas. This publication addresses considerations for providing an ideal growing environment for table grapes in a high tunnel, focusing on temperature management, irrigation, and soil fertility.

Introduction

This publication is the third in our series on high tunnel grape production, based largely on research conducted by Dr. Elena Garcia and her research team at the University of Arkansas, who have investigated seedless table grape production in high tunnels throughout Arkansas. Research results have indicated significant yield increases in high tunnels and a reduction in disease pressure. This publication will discuss key considerations for temperature management, irrigation, and soil fertility when growing high tunnel grapes.

The high tunnel is kept open in the winter to allow grapevines to go dormant. Photo: Luke Freeman, NCAT

Environmental Considerations

Grapes are grown throughout the world in a diversity of climates, though Mediterranean climates are considered ideal. Most grape cultivars need 150 to 180 frost-free days in order to produce a crop and will not grow at temperatures below 45°F (Galetta and Himelrick, 1990). For reference, Fayetteville, Arkansas, has an average of 187 frost-free days per year. Although the high tunnel can add a few frost-free days on either end of the season, grape cultivars should be selected that match the average number of frost-free days for your region.

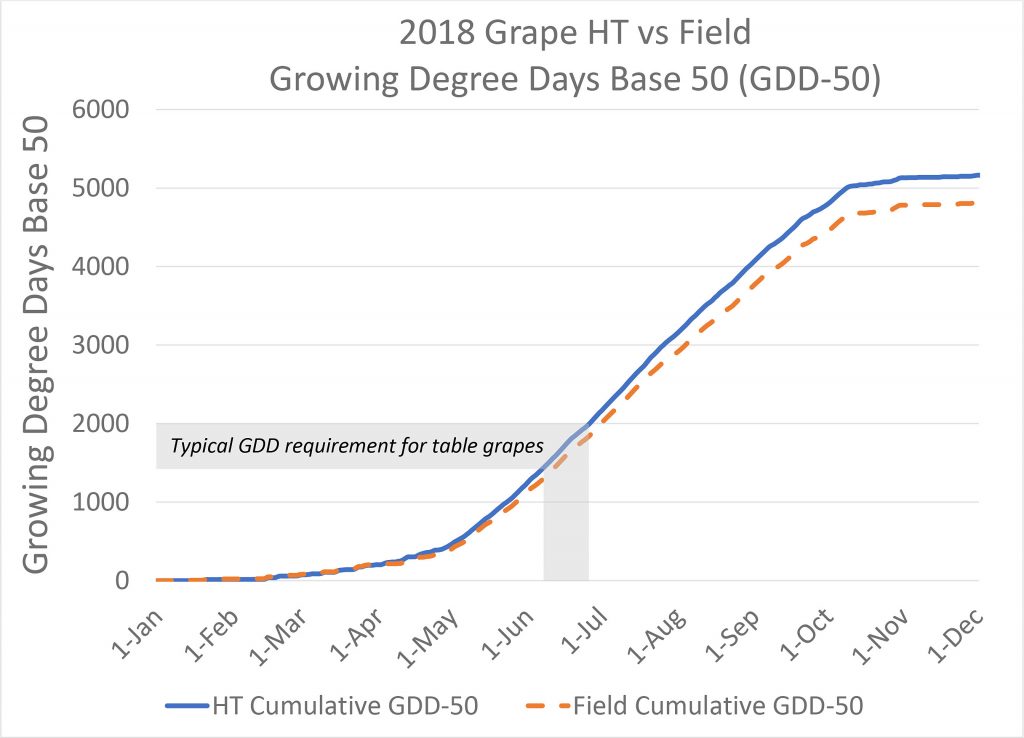

High tunnels increase the number of growing degree-days (GDD) that grapes receive, resulting in faster growth and development. GDD for grapes are calculated by subtracting 50 from the average air temperature (°F) for the day, with negative numbers recorded as a zero. GDD will accumulate over the season and can be used to predict when growth stages and fruit development will occur. Most grapes require between 1,500 and 2,000 GDD. The high tunnel will increase the average air temperature and allow GDD to accumulate more rapidly, leading to faster vine growth and fruit development.

Relative humidity is another important environmental factor to consider because of its influence on fungal disease and cultivar suitability for a region. High humidity is one of the reasons why it is difficult to grow European vinifera cultivars in the southeastern United States, while California can successfully grow these cultivars in its Mediterranean climate. The high tunnel will reduce leaf wetness by sheltering the vines from rain, but humidity inside the tunnel will need to be managed through ventilation.

Chilling Requirements and Cold Tolerance

Like other perennial fruit crops, grapes require a certain amount of exposure to cold temperatures before they can break bud normally in the spring. This is called a chilling-hours requirement and it is generally calculated as the number of hours at which temperatures are between 45°F and 32°F. Chilling-hour calculations begin at the first frost of the winter. The chilling requirement for grapes is quite low, with studies indicating a range between 50 and 400 hours (Dokoozlian, 1999). Because of this chilling requirement, it is important keep the high tunnel open after the grape harvest and allow the vines to be exposed to normal winter temperatures until spring.

Cumulative growing degree-days in a Haygrove high tunnel compared to the ambient field temperatures during the 2018 seasons at the Arkansas Agriculture Experiment Station in Fayetteville. Data used with permission from Dr. Donn Johnson and Dr. M. Elena Garcia, University of Arkansas.

Although grapes need some amount of cold during their dormancy, they can also be sensitive to extremely cold temperatures during winter. Cold tolerance is an important consideration when selecting grape cultivars to grow in your location. The majority of grape production is located in Mediterranean climates with mild winters, though certain cultivars can be grown in environments with very cold winters, such as the Upper Midwest and Northeast. The tolerance that grapevines have to cold temperatures involves several factors, including the cultivar, vine health, yield of the previous season, dormancy of the vine, how quickly the temperatures get cold, and how long they stay cold. American grapes (such as V. labrusca) are more cold-hardy than European types (V. vinifera). The University of Arkansas cultivar ‘Jupiter’ is cold-hardy down to -20°F, ‘Mars’ is hardy down to -10°F, and ‘Reliance’ is hardy down to -20°F (Strik, 2011).

Symptoms of frost damage on young grape leaves. Photo: Jose Hernandez, University of Arkansas

Spring Frost Damage

Grapevines are very sensitive to frost damage in the spring after bud break, as new shoots are beginning to emerge. At this point, frost injury can lead to a less-developed shoot or bud that will produce a partial crop. If the plant tissues in developing shoots spend just 30 minutes at 31°F or lower, significant damage can occur (Poling and Spayd, 2015). Upon thawing, shoots that have been damaged by frost will lose turgor, darken, and become water-soaked. A closed high tunnel can help reduce the risk of frost damage by trapping warm air during the day and buffering drops in night-time temperatures by a few degrees.

Even in a high tunnel, more active frost protection measures may be needed to keep the air temperature around tender shoots from dropping to 31°F or below, especially in the event of a hard freeze. The goal of active frost protection is to keep plants safely in the range of 31.5°F or above (Poling and Spayd, 2015). Supplemental heating can be provided in the high tunnel by portable heaters (gas or electric) used in conjunction with fans to mix the air, with heaters turned on before the temperature reaches 32°F. Heaters should be used with caution inside the high tunnel because of the risk of fire or carbon monoxide accumulation.

High Tunnel Temperature Management

Temperature management is an important factor in successful high tunnel grape production. Because high tunnels modify the air temperature, growers must take care to ensure that the temperature in the high tunnel is maintained in the ideal range for grapes. High tunnels are passively heated and cooled, meaning the tunnel will need to be manually closed to trap hot air and manually opened to vent hot air and cool down. The optimal mean temperature range for grapevine growth is 54°F early in the growing season and 75°F at maturation and harvest. However, grapes have a wide range of temperature adaptability, depending on the cultivar (Fraga et al., 2013). The goal of high tunnel temperature management should be to keep the air temperature as close to the cultivar’s adaptable range as possible.

Haygrove high tunnels are ventilated by manually bunching up the plastic on each side. Photo: Luke Freeman, NCAT

Ventilation Methods

Different high tunnel styles have different methods of ventilation. The Haygrove high tunnels used for most of the Arkansas grape research are caterpillar-style tunnels vented by manually pushing up and bunching the plastic at the hips on either side. This allows air to move in through the sidewalls and across the grape canopy. This method of ventilation is time-intensive and best suited for climates and crops where tunnels will not need to be closed and opened frequently.

Other high tunnel styles feature roll-up or roll-down sidewall curtains that are operated by a reel or series of pulleys. This style of ventilation takes much less time to operate and allows for more adjustment of the size of the vented area, thus allowing for more control of the high tunnel temperature. A small vent opening will allow for less hot air escape than a wide vent opening, which will allow for more rapid cooling.

In hot and humid areas such as the Southeast, a high tunnel design should allow for significant ventilation and efficient release of warm, humid air. Although high tunnels can be screened to exclude insect pests, mesh netting over the side vents will significantly reduce air flow and reduce the effectiveness of passive cooling. The use of ProtekNet insect netting in University of Arkansas research led to elevated temperatures and increased humidity in the high tunnel, which caused an increased incidence of foliar disease on the grapevines. A potential solution to allow for effective ventilation along with the use of insect netting would be the installation of eave vents or ridge vents on the high tunnel to allow for the evacuation of warm, humid air at high points in the tunnel.

Sterno burners being used to provide supplemental heat in the grape high tunnel during a freeze event. Photo: Jose Hernandez, University of Arkansas

Frost Protection

High tunnels have the ability to trap warm air during the day and maintain elevated air temperatures throughout the night, buffering against cold temperatures and frost events. The style of high tunnel and the ability to completely close and seal the structure will play a role in the effectiveness of the tunnel in providing frost protection.

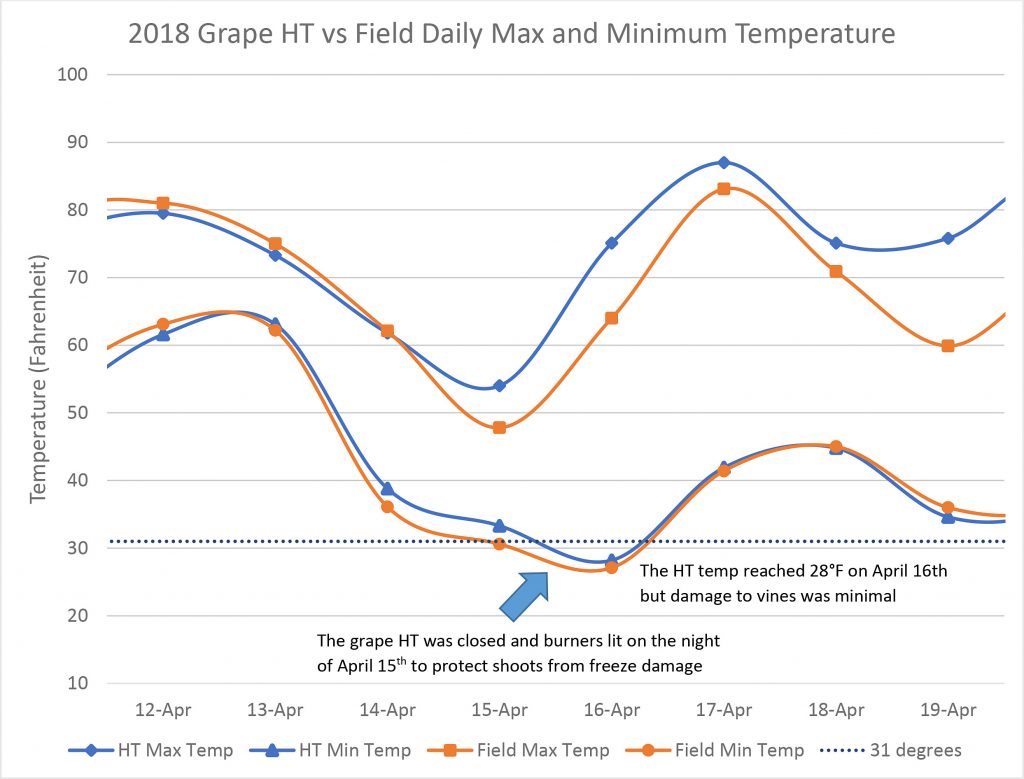

The grape research team at the University of Arkansas has been able to protect grapes from spring frost damage in the Haygrove high tunnel by closing down the tunnel and adding supplemental heat with Sterno burners. On April 16, 2018, outside air temperatures dropped to 27.1°F, while the air temperature inside the high tunnel only dipped to 28.2°F momentarily because of the tunnel being closed and the added heat from Sterno burners, which was enough to save the tender shoots from frost damage.

Researchers at the University of Georgia found that gothic-style high tunnels are able to increase daily average air temperatures by 1 to 3°F compared with the field, with tunnels maintaining a temperature of 5 to 9°F warmer than the field on the coldest nights (Jayalath et al., 2017). During the 2018 season in Fayetteville, the grape high tunnel had an average daily temperature that was 2.1°F higher than the average daily temperature of the field from March to August (data provided by Dr. Donn Johnson, University of Arkansas).

Daily maximum and minimum temperatures in the grape high tunnel compared to the field between April 12 and 19, 2018, at the Arkansas Agriculture Experiment Station in Fayetteville. Data used with permission from Dr. Donn Johnson and Dr. M. Elena Garcia, University of Arkansas.

Irrigation Management

Drip Irrigation Systems

Because it does not rain in a high tunnel, providing irrigation to the grapes is essential. On established vines, rates of 12 to 15 gallons of water per vine may be required per week (Hamman et al., 1998). Drip irrigation is the recommended method for irrigating high tunnel grapes, as it efficiently delivers water directly to the root zone. Wetting the leaves during irrigation should be avoided, as it will increase the incidence of disease. Either drip tube or micro-irrigation with drip emitters can be used with the irrigation line laid on the ground or tied to a trellis wire 12 to 24 inches above ground level. If rodent damage to the irrigation lines is a problem, it is recommended to elevate the lines above the ground.

A tensiometer can be used to monitor soil moisture levels and determine when to irrigate. Photo: Oregon Department of Agriculture

Drip tube is used for irrigation in the grape high tunnel at the Arkansas Agriculture Experiment Station. Photo: Luke Freeman, NCAT

Irrigation Frequency

Consistent irrigation will ensure good plant growth and fruit production and will help prevent berry splitting (Strik, 2011). The most important stages to avoid water stresses are: 1) from flowering to pea-size grapes; 2) from softening of grapes to harvest; and 3) after harvest. Water use is relatively low from leaf emergence to flowering and also in the fall as the air temperature decreases. During the ripening stage, from softening to harvest, water use is high due to increased grape size and increased transpiration due to hot temperatures. Water stress should also be avoided after harvest, so plants can build reserves for next season and grow roots (Maughan et al., 2017).

Some wine-grape growers intentionally drought-stress their plants at certain stages of crop development, which is called Regulated Deficit Irrigation (RDI). RDI can reduce berry size, allowing for better airflow within the cluster to reduce the potential for disease and split berries, and it can improve the color of red varieties (Maughan et al., 2017). Although total yield is reduced by RDI, growers will accept this cost because of the increase in wine-grape quality. This technique is not practiced in table-grape production, however.

Soil moisture can be measured in terms of soil water potential, which indicates how hard plant roots have to “pull” to obtain water from the soil. Tools used to measure soil water potential include tensiometers and electrical resistance blocks, such as the Watermark™ sensor manufactured by Irrometer Co. It is recommended to monitor soil moisture at several depths, including the primary root zone (12 inches) and at a lower depth where the branched lateral roots grow (30 to 36 inches) (Maughan et al., 2017). The soil moisture should not be allowed to drop below 60% available water, which corresponds to a soil water potential of 65 to 95 centibars for a loam soil. See Table 1 for 60% depletion values for each soil texture. Water potential is inversely related to available water, so a lower number indicates more available water and a higher number indicates less available water. When the soil water potential reaches these values for your soil, it is time to irrigate.

Fertility Management

One of the keys to fertility management is managing soil pH. In the Southeast, soils tend to be acidic. The ideal soil pH for grapevines is between 6.0 and 6.5. If the soil pH is outside of the recommended range, nutrient uptake by the vine will be inhibited, and nutrient deficiencies or toxicities may develop. More information on adjusting soil pH prior to planting grapevines can be found in the first ATTRA publication in this series, High Tunnel Grapes: Establishment.

Grapevines do not need very fertile soil to thrive. In fact, overly fertile soils can cause problems, including overly vigorous growth and delayed onset of dormancy in the fall that may result in cold damage. As discussed in High Tunnel Grapes: Establishment, the soil should be tested and amended to bring the soil pH, organic matter, and soil nutrients—especially P, K, Mg, B, and Zn—into the recommended range prior to planting.

Grape vines only need 0.5 to one ounce of nitrogen per plant in the first year and one to 1.5 ounces per plant in the second year (Strik, 2011). If the soil is low in native fertility, this nitrogen can be provided through the application of fertilizer broadcast in a circle six to 18 inches from the trunk just after bud break (Poling and Spayd, 2015). An application rate of one ounce of nitrogen per vine would equate to 0.63 pounds of a 10% N fertilizer, for example. Established grapevines will require annual applications of nitrogen at a rate of 30 to 80 pounds of actual nitrogen per acre, applied around fruit-set but no later than veraison (Dami et al., 2005). Multiple small applications of fertilizer are preferred over one large single application. Late applications of high rates of nitrogen will encourage prolonged vegetative growth in the fall and delay hardening-off for winter.

For organic growing, nitrogen can be provided through compost, fish emulsion, pelletized poultry litter, or alfalfa-based fertilizers applied in the spring. Many organic vineyards maintain soil fertility by adding one to two inches of mature compost under the grape vines every year. It is common practice to use compost made from pomace, which is a byproduct of winemaking, mixed with wood chips or chipped vine trimmings (Rombough, 2002). An important consideration for organic fertilizers is that moisture is needed to allow the fertilizer to break down and become plant-available. Because of this, organic fertilizers should be shallowly incorporated into the soil or irrigated after application in the high tunnel.

Soil Salinity

Because a high tunnel excludes rain, it is possible to develop high concentrations of salts in the soil under a high tunnel over many years of fertilization. Symptoms of high salts (or salinity) in the soil include leaf burn, stunted growth, and reduced yields. The salt content of the soil can be measured by electrical conductivity (EC), which is available on most soil test reports. The soil EC for grapevines should not exceed 2.7 dS/m (Neja et al., 1978). If the soil EC exceeds these levels, it is recommended to remove the plastic from the high tunnel and allow natural rains to leach the salts from the soil profile. This can be accomplished over the fall and winter, when the vines are dormant.

Grape leaf petioles can be sampled and tested to assess the nutrition status of the vine. Photo: Luke Freeman, NCAT

Plant Tissue Nutrient Testing

Grape leaf petioles can be tested to determine the nutrient status of the vine and assess whether sufficient fertility is being provided. Petiole sampling should be done in the spring at full bloom or in the summer at veraison, with petioles sent to a lab for nutrient analysis. Petiole sampling of vines with suspected nutrient deficiencies can be done at any time, and results should be compared to samples taken from healthy vines. Nutrients applied are most likely to impact crop production in the following year, and, for this reason, petiole nutrient sampling is recommended every one to two years, to identify possible nutrient deficiencies in the crop before symptoms appear. More information on petiole testing, along with a list of laboratories, can be found on the Southern Region Small Fruit Consortium website and on the Arkansas Extension webpage (see Further Resources section for links).

Potassium (K)

Multiple fruit-quality factors, including sugar content and coloring, are influenced by potassium. Deficiencies appear as yellowing on the outer edges of the leaves, which may proceed inward on the leaf as symptoms develop. Applications of potassium fertilizer should be based on petiole sampling results. If mild deficiencies appear, 100 pounds of actual potassium per acre should be applied. Organic sources of potassium include potassium sulfate, kelp meal, and greensand (also known as Glauconite).

Grapevine in June in the high tunnel at the Arkansas Agriculture Experiment Station. Photo: Luke Freeman, NCAT

Magnesium (Mg)

Magnesium deficiency is common on vines grown in acidic soils (pH lower than 5.5) or in soils containing high levels of potassium. Deficiencies usually appear late in summer as yellowing between the veins of the leaves, called interveinal chlorosis. Dolomitic limestone can be applied to correct magnesium deficiencies caused by low soil pH. Other organic sources of magnesium include Epsom salts (magnesium sulfate) and Langbeinite (potassium magnesium sulfate).

Summary

Grapes thrive in dry Mediterranean climates, which can make grape production in the humid Southeast a challenge. High tunnels allow for the exclusion of rainfall and modification of temperature, dramatically improving the productivity of vines in the Southeast and other areas with marginal climates. High tunnels can protect grape vines from late frosts and increase the average ambient temperature, but the tunnels need to be actively managed to allow for ventilation and prevent temperature spikes. High tunnels also require irrigation because rainfall is excluded.

High Tunnel Grapes: Temperature and Soil Management

By Luke Freeman, NCAT Agriculture Specialist; Dr. Elena Garcia, University of Arkansas Division of Agriculture, Agriculture Experiment Station; and Dr. Amanda McWhirt, University of Arkansas Division of Agriculture, Cooperative Extension Service

Published December 2019

© NCAT 2019

IP578

Slot 604

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development. This publication was also made possible in part by funding from the Southern SARE, through the project “High Tunnel Grape Production Systems: A Novel Sustainable Approach to Growing Grapes,” in collaboration with the University of Arkansas, Arkansas Cooperative Extension, and the Arkansas Association of Grape Growers. ATTRA.NCAT.ORG.