Biodiesel: The Sustainability Dimensions

By Al Kurki, Amanda Hill, and Mike Morris, NCAT Agriculture Specialists

Biodiesel is a renewable and environmentally friendly fuel. This publication surveys many dimensions of biodiesel production and use. Net energy balance, sustainable bioenergy crops, scale of production, consumer access and the economics of biodiesel are all critical when discussing a sustainable energy future for this country. Above all, increased fuel efficiency and possibly increased diesel engine use in the United States will be needed in order for biodiesel to become a significant part of our energy future.

Introduction

Biodiesel offers well-publicized environmental, economic and national security benefits. Biodiesel combustion emits fewer regulated and non-regulated pollutants than petrodiesel. Further, biodiesel is biodegradable and its lubricity extends engine life.

Biodiesel could benefit farmers and rural communities, depending on ownership of production facilities and the mix and marketability of useful co-products. Also, biodiesel could reduce dependence on foreign oil and corresponding fluctuations in availability and price. This publication addresses the sustainability dimensions of biodiesel production and use. These dimensions include the net energy balance of biodiesel relative to other fuels and the link between raising bioenergy crops and sustainable, soil-building practices. Other considerations include the qualities of different biodiesel feedstocks and the economics of production and use. This publication also raises other issues, such as access, scale and ownership of production, co-product development and the extent to which biodiesel and other biofuels can effectively replace petroleum fuels.

All dimensions of biodiesel production and use are fundamentally intertwined with each other and with the topic of environmental sustainability. To isolate and address any single aspect of biodiesel invites reference to others.

Background and Context

The Bigger Picture

The United States consumes transportation fuels at an extremely high rate per capita compared with other industrialized countries. In 2005, for example, 559 gallons of petroleum transportation fuels were expended for every man, woman and child in this country, compared with 429 gallons per capita in Canada, 184 gallons in Germany and 182 gallons in Japan (Earth Trends, 2009).

Two major policy and practical changes must occur for biodiesel to have a real effect on this country’s energy future:

1) A national commitment to energy efficiency in every facet of American life. This may include community redesign, broad changes in food production and delivery systems, greater commitment to mass transit and increased mileage efficiency for vehicles. Reducing our fuel consumption would mean biofuels over time would make up a larger portion of overall transportation fuel.

2) A massive conversion from gasoline-powered automobiles and light trucks to cleaner-burning diesel automobiles. This sort of change is not without precedent. Farmers in the United States switched from gasoline to diesel-powered farm equipment in the late 1970s and 80s. This is an important factor in agriculture’s big energy-use reduction since the 1970s.

Most farmers and ranchers operate on tight margins. Capturing energy efficiencies and making the best use of biofuels may be nearly impossible without retooling current food production and distribution systems. For example, when food is shipped over shorter distances, energy consumption and freight costs are reduced. Creating local markets for locally grown foods can accomplish this. Rotating nitrogen-producing or phosphorous-availing crops with cash crops can save energy on the farm. Changing tillage methods or technologies and properly scaling equipment to the farm operation can also save energy. These changes may be important precursors to the cost-effective production and use of biodiesel.

Biodiesel as a Transportation Fuel

Simply put, biodiesel is the product of mixing vegetable oil or animal fat with alcohol (usually methanol or ethanol) and a catalyst, usually lye. Glycerin is the main by-product.

Biodiesel performs very similarly to low-sulfur petroleum-based diesel in terms of power, torque and fuel efficiency, and does not require major engine modifications. Joshua Tickell, the author of several books on biodiesel, claims biodiesel contains about 12 percent less energy than petrodiesel (biodiesel has 37 megajoules per kilogram versus petrodiesel at 42 megajoules per kilogram). This difference is partially off set by a 7-percent average increase in combustion efficiency of biodiesel. No overall perceived decrease in performance is noted for most vehicles using biodiesel, even though, on average, there is 5 percent less torque, power and fuel efficiency (Tickell, 2000).

Biodiesel is considered a safer fuel than petrodiesel. Biodiesel has a high flashpoint of over 300 degrees Fahrenheit (150 degrees Celsius), compared to 125 degrees F (52 degrees C) for petrodiesel. The flashpoint is the temperature at which a fuel’s vapor can be ignited. Biodiesel also has a relatively high boiling point and is generally considered safer to handle.

Modern diesel fuels are injected into a highly compressed chamber where combustion occurs without a spark plug. Biodiesel reacts more rapidly in the chamber with less combustion delay than most petrodiesel fuels and is, therefore, assigned a higher cetane number. Cetane is the measure of ignition quality. Many of biodiesel’s emission benefits stem from its high ignition quality (NBB, 2009). Biodiesel can be produced from virtually any kind of vegetable oil, new or used. The U.S. Department of Energy estimates that about 450 million gallons of biodiesel were sold in 2007. Total U.S. diesel consumption that year was more than 45.3 billion gallons.

| The Chemistry of Biodiesel

Transesterification is the term used to describe the transformation of vegetable oil into biodiesel. Vegetable oil is made up of three esters attached to a glycerin molecule; this is called a triglyceride. An ester is a hydrocarbon chain available to bond with another molecule. During transesterification, the esters in vegetable oil are separated from the glycerin molecule, resulting in the by-product glycerin. The esters then attach to alcohol molecules (either methanol or ethanol) to form biodiesel. In order to prompt the esters to break from the glycerin and bond with the alcohol, a catalyst (sodium hydroxide or potassium hydroxide) must be used. The glycerin by-product can be further processed to make soap. Free fatty acids (FFAs) are present in vegetable oil when it has been used in cooking. When free fatty acids are present, as in waste vegetable oil, more base catalyst is required to neutralize the FFAs, which renders the biodiesel fit for use. (Adapted from Tickell, 2000) |

Qualities and Quantities of Biodiesel and Biodiesel Feedstocks

At cold temperatures, diesel fuels form wax crystals that cloud the product and affect fuel performance. This temperature threshold is called the cloud point, and occurs at 20 degrees F (-7 degrees C) for most commonly used grades of petrodiesel. Biodiesel fuels generally have a cloud point between 25-60 degrees F (4-16 degrees C), depending on the amount of FFAs in the product. Waste vegetable oil contains more FFAs than virgin oils. FFAs raise the cloud point of the fuel, so biodiesel made from used cooking oil or animal fat will cloud at higher temperatures than biodiesel made from new vegetable oil feedstock.

The American Society for Testing and Materials (ASTM) recommended in 1996 that biodiesel have a cloud point of at most 38 degrees F. The cloud point can be lowered with winterizing additives formulated for diesel fuels. Biodiesel blends such as B20 (20 percent biodiesel and 80 percent petrodiesel) typically require no action beyond that necessary for ordinary petrodiesel (Tickell, 2000).

The United States produces approximately 3 to 5 billion gallons of waste vegetable oil every year in restaurants (Groschen, no date). Much of this product goes to landfills; some is used in the soap and cosmetics industry. Waste cooking oil could meet only a small percentage of total U.S. diesel demand. Converting this waste into a relatively low-cost resource, however, reduces the environmental degradation and costs of disposal in landfills.

The quantity of biodiesel that can be produced from crops is also limited. If rapeseed were grown on every acre of cropland available in the United States in 2002, an estimated 36.3 billion gallons of oil could be produced — fairly close to current national demand (Peterson, no date). But it is not practical to use all available farmland to produce transportation fuels. Moreover, very serious ethical issues are raised by sacrificing croplands for vehicle fuel in a world where people are hungry and populations are growing. For a discussion of the food versus fuel controversy, see Journey to Forever.

Soybean oil is a common virgin feedstock for biodiesel. Photo: USDA ARS

Ninety percent of the biodiesel virgin oil feedstock in the United States in 2001 was from soybeans. There are many reasons why soybeans draw most of the market share as a biodiesel feedstock. Soy is a versatile, nitrogen-fixing crop that yields oil and food for humans and livestock. Soybean meal is of a higher market value than soy oil. Consequently, soy oil is a low-priced by-product available in relatively large volumes.

Soybean production is subsidized by the federal government and benefits from subsidized crop insurance plans. Currently, soy oil is a cheaper virgin feedstock than other oilseeds. The processing and distribution infrastructure for soybeans is already in place, with more capacity being added as more biodiesel production facilities come online.

However, the list of the top 30 plant species with the highest oil yield per acre for biodiesel doesn’t even include soybeans. Of the more common commodity-style crops that can be raised for biofuels in this country, soy ranks as only the eighth-best oil-yielding crop.

This may be good news for farmers who don’t or can’t grow soybeans on their farms. Rapeseed (Brassica napus) rates as the highest-yielding oil source in this country at 122 gallons an acre. Sunflower has the third-best yield at 98 gallons an acre, followed by safflower (80 gallons an acre) at fourth and mustard rated seventh (59 gallons an acre). Table 1 shows the oil yields in gallons per acre. One gallon of oil equals 7.3 pounds (USDOE, 2004). Please keep in mind as you examine this table that the yields will vary in different agroclimatic zones.

Canola is the edible version of rapeseed. Photo: USDA ARS.

Higher-yielding oil crops like safflower, mustards and sunflower have significant rotational benefits. For example, deep safflower and sunflower roots help break up hardpan and improve soil tilth. Canola and rapeseed can make soil nutrients available for succeeding years’ crops. Oil-yielding brassicas such as mustards, canola and rapeseed help reduce soilborne diseases and pathogens.

State agricultural experiment stations, the Cooperative Extension Service or the Natural Resources Conservation Service (NRCS) may have information on specific oilseed crops that can be raised in certain locations and the best rotations for soil-building and pest suppression benefits. Sustainable agriculture groups are often helpful, since they may have farmer members who have experience raising brassicas or other oilseed crops in rotation. Rotational benefits are also outlined in other sources listed in the Further Resources section of this publication.

The Bulk Commodity Treadmill

Large plots of undifferentiated plant species grown on the same ground year after year or in very short rotations are known as monocultures. The negative environmental aspects of monocultures are researched and proven. The same aspects hold true for any oilseed crop considered for biodiesel. Monoculture crop production can deplete the soil of organic matter and essential nutrients, which can result in soil compaction, erosion or downstream nutrient loading. Monocultures also create more insect, pathogen and weed management challenges.

Monocultures exhibit an economic dimension as well. At what point does any cash crop become an undifferentiated bulk commodity raised in such high volumes that it doesn’t have enough value for growers to turn a profit? Many farmers and ranchers are raising more diverse, higher-value food crops and animals because they perceive that subsidized, bulk commodity production is economically unsustainable for them. This is a factor to consider in producing biofuel crops as well.

The Energy Balance of Biodiesel Compared to Ethanol and Petroleum Diesel

Debates within scientific and policy circles center on the net energy balance of various ethanol and biodiesel feedstocks. The energy balance is “a comparison of the energy stored in a fuel to the energy required to grow, process and distribute that fuel” (Tickell, 2000). In this publication we use the most commonly quoted energy balance statistics available at press time.

Biodiesel provides a positive energy balance, according to most sources. For every unit of energy needed to produce biodiesel, 3.2 units of energy are gained. Evidence suggests virgin oil from sources other than soy may have even higher energy content. Overall, biodiesel is said to have the highest energy yield of any liquid fuel. According to the Minnesota Department of Agriculture website (Groschen, no date):

- Biodiesel provides an energy yield of 3.2 (soybean oil)

- Bioethanol provides an energy yield of 1.34

- Petrodiesel provides an energy yield of .843

- Petro gasoline provides an energy yield of .805

Economics of Biodiesel Production and Use

Commercial-scale biodiesel production has been through some dizzying and difficult growth and retrenchment periods in the past few years. After rapid growth and reports of profits in 2006-2007, 2008 spikes in commodity prices and the collapse in petroleum prices have made for some hard lessons for biodiesel investors and advocates. Some planned biodiesel plants were not built and existing plants cut production or closed in 2008. One can now draw on some of these experiences to assess the economics of biodiesel production.

Many studies have been conducted on the potential macroeconomic benefits of large-scale biodiesel production in various locations around the country. According to the Hampel Oil Distributors’ Biodiesel Fact Sheet (Hampel Oil, 1998), and Dr. Donald Van Dyne, seven major economic benefits would accrue to state and local communities that produced biodiesel:

- Biodiesel expands demand for soybean oil, which raises the price processors pay for soybeans.

- Soybean farmers near the biodiesel plant receive slightly higher prices for soybeans.

- The presence of a facility that creates energy from soybeans adds value to the state’s industrial and income base.

- More jobs and increased personal income in rural communities.

- Additional and more diversified markets for both starch-based and oilseed-based crops that can help production agriculture be more competitive.

- Investment in production plants also provides an increased tax base to help support local governments, schools and other public services (Van Dyne, 1998).

Van Dyne’s first and second assertions have been confirmed by a 2009 study commissioned by the United Soybean Board. That study found that “U.S. soybean farmers received an additional $2.5 billion in net returns over the last four years due to the biodiesel industry’s demand for soybean oil.” or about a 25-cents-per-bushel increase in the price of soybeans. The study asserts “that the biodiesel industry has essentially created a new floor for soybean oil prices. Additionally, the study found that higher demand for soybean oil led to an increased supply of soybean meal, resulting in meal prices dropping by $19 to $45 per ton.” (Feedstuffs, 2009)

A 30-million-gallon-a-year (MGY) biodiesel plant in Ralston, Iowa, currently employs 28 full time workers. The nearby 12- million-bushel-a-year capacity oilseed crusher employs 16 fulltime-equivalent workers (Raney, 2009). If this plant is indicative of larger-scale biodiesel production, the late 1990s projections of 100 jobs created for each 100 MGY of biodiesel production seem to hold true.

Scale is a strong determinant of who can afford to own all or part of a plant or biorefinery, bear the risks and accrue the benefits of that ownership. The rule of thumb for the price of a new, larger-scale biodiesel plant is about $1 for a gallon of annual production capacity.

The cost of the vegetable oil feedstock is the single largest factor in biodiesel production costs. In recent years, biodiesel costs ranged between $1.25 and $2.50 a gallon, before taxes, depending on transportation, distribution and feedstock costs (Radich, 2004).

Waste vegetable oil can be used to make biodiesel. What was once considered a waste product to be given away or disposed of in a landfill now has value and a price for reuse in many communities. This has the net effect of driving up this biodiesel feedstock cost as well.

Biodiesel that is sold, traded or otherwise publicly distributed has to meet the ASTM D-6751 quality standards. Processing and testing to these standards can add considerably to the costs of biodiesel production for smaller producers. Some biodiesel users and homebrewers are willing to accept tradeoffs in small-scale production, meeting only the most critical indicators of fuel quality.

The economics of producing and using biodiesel on a small scale are outlined in Maria “Mark” Alovert’s excellent Biodiesel Homebrew Guide. There are several calculators that can help determine the costs of oilseed crushing and biodiesel production. See the Further Resources section at the end of this publication for more details.

Ownership and Design of Biodiesel Production

Ownership and design of biodiesel production is also related to feedstock price and a fair rate of return to farmers. Farmer ownership of at least part of the production process beyond the farm gate keeps more dollars in farmers’ pockets and in the local community. This has been proven time and again, most recently in the Midwest with ethanol production. According to David Morris of the Institute for Local Self-Reliance, “If farmers own the ethanol plants; that is, if they own a share of the manufacturing facility that converts their raw material into a finished product, they can receive dividends of 20-30 cents per gallon.” (Morris, 2005)

Another dimension related to farmers making a reasonable profit is the value of biodiesel co-products. For example, entrepreneurs and scientists in Montana considering biodiesel development in that state discovered in 2006 that a biodiesel plant could not pay farmers a sustained fair price for their bioenergy crops (canola or industrial rape) unless the co-products could be manufactured and sold.

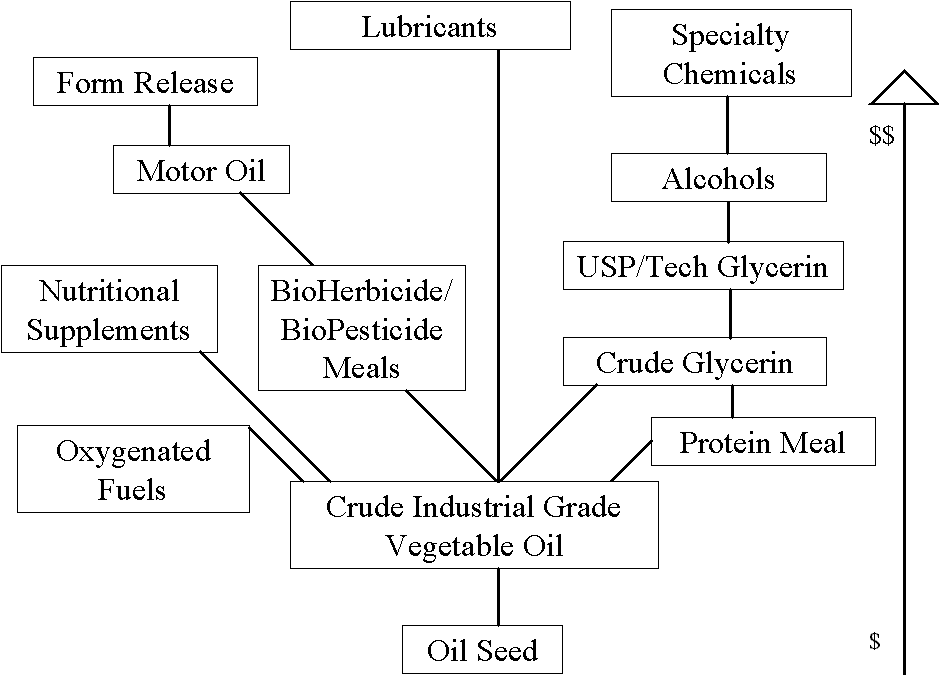

This means that a biorefinery may be the most economically sustainable means of larger-scale biodiesel production. Within this production design or paradigm, the crude vegetable oil pressed from bioenergy crops is the base for all sorts of products, ranging from relatively lower-value biodiesel to biolubricants for motors. The crop pressings have potential value as biopesticides and animal feed. Figure 1 shows some of the possible co-products of biodiesel (Miller, 2003).

Biorefineries are not a new concept. They are, in fact, similar to petroleum refineries. However, their process complexities, capitalization and permitting requirements go far beyond making biodiesel in the garage or farm shop.

Scale of Biodiesel Production

In the Kansas-based Land Institute’s Sunshine Farm project, researchers concluded that farm-scale biodiesel production might not be cost-effective for farmers to pursue individually, but that some level of community-scale biodiesel production with standards satisfactory to engine manufacturers would be more feasible (Bender, 2001). Individuals would each have to spend too much energy and resources to produce biodiesel on a farm. This conclusion has been verified by Montana farmers who participated in a statewide biodiesel testing project (Kurki, 2009).

Small community-scale biodiesel production would likely produce more biodiesel for less effort. That scale of production was not precisely defined in the Land Institute report. Far more research and documented practical experience in biodiesel production in dispersed, near-farm and community-level settings is needed.

Larger-scale biodiesel production has slowed after an enormous growth spurt. In March 2008, 173 biodiesel production plants were online in the United States. The new plants range in initial production capacity from about 1.25 MGY at a plant in Texas to a proposed 30 MGY plant in Iowa. Archer Daniels-Midland has an 85 MGY plant in North Dakota (using canola) and Cargill has a 37.5 MGY plant in Iowa.

Access to Biodiesel

Biodiesel bus. Photo: USDA ARS.

Biodiesel is currently available in most states that produce oilseed crops, and many farmers use biodiesel as a means of fostering production and raising public awareness. Nonetheless, farmers’ access to biodiesel for farm use is another dimension that requires consideration and raises potential for a sad irony. Farmers who raise crops for biodiesel in isolated rural areas may not have ready access to the finished fuel. Unless farmers intend to make biodiesel on-location, or a larger-scale local biodiesel production facility is online, many farmers may find they cannot use the fuel they are working to create. On its Web site, the National Biodiesel Board lists about 1,400 suppliers across the United States, but some have discontinued biodiesel distribution. Almost every state has at least one pump station that offers some blend of biodiesel, though not necessarily within practical distance for most potential customers. The site posts a map of retail outlets for biodiesel across the country. The board recommends asking regional fuel distributors to get more biodiesel supplied locally (NBB, 2009).

Conclusion

Resources are available to help farmers and consumers determine the best means to manage the advantages biodiesel has to offer. Biodiesel has tailpipe benefits and holds great promise as a sustainable energy source, if several sustainability principles are treated seriously:

- Capture as much energy efficiency as possible on and off the farm to reduce transportation fuel demand, reduce production costs and improve energy balance.

- Convert as much waste as possible into a useable resource, such as converting waste vegetable oil into fuel.

- Put oil-producing crops and high-quality agricultural lands to their highest and most sustainable use, which will often be food production instead of energy production.

- Raise bioenergy crops that enhance soil and water resources.

- Create a range of diverse opportunities for biodiesel production in terms of the scale, design and ownership, so farmers and rural communities can share in the economic benefits.

Biodiesel: The Sustainability Dimensions

By Al Kurki, Amanda Hill and Mike Morris, NCAT Program Specialists

© NCAT

IP281

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development. ATTRA.NCAT.ORG.