Ferments and Biochar: A Practical Guide to Utilizing Local Resources

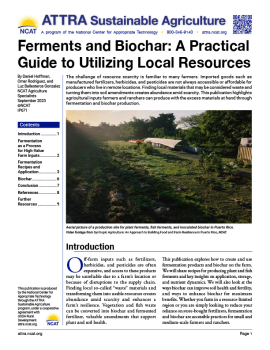

Aerial picture of a production site for plant ferments, fish ferments, and inoculated biochar in Puerto Rico. Video footage from Syntropic Agriculture: An Approach to Building Food and Farm Resilience in Puerto Rico, NCAT.

By Daniel Hoffman, Omar Rodriguez, and Luz Ballesteros Gonzalez

NCAT Agriculture Specialists

Abstract

The challenge of resource scarcity is familiar to many farmers. Imported goods such as manufactured fertilizers, herbicides, and pesticides are not always accessible or affordable for producers who live in remote locations. Finding local materials that may be considered waste and turning them into soil amendments creates abundance amid scarcity. This publication highlights agricultural inputs farmers and ranchers can produce with the excess materials at hand through fermentation and biochar production.

Contents

Introduction

Fermentation as a Process for High-Value Farm Inputs

Fermentation Recipes and Application

Biochar

Conclusion

References

Further Resources

Introduction

Off-farm inputs such as fertilizers, herbicides, and pesticides are often expensive, and access to these products may be unreliable due to a farm’s location or because of disruptions to the supply chain. Finding local so-called “waste” materials and transforming them into usable resources creates abundance amid scarcity and enhances a farm’s resilience. Vegetation and fish waste can be converted into biochar and fermented fertilizer, valuable amendments that support plant and soil health.

This publication explores how to create and use fermentation products and biochar on the farm. We will share recipes for producing plant and fish ferments and key insights on application, storage, and nutrient dynamics. We will also look at the ways biochar can improve soil health and fertility, and ways to enhance biochar for maximum benefits. Whether you farm in a resource-limited region or you are simply looking to reduce your reliance on store-bought fertilizers, fermentation and biochar are accessible practices for small and medium-scale farmers and ranchers.

Fermentation as a Process for High-Value Farm Inputs

Fermentation is a simple way to transform excess organic materials such as plant residues, manure, or fish waste into readily available sources of nutrients for plants and soil microbes. Many microbes respire oxygen, just like humans. However, in the absence of oxygen, some species of bacteria, yeast, and fungi can break down sugars and convert them into energy. This anaerobic process, sometimes referred to as anaerobic digestion, is fermentation. Byproducts of fermentation include lactic acid and acetic acid, as well as ethanol. These acids lower the pH of the material, inhibiting microbial growth and supporting food preservation. Ethanol also reduces microbial growth and assists in food preservation.

An Age-Old Practice

People around the world have used fermentation for thousands of years to transform and preserve food. The Natufian people who lived in the Levant are believed to have been fermenting beer around 13,000 years ago (Liu et al., 2018). Many other ancient peoples enjoyed fermented alcoholic beverages as well, from fermented rice, fruit, and honey in China (7,000 B.C.E.), to beer in Mesopotamia (7,000 B.C.E.), to wine in western Iran (6,000 B.C.E.), to fermented agave by the Otomi people in Mexico (2,000 B.C.E.) (Escalante et al., 2016; Ray et al., 2024). Cheese, another product of fermentation, was documented in Mesopotamia, in what is modern-day Iraq, between 6,000 and 7,000 B.C.E. (Ray et al., 2024). If you have eaten foods like sauerkraut, kimchi, yogurt, or sourdough bread, you are part of a long tradition of consuming fermented foods.

Many cultures have also used fermentation to break down organic materials to preserve plant nutrients and make them more accessible to animals, plants, and microorganisms. Silaging, the process of fermenting grass to preserve it for animal feed, is in the Old Testament book of Isaiah, which was written around the 8th Century B.C.E. (Cai and Ataku, 2025; Woolford and Pahlow, 1998). Kunapajala, a fermented liquid manure, is referenced in Vrikshayurveda, an Indian book whose title translates to “the science of plant life,” written around the 10th century C.E. (Nene, 2018; Thakur et al., 2025).

Aerial picture of Finca Tintillo, a farm in Carolina, Puerto Rico run by José Ángeles Ríos. Video footage from Syntropic Agriculture: An Approach to Building Food and Farm Resilience in Puerto Rico, NCAT.

Fermentation on the Modern Farm

The process of fermenting agricultural residues or other organic materials is simple and requires minimal time commitment. Given the right conditions, many ferments can also be stored for months. If you use the proper ratio of ingredients, you can make a relatively consistent product. Because it requires minimal time and resource investment, fermentation is an ideal process for small or medium-scale producers interested in making fertilizers and amendments that are inexpensive and accessible.

Fermented products contain plant available nutrients and beneficial microbes that support plant resilience. As microorganisms convert sugars to energy through fermentation, they also break down nitrogen-rich materials such as proteins into their constituent parts (peptides and amino acids). Microorganisms and plants use these smaller nitrogen-rich molecules as building blocks for growth, making these molecules an important source of nitrogen (Jones and Darrah, 1994; Farrell et al., 2011; Blachier, F., 2025; Tegeder and Rentsch, 2010). In addition, amino acids and peptides have been shown to have beneficial effects on plants, even at a low rate (Costa et al., 2024), including increased nutrient uptake, increased nutrient use efficiency, and increased resilience to salinity, heavy metals, nutrient stress, and water stress (Calvo et al., 2014; Colla et al., 2017).

Fermentation products are particularly useful during soil preparation, early crop development, and flowering phases. They can be applied as foliar sprays, root drenches, or incorporated into compost teas. They can increase the presence of plant beneficial microorganisms and microbial enzyme activity, which improves nutrient absorption and availability and reduces the need for synthetic fertilizers (Kolambage et al., 2024; Vassileva et al., 2021).

Fermentation Recipes and Application

In fermentation, producers combine organic materials such as food scraps, green plant matter, crop residues, or fish waste with a sugar source, typically molasses or raw cane sugar, to provide energy for microbial activity. Sometimes microbial inoculants such as Lactobacillus species can be added to accelerate the fermentation process. The mixture ferments for 7–30 days (recipes will vary), depending on the ambient temperature and desired microbial profile. The result is a potent, nutrient-rich liquid that farmers can apply directly to plants or soil.

Recipe for Plant Ferments

To begin fermenting plant matter on the farm, farmers can follow a simple recipe.

Materials:

- Container: clay, plastic, glass, ceramic, or stainless steel

- Towel or heavy cheesecloth

- Strainer

- Storage container with lid

Ingredients:

Equal parts by weight:

- Fresh, unwashed, green plant material (e.g., comfrey, sweet potato vines, pig weed, water hyacinth, purslane, etc. – whatever you have in abundance in your locality)

- Brown sugar

Instructions:

- Mix and coat as much of the plant material with sugar as possible, to speed up the osmotic process and help to draw fluids out of the plant material.

- Pack the mixture into a container that won’t react with the ferment, such ceramic, glass, plastic, or stainless steel, and leave loosely covered with a towel or heavy cheesecloth.

- Place the container in a shaded location for 7–10 days to ferment. In general, the optimal temperature range is between 60 and 85 degrees. Fermentation will speed up with higher temperatures and slow down with lower temperatures. The ideal temperature will vary based on the bacterial species that colonize your ferment. Look for bubbles to confirm that fermentation is occurring. These can usually be seen by the second day.

- A fermentation is finished, according to Miller et al. (2013), when “the plant material floats and the liquid settles at the bottom (note: if too much brown sugar was used, this separation is not distinct); there is a light alcohol smell due to breakdown of chlorophyll; and the liquid tastes sweet, not bitter.”

- Strain out the solids with a colander, strainer, or mesh, and discard.

- Store the strained liquid in sanitized containers in a cool, dark place. Close the storage containers loosely because the solution is alive and will continue to produce gases.

The nutrient profile of the resulting ferment will depend on the original nutrients in the feedstock used. For example, fermenting leguminous plants results in a fertilizer with higher nitrogen levels than a ferment that uses grass as a feedstock. Fermentation conditions can be further optimized for nitrogen production by purchasing specific microorganisms for inoculation (Kolambage et al., 2024; Vassileva et al., 2021).

It is worth noting that almost any excess and readily available plant material can be feedstock for fermentation. The parts of plants with high proportions of cellulose and lignin, like wood, are harder to break down and will slow the fermentation process. Conversely, selecting plants with high levels of readily available sugar, starch, and other nutrients will promote microbial growth and speed up the process. Leaves, non-woody stems, flowers, and immature fruit all make good feedstock.

How to Apply Plant Ferments

For optimal results, use a blend of both fresh and aged ferments (more than one month old) in your preparations. When ready to do your application, dilute the ferment at a ratio of one part fermented plant juice to 500 parts water (1:500 is approximately 1 tablespoon per 2 gallons or one cup per 31 gallons). However, under certain conditions, a more diluted solution—between 1:800 and 1:1,000—is recommended to prevent potential plant damage such as leaf burn. You might need to dilute the solution more if:

- Combining more than three ingredients in a single application (a “cocktail” of inputs)

- Applying during periods of hot weather

- Using fermented plant juice that is over a year old, as it may have become more concentrated over time.

Apply the solution to crops once per week, preferably in the early evening to prevent leaf burn, particularly when applying ferments as foliar amendments. It can be administered in several ways: as a foliar spray, or watered directly onto the soil, focusing on the root zone (Miller et al., 2013).

Foliar vs. Soil Application

Foliar fertilization involves applying nutrients directly to plant leaves, allowing for fast absorption through the stomata and cuticle. It is especially effective for correcting micronutrient deficiencies and providing rapid support during stress or peak growth stages. Because it bypasses the soil, foliar feeding is ideal when root uptake is impaired—such as in compacted, dry, or biologically inactive soils. However, its effects are short-lived, it can only deliver small amounts of nutrients, and it is sensitive to weather conditions like rain or intense sun.

In contrast, soil fertilization delivers nutrients to the root zone, offering longer-lasting effects and the ability to supply full macronutrient needs. It supports soil health and microbial activity, making it ideal for building long-term fertility. However, nutrient uptake is slower and can be limited by poor soil conditions or environmental factors.

Fish Fermentation

In coastal areas, fish scraps are a valuable resource to produce high-quality soil amendments. During the fermentation process, enzymes and water break apart the abundant proteins in fish in a process called hydrolysis. The resulting protein constituents—amino acids and peptides—are valuable building blocks for both plants and microbes, and are an important source of nitrogen. For this reason, fish ferments are often known as fish protein hydrolysates, or fish amino acids, in reference to the valuable, easily accessible nitrogen-rich molecules derived from the fish protein.

Recipe for solid-state fish ferment

Materials:

- Container: clay, plastic, glass, ceramic, or stainless steel

- Rocks (grapefruit size)

- Fine mesh or cloth cover

- Strainer

- Storage container

Ingredients:

- Fish byproducts

- Sugar source (e.g., fruit peels, excess fruit, molasses, or brown sugar)

- Lactobacillus inoculant (optional)

Compost Instructions:

- Line the bottom of the container with grapefruit-sized rocks, which provide aeration, minerals and space for the liquid created during the fermentation process (Weinert Jr. et al., 2014).

- Mince the fish parts as finely as possible to accelerate the fermentation process.

- Add equal parts fish and a sugar source (by weight), in alternating layers in the container. The fish parts will provide organic materials for the microbes to break down and repurpose as they grow and reproduce; the sugar will provide energy for the microbes.

- While the fish will contain microorganisms that will naturally begin the fermentation process, adding an inoculant of Lactobacillus, though optional, will assist in the fermentation and help prevent putrefaction.

- Fill the top six inches of the container with compost or decomposing leaf mold.

- Cover the container with a fine mesh or cloth to keep out insects but allow aeration.

- Leave in a cool place out of direct sunlight. The fermentation process should take between two to six months (Weinert Jr. et al., 2014).

- At the end of this period, strain to remove any remaining bones and store in a cool place with a sealed lid.

Applying solid-state fish ferment products

Dilute the mixture before application to at least 1:1,000 ferment to water. This is equivalent to one milliliter of fish ferment per liter of water. Then apply either to the soil or to plant leaves as a foliar application. This fermented product is high in available nitrogen in the form of amino acids and lipids, which will stimulate soil microbial activity as well as plant vegetative growth.

Fish amino acid starter. Video footage from Syntropic Agriculture: An Approach to Building Food and Farm Resilience in Puerto Rico, NCAT.

Recipe for liquid-state fish ferment

The process for making a liquid-state fish ferment is similar to the process for making the solid-state fish ferment described above, except with different ratios of ingredients and with the addition of water. Similar containers may be used as are used in solid-state fish fermentation. However, in this case the lid on your fermentation container should be airtight to prevent the admission of oxygen.

Instructions:

- Combine minced fish with a sugar source at a ratio of 1 part sugar to 3 parts fish (by weight).

- Add unchlorinated water at a ratio of 1 part fish to 3 parts water (by volume).

- Add an inoculant of Lactobacillus at a ratio of 2 tablespoons lactobacillus serum for every 1 liter of the fish mince, water, and sugar mixture (Mantha and Sturm, 2021).

- During the fermentation process, the mixture will release gases, so periodically open the lid of the container to vent the gases or install an airlock to passively allow gases to leave the container.

- Allow the mixture to ferment in a cool, dark area for three to four weeks, or until the mixture loses its pungent odor and retains a mild, vinegar smell. This smell is an indication that the pH has lowered and the fermentation is complete (Mantha and Sturm, 2021).

- Strain the resulting fermentation to remove any remaining bones and store in a cool place with a sealed lid.

Applying liquid-state fish ferment products

Liquid fermentation products do not need to be diluted like a solid-state fermentation. Like solid-state fermentation products, liquid-state fermentation products are also high in available nitrogen in the form of amino acids and lipids, and can be applied either to the plant leaves or the soil.

Inoculated Biochar. Video footage from Syntropic Agriculture: An Approach to Building Food and Farm Resilience in Puerto Rico, NCAT.

Biochar

Biochar is a type of charcoal created by burning biomass at high temperatures under low oxygen conditions in a process called pyrolysis. Biochar can be made on-farm with simple technology and with a variety of feedstocks, and has been used as a soil amendment for thousands of years. Indigenous peoples of South America have used biochar for over 2,500 years; the terra preta black soils of the Amazon Basin are a result of the consistent addition of biochar to the highly weathered and acidic soils of the region (Wilson, 2014).

Biochar is a beneficial soil amendment in part due to its porous structure (Glaser et al., 2002; Lehmann et al., 2011). Adequate pore space allows for soil aeration, increases a soil’s water holding capacity, and provides habitat for microorganisms (Tecon and Or, 2017). While 50% pore space is ideal for plant growth, many agricultural soils have porosity below 50% due to tillage, compaction, and loss of organic matter (Brady and Weil, 2016). Biochar can improve soil aggregation, which increases a soil’s overall porosity (Blanco-Canqui, 2017; Joseph and Cowie, 2021). In sandy soils where water retention is a challenge, biochar’s porosity may increase the soil’s ability to hold water (Tryon, 1948).

Biochar’s porous structure provides other benefits as well. Biochar may facilitate soil microbial growth and diversity (Thies and Rillig, 2009; Lehman et al., 2011). Biochar’s structure means it also has a higher cation exchange capacity than most mineral soils (Liang et al., 2006). Cation exchange capacity indicates a soil’s ability to retain positively charged ions such as ammonium (NH₄+), calcium (Ca2+), magnesium (Mg2+) and potassium (K+). Adding biochar to a soil can increase the soil’s overall cation exchange capacity and therefore increase its ability to retain these important plant nutrients (Glaser et al., 2002).

Biochar is typically made through pyrolysis at a temperature of 400 – 700 °C (Khater, 2024). The high temperature required for pyrolysis releases volatile compounds and water, creating the highly valuable porous structure of biochar. Different materials and different processes will result in different pore structures and properties of biochar (Muzyka, 2023).

Biochar can be made in something as simple as a carefully controlled pit fire, in a biochar retort, or in a variety of other low-tech ways. To learn more about these processes, see the Further Resources section of this publication.

Biochar Terminology

Raw Biochar – Biochar that has not been inoculated, activated, or altered.

Activated Biochar – Biochar that has been combined with nutrients and/or beneficial microorganisms. This is an umbrella term that may refer to either inoculated biochar or charged biochar.

Inoculated Biochar – Biochar that has been inoculated with beneficial microbes, such as mycorrhizal fungi, which promote healthy soil and facilitate plant growth. Biochar can be inoculated with a fermentation, compost, or another source of beneficial microorganisms.

Charged Biochar – Biochar with positively charged ions such as calcium, magnesium, potassium, and ammonium added to it. These ions adsorb (bind) to the negatively charged cation exchange sites on the surface of the biochar particles. These cations can be added to biochar in the form of fermentation, compost, manure, or another source.

Cation Exchange Capacity (CEC) – The total capacity of soil to hold positively charged ions (cations). Soils with higher CEC values can retain more nutrients than soils with a lower CEC. You may see it reported as ECEC on soil test results, which stands for estimated cation exchange capacity.

Pyrolysis – Chemical decomposition of organic matter through high heat and very little oxygen, resulting in biochar.

Co-composting Biochar

While the feedstocks used to produce biochar can also be used to make compost, different materials are better suited for each practice. Feedstocks with 60-70% moisture content tend to be better for composting, while feedstocks with 10-20% moisture content, such as woody biomass, are better for biochar production (Camps and Tomlinson, 2015). Producers can mix biochar with compost to create a soil amendment with many benefits. Mixing biochar with compost inoculates the biochar with microbes before it is applied to soil. Just like a sponge, the porous structure of biochar provides a habitat for microbes.

Combining biochar and compost enhances soil nutrient retention and reduces nutrient leaching (Fischer, 2012; Joseph et al., 2012). Add biochar at a rate of 5% to 10% by volume to finished compost. If adding biochar to very high nitrogen compost, add at a rate of 10% to 20% by volume (McIntosh and Hunt, 2023). According to the International Biochar Initiative, combining biochar with compost may result in:

- Shorter composting times – The addition of biochar to composting piles has been shown to accelerate composting by stimulating microbial activity and increasing temperature.

- Reduced methane and nitrous oxide emissions – Biochar can capture the volatile compounds methane and nitrous oxide, reducing emissions of these greenhouse gases.

- Reduced odor – Adding biochar to high-nitrogen feedstocks may reduce the odor by reducing ammonia loss.

Fermentation and Biochar

Similar to co-composting, biochar can be used as an additive in the fermentation process or combined with a fermentation product. The goal of mixing biochar and a fermentation product is to enrich the biochar with nutrients and microbes before adding it to the soil. The beneficial microbes in fermentation colonize biochar’s porous structure. Biochar infused with microorganisms from a ferment supports soil microbial growth and may improve microbially mediated nutrient cycling (Zhang et al., 2023).

Conclusion

By utilizing abundant, readily available “waste” materials, farmers and ranchers can produce high-quality soil amendments at a low cost through the processes of fermentation and biochar. Producers can reduce input costs, improve soil health, and improve crop productivity while reducing their environmental impact. As farmers and ranchers face increasing resource scarcity, the transformation of “waste” into abundance offers a sustainable path forward.

References

Blachier, F. 2025. Amino Acid Metabolism for Bacterial Physiology. In: The Evolutionary Journey of Amino Acids. Fascinating Life Sciences. Springer, Cham.

Blanco-Canqui, H. 2017. Biochar and soil physical properties. Soil Science Society of America Journal.

Brady, N.C., and R.R. Weil. 2015. The Nature and Property of Soils, 15th Edition. Pearson.

Cai, Y., and K. Ataku. 2025. Cultural History and Modern Production Technology of Silage. Springer, Singapore.

Calvo, P., L. Nelson, and J.W. Kloepper. 2014. Agricultural uses of plant biostimulants. Plant and Soil. Vol. 383. p. 3-41.

Camps, M., and T. Tomilson. 2015. The Use of Biochar in Composting. International Biochar Initiative.

Colla, G, L. Hoagland, M. Ruzzi, M. Cardarelli, P. Bonini, R. Canaguier, and Y. Rouphael. 2017. Biostimulant action of protein hydrolysates: Unraveling their effects on plant physiology and microbiome. Frontiers in Plant Science.

Costa, O.Y.A., J. Chang, J.Y. Li, L. van Lith, and E.E. Kuramae. 2024. Unraveling the impact of protein hydrolysates on rhizosphere microbial communities: Source matters. Applied Soil Ecology.

Escalante, A., D.R. López Soto, J.E. Velázquez Gutiérrez, M. Giles-Gómez, F.F. Bolívar, and A. López-Munguía. 2016. Pulque, a traditional Mexican alcoholic fermented beverage: Historical, microbiological, and technical aspects. Frontiers in Microbiology.

Farrell, M., P.W. Hill, S.D. Wanniarachchi, J. Farrar, R.D. Bardgett, and D.L. Jones. 2011. Rapid peptide metabolism: A major component of soil nitrogen cycling? Global Biogeochemical Cycles.

Fischer, D., and B. Glaser. 2012. Synergisms between Compost and Biochar for Sustainable Soil Amelioration. Management of Organic Waste.

Glaser, B., J. Lehmann, and W. Zech. 2002. Ameliorating physical and chemical properties of highly weathered soils in the tropics with charcoal – a review. Biology and Fertility of Soils.

Jones, D.L., and P. R. Darrah. 1994. Amino-acid influx at the soil-root interface of Zea mays L. and its implications in the rhizosphere. Plant and Soil. Vol. 163. p. 1-12.

Joseph, S., C.I. Kammann, J.G. Shepherd, P. Conte, H.P. Schmidt, N. Hagemann, A.M. Rich, C.E. Marjo, J. Allen, P. Munroe, D.R.G. Mitchell, S. Donne, K. Spokas, and E. R. Graber. 2018. Microstructural and associated chemical changes during the composting of a high temperature biochar: Mechanisms for nitrate, phosphate and other nutrient retention and release. Science of The Total Environment. Vol. 618. p. 1210–1223.

Joseph, S., A.L. Cowie, L. Van Zwieten, N. Bolan, A. Budai, W. Buss, M.L. Cayuela, E.R. Graber, J.A. Ippolito, Y. Kuzyakov, Y. Luo, Y. S. Ok, K.N. Palansooriya, J. Shepherd, S. Stephens, Z. Weng, and J. Lehmann. 2021. How biochar works, and when it doesn’t: A review of mechanisms controlling soil and plant responses to biochar. Global Change Biology Bioenergy.

Khater, E.S., A. Bahnasawy, R. Hamouda, A. Sabahy,W. Abbas, and O.M. Morsy. 2024. Biochar production under different pyrolysis temperatures with different types of agricultural wastes. Scientific Reports. Vol. 14. p. 2625.

Kolambage, S., P. Gajanayake, U. Kumarasinghe, D. Manatunga, R. Dassanayake, R. Jayasinghe, N. Jayasiri, and A.Wijethunga. 2024. Nitrogen-enriched liquid organic fertilizers (LOFs) production for sustainable agriculture: A review. International Journal of Recycling of Organic Waste in Agriculture. Vol. 13, No. 4.

Lehmann, J., M.C. Rillig, J. Thies, C.A. Masiello, W.C. Hockaday, and D. Crowley. 2011. Biochar effects on soil biota – a review. Soil Biology and Biochemistry. Volume 43, Issue 9.

Liang, B., J. Lehmann, D. Solomon, J. Kinyangi, J. Grossman, B. O’Neill, J.O. Skjemstad, J. Thies, F.J. Luizão, J. Petersen, and E.G. Neves. 2006. Black carbon increases cation exchange capacity in soils. Soil Science Society of America Journal.

Liu, L., J. Wang, D. Rosenberg, H. Zhao,, G. Lengyel, and D. Nadel. 2018. Fermented beverage and food storage in 13,000 y-old stone mortars at Raqefet Cave, Israel: Investigating Natufian ritual feasting. Journal of Archaeological Science: Reports, Vol. 21, p. 783-793.

Mantha, P., and P. Sturm. 2021. Soil Amendments for Increased Agriculture Output. In: Agriculture in Palau. Japan International Research Center for Agricultural Sciences. [PDF]

McIntosh, C., and Hunt, J. 2023. Biochar + Compost. Pacific Biochar. Pacific Biochar_Biochar + Compost_January 2023

Miller, S. A., D.M. Ikeda, E. Weinert, K.C.S. Chang, J.M. McGinn, C. Keliihoomalu, and M.W. DuPonte. 2013. Natural farming: Fermented plant juice (SA-7). [PDF] Sustainable Agriculture. College of Tropical Agriculture and Human Resources, University of Hawai‘i at Mānoa.

Muzyka, R., M. Edyta., H. Joanna, S.W. Banks, and M. Sajdak. 2023. Various biomass pyrolysis conditions influence the porosity and pore size distribution of biochar. Energy. Vol. 263, Part E.

Nene, Y.L. 2018. Concept and Formulation of Kunapajala, the World’s Oldest Fermented Liquid Organic Manure. [PDF] Asian Agri-History. Vol 22, No. 1.

Ray, R.C., S. Paramithiotis, A. Thekkangil, V. Nethravathy, A.K. Rai, and J.P.G. Martin. 2024. Food Fermentation and Its Relevance in the Human History. In: Martin, J.G.P., J. De Dea Lindner, G.V., Pereira, M., and Ray, R.C. (eds). 2024. Trending Topics on Fermented Foods. Springer, Cham.

Tecon, R., and Or, D. 2017. Biophysical processes supporting the diversity of microbial life in soil. FEMS Microbiology Reviews.

Tegeder, M., and D. Rentsch. 2010. Uptake and partitioning of amino acids and peptides. Molecular Plant. Vol 3, No. 6. p. 997-1011.

Thakur, A.K., D.N. Pandey, and G. Kumar. 2025. Evolution of Kunapajala: from Surapala’s Vrikshayurvda to modern organic formulations. Journal of Biodiversity and Conservation. Vol. 9, No. 2. p. 4-12.

Thies, J.E., and M.C. Rillig. 2009. Characteristics of biochar: biological properties. In: J. Lehmann, S. Joseph (eds.), Biochar for Environmental Management Science and Technology, Earthscan, London. p. 85-105.

Tryon, E.H. 1948. Effect of Charcoal on Certain Physical, Chemical, and Biological Properties of Forest Soils. Ecological Monographs.

Vassileva, M., E. Malusà, L. Sas-Paszt, P. Trzcinski, A. Galvez, E. Flor-Peregrin, S. Shilev, L. Canfora, S. Mocali,and N. Vassilev. 2021. Fermentation Strategies to Improve Soil Bio-Inoculant Production and Quality. Microorganisms. Vol. 9, No. 6.

Weinert Jr. E., S.A. Miller, D.M. Ikeda, K.C.S. Chan, J.M. McGinn, and M.W. DuPonte. 2014. Natural Farming: Fish Amino Acid. Sustainable Agriculture. [PDF] College of Tropical Agriculture and Human Resources. University of Hawai‘i, Mānoa, HI.

Wilson, K. 2014. How Biochar Works in Soil. The Biochar Journal. Arbaz, Switzerland. October 31.

Woolford, M.K., and G. Pahlow. 1998. The silage fermentation. In: Wood, B.J.B. (ed.) Microbiology of Fermented Foods. Springer, Boston, MA.

Zhang, L., T.H. Tsui, Y. Wah Tong, S. Sharon, O. Shoseyov, and R. Liu. 2023. Biochar applications in microbial fermentation processes for producing non-methane products: Current status and future prospects. Bioresource Technology.

Further Resources

Bioferments, Biostimulants and Biofertilizers: Making them on the Farm. [PDF] 2018. By Gerry Gillespie and David Hardwick. Soil Land Food and Returning Organics to Soil.

“There are a number of simple biotechnologies that can be made on the farm to help improve soil condition, stimulate plant growth and improve plant health. These include bioferments, biostimulants, biofertilizers and compost inoculants. This booklet outlines some basic recipes for making these on-farm.”

Chapter 11: Soil Amendments for Increased Agricultural Output. [PDF] 2021. By Phal Mantha and Paul Sturm, Ridge to Reefs, Inc. In: Agriculture in Palau: A Manual for Production through Soil Assessment. Published by Palau Community College and Japan International Research Center for Agricultural Sciences.

Recipe for Success: Brew Your Own Biofertilizer. 2019. By Anna Birn. Cornell Small Farms Program.

This blog and video link give how-to instructions on making “Super Magro biofertilizer.”

Building a Biochar Retort Kiln. ATTRA Video. 2014. National Center for Appropriate Technology, Butte, MT.

How to Make Biochar with Only a Match. 2013. By Josiah Hunt. Pacific Biochar

Biochar Trench Method: Transforming Organic Waste into Black Gold. 2024. Video. Porterhouse and Teal.

Pacific Biochar’s Biological Activation Process to Improve Biochar Materials. 2015. By Josiah Hunt. Pacific Biochar.

Biochar Selection Tool. American Farmland Trust.

Biochar and Sustainable Agriculture. ATTRA Publication. 2018. By Jeff Schahczenski. National Center for Appropriate Technology, Butte, MT.

The National Center for Appropriate Technology’s Biochar Policy Project was created in 2019 to support development of a carbon-negative biochar and biofuel industry that creates good jobs and opportunity in rural America, while sequestering carbon and building soil health and productivity. The project works with farm groups, conservation organizations, soil scientists, farmers, ranchers and foresters that think an important solution can be found in biochar.

Ferments and Biochar: A Practical Guide to Utilizing Local Resources

Ferments and Biochar: A Practical Guide to Utilizing Local Resources

By Daniel Hoffman, Omar Rodriguez, and Luz Ballesteros Gonzalez,

NCAT Agriculture Specialists

October 2025

©NCAT

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable

Agriculture Program, under a cooperative agreement with USDA Rural Development. This publication is also produced in partnership with Ridge to Reefs and their agreement with the United States Department of Agriculture’s Natural Resource Conservation Service (USDA-NRCS), Award Number R213A750013G006.