Organic Tomato Production

By Steve Diver, George Keupper, and Holly Born, NCAT Agriculture Specialists, Updated by Tammy Hinman, Ann Baier, and Leah Riesselman, NCAT Agriculture Specialists

Organic local tomatoes are always in high demand. Growers can receive price premiums earlier and later in the season. Photo: NCAT

Abstract

This publication addresses practical questions on organic tomato production. It focuses on the specific production challenges, including site selection (soil and climate), variety selection, sources of organic seeds and organic annual transplants, organic grafting, planting and training/staking arrangements, soil fertility and fertilization, crop rotation, and pest (insect, disease, and weed) management. Harvest and yield/productivity are closely related to marketing possibilities. While market conditions are extremely region-specific, this publication also addresses a few general principles on marketing and economics of organic tomatoes.

Contents

Introduction

Soils and Organic Fertility for Tomato Production

Irrigation

Processing Tomatoes

Training

Managing Weeds: Basic Concepts

Managing Insects, Pests, and Diseases: Basic Concepts

Harvesting and Handling

Marketing and Economics

References

Further Resources

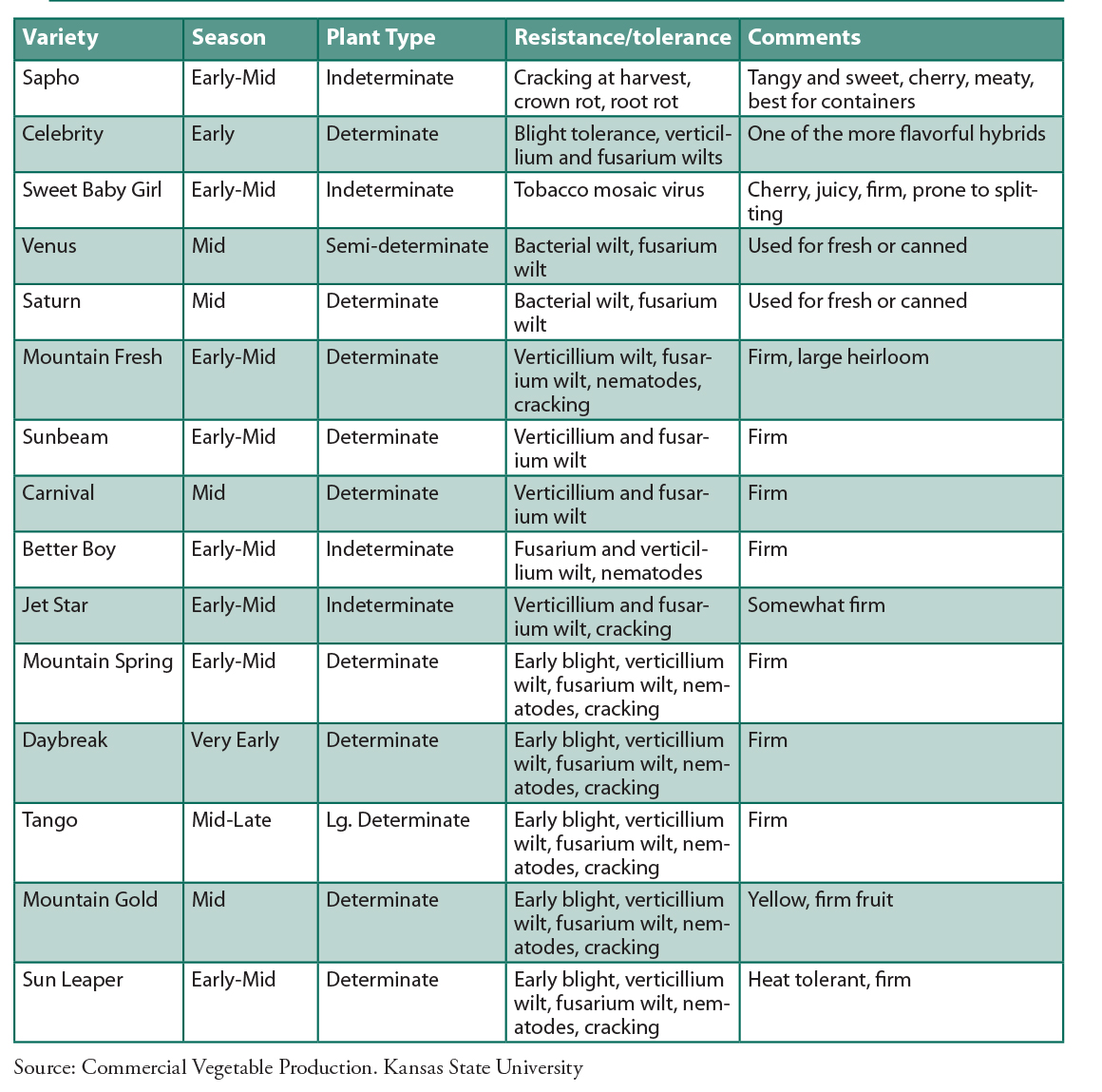

Appendix 1: Recommended Tomato Varieties

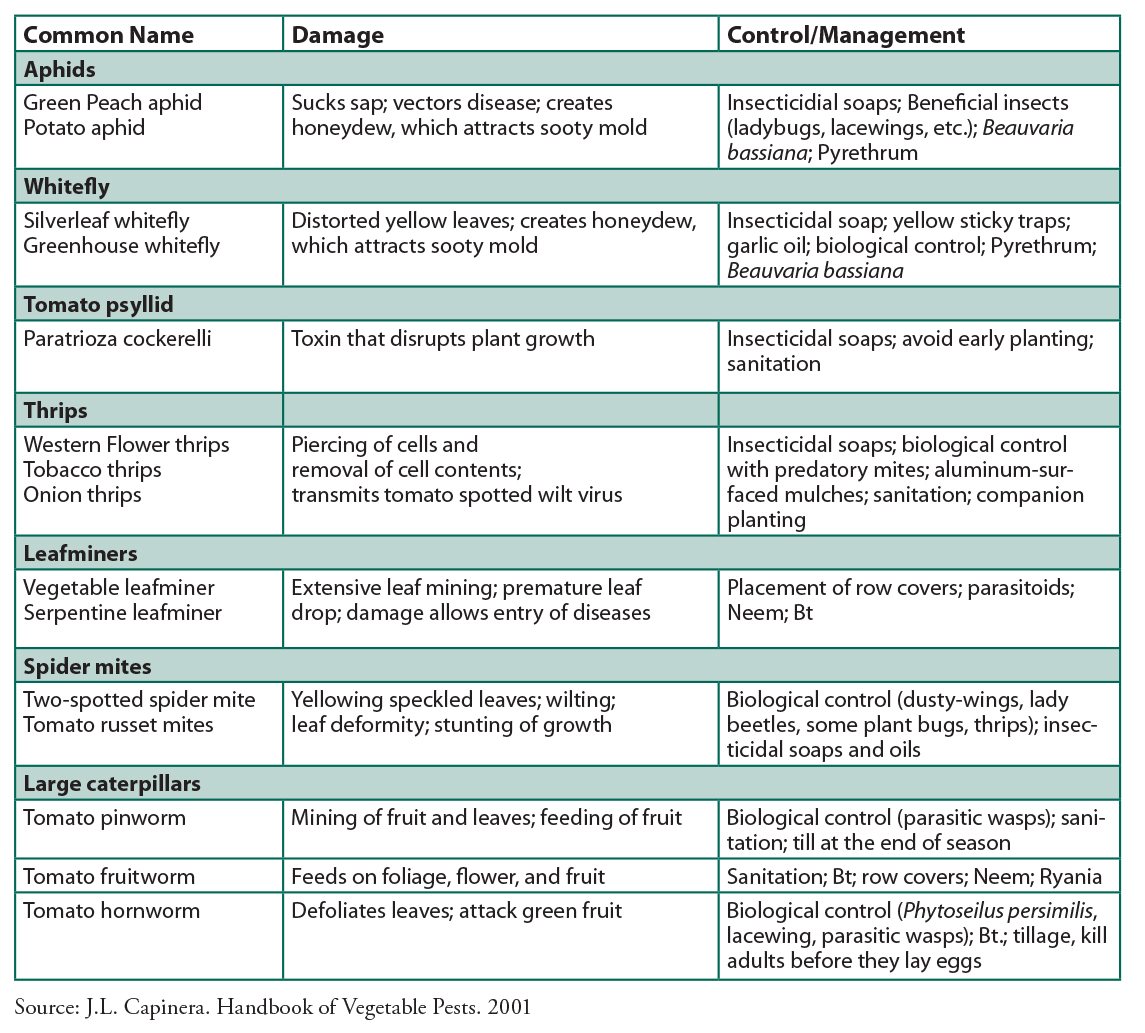

Appendix 2: Major Insects that Attack Tomatoes and Their Control

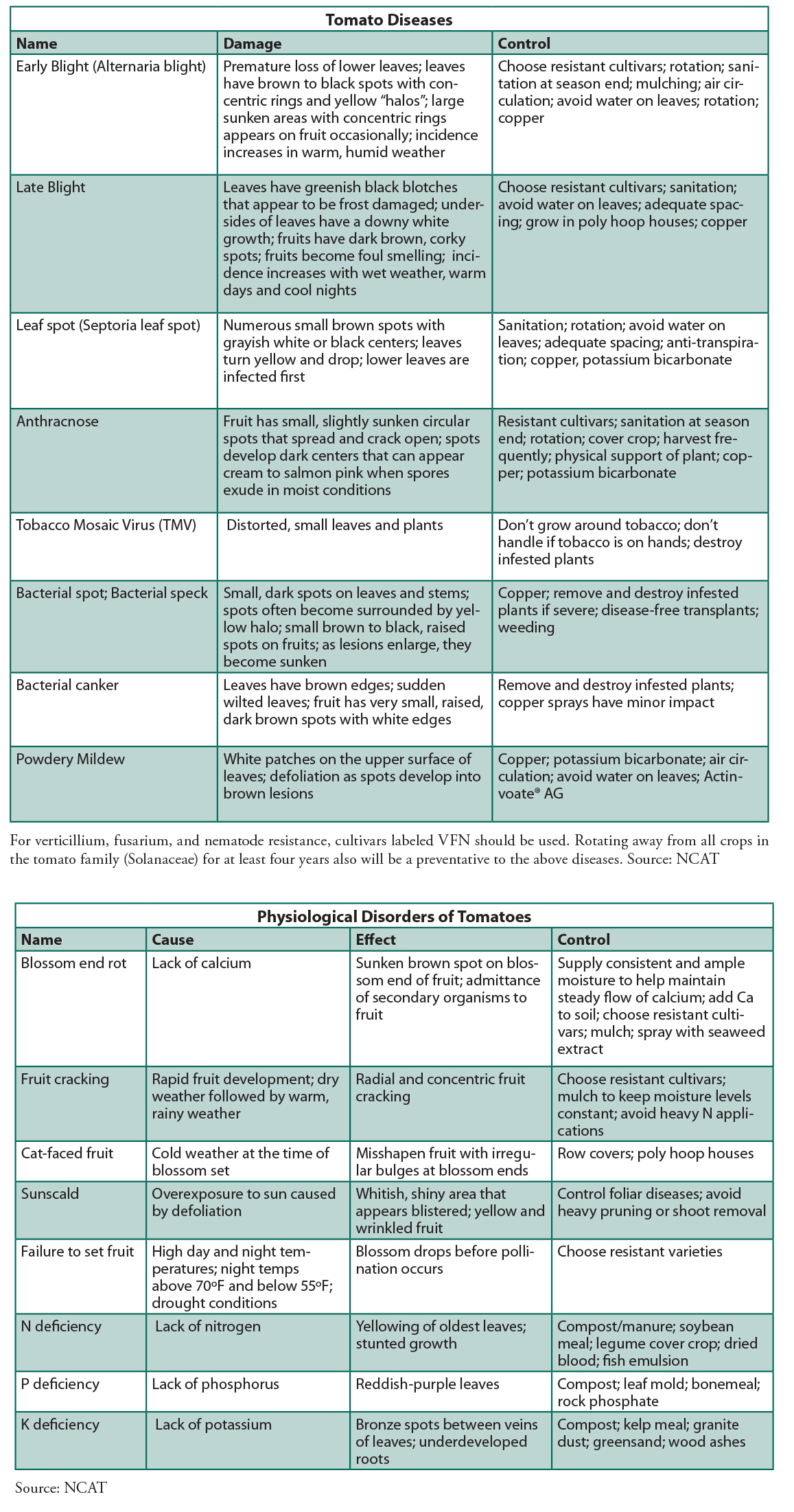

Appendix 3: Guide to Common Tomato Diseases and Disorders

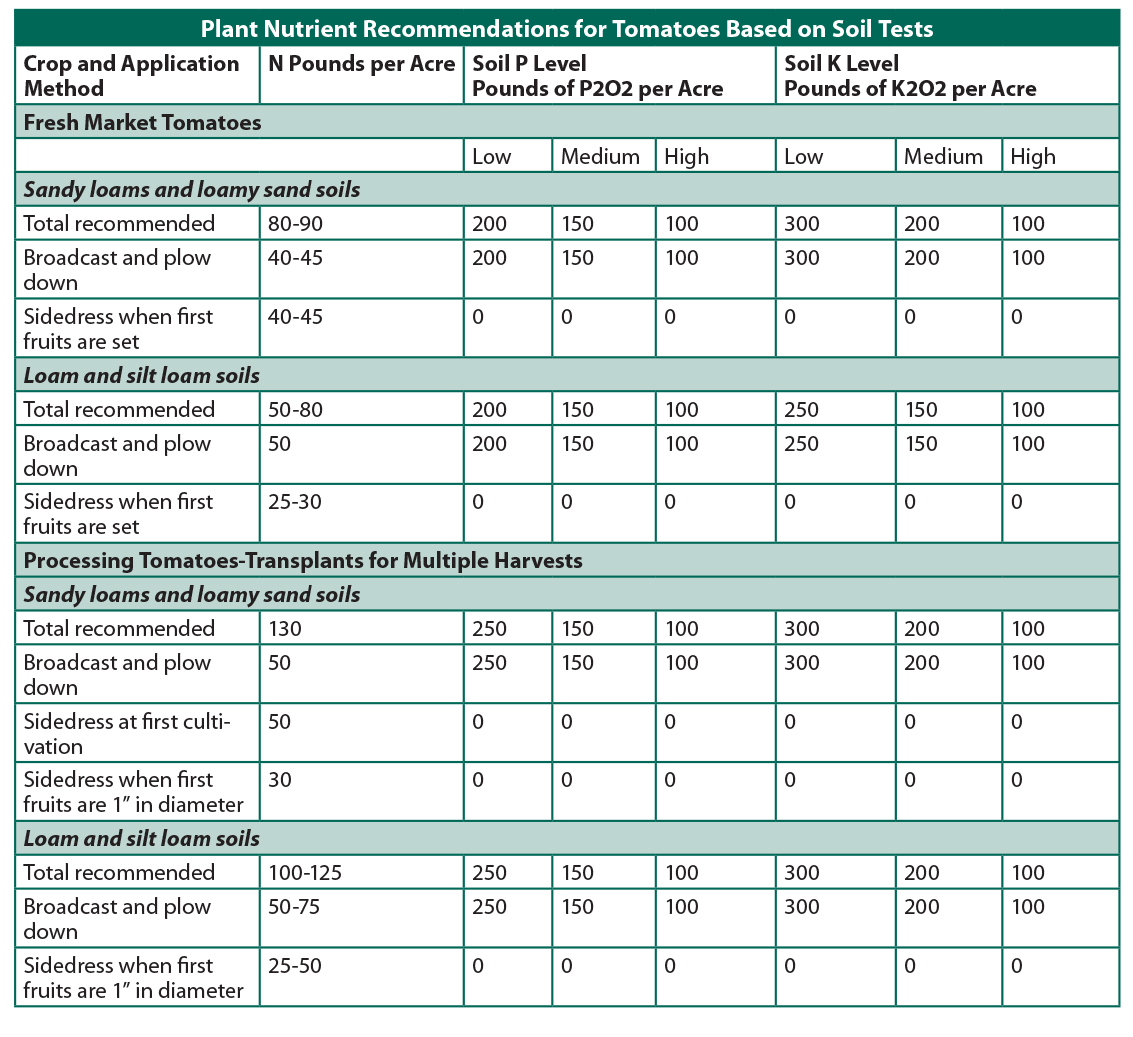

Appendix 4: Plant Nutrient Recommendations Based on Soil Tests

Introduction

Organic tomatoes are always in high demand in both local and wholesale markets. With proper production techniques, they can yield a high return on your investment. Returns are significantly higher when you sell earlier and later in the season.

Taste is in the mouth of the beholder, but consumers are generally willing to pay a premium price for organic tomatoes, depending on their specific region of the country, specific marketing techniques, and seasonal fluctuations. See Appendix 1 for information on tomato varieties and their characteristics.

This publication will address organic production and marketing techniques for tomatoes. It focuses on soil, pest, and weed management as well as economic and marketing aspects that are specific to organic production. It also briefly discusses hoop house tomato production, which enables growers to extend their season with this crop. For more details on this topic, see ATTRA’s Organic Greenhouse Tomato Production.

Soils and Organic Fertility for Tomato Production

A wide variety of soil textures can be used for tomato production. Ideal soil textures range from sandy to fine-textured clays as long as the soil is well drained (tomato roots will not tolerate being waterlogged), has good structure, and is well aerated. Planting dates can be determined by the type of soil a grower has. For example, sandy soils are preferred for early plantings in California due to adequate drainage during wet weather and rapid increase in soil temperature in the spring, which, in turn, can lead to early growth (Strange et al., 2000). However, loam and clay loam soils are the most productive soils for production. A mixture of one-quarter to one-half sand, one-quarter to one-half silt, and no more than 27% clay gives loam soils the best possible properties for plant growth. These mixtures supply adequate drain- age and good soil structure. Conversely, heavier clays can be a serious problem due to poor soil drainage and excess soil moisture for extended periods, making tomatoes more prone to disease.

One of the foundations of organic farming is maintaining and building a microbial-active soil enriched with organic matter and a balanced mineral diet. Humus-building practices and addition of minerals not only supply plant nutrients but also increase tolerance to insects and diseases, help control weeds, retain soil moisture, and ensure produce quality.

A typical organic fertility system revolves around a combination of practices such as using crop rotation, forage legumes, cover crops, green manures, composted livestock manures, and lime, rock phosphate, and other rock minerals, as well as supplemental organic fertilizers. Depending on the soil type, soils with no history of organic management will probably need additional fertilization to be incorporated during field preparation and bedding operations or banded to the side of the row at planting.

Soil tests provide a baseline for your soil. Most state Extension services provide tests for a nominal fee. For information that is specific to organic production, see the ATTRA database on Directory of Alternative Soil Testing Laboratories. In general, tomato plants have a high requirement for the macro elements potassium (K) and calcium (Ca) and the micro- nutrients iron (Fe), manganese (Mn), and zinc (Zn). Without a good supply of both K and Ca for plant uptake and utilization, the fruits will lack the recommended soluble solids content (sugars) and will be more susceptible to physiological dis- orders such as blossom end rot. Smaller requirements of the elements nitrogen (N), magnesium (Mg), phosphorus (P), boron (B), and copper (Cu) also are needed for proper plant development (Jones, 2008).

As shown in Table 1, tomatoes need moderate to high levels of P and K. On deficient soils, most needs can be met by applying rock powders such as rock phosphate, colloidal phosphate, untreated (mined) potassium sulfate, and sulfate of potash- magnesia in advance of planting. Supplementary P and K may be added as indicated by the soil test results. Always conduct a soil test to deter- mine the proper amount of nutrients to apply. See Appendix 4 for additional information on plant nutrient recommendations based on soil tests from Rutgers University.

| Table 1: Desirable Soil Nutrient Levels for Tomatoes | ||||

| The amounts are in pounds per acre and are tested in Missouri. | ||||

| Phosphorus (P) | Exchangeable potassium (K) | Exchangeable magnesium (Mg) | Exchangeable calcium (Ca) | |

| Sandy or gravelly loam | 100 to 125 | 225 to 325 | 150 to 300 | 2,000 to 3,000 |

| Medium silt loam | 125 to 150 | 325 to 425 | 300 to 450 | 3,000 to 4,500 |

| Heavy loam and clays | 150 to 175 | 425 to 500 | 450 to 600 | 4,500 to 7,000 |

| Source: Gaus et al. 1993. | ||||

Depending on the soil type, fresh market tomatoes also require about 75 to 100 pounds per acre of N. Most, if not all, can be supplied by legumes in rotation; composts or manures can also fill in the balance. If manure is chosen as the supplemental fertilizer, the USDA National Organic Program (NOP) regulations require that the manure be incorporated into the soil at least 120 days prior to harvest [NOP standard 205.203 (c)1]. Some farmers provide additional supplemental N at transplanting; a mixture of animal meal by-products, rock phosphate, and kelp meal is commonly used. If reliance is based primarily on supplemental fertilizers, about 50 pounds of actual N should be applied pre-plant and the remainder side-dressed when fruits are about nickel-size.

Tomato plants grow best when the soil pH is between 6.0 and 6.5. Liming to this range improves plant growth and optimizes fertilizer efficiency. If the pH is less than 5.5, Mg avail- ability decreases significantly. Consequently, this increases the level of available Mn and aluminum (Al). Unless a deficiency of magnesium is noted, application of high-calcium (nondolomitic without magnesium) lime is advised. In addition, when a low pH is coupled with low Ca, blossom end rot is likely to occur. However, when soil tests are high in both P and pH levels, Zn will become insoluble, resulting in deficiency symptoms such as cupped leaves and splotchy chlorosis (Jones, 2008).

Research and Field Experience in Tomato

• In a California study, soils well prepared with cover crops (legumes or legume-grass mixtures, grown during the winter preceding all other cash crops) and composted poultry manure showed no yield response over four years of replication as compared to conventionally based two-year rotation (tomato and wheat) and four-year rotation (tomato, safflower, corn, bean). Yields averaged 70 to 80 t/ha across the treatments. However, greater inputs were needed in the organic treatments, such as higher levels of irrigation because of greater infiltration rates, whereas the conventionally managed soils had poor infiltration rates. The total nitrogen inputs were also greater, applying twice the amount of nitrogen (N) to the organic as the conventional system in the last two years of treatment. High N input suggested N immobilization or insufficient decay by the microbial community. Many studies have shown that providing N via cover crops and/or composts can provide adequate fertility; however, this study demonstrates that total N inputs cannot rely on cover crops and/or composts alone. (Clark et al., 1999)

• In an Iowa study, two natural soil amendment/fertilizer products were used in an organic tomato production trial as a comparison to tomato plants that received no soil amendment. Chilean nitrate, also known as sodium nitrate, was applied at a rate of 40 pounds N/acre acre plus composted manure at 160 pounds N/acre. Cinagro™ was used as the other treatment at the application rate of 200 pounds N/acre. Results of the amendments were much the same: the tomato plants treated with the fertilizers were taller and had more leaves than the unfertilized soil. Flower, fruit number, and yield were numerically greater in the fertilized plots as compared to the untreated soil. No differences were statistically shown between the two amendments. (Delate et al., 2008)

• In a two-year Ohio study, fall-applied organic composted cannery waste (40% tomato processing byproducts, 20% duck manure, 20% municipal yard waste, and 20% reed canary grass straw) at a total of 26 t/ha in 1996 and 35 t/ha in 1997 produced 33% higher yields of ripe tomatoes than the nonamended conventional plots that were receiv- ing supplemental nutrient fertilizers. In addition, the composted cannery waste incorporated into organic tomato plots reduced the incidence of anthracnose root rot when disease was severe in the conventional plots. The organic plots also seemed to have better water retention than the conventional plots during two unusually dry months of the year when they received no supplemental irrigation. (Abbasi et al., 2002)

• In a long-term field experiment set up in North Carolina, three tomato subplots were amended each May with syn- thetic fertilizers (for the conventional method), cotton-gin trash, and animal manure (poultry and swine manure) at a rate of 67 kg N/ha. A fourth subplot consisted of rye/vetch green manure at a rate of 45 kg N/ha. Results showed that microbial biomass and microbial activity were generally higher in organically, rather than conventionally, managed soils with cotton-gin trash being the most effective, followed by animal manure, rye/vetch, and the syn- thetic soil. Likewise, the highest extractable carbon (C) and N levels occurred in plots amended with cotton-gin trash, followed by animal manure, rye/vetch, with the conventional plot showing the least amount of extractable C and N. Cotton-gin trash, animal manure, and rye/vetch treatments increased soil moisture by 25% to 58%, 11% to 13%, and 8% to 12%, respectively, compared to the synthetic fertilizer treatment. In addition, data showed that mulching the plots enhanced the soil microbial biomass N and potential N supply by 45% compared to the amended organic plots not mulched. (Tu et al., 2005)

Gallatin Valley Botanical hoop house tomatoes. Many growers have started growing tomatoes in hoop houses (also called high tunnels) to moderate temperatures and plant earlier for earlier harvests in the summer and later harvests in the fall. Photo: NCAT

Irrigation

All processing and fresh-market tomatoes are irrigated. Water must be supplied uniformly from the time of first fruit set to harvest. Uneven moisture periods will give rise to disorders such as blossom end rot and fruit cracking.

Drip, furrow, and sprinkler irrigation methods are used for tomato production. Drip irrigation is increasing in usage each year. As of 2008, more than 20% of processing tomato acreage was under drip irrigation. Generally, drip irrigation enhances yield and promotes efficient irrigation methods even in situations with challenging slopes and soil properties.

In California, drip irrigation maintains productivity by keeping the root zone relatively salt- free and limits excess water runoff (Hartz et al., 2008). Drip irrigation also improves irrigation efficiency and permits the grower to harvest at regular intervals by hand. A typical drip-irrigation system includes a single drip tape that is either buried two to 12 inches deep in the center of the bed or placed on top of the soil surface and secured with pins.

Using weather-based reference evapotranspiration (ET) data and crop growth stages, proper drip irrigation requirements should be determined by the site-location requirements. ET is a calculation of the water lost from soil and plants and is measured in inches. The effects of ET are increased by solar radiation, wind, low relative humidity, and high temperatures. The number of inches measured is the amount of irrigation water that needs to be delivered to the root zone of the plant in the field. To find state-based ET data, click here.

Furrow irrigation is sometimes used in collabo- ration with drip irrigation. In furrow irrigation, rates vary by soil type and crop growth stage. In most instances, seven- to 14-day intervals are used.

Sprinkle irrigation often is used to establish newly transplanted seedlings up to the time of first bloom. Drip irrigation, however, is used thereafter. Continued sprinkler use after establishment may increase susceptibility to bacterial diseases such as bacterial speck (Pseudomonas syringae), bacterial spot (Xanthomonas campestris), both early and late blight (Alternaria solani and Phytophthora infestans), and molds (Pythium and Sclerotinia spp.) (Strange et al., 2000).

Generally, tomatoes require one inch of water from rain or irrigation once a week for optimal growth. Tomatoes have a deep root system and therefore thrive on deep, infrequent irrigation methods. Watering less frequently decreases the susceptibility to root-rot diseases and increases efficient weed management.

Compared with field-grown tomatoes, high-tunnel tomatoes have several advantages:

• Earlier harvests in summer

• Later harvests in fall

• Better fruit quality

• Less foliar diseaseMost growers transplant tomatoes into tunnels nearly one month ahead of field tomatoes. For zones 4 to 5 (see the USDA hardiness zones map), late April to early May trans-planting would be appropriate, with adjustments for warmer conditions in the South and colder conditions in the North, at higher elevations, and in other cold pockets.

To reduce risk of plant-killing frosts inside the tunnel, it’s good to have a backup heat source (Cornell University Department of Horticulture, 2012).

Processing Tomatoes

Most, but not all, processing tomatoes are grown in California. Of the 331,000 acres planted to processing tomatoes in the United States, 312,000 (94%) were in California (USDA/ERS, 2009). According to the California Department of Food and Agriculture Organic Program, organic processing tomato acreage in California was just under 7,400 acres in 2007, worth $10.6 million. Compare this number with fresh market tomatoes, which were planted on only about 1,000 acres but worth $33.8 million. The difference in value reflects the fact that processing tomatoes are mechanically harvested and, because these tomatoes are processed, cosmetic damage is much less important compared to fresh market tomatoes. Other states with significant processing tomato acreage (nonorganic) include Indiana with 9,800 acres in 2009, Ohio with 6,600 acres, and Michigan with 3,500 acres. Over the last several years, acreage of processing tomatoes in the United States has been in the neighborhood of 300,000 acres. In the last decade or so, almost all processing tomatoes have been transplants.

Twenty years ago, most processing tomatoes were direct seeded. Transplanting gives the grower a one- to two-week head start against weed competition and reduces the likelihood of major “skips” in the planting process. There is a second major change in the way processing tomatoes are being grown. Buried drip tape is increasingly common, compared to furrow irrigation, and it’s estimated that over 60% of processing tomatoes in California are grown using buried drip (Johnson, 2010). One of the major advantages of buried drip is that since the water and fertilizer are applied directly in the root zone, very few weed seeds germinate on the surface, reducing competition from weeds and also reducing the costs associated with weed management. Buried drip requires substantial investment, as well as substantial maintenance to prevent the drip emitters from becoming plugged by bacteria. Conventional growers have reported yield increases after switching to buried drip, and water requirements generally are reduced.

Good soil management is critical to supporting production of organic processing tomatoes. Part of this comes from using diverse rotations, which can include alfalfa, wheat, corn, and dry beans, and can also include winter cover crops of vetch or oat-vetch mixes. Cover crops of vetch can be planted in the fall (October/November) on beds prepared for tomato production. The vetch is mowed in March and allowed to dry down, and it can be disked lightly with a Lilliston cultivator to incorporate, with transplanting being done one to two weeks later. Good soil management will allow for processing tomato yields in excess of 40 tons per acre.

Training

Healthier plants, more bountiful harvests, and earlier harvests are three reasons why training tomato plants is beneficial. Since training allows foliage to dry quickly, it limits several factors that encourage harmful fungal spores to reach fruits and leaves, such as wet leaves, poor air circulation, and soil splashed up by rain. Training also allows for faster identification of a pest problem. It also is a preventative management tool used to keep pests such as burrowing insects, snails, or slugs away from the fruit. Fruits can ripen faster as a result of more light penetration from training, in turn lengthening the harvest season.

Depending on the plant type— determinate or indeterminate—plant densities per acre may range from 4,860 to 14,760 plants (Jones, 2008). Determinate plant types are typically short and stout, stop growing at 3 feet, and set fruit all at once. Determinate tomatoes require less support and can be planted at greater densities, which is why they are favored by large commercial growers (Evans, 2004). Determinate varieties can be spaced 24 inches apart in the row and 3.5 feet apart between rows. Indeterminate varieties require a stronger support system, such as T-posts or heavy-duty wooden stakes, because they grow much taller and wider than their counterparts and they fruit until frost. They are often favored by producers who sell at farmers markets (Joslin, 2004). Indeterminate varieties should be 5 to 6 feet apart between rows and 30 to 36 inches apart within the row (Jones, 2008). See Appendix 1 for a list of determinate and indeterminate varieties.

Several training systems can be used in tomato culture. These include unsupported, either on bare ground or grown on plastic or organic mulch; the basic stake approach that can also be supported by wire cages, trellis/tunnels on either bare or mulched ground; and stake-and-weave systems.

Staked Systems

The basic stake approach is best for both indeterminate and determinate tomatoes. It provides support to the seedling during development and will prevent the tomato stem from snapping during moderate winds. Using a naturally rot- resistant wood stake such as cedar will help pre- vent the stakes from rotting and toppling over. Treated wood stakes are prohibited under the USDA organic regulations. For more information on alternatives to treated wood, see the ATTRA publication

Pressure-Treated Wood: Organic and Natural Alternatives.

Wire cages are best for indeterminate plant types on smaller farms. This system is most common among home and market gardeners because the added support assures optimal growth, but it is often expensive and time consuming. Threading two stakes through the wires assures optimal sturdiness.

Staking on plastic mulch, used for both determinate and indeterminate types, is typically accompanied by drip irrigation and tensiometers to monitor soil moisture. Floating row covers and tunnels are used in some instances to provide frost protection and to enhance early production.

Staking on organic mulch is similar to using plastic mulch, but unlike plastic, organic straw mulch has soil-enhancing benefits that are often preferred by the organic grower. These mulches cool the soil, as compared to plastic mulches, which can be a disadvantage in the spring when plastic mulches are promoting more plant growth. However, later in the season when temperatures are higher, organic mulches have an advantage over plastics.

A trellis system is best used to train indeterminate tomatoes. Plants usually produce fewer fruits with this system as compared to others, but the fruits are larger and typically ripen earlier. Sun- burned fruit may be a problem, however, due to the decreased leaf canopy.

The stake-and-weave method can be used for both plant types. Weaving the string in and out of the plants ensures support when the plants are loaded with fruit. This method is easy to maintain, sup- ports a large number of tomatoes in a small space, is inexpensive, and requires little storage space (Evans, 2004).

Unsupported Systems

Raising plants on bare soil and allowing them to sprawl—also known as ground culture—is still a commercial method in some regions. Low input costs are the chief advantage of this system. How- ever, lower yields, lower fruit quality, and a higher incidence of fruit and foliage diseases may be expected when compared to supported systems.

Transplanting tomatoes through plastic mulch and allowing them to sprawl out on the plastic is an alternative to ground culture. Plastic mulch reduces soil splashing onto the leaves and fruit, thus reducing disease. Either determinate or indeterminate types can be grown this way. Straw mulch can also be used in ground culture.

A Comparison of Systems to Train Tomatoes

Researchers at Oklahoma State University examined the economics and performance of tomato training systems. They compared four different training systems in Table 2. Ultimately, the vulnerability of tomatoes to disease and the limited efficacy of organically certified materials to control them, especially in humid climates, weighs heavily in favor of supported culture systems for organic production.

| Table 2: A Comparison of Tomato-Training Systems | ||||

| Factor | Ground1 | Cage2 | Stake & Weave3 | Trellis4 |

| Earliness |

3rd |

4th | 2nd |

Best |

| Fruit size |

4th |

3rd | 2nd |

Largest |

| Marketable yield |

4th |

Largest | 2nd |

3rd |

| Fruit cracking |

3rd |

4th | 2nd |

Worst |

| Fruit rotting |

Worst |

2nd | 2nd |

2nd |

| Fruit quality |

Worst |

2nd | 2nd |

2nd |

| Fruit sunburn |

Worst |

4th | 3rd |

2nd |

| Cost per acre |

4th |

2nd | Largest |

3rd |

| Pest control |

4th |

3rd | 2nd |

Best |

| 1 Ground – No support system.

2 Cage – Two-foot-tall wire cage 14 inches in diameter made from No. 10 mesh on 6-inch by 6-inch spacing. 3 Stake & Weave – Stake is driven between every other plant and twine woven between and around stakes four to six times. All suckers but one below the first fruit cluster are removed. No other suckers are removed above the first cluster. 4 Trellis – Post support No. 10 wire. Strings are dropped from wire and tied to base of plant. Plants are twined around string. |

||||

Managing Weeds: Basic Concepts

Organic farmers use a wide variety of approaches to control weeds without the use of synthetic chemicals. Crop rotations in combination with cover crops have proven to be the foundation of organic farming. Crop rotation not only enhances the competitiveness of the crop plant, but it also inhibits weed growth and breaks the life cycles of insects and diseases in the field.

Complementary to crop rotations is the use of mulching for adequate weed control. Both natural mulches and synthetic mulches, including polyethylene film and polypropylene landscape fabrics, are used in organic production. However, according to USDA organic regulations, synthetic mulches must remain intact during the growing season and must be removed from the field at the end of the season. Still, synthetic mulches have demonstrated their durability for multiple years in organic vegetable production systems.

Natural mulches such as leaf matter, straw, hay, or switchgrass have multiple benefits for the organic farmer. First, they are capable of regulating soil surface temperatures and moisture. Second, natural mulches improve overall soil quality by adding organic matter to the soil, increasing nutrient availability, soil porosity, cation exchange capacity, water-holding capacity, and microbial organisms while controlling the weed pressure (Delate and Hartzler, 2003).

To prevent stimulation of weed growth, mulches should be maintained at a depth of six inches. With that depth, weed emergence is greatly decreased by the reductions of both light transmittance and soil temperatures.

In a two-year Iowa study, researchers compared three no-till cover cropping systems for organic tomatoes: control (no cover), hairy vetch/rye treatment, and winter pea/wheat treatment. The results showed that cover crops such as a hairy vetch/rye treatment provided greater management of broadleaf weeds earlier in the season, when weed management is most critical, as compared to the pea/wheat treatment, because of the pea/ wheat treatment’s faster decomposition rate. Grass weeds were also lower in the hairy vetch/rye treatment at the end of the season. Likewise, a trend of greater fruit harvest and a greater number of No. 1 grade tomatoes were seen with the hairy vetch/rye treatment. Equal yields were found in the control and winter pea/wheat treatments (Delate et al., 2007).

Managing Insects, Pests, and Diseases: Basic Concepts

Cover crops play a vital role in the management of pests and diseases in an organic production system. Cover crops are any crop grown to provide soil cover. Generally speaking, cover crops are used to prevent soil erosion on soils with a slope that would otherwise be eroded by wind or water in any production system. However, in an organic system, cover crops also provide nitrogen. If the cover crop is a legume, it will suppress weeds, prevent nutrient leaching, and reduce insect pests and diseases. The ATTRA publication Overview of Cover Crops and Green Manures provides extensive information on the types of cover crops used today.

Cover crops also attract beneficial insects, a method known as farmscaping. Beneficial insects such as lacewings, parasitic wasps, and ladybird beetles need shelter, pollen, nectar, and food prey to survive. Plants that act as a host for these beneficial predators include sweet clover, buckwheat, fava beans, vetch, red clover, white clover, mustards, cowpeas, and species in the carrot (Umbelliferae), sunflower (Compositae), and mint (Lamiaceae) families. The ATTRA publication Farmscaping to Enhance Biological Control provides extensive resources for establishing beneficial insect habitats.

Prevention and sanitation procedures are also important. Practices such as removal of dead or diseased plants, frequent cleaning of tools, using disease-free stock, planting resistant varieties, and post-season cleanup of vines via tillage, burning, or composting are some preventative measures of contamination of pests and diseases between fields.

Other cultural practices include giving the plants adequate spacing to allow air circulation through the rows, in order to help the foliage dry rapidly. Watering at the base of plants via drip or trickle irrigation reduces the amount of moisture on the leaves, thus minimizing foliar disease occurrence. Watering in the morning, rather than the evening, minimizes the length of time that the leaves are wet. Allow foliage to dry before working with it again to avoid spreading disease-causing microorganisms such as Septoria lycopersici, tomato leaf spot, and other foliar diseases (Gleason and Edmunds, 2006).

Perhaps the most important method of cultural control for tomatoes is rotating the crops between soils every three or four years to reduce populations of the fungus Fusarium oxysporum f. sp. lycopersici in the soil. This includes rotation of crops within the tomato family (Solanacae), including pepper, potato, eggplant, and husk tomatoes.

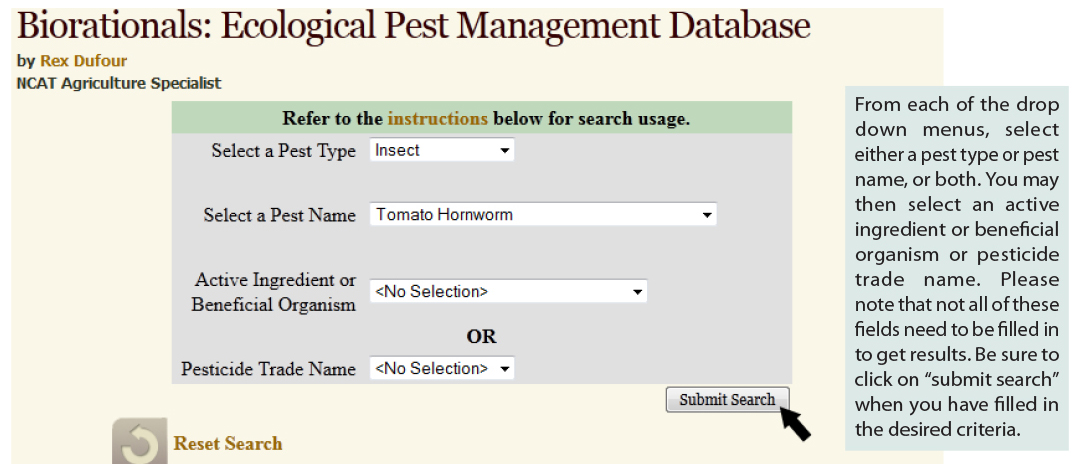

The ATTRA Ecological Pest Management Database lists organic pesticides with minimal environmental impact by disease, insect, and type of pesticide. It is a useful tool for finding management methods if you know which pest you have.

Insects

There are numerous insect pests that affect tomato crops. Control of pests requires continual monitoring and integration of biological and cultural practices. Refer to Appendix 2 for more detailed information about the major insect pests of tomatoes and their control methods.

The best pest-management system is based on prevention rather than control. Consistent monitoring of your tomatoes along with determining fast and correct prognosis is the key to managing pests before they get out of hand. Doing so will also help save time and money in the future. As the grower, you have a number of control options.

One option is to use natural repellants. Garlic, onions, zinnia, marigolds, and nasturtium are used as natural repellants to repel insects such as aphids or whitefly, a method known as companion planting. For more information on companion planting, refer to the ATTRA publication Companion Planting & Botanical Pesticides: Concepts & Resources.

Another control procedure available to organic producers is using insecticidal soaps or sprays. Neem oil is an insecticidal soap that is advertised to control a wide range of insects that are commonly found in the greenhouse, such as aphids, mealybugs, whiteflies, and mites. For it to be effective, plants need to be completely saturated with the soap and may need repeated applications to control an infestation. To avoid repeated applications, inspect your field daily to prevent an infestation from occurring.

Other natural pesticides such as biopesticides and botanical extracts, which are generally made from plants, are also available as a means of gaining control of an infestation. Pyrethrum, a botanical extract from chrysanthemums, is one example that is effective in controlling aphids. Most botanical insecticides tend to degrade quickly in the environment but are generally toxic to humans, bees, and beneficial insects. These should be used when the insect pest population is reaching economically damaging levels.

Microbial insecticides, derived from insect-pathogenic microorganisms, tend to be more specific and are safe to most nontarget organisms (Capinera, 2001). The most common microbial insecticide used today is Bacillus thuringiensis (Bt); it controls a variety of crop pests, mainly caterpillars and some beetles, depending on the strand used. However, no matter what strand it is, Bt must be used on the pests when they are immature, thus causing disease to the immature insect and eventually death. Bt is not effective when the pests are in the adult stage.

Biological control—using predator insects to control various insect pests—is another option to control pest populations. For example, Aphelinus abdominalis, a parasitic wasp, and Chrysoperla rufilabris, a lacewing species, can be introduced to the area to control aphids (Jones, 2008). Keep in mind that using the beneficial insects when pest populations are exceedingly high probably won’t provide enough control to eradicate the problem. Careful monitoring of the predators and maintaining optimum humidity and temperature levels are also important factors that can influence the effectiveness on both the target insect and the predators. Refer to the ATTRA publication Farmscaping to Enhance Biological Control, for things to keep in mind when using biological control procedures.

Most recommended tomato cultivars and varieties in the market today have a wide range of resistance to diseases, including some resistance to nematodes. Therefore, choosing resistant cultivars and varieties could help prevent the damage of root knot, stubby root, and sting nematodes to your tomato roots.

Organically approved pesticides are also available to keep pests below damaging levels. Refer to Appendix 2 for more details on approved, nonsynthetic pesticides. As with any pest problem, using a combination of controls is essential for success in keeping insect populations from reaching detrimental levels.

Diseases

Tomatoes are injured by pathogenic diseases caused by fungi, bacteria, and viruses, as well as abiotic diseases, such as catfacing and blossom end rot, which are caused by environmental and physiological disorders. Pathogenic diseases develop through soil-borne and above-ground infections and, in some instances, are transmitted through insect feeding.

Grafting is an innovative way that tomato growers are managing tomato diseases. Since grafting is a time-intensive process, it is typically used for higher value tomatoes in hoop houses or greenhouses. Grafting tomatoes is similar to grafting trees—the desirable fruit trait is used as the top portion (scion), and the disease resistance and hardiness is used for the bottom portion, or root stock. See Table 3 for a list of common rootstocks and their disease resistance.

| Table 3: Disease Resistance and Vigor of Commercial Tomato Rootstock Cultivars | ||||||||

| Seed Supplier Root stock variety | Disease | |||||||

| Tomato Mosaic | Corky Root | Fusarium (Both races) | Verticillium wilt | Bacterial wilt | Nematodes | Vigor | ||

| Deruyter Seeds | ||||||||

| Maxifort | High | High | Mod | high | high | Susceptible | high | 5 |

| Beufort | High | High | Mod | high | high | Susceptible | high | 3 |

| Takii Seeds | ||||||||

| Anchor- T | High | Susc | High | High | High | Moderate | High | 5 |

| Survivor | High | Susc | High | High | High | Moderate | High | 5 |

| Aegis | High | Mod | High | High | High | Moderate | High | 4 |

| Bruinsma Seeds | ||||||||

| Body | High | High | Susc | High | High | Susc | High | 5 |

| Robusta | High | High | Susc | High | High | Susc | Susc | 3 |

| Ratings are based on seed supplier information. Vigor is measured on a scale of 1 to 5, where 1 represents poor and 5 represents excellent. This table is used with permission from the North Carolina State University publication Grafting for Disease Resistance in Heirloom Tomatoes. Rivard and Louws. North Carolina State University Department of Plant Pathology. | ||||||||

Major tomato diseases include those that attack the root system (fusarium wilt, verticillium wilt, bacterial wilt, nematodes, rhizoctonia), above-ground stems and foliage (early blight, late blight, septoria leaf spot, bacterial canker), and fruit (bacterial spot, bacterial speck, anthracnose). Thus, a disease-control program is important at each stage of growth. Verticillium wilt, one of the most damaging soilborne diseases of tomatoes, also attacks more than 200 other plant species, including potato, pepper, eggplant, strawberry, watermelon, and radish (Gleason and Edmonds, 2006).

A considerable amount of progress has been made in breeding disease resistance or tolerance to naturally occurring tomato plant diseases and viruses. Such resistance is found in cultivars such as Venus, Saturn, Kewato, and Rosita for bacterial wilt disease; the Mountain series (Mountain Pride, Mountain Supreme, Mountain Gold, Mountain Fresh, and Mountain Belle) for resistance of early blight; and verticillium wilt, root knot, tobacco mosaic virus, gray leaf spot, and Alternaria stem canker resistance found in common tomato hybrids (Jones, 2008). See Appendix 1 for tomato variety disease resistance. An organic grower cannot base his or her success on variety selection alone, however—site selection, cultural control, the use of biological control agents, and nonsynthetic fungicides are other factors to consider. While the use of pesticides is generally restricted in certified systems, the NOP permits various products under its organic regulations.

Johnny’s Selected Seeds has developed a useful video on grafting.

Copper-based products have been widely used in organic vegetable and fruit production. Used to control anthracnose, bacterial speck, bacterial spot, early and late blight, gray leaf mold, powdery mildew, and septoria leaf spot, copper has been used as a routine disease control practice in organic tomato production. Copper is, however, classified as a “restricted” substance by the NOP. A certified organic farm must document application time and rates and show a documented history of the disease organism. Most formulations of copper fungicides such as Bordeaux, basic sulfates, hydroxides, oxychlorides, and oxides are allowable, with restrictions, in organic certification systems. However, they pose a problem with potential soil toxicity, contamination of water run-off, and toxicity to nontarget organisms, particularly earthworms and some soil microbes.

The use of copper fungicides also increases the potential risk of injuring the leaves and fruit of most crops. Using excessive amounts of copper coupled with slow drying conditions after a rain and hot weather conditions (above 85 degrees Fahrenheit) may be the cause of injury. Thus, organic growers often monitor soil copper applications and do not rely on copper alone for disease management. Integrated control methods might include choosing disease-resistant varieties, disinfecting seeds with heat treatments, rotating crops, applying compost, managing weeds, and, when necessary, using other effective, approved products for disease management. Garlic and neem oils, Bacillus subtilis, and seaweed extract significantly reduced foliar disease on tomatoes compared to the control in one study (Wszelaki and Miller, 2005).

Elemental sulfur has been used in the organic vegetable industry as a preventative fungicide against powdery mildew and as an insecticide for mite control. The key to its fungicide success is that it prevents spore germination and, for this reason, is only effective when applied prior to disease development. However, like copper, sulfur has also shown phytotoxic effects. Avoid applications in hot temperatures to reduce injury to plants.

Bicarbonate salts, essential oils, plant and soil extracts, and biological control organisms are other materials allowed under the NOP regulations for disease control. Essential oils such as garlic and neem oils (Bacillus subtilis), and seaweed extract were shown to significantly reduce foliar disease injury in one study by Ohio State University in 2002 and 2003. The results, however, were variable in other years.

Potassium bicarbonate, more commonly known as baking soda, has been found to posses fungicidal properties as well. It is used as prevention or as treatment at the first signs of infection caused by anthracnose, early blight, leaf blight, leaf spot, and powdery mildew.

Research and Field Experience in Tomato Diseases

• A two-year study in North Carolina found that organic soil fertility amendments (composted cotton-gin trash, swine manure, or a rye-vetch green manure) applied to bare ground resulted in limited southern blight disease incidence as compared to greater disease incidence in bare soil that received synthetic fertilizers. The composted cotton-gin trash ranked first on reducing the incidence of southern blight on processing tomatoes and also best enhanced the populations of beneficial soil microbes (Bulluck and Ristaino, 2002).

• In Florida, interplanting with Chinese chive (Allium tuberosum) in tomato production has been shown to drop the population of the organism responsible for bacterial wilt (Pseduomonas solanacearum) in the soil (Berkelaar, 2002).

Harvesting and Handling

Production practices have a tremendous effect on the quality of fruit at harvest, postharvest, and during shelf life. For example, some cultivars are known to have a longer shelf life and to ship better than others. Because of this, you should consider your market before considering which varieties to plant. In addition, environmental factors such as soil type, temperature, frost, and rainy weather also have unfavorable effects on the crop’s harvest quality. For example, some tomato varieties have a tendency to crack after a rain. Therefore, choosing varieties such as Sapho and Mountain Fresh, which are resistant to cracking, may help alleviate the problem of poor fruit quality at the time of harvest. Management practices such as too little or too much water, mechanical injury, or high fertilizer rates can also affect postharvest quality.

Tomatoes should be harvested during the coolest time of the day, which is typically in the morning, and produce should be kept shaded in the field. Harvesting tomatoes requires extensive labor; harvesting may be done every day during the peak of the season along with continuous discarding of culled fruit from the field to prevent the spread of diseases and pests. Harvesting is done either by hand or with a harvesting aid; only processing tomatoes are harvested by machine due to increased bruising of the produce. Produce should be graded, separating the marketable tomatoes from the cull tomatoes that show signs of bruises, cracking, spots, rots, or decay. Damage such as this can be prevented if tomatoes are handled with care at the time of harvest, harvested at proper maturity, harvested during dry weather, and handled minimally. Tomatoes should be harvested with no more than two to three stacked deep into strong cardboard or stackable flat boxes. Growers have used bread racks in the past with great success. Check with a local bakery to see if they would be willing to sell some to you.

Tomatoes are very susceptible to chilling injury; therefore, maintaining precise storage temperature is critical for postharvest storage quality. Storage temperatures differ with the maturity of the fruit. Tomatoes picked with a slight pink color all the way up to a mature red color should be stored at temperatures between 48ºF to 50ºF. These fruits will have a maximum shelf life of two weeks. Tomatoes that are picked green are best stored at temperatures between 58ºF to 60ºF and have a three- to four-week shelf life.

Proper sanitation is of great importance in preventing postharvest diseases and the spread of foodborne illnesses. Thus, strict regulations of sanitary facilities and the use of disinfectants in wash water are used to help prevent both the spread of postharvest diseases and foodborne illnesses. Disinfectants such as chlorine, at a residual of 4 ppm, or hydrogen peroxide, at a concentration of 0.5%, have been effective disinfectants in organic programs. Always check with your certifying agent to see what concentrations are allowed under the regulations.

The publication Wholesale Success: A Farmers Guide to Selling, Post Harvest Handling, and Packing Produce offers useful information on cleaning and grading specifics as well as harvest maturity indicators. See the Further Resources section for more information. The ATTRA publication Postharvest Handling of Fruits and Vegetables is also an excellent source for additional information on postharvest and storage considerations.

Marketing and Economics

ATTRA has various resources available for beginning market farmers. Refer to the ATTRA publication Marketing Gardening: A Start-Up Guide for more information.

The outlook for organic tomatoes is strong. According to the USDA Economic Research Service, the top three organic vegetables grown in the United States are tomatoes, lettuce, and carrots (Economic Research Service, 2008). Direct markets for organic tomatoes include farmers markets, roadside stands, subscription marketing arrangements (CSAs), and restaurants. Local wholesale markets, such as grocery stores and restaurants, can also fetch price premiums. Wholesale markets will require packing and grade standards. The perishibility of organic tomatoes is an important consideration in wholesale markets. If you anticipate growing tomatoes for market, it is always a good idea to find markets and develop a marketing plan before you even plant the tomatoes in the ground. Organically grown tomatoes can command premium prices, especially for early- and late-season sales. Growing tomatoes in hoop houses is the best way to assure early and late season tomatoes.

ATTRA has a series of marketing tip sheets that outline advantages, considerations, tips, and questions to ask yourself for 13 different marketing channels. The tip sheets are available here.

How to Assess Your Markets

Market research is one of the most important parts of developing a marketing plan. This may sound intimidating, but market research is really just gathering information from the sources that you would like to sell to.

To find out who your potential customers might be, and what they want, talk to people in the markets that you are most interested in selling to. These include restaurant chefs, grocery store managers, local produce distributors, and farmers market managers.

Some questions to ask these businesses and important things to observe are:

- What products are missing that they would like to stock, sell, serve, or buy?

- What new products do they think are emerging trends?

- Are they interested in getting more local products?

Organic Tomato Costs of Production

According to a recent organic tomato publication by the University of Kentucky Extension, production costs for drip irrigated, staked tomatoes are estimated at $2,630 per acre, with harvest and marketing costs for 1,200 boxes at $6,705 per acre. Total costs are estimated at approximately $10,200 to $12,000 per acre.

A Northeast Organic Network study on organic costs and returns per acre estimated the revenue for tomatoes at New Leaf Farm in Durham, Maine. Table 4 shows the results.

| Table 4: Organic Tomato Costs and Income per Acre | |||||

| Year | Amount sold (lbs per acre) | Average price per pound | Revenue | Total costs of production per acre | Profit per acre |

| 2002 | 24,900 | $2.57 | $63,900 | $18,900 | $45,000 |

| 2003 | 22,600 | $2.20 | $49,700 | $22,100 | $27,700 |

| NEON. Focal Farm Case Study. New Leaf Farm data. 2003. Cornell University. | |||||

References

Abbasi, P., Al-Dahmani, J. Sahin, F. Hoitink, H. and S. Miller. 2002. Effect of Compost Amendments on Disease Severity and Yield of Tomato in Conventional and Organic Production Systems. The Ohio State University Press. Vol. 86, No. 2. p. 156-161.

Berkelaar, E. 2002. Partial Control of Bacterial Wilt of Tomato with Chinese Chives. ECHO Development Notes. Vol. 77. p. 8.

Bulluck, L., and J. Ristaino. 2002. Effect of Synthetic and Organic Soil Fertility Amendments on Southern Blight, Soil Microbial Communities, and Yield of Processing Tomatoes. North Carolina State University. Vol. 92, No. 2. p.181-189.

Capinera, J. L. 2001. Handbook of Vegetable Pests. University of Florida.

Clark, M., W. Horwath, C. Shennan, K. Scow, W. Lantni, H. Ferris. 1999. Nitrogen, weeds and water as yield-limiting factors in conventional, low-input, and organic tomato systems. University of California Davis. Vol. 73. p. 257-270.

Coolong, Tim. 2010. Tomatoes. University of Kentucky Cooperative Extension Service.

Cornell University Department of Horticulture. 2012. Cornell High Tunnels: Tomato Production.

Delate, K. and R. Hartzler. 2003. Weed Management for Organic Farmers. Iowa State University Extension. PM 1883.

Delate, K., A. McKern, and B. Burcham. 2007. Evaluation of an Organic No-Till System for Organic Corn, Soybean, and Tomato Production. Iowa State University Annual Progress Reports – 2007. Vol. 12.

Delate, K. et al. 2008. Evaluation of Soil Amendments in Organically Managed Peppers and Tomatoes – Armstrong Trial, 2008. Iowa State University. Vol. 13.

Economic Research Service. 2008. Certified organic vegetables. Acres of tomatoes, lettuce, carrots, mixed vegetables, and unclassified vegetables by State, 1997 and 2000-08. USDA.

Economic Research Service, U.S. Tomato Statistics. Tables 002 and 007. USDA.

Evans, W. 2004. Bringing Up Tomatoes. Organic Gardening Magazine. June/July. p. 34-37.

Gaus, A., H. DiCarlo, and C. DeCourley. 1993. Fresh Market Tomatoes. University of Missouri Extension Service.

Gleason, M. and F. Edmunds. 2006. Tomato Diseases and Disorders. Iowa State University Extension. PM 1266.

Hartz, T., G. Miyao, J. Mickler, M. Lestrange, S. Stoddard, J. Nunez, and B. Aegerter. 2008. Processing Tomato Production in California. University of California Division of Agriculture and Natural Resources. 7228.

Huang, C.L. and B. H. Lin. 2007. A Hedonic Analysis of Fresh Tomato Prices among Regional Markets. Review of Agriculture Economics. Vol. 29, 4. p. 783-800.

Johnson, B. 2010. Drip is the method of choice for processing tomato irrigation. Ag Alert, August 18.

Jones, J. 2008. Tomato Plant Culture in the Field, Greenhouse, and Home Garden. Ed. 2.

Joslin, K. R. 2004. Control of the foliar disease, Septoria lycopersici, in organic tomato production. Iowa State University: Graduate Thesis.

Marr, C., Tisserat, N., Bauernfeind, B. and K. Gast. 1998. Commercial Vegetable Production: Tomatoes. Kansas State University Agricultural Experiment Station and Cooperative Extension Service. MF- 1124.

National Organic Program. Soil Fertility and Crop Nutrient Management Practice Standard. 205 Subpart C. 205.203(c)1. USDA.

Padgham, J. and H. Behar. 2008. Guidebook for Organic Certification. Midwest Organic & Sustainable Education Service. Ed. 2.

Porter, W. 2007. Facing Scientific Realities, Debunking the “Dose Makes the Poison” Myth. The Big Picture: Linking pesticide science and health effects. Pesticides and You. Vol. 27, No. 4, 2007-2008.

Rawson, J.M. 2007. Organic Agriculture in the U.S: Program and Policy Issues. Organic Agriculture in the U.S. p. 1-53.

Strange, M., W. Schrader, and T. Hartz. 2000. Fresh-Market Tomato Production in California. University of California, Division of Agriculture and Natural Resources. 8017.

Sustainable Agriculture Network. 2003. Transitioning to Organic Production. Sustainable Agriculture Network Publications. 408.

Tu, C., J. Ristaino, and S. Hu. 2005. Soil microbial biomass and activity in organic tomato farming systems: Effects of organic inputs and straw mulching. North Carolina State University. Vol. 38. p. 247-255.

Wszelaki, A. L. and Miller, S. A. 2005. Determining the efficacy of disease management products in organically-produced tomatoes. Plant Health Progress doi: 10.1094/PHP- 2005-0713-01-RS.

Further Resources

Extension Fact Sheets on Production and Handling

Fresh Market Tomatoes. 1993. By Arthur E. Gaus, Henry F. DiCarlo, and Chuck DeCourley. Fact Sheet G6370. University of Missouri Extension.

Training Systems and Pruning in Organic Tomato Production. 2011. By Bonnie Cox. Oregon Tilth, Organic Agriculture eOrganic Extension. eOrganic 2620.

Processing Tomato Production in California Cooperative Extension Service. No date. By Tim Hartz, Gene Miyao, Jan Mickler, Michelle Lestrange, Scott Stoddard, Joe Nunez, Brenna Aegerter. Publication 7228. University of California.

Postharvest Cooling and Handling of Field- and Greenhouse-Grown Tomatoes. No date. By M.D. Boyette, D.C. Sanders, and E.A. Estes. North Carolina Cooperative Extension Service.

IPM for Tomatoes

Crop Knowledge Master: Tomato IPM. University of Hawaii—College of Tropical Agriculture and Human Resources.

UC Pest Management Guidelines: Pests of Tomatoes. University of California Agriculture & Natural Resources.

Control of the Foliar Disease, Septoria lycopersici, in Organic Tomato Production. 2004. By Karen R. M. Joslin and Henry G. Taber. Department of Horticulture, Iowa State University, Ames, IA.

Grafting for Disease Resistance in Heirloom Tomatoes. 2006. By Cary Rivard and Frank Louws. North Carolina State University Department of Plant Pathology.

Managing Diseases of Organic Tomatoes in Greenhouses and High Tunnels. 2009. By Sally A. Miller. Ohio Cooperative Extension, Ohio State University.

Sustainable Practices for Growing Tomatoes and Vegetables

What’s At Stake: Selecting a Training System. No date. By Bonnie Cox. Oregon Tilth.

Cover Crop Residues Enhance Growth, Improve Yield, and Delay Leaf Senescence in Greenhouse-grown Tomatoes. 2005. By Vinod Kumar, Aref Abdul-Baki, James D. Anderson, and Autar K. Mattoo. HORTSCIENCE 40(5):1307- 1311.

Hoop House Tomato Production

Cornell High Tunnels: Tomatoes

Production of Tomatoes within a High Tunnel. By Lewis Jett. University of Missouri, Columbia, MO.

Markets, Economics, and Crop Budgets for Tomatoes

Identifying Factors Affecting Consumer Purchases at Direct Market Operations. C.E. Carpio1, C.D. Safley, M.K. Wohlgenant, and R. Williams. North Carolina University Extension, Raleigh, NC.

Sample Costs to Produce Fresh Market Tomatoes. 2007. University of California Cooperative Extension Service, Davis, CA. TM-SJ-07

National Organic Program, United States Department of Agriculture.

Tomato Food Trends Profile. Agricultural Marketing Resource Center.

Organic Production. U.S. Department of Agriculture Economic Research Service.

Organic Premiums of US Fresh Produce. Renewable Agriculture and Food Systems

United States Standards for Grades of Fresh Tomatoes. USDA-Agricultural Marketing Service

Wholesale Success: A Farmers Guide to Selling, Post Harvest Handling, and Packing Produce.

This useful manual includes harvesting, cooling, storing, and packing information for 103 different fruits and vegetables.

Appendix 1: Recommended Tomato Varieties

Appendix 2: Major Insects that Attack Tomatoes and Their Control

Appendix 3: Guide to Common Tomato Diseases and Disorders

Appendix 4: Plant Nutrient Recommendations Based on Soil Tests

Organic Tomato Production

By Steve Diver, George Keupper, and Holly Born,

NCAT Agriculture Specialists

Published April 1995

Updated April 2012

by Tammy Hinman, Ann Baier, and Leah Riesselman,

NCAT Agriculture Specialists

© NCAT

IP439

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development. ATTRA.NCAT.ORG.