Practical Farm Energy Efficiency

Hands use the phone to scan QR codes to receive discounts on electricity bill payments at the office.

By Stacie Peterson, NCAT Energy Program Director

Abstract

There are many low-cost, practical ways to save energy on your farm. This publication covers the basics of identifying energy-efficiency issues and helps you develop an energy-conservation plan for your entire operation.

Contents

Introduction

Understanding Your Energy Usage

Energy Conservation

Efficiency Opportunities

Summary

Further Resources

Introduction

The least expensive energy for your farm is energy that is never used. Low and no-cost projects such as consolidating operations, creating efficient operation schedules, installing timers, using passive ventilation can add up to significant savings over time. This publication can help you understand your energy use and how your operations affect your energy bill. It also steps you through a high-level energy assessment, so that, armed with this information, you will be able to prioritize your energy-efficiency projects.

Understanding Your Energy Usage

Your energy bill can tell you a lot about how you use energy, how you are charged for that energy, and where and when you should focus on efficiency. The electricity you use is measured in kilowatts and kilowatt hours (kWh), which are the number of kilowatts used in a one-hour period. On the other hand, natural gas that you use is typically measured in therms. A therm is equal to 100 cubic feet of natural gas.

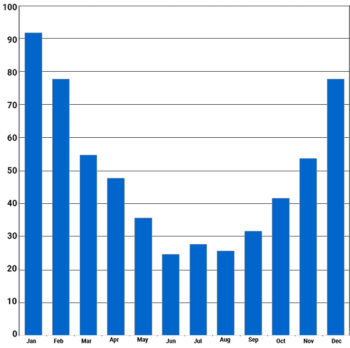

Figure 1 below shows the electric usage at a farm in a northern climate that uses electric baseboard heat for buildings in the winter. The “shape” of the energy use (in Figure 1) shows an increase of energy usage in winter months, when more energy is used for heat and lights operate for longer hours. The constant use of 25 kwh indicates that 25 kwh is the consistent energy use of the farm or building, regardless of time of year.

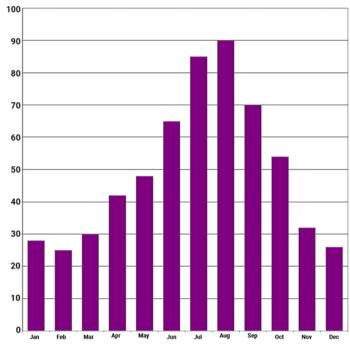

Figure 2 below shows a farm in a southern climate, with hot summers and more consistent daylight and lighting needs. The shape of the energy bill indicates more energy use in the summer, most likely for cooling, fans, and processing. This farm has a consistent energy use of around 30 kwh.

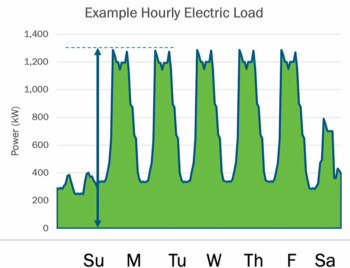

In addition to taxes and fees, commercial energy bills often include consumption and demand charges for electricity. Residential energy bills typically do not include what is known as a “demand charge.” The electric consumption charge is based on the amount of electricity used over time, with a fixed rate charged for each kWh consumed. Meanwhile, the electric demand charge is based on the highest wattage in the billing period, typically within a 15-minute or 30-minute interval. To reduce the amount of demand charges in future billing cycles, you can pinpoint and reduce your highest demand for energy. For example, if you usually start all your pumps at once, you could, instead, stage the pumps in half-hour intervals to lower the demand charge.

Figure 3 below illustrates the peak demand for one week, indicated by the dotted blue line. If you are unsure of your charges after looking at your bill, you can talk to one of your utility’s customer service representatives for an explanation of the rate structure.

Energy Conservation

Once you understand your energy-use

patterns, you can then develop a strategy to decrease your energy use. Energy use on a typical farm includes the following:

- Heating, ventilation, and cooling

- Lighting

- Motors

- Pumps

- Refrigeration

- Water heating

- Machinery

- Irrigation

- Processing

- Stock watering

Figure 4. Nameplate of a 250-horsepower motor.

Photo: NCAT

After analyzing your energy bills, start an energy assessment of your operation by developing a list of energy-consuming equipment. You could approach this list in terms of individual building(s) or process(es) or address the whole farm. If your buildings or processes are on different meters, try to develop a list of energy consumption for each meter, so you can see the energy conservation effect on the corresponding energy bill as you complete energy-conservation projects.

As you develop the list, quantify the energy used by individual pieces of equipment to prioritize energy conservation projects. You can find this information on pumps, motors, heating equipment, and most machinery by looking for a name plate, as in Figure 4, which shows a motor that draws 250 horsepower with 95% efficiency.

To convert horsepower to kilowatts, use this equation:

(Horsepower of the motor) * (.746 kwh/hp)/

(Motor efficiency) = Kilowatts used by the motor

As an example, for the motor in the photograph above, the energy usage is calculated like this:

(250 HP) (.746 kw/HP)/.95 = 196.3 kilowatts

To determine the energy cost of the motor, multiply its energy usage by the hours of usage and then multiply this number by your energy cost per kilowatt-hour (kWh). For example, if you operate the motor in the photo 3,000 hours in one year and your energy cost is $0.08/kWh, it will cost:

200.24 kW*3,000 hours * $0.08/kWh = $48,057.60

Once you’ve developed a list of energy consumption on your farm, you can create a plan to make operations and equipment more efficient.

Efficiency Opportunities

There are many low and no-cost opportunities for achieving energy efficiency that typically involve do-it-yourself projects and organization. After you’ve developed an inventory and understand the energy use and charges on your energy bill, you can then consider the layout of your farm and your operations.

If there are unoccupied spaces that are being heated, possibly with a shop heater or a milk house heater, remove the heater or place it on a timer, so it is only used when needed. Similarly, look for ways to consolidate operations that need heating, cooling, and lighting and operations that don’t, so you can curtail or eliminate heating, cooling, and lighting wherever and whenever possible. While consolidating your operations, develop an operating schedule, so you can limit energy use with timers or an operating schedule.

Figure 5. A Simple outlet

timer.

Programable thermostats and timers can save significant amounts of energy. Timers can be the simple plug-in type (as shown in Figure 5); they can be controlled with computerized sensors, such as “smart” electronics; or they can be controlled by sensors that detect movement or sound. They can also be controlled by an energy-management software system. For instance, if you use engine block heaters for tractors or other vehicles, you can install a time clock that turns the heater on one to two hours before it is needed, instead of 10 or 12 hours overnight, and this could save you around $80 per year. To reduce lighting energy use, install sensors in the space, on individual lights, or as a part of an electronic control system.

When you consolidate your operations and your operating schedule, bear in mind any effect this could have on demand charges and then adjust your operations to reduce your peak demand charges. Staging the timing of turning on motors, pumps, and energy-intensive equipment can reduce peak demand. Scheduling higher-energy-use operations at different times can also reduce peak demand charges.

Once you’ve consolidated operations, set an operating schedule, installed timers, and eliminated or reduced energy use in applicable areas, it is time to look for do-it-yourself energy conservation projects. First, walk the perimeter of each building, inside and out, and look for air leaks in the roof, walls, windows, and doors. Replace inefficient doors, windows, and roofing as your budget allows. Replace worn or missing caulking and defective weatherstripping in windows and doors, and then install curtains on windows to conserve heating and cooling energy. Pay attention to areas where electrical and plumbing utilities enter the building and use spray foam insulation to control air leaks.

No-cost and Low-cost Energy-efficiency Opportunities

- Develop an equipment inventory.

- Understand energy use and charges.

- Look to consolidate operations that require heating, cooling, or lighting.

- Install timers and controls on heating and lighting systems.

- Look for do-it-yourself energy conservation projects: air leaks and circulation, insulation, boiler adjustments

Figure 6. Well-sealed air leaks around plumbing.

Photo: NCAT

Most older buildings have single-pane windows. These are the least efficient type of windows, as they have only one thermal barrier. Double-pane and triple-pane windows are much more efficient than single-pane, because they include gases, such as argon, between the panes to slow the thermal flow through the window. ENERGY STAR certifies energy-efficient windows, and the ENERGY STAR label will be clear on the product if it is certified.

Once you’ve sealed leaks and strengthened the exterior envelope of your building, you can work on insulating exterior walls. When choosing insulation, pick a type with a high R-value. The R-value represents how resistant a material is to heat flow. A higher R-value means the insulation is more efficient.

Air leakage within a heating, ventilation, or cooling system can lead to higher energy bills. Air leakage often comes from unbalanced fan systems, in which fans in one part of the building exhaust air at a different rate than fans bring air into the building.

In searching for sources of inefficiency, look at the nameplates on your fans to see if the sizes of the inlet and outlet are the same. If they are not, replace fans with high-efficiency fans of the same size to balance the inlet and outlet, with an optimal air exchange of 1 air volume per minute. An HVAC professional can help with this project. Regular fan maintenance can also aid in the efficiency and balancing of air movement.

In addition to fans, look for outside air louvres and dampers that are broken, clogged, or misaligned. You can install automated louvres on vents, shutters, and dampers and bring cool nighttime air into your building during hot summer months. Additionally, natural ventilation in high tunnels and greenhouses can reduce the need to run ventilation fans.

Your farm could also include air-handling units, which provide air movement, air filtration, heating, cooling, and humidity control. To ensure your air-handling system is working efficiently, replace filters every three months, insulate and seal ducts, install programmable thermostats and time clocks, and insulate bare pipes.

You can work with a certified HVAC professional to ensure the system is properly sized for your building, optimize ventilation controls, and perform equipment tune-ups and maintenance. HVAC technicians can also assist with water-heater or boiler tune-ups. During the boiler tune-up, check the water temperature set points on your boiler or water heater. If they are too high, adjust accordingly. You can check your boiler set point without a tune-up, but regular tune-ups ensure the boiler is working properly and efficiently.

ENERGY STAR guidelines are available for evaluating the relative efficiency of HVAC equipment like boilers, fans, and air conditioners, as well as many other appliances. High-efficiency equipment achieves ENERGY STAR certification. Certified products and their manufacturers are listed on the ENERGY STAR website.

Motors and Pumps

Pumps, motors, fans, and aerators can use a lot of electricity. By upgrading and maintaining these pieces of equipment, you save energy and money while operating an efficient system.

You can also install high-efficiency pumps and motors, or rewind and rebuild older motors and pumps if premium-efficiency motors are too expensive. The example above illustrated that a 95% efficient motor would cost $48,057 to operate during one year. By contrast, here’s what an 80% efficienct motor would cost:

(255 HP) (.746 kw/HP)/.80 = 237.79 kilowatts

237.79 kW * 3,000 hours * $0.08/KWh = $57,069

That’s a difference of $9,012 per year.

Electronically commutated motors, also known as ECMs are more efficient because they have electronic controls and use less energy to run the motor. In air conditioning or refrigeration applications, there is less heat generation from the ECMs powering the fans, and this saves additional cooling energy.

f the load on a motor, pump, or fan is variable, you can also install a Variable Frequency Drive (VFD) to save energy. A VFD is an electronic device that controls the rotational speed of an AC motor by controlling the frequency of the electrical power supplied to the motor. A VFD can save up to 75% of energy use, depending on the variation of the load. It is important to note that if your pump, fan, or motor is operating continuously at the same load, a VFD will not save energy.

Figure 7. 400-watt bulb.

Lighting

Lighting is one of the easiest, most cost-effective ways to save energy. Beyond looking for energy savings, it is important to consider whether you’re happy with your current lighting levels and if a new fixture could alleviate your concerns.

First, determine what type of lights you have and the amount of energy they use. To determine how much energy your lights use, first determine the watts required to power the fixture. You can find this information on the bulb itself, as shown in Figure 7, or on the bulb packaging. Then determine the amount of time, in hours, the fixture is powered per year, in order to determine the kilowatt-hours per year. If your fixture has a ballast, don’t forget to add in the wattage used by the ballast.

To determine the light output of your bulb, look on the packaging or manufacturers’ website for the lumens produced by that particular bulb. Lumens are a measurement of the amount of light produced by a bulb. You can determine the efficacy of the light by dividing the wattage by the lumens. Efficacy is important in lighting because it shows how many lumens a light produces for each watt it uses. The greater the efficacy, the more efficient the bulb.

To save energy, pick a new bulb or fixture with a lower wattage than your current bulb or fixture. In an LED conversion, you can typically reduce wattage by 25% to 50% while retaining current light levels. If you need more light in an area, you should replace the current bulb with a bulb that produces more lumens. You can still reduce energy use and costs while increasing lumens, if you pick a bulb with higher efficacy. It is also a good idea to properly clean the fixture that harnesses the bulb.

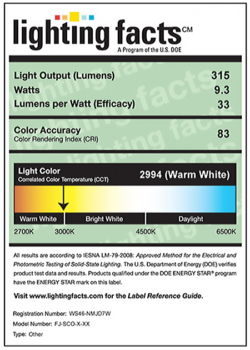

Figure 8. LED lightbulb label showing lumens, color temperature, efficacy, and certification. Photo: NCAT

Be sure to pay attention to color temperature and color rendering when you select your next lighting fixture. These considerations can make a great difference in comfort and light quality. The color rendering index, also called CRI, is a measure of how accurately the light reproduces the color of the objects it illuminates. The scale ranges from 0 to 100, with 100 being the best. The CRI of a bulb usually appears on the label of the bulb box or in the manufacturer’s cut-sheet materials. Most LED lights have high CRI values.

The color temperature of a bulb is given in degrees Kelvin. LED and fluorescent lamps are available in a range of color temperatures. Preferred color temperature can be a matter of personal preference, but most residential applications are close to the 2,700-degree value. Industrial and outdoor applications range from 4,000 to 5,000 degrees.

Figure 8 shows a typical label for an LED light bulb. The label lists the lumens that the bulb will produce, watts used by the bulb, efficacy, color rendering index, and color temperature. As explained, the wattage of the bulb indicates the power draw of the bulb, and the efficacy indicates how many lumens per watt the bulb produces. This is especially helpful when comparing bulbs. The higher the efficacy, the more energy-efficient the bulb is. Before changing out lighting in an entire area, test one bulb or a section of bulbs to make sure you are happy with the color temperature. The Design Lights Consortium can help you determine if a lighting product is certified, provide data on quality, and furnish a wealth of resources on effective, energy-efficient lighting.

Figure 9. Lighting retrofit to LEDs with improved color rendering, efficacy, and efficiency. Photos: NCAT

Figure 9 provides a side-by-side comparison of a lighting retrofit from high-pressure sodium fixtures to LEDs. In this retrofit, the LEDs use half of the energy and have a CRI of 95. The color temperature was 3,000k pre-retrofit and 4,000k after.

Summary

Energy conservation starts with understanding your energy use, how you are charged for your energy, and how your operations affect your energy bill. Once you’ve analyzed your energy bills, developed a list of energy-consuming equipment, consolidated operations and schedules, and installed timers, you can focus on sealing leaks and securing the airflow of your buildings. Once you are ready to analyze your operation’s equipment, prioritize the steps you’ll need to take to maximize energy efficiency by identifying high-energy usage equipment or activities, ease of each project, cost of each project, and impact to your operations. There are many simple ways to save energy in heating, ventilation, cooling, pumps, motors, and lighting, including maintaining and balancing your systems and ensuring the equipment is the right size and set point for your operations. Keep in mind that there are licensed professionals who can help you with HVAC, lighting, pumps, and motors, and they can help you install high-efficiency replacements when it is time to replace equipment. Organizations and agencies like Energy Star, Design Lights Consortium, and the Department of Energy provide helpful guides on equipment certification, efficiency, and efficacy.

Further Resources

Resources include searchable DLC Qualified Products Lists (QPLs) that help users find verified, high performing LED lighting, horticultural LEDs, and control systems that save energy.

Introduction to Energy Efficiency and Conservation on the Farm – Farm Energy

Farm Energy Extension’s Efficiency page has links to information and checklists on conserving energy in many areas of agricultural operations, including farm buildings, motors, water heating, refrigeration, greenhouses, livestock, irrigation, equipment and grain drying.

A list of certified products that will help optimize energy efficiency, including appliances, electronics, building products, and equipment.

On-Farm Energy Initiative, USDA Natural Resources Conservation Service

This program can help farmers with an energy audit on their farm and can help with voluntary energy efficiency improvements.

Practical Farm Energy Efficiency

By Stacie Peterson, NCAT Energy Program Director

Published May 2025

© NCAT

IP663

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development.