Tag Archive for: Farm to School

The Full Circle of Local Food Systems

By Maura Henn, NCAT Local Food Systems Specialist

What do…

Episode 368: Lessons from ‘The Principal Farmer’

In this episode of Voices from the Field, NCAT Gulf States Regional…

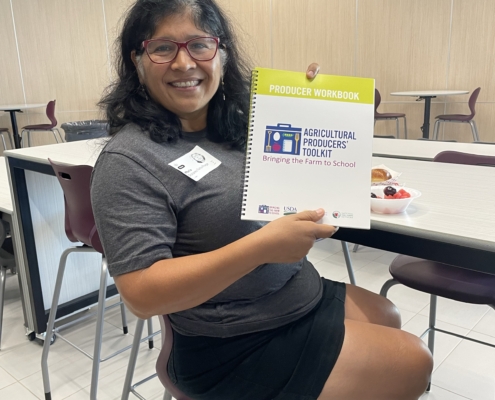

Bringing the Farm to School Through New Connections

By Tammy Howard, NCAT Senior Manager

With October being National…

Microgreens: Tiny Crops, Big Profits – A Nutritional Powerhouse for Farmers and Winter Menus

By Gabriella Soto-Velez, NCAT Agriculture Specialist

Tiny…

Episode 358. Abundant Montana “Meet Up” Meets with Success

In this episode of Voices from the Field, NCAT Local Foods Specialist…

NCAT

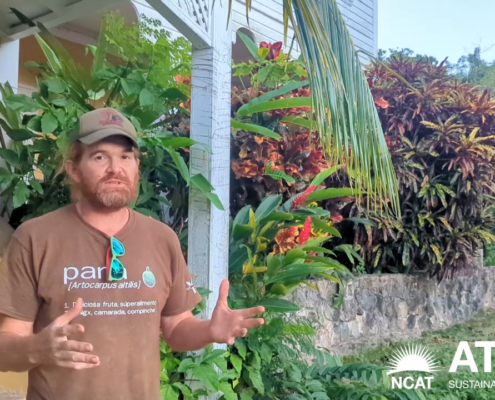

NCATEpisode 349. Farm to School with Ridge to Reef Farm on St. Croix, US Virgin Islands

In this episode of Voices from the Field, NCAT Sustainable Agriculture…

Market-Diversification Strategies with Ridge to Reef Farm on St. Croix, US Virgin Islands

In this video, Nate Olive, the owner of Ridge to Reef Farm on…

How Sweet It Is: South Texas Citrus Stays Home to Delight Local School Kids

By Robert Maggiani, NCAT Agriculture Specialist

It's National…

Montana-Grown Food to be Showcased at Farm to School Workshop in Gardiner

Montana-grown and raised foods will take center stage in Gardiner…

Tag Archive for: Farm to School

The Full Circle of Local Food Systems

By Maura Henn, NCAT Local Food Systems Specialist

What do…

Episode 368: Lessons from ‘The Principal Farmer’

In this episode of Voices from the Field, NCAT Gulf States Regional…

Bringing the Farm to School Through New Connections

By Tammy Howard, NCAT Senior Manager

With October being National…

Microgreens: Tiny Crops, Big Profits – A Nutritional Powerhouse for Farmers and Winter Menus

By Gabriella Soto-Velez, NCAT Agriculture Specialist

Tiny…

Episode 358. Abundant Montana “Meet Up” Meets with Success

In this episode of Voices from the Field, NCAT Local Foods Specialist…

NCAT

NCATEpisode 349. Farm to School with Ridge to Reef Farm on St. Croix, US Virgin Islands

In this episode of Voices from the Field, NCAT Sustainable Agriculture…

Market-Diversification Strategies with Ridge to Reef Farm on St. Croix, US Virgin Islands

In this video, Nate Olive, the owner of Ridge to Reef Farm on…

How Sweet It Is: South Texas Citrus Stays Home to Delight Local School Kids

By Robert Maggiani, NCAT Agriculture Specialist

It's National…

Montana-Grown Food to be Showcased at Farm to School Workshop in Gardiner

Montana-grown and raised foods will take center stage in Gardiner…