Standard Operating Procedures for a Profitable Farm Business

By Dan Birnstihl, NCAT Agriculture Specialist

Abstract

Standard Operating Procedures (SOPs) can help small farms increase profits by streamlining training of new employees and increasing consistency among farm tasks. This brief publication provides an overview of SOPs, including how to create and use one.

Introduction

A Standard Operating Procedure, or SOP, is a step-by-step instruction guide for tasks performed on the farm. Many farms experience high turnover of seasonal labor, and SOPs serve as a tool to help new employees learn new tasks quickly and correctly without the need for constant supervision. If SOPs are designed correctly, they help even the most untrained employee complete the task with no confusion. Having robust, well written, easily accessible, and properly located SOPs can make farm tasks and products more consistent by ensuring a uniform process among new and old employees.

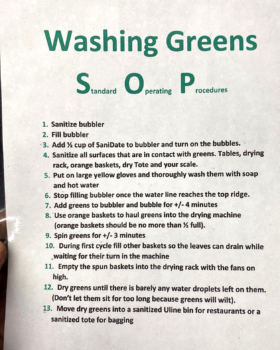

Sample SOP for washing greens. Image: NCAT

Which Tasks Require a SOP?

Almost any task on the farm that is performed regularly could benefit from a set of written instructions. A small vegetable farm could use one SOP for each crop, outlining each stage of the crop’s lifespan, from seeding to sale. You also may want SOPs for when and how to clean facilities like wash-pack rooms, nurseries, or delivery vans; how to perform farm tasks like preparing fields or raised beds, or cleaning and sanitizing reusable storage and harvest totes; or how to perform marketing tasks like taking orders, handling deliveries, or restocking supplies.

Creating an SOP

The first step in creating an SOP is to outline what information is important for your staff to know. For example, on a small vegetable farm, the farmer may want SOPs for each crop grown on the farm. Each crop’s SOP should outline which cultivars are used, proper spacing when planting, fertilization and irrigation requirements, equipment needed, the timing and theory of growing that crop, weed-management and pest-protection strategies, and step-by-step instructions for planting, harvesting, conditioning, and storing the crop. The following template uses radish microgreens as an example SOP.

Once the rough draft of an SOP is created, try performing the task using only the steps outlined in the SOP. If any steps are missing or unclear, amend the document. Once you feel the instructions are complete, have an employee attempt the same process, and then revise the SOP again, if necessary. When the final draft is completed, an untrained individual should be able to successfully perform the task from beginning to end using only the information contained within the SOP.

While SOPs do not need to be fancy, they should have a consistent organization and format, so that it is easy for employees to quickly find the information they need. If you have employees on your farm who don’t speak English as their primary language, consider asking them to help you translate the SOPs into their language so that you can maintain SOP manuals for multiple languages.

Using an SOP

Master SOP manuals should be printed and kept in high-traffic areas, such as employee break rooms, tool sheds, offices, processing facilities, company vehicles, or other places that employees frequently use. Extra SOP binders should be kept on hand so that whenever employees are performing tasks, they can have a copy of the SOP with them and open to the page of the task they are performing. Ensure that employees are referencing these SOPs while performing tasks.

For SOPs performed in a particular area, such as a nursery or pack house, it can be helpful to print the relevant SOPs and hang them in visible areas, in addition to keeping them in the SOP master manual.

As a farm owner or manager, it is important to set a good example and show the newer employees that even seasoned veterans still utilize the SOPs to ensure that no steps are being unintentionally skipped.

Conclusion

SOPs have been adopted by most large companies, as well as the U.S. military, to ensure that consistent work is being performed by employees of all backgrounds and skill levels. They can aid in reducing confusion among employees, ensuring uniformity in the company’s product, and in protecting business owners by showing external investigators that there are systems in place to ensure that employees are performing tasks in accordance with regulation. For farms of any size, it is especially important to take advantage of these tools to ensure that food is grown safely, efficiently, and profitably.

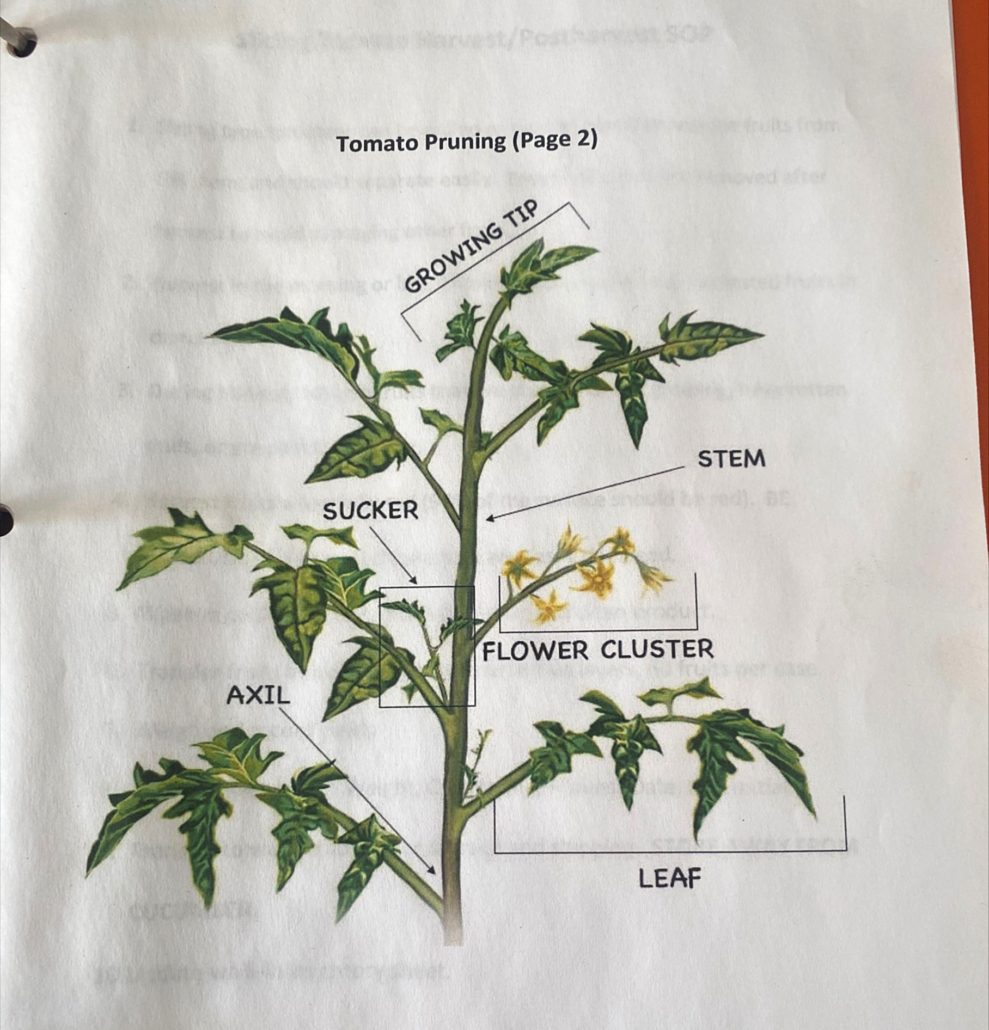

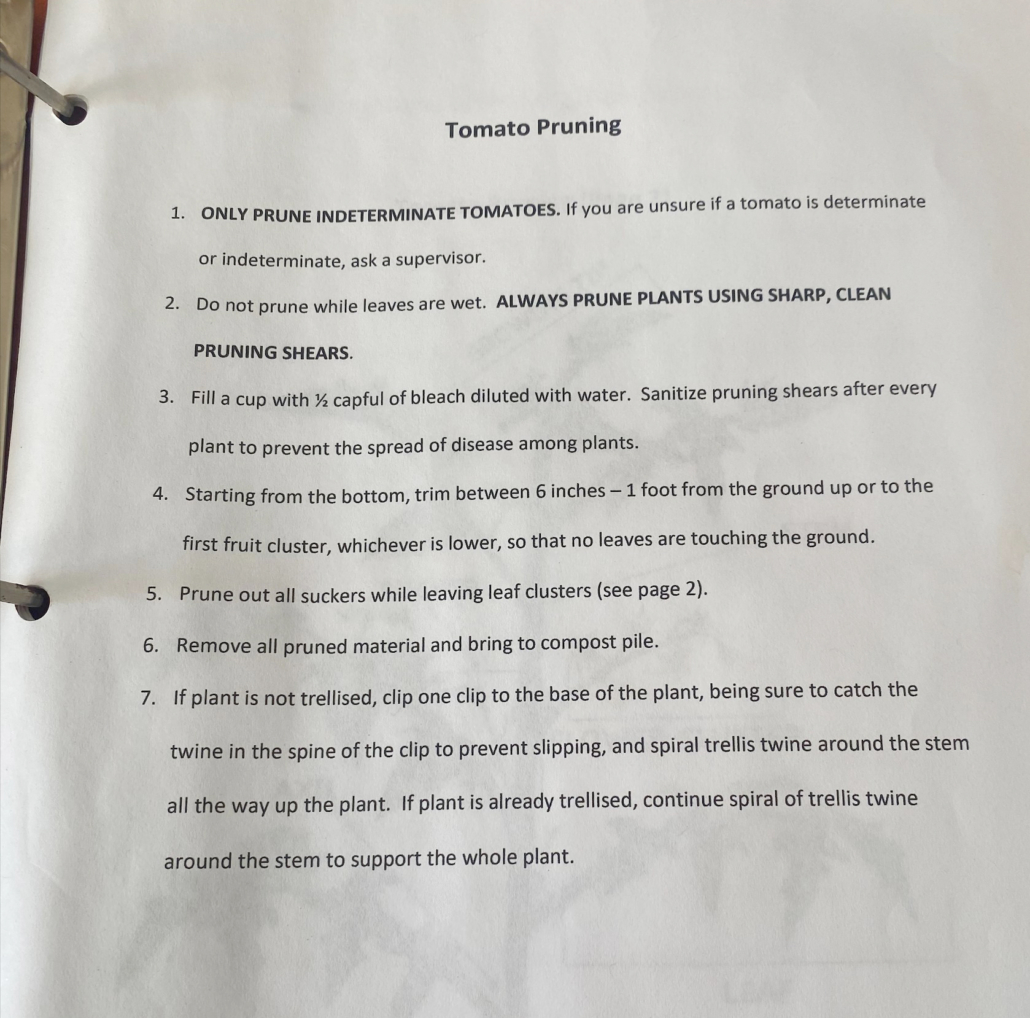

Sample SOP for tomato pruning. Images: Hip Peas Farm

Case Study: Hip Peas Farm

Hip Peas Farm is a small-scale vegetable farm in peri-urban New Hampshire. The farm employs two full-time employees, as well as four to 10 part-time employees during the main growing season. They use a quarter-acre of greenhouse space to supply farmers markets, restaurants, and a 30-member CSA, while also managing an event venue on site.

Use of SOPs

Like many farmers, Hip Peas Farm sees a high turnover of their seasonal employees each year. As a result, they use SOPs to help their team members keep consistent practices on the farm. “Using SOPs has saved time, reduced confusion, and reduced food waste,” says Jacob Midura, the farm’s manager. “Many employees will be unsure of how to perform their tasks but having an SOP available will help guide them and answer most of their questions.” SOPs have helped employees with specific tasks, such as proper cleaning and sanitization of their wash area, while also increasing shelf life of harvested crops, reducing the training time to teach employees how to prune and trellis specific crops, and increasing uniformity among tasks. Midura says SOPs help make the farm employees perform their work in an efficient way that maintains consistency among products.

Standard Operating Procedures for a Profitable Farm Business

By Dan Birnstihl, NCAT Agriculture Specialist

Published August 2022

© NCAT

IP628

Slot 666

Version 083022

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development.