Vertical Farming

Interior view of Freight Farms’ shipping-container vertical farm. Photo: Freight Farms

By Jeff Birkby, NCAT Smart Growth Specialist, and Gabriella Soto-Velez, NCAT Agriculture Specialist

Introduction: What Is Vertical Farming?

Prime agricultural land can be scarce and expensive. With worldwide population growth, the demand for both more food and more land to grow food is ever increasing. But some entrepreneurs and farmers are beginning to look up, not out, for space to grow more food.

One solution to our need for more space might be found in the abandoned warehouses in our cities, new buildings built on environmentally damaged lands, and even in used shipping containers from ocean transport. This solution, called vertical farming, involves growing crops in controlled indoor environments, with precise light, nutrients, and temperatures. In vertical farming, growing plants are stacked in layers that may reach several stories tall (Despommier, 2011).

The inception of the contemporary vertical farming concept can be traced back to the visionary idea proposed by Columbia University professor Dickinson Despommier. Collaborating with a group of students, his team conceptualized a groundbreaking skyscraper farm designed to sustainably produce enough food to feed 50,000 people. Since this pioneering initiative, the vertical farming industry has experienced exponential growth and is expected to reach 18.9 billion dollars in the United Sates by 2028 (Martinez, 2023).

By 2022, the landscape had transformed, witnessing the emergence of approximately 2,000 vertical farms across the United States. Among the industry leaders spearheading the charge in mechanized indoor vertical farming are notable entities such as Plenty, Bowery Farms, and AeroFarms. These innovative ventures represent a paradigm shift in agricultural practices, harnessing advanced technologies to maximize efficiency and sustainability in food production (Rogers, 2024).

Types of Vertical Farms

Vertical farms come in different shapes and sizes, from simple two-level or wall-mounted systems to large warehouses several stories tall. But all vertical farms use one of three soil-free systems for providing nutrients to plants—hydroponic, aeroponic, or aquaponic. The following information describes these three growing systems:

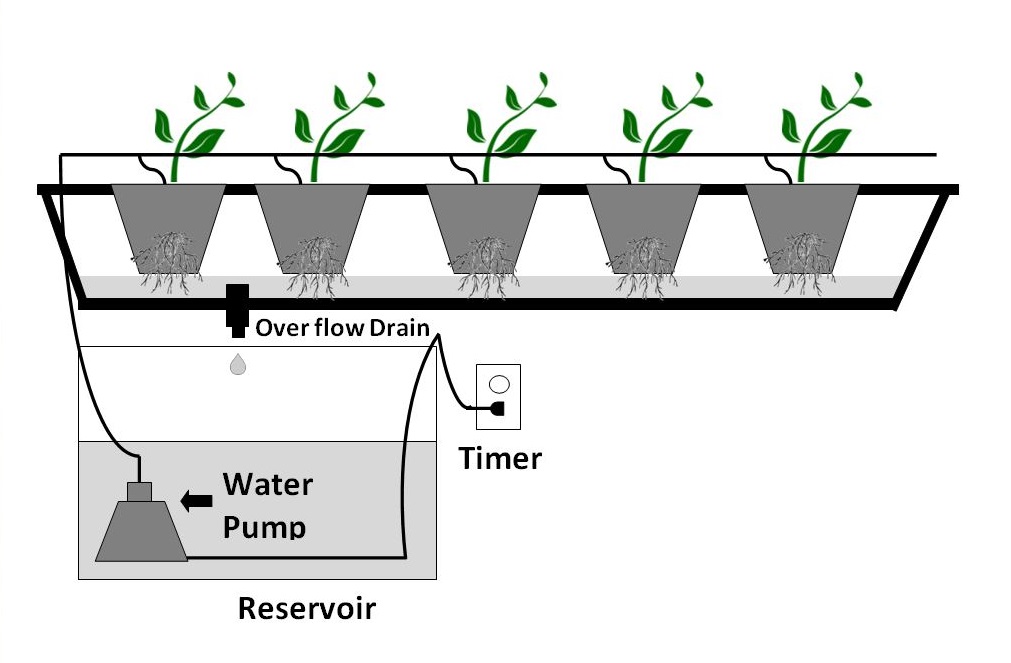

Hydroponic graphic. Illustration: NCAT

1. Hydroponics. The prevailing cultivation method employed in vertical farms is hydroponics, a soil-less technique that involves growing plants in nutrient solutions. In this system, plant roots are immersed in a carefully monitored nutrient solution, ensuring precise chemical composition. Different types of hydroponic systems include ebb and flow, where nutrient solution periodically floods and drains the root zone, and nutrient film technique (NFT), where a thin film of nutrient solution continuously flows over the roots. To enhance stability and mitigate potential system malfunctions, plants may also be embedded in a growth medium, such as coconut coir, maintaining root moisture and facilitating nutrient access (Rajaseger et al., 2023).

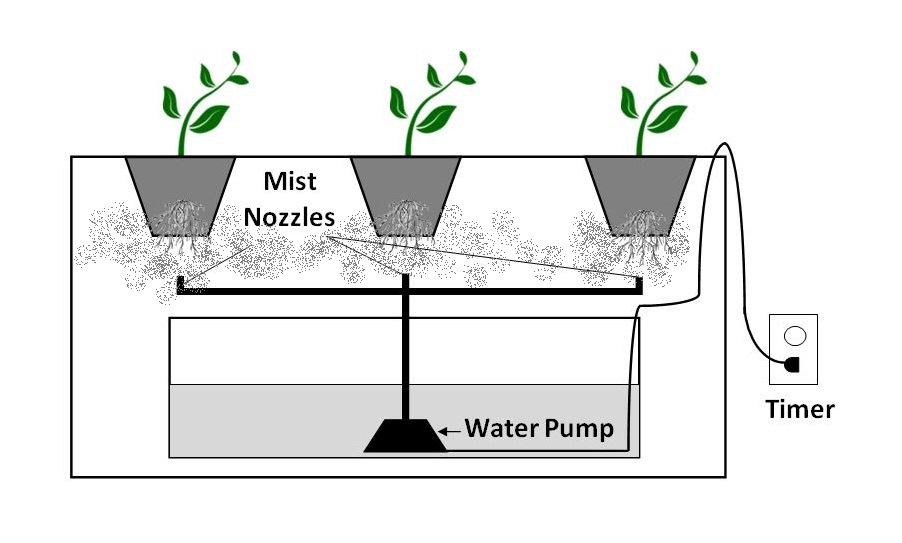

Aeroponic graphic. Illustration: NCAT

2. Aeroponics. The National Aeronautical and Space Administration (NASA) is responsible for developing this innovative indoor growing technique. In the 1990s, NASA was interested in finding efficient ways to grow plants in space and coined the term aeroponics, defined as “growing plants in an air/mist environment with no soil and very little water.”

Aeroponics systems, once an anomaly in the vertical farming world, are now gaining significant traction. Companies like AeroFarms are leading the way, demonstrating the efficiency and scalability of aeroponic systems. These systems are among the most efficient for vertical farms, using as much as 95% less water than even the most efficient hydroponic systems. Additionally, plants grown in aeroponic systems have been shown to uptake more minerals and vitamins, making them healthier and potentially more nutritious, thus attracting increasing interest and investment in the sector (Gurley, 2020)

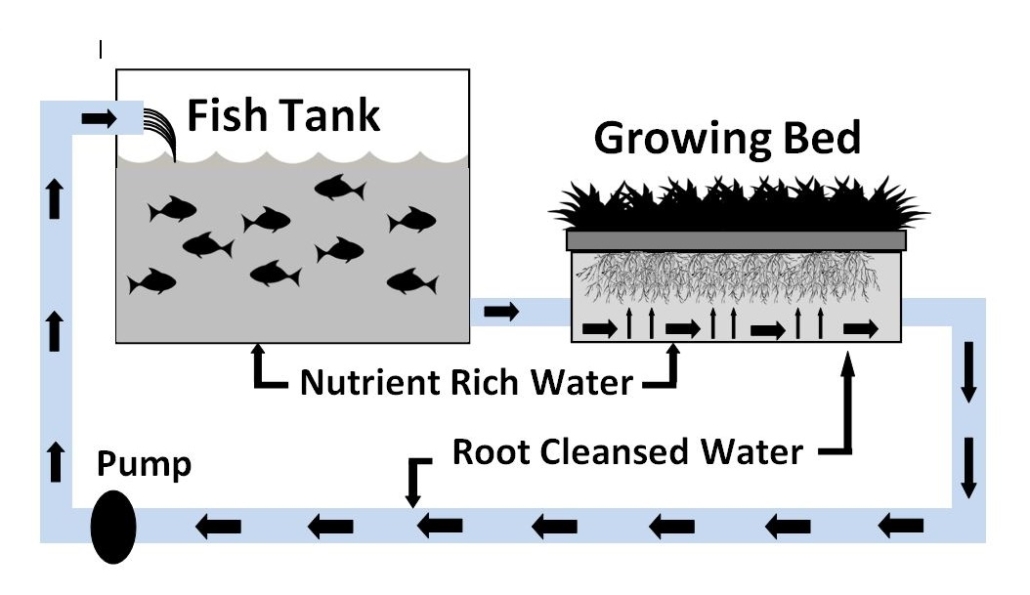

Aquaponic graphic. Illustration: NCAT

3. Aquaponics. An aquaponic system takes the hydroponic system one step further, combining plants and fish in the same ecosystem. Fish are grown in indoor ponds, producing nutrient-rich waste that is used as a feed source for the vertical farm plants. The plants, in turn, filter and purify the wastewater, which is recycled back to the fishponds (Khandacker and Kotzen, 2018).

Arkansas Agricultural Experiment Station and 80 Acre Farms. Photo: Wikimedia Commons

The largest aquaponics farm in the United States, Wisconsin-based Superior Fresh, uses 1.1 tons of fish feed to produce 1 ton of fish and 10 tons of leafy greens and vegetables in a 3-acre greenhouse (Fletcher, 2019).

Vertical farming systems can be further classified by the type of structure that houses the system.

Building-based vertical farms are often housed in abandoned buildings in cities, such as Virgina-based vertical farm Area 2, an old paper factory where they grow root vegetables, leafy greens, and herbs for the surrounding community.

Shipping-container vertical farms are an increasingly popular option. These vertical farms use 40-foot shipping containers, normally in service carrying goods around the world. Shipping containers are being refurbished by several companies into self-contained vertical farms, complete with LED lights, drip irrigation systems, and vertically stacked shelves for starting and growing a variety of plants. These self-contained units have computer-controlled growth-management systems that allow users to monitor all systems remotely from a smart phone or computer. Three of the leading companies producing shipping-container vertical farms are Freight Farms, CropBox, and Growtainers.

Urban vertical farm “RusEco.” Photo: S. Sobyanin; Wikimedia Commons

Pros and Cons of Vertical Farms

Dickson Despommier, in his book The Vertical Farm: Feeding the World in the 21st Century, listed a number of environmental and social benefits of vertical farming. The following is an adaptation of Despommier’s major points:

- Continuous Crop Production. Vertical farming technology can ensure crop production year-round in non-tropical regions. Production is much more efficient than land-based farming. According to Despommier, a single indoor acre of a vertical farm may produce yield equivalent to more than 30 acres of farmland, when the number of crops produced per season is considered.

- Elimination of Herbicides and Pesticides. The controlled growing conditions in a vertical farm allow a reduction or total abandonment of the use of chemical pesticides. Some vertical farming operations use ladybugs and other biological controls when needed to deal with pest infestations.

- Protection from Weather-Related Variations in Crop Production. Because crops in a vertical farm are grown under a controlled environment, they are safe from extreme weather occurrences such as droughts, hail, floods, and even hurricanes.

- Water Conservation and Recycling. Hydroponic growing techniques used in vertical farms use about 70% to 95% less water than normal agriculture.

- Climate Friendly. Growing crops indoors reduces or eliminates the use of tractors and other large farm equipment commonly used on outdoor farms, thus reducing the burning of fossil fuel. According to Despommier, deploying vertical farms on a large scale could result in a significant reduction in air pollution and in CO2 emissions. Furthermore, carbon emissions might be reduced because crops from a vertical farm are usually shipped just a few blocks from the production facility, instead of being trucked or shipped hundreds or thousands of miles from a conventional farm to a market.

- People Friendly. Conventional farming is one of the most hazardous occupations in the United States. Some common occupational hazards that are avoided in vertical farming are accidents in operating large and dangerous farming equipment and exposure to poisonous chemicals (Despommier, 2011).

Despite these perceived advantages of vertical farms, some agricultural experts are skeptical that the costs and benefits will pencil out. Some think that expensive urban real estate in many cities may rule out vertical farms (although using abandoned warehouses or environmentally contaminated sites may help the economics). And the high electricity usage to run lighting and heating/cooling in a vertical farm impacts the economics. Following is a summary of the perceived disadvantages of vertical farming:

- Land and Building Costs. Urban locations for vertical farms can be quite expensive. Some existing vertical farms are based in abandoned warehouses, derelict areas, or Superfund sites, which can be more economical for construction.

- Energy Use. Although transportation costs may be significantly less than in conventional agriculture, the energy consumption for artificial lighting and climate control in a vertical farm can add significantly to operations costs. A 2021 report by the Global CEA Census highlights that while greenhouses use roughly 5.4 kWh per kilogram of produce produced, indoor vertical farming uses 38.8 kWh per kilogram of produce produced. While there are LEDs being developed that can reduce energy consumption and in sunnier climates solar can be used, the debate is still ongoing as to the true ecological impact of vertical farming in comparison to traditional farming (Tahir, 2024).

- Limited Number of Crop Species. In hydroponic systems, leafy greens such as lettuce, spinach, and kale are the most popular crops due to their short life cycles and relatively low nutrient needs. These characteristics make them well-suited for the controlled environment of hydroponic farming, allowing for quicker harvests and efficient use of resources. Conversely, crops with longer life cycles and more complex nutrient requirements, such as tomatoes and cucumbers, are less preferred as they demand more intensive management and resources. This makes leafy greens the optimal choice for maximizing productivity and profitability in hydroponic systems (Stanghellini and Katzin, 2024).

- Pollination Needs. Crops requiring insect pollination are at a disadvantage in a vertical farm since insects are usually excluded from the growing environment. Plants requiring pollination may need to be pollinated by hand, requiring staff time and labor. However, in 2017, the Italian startup BuzzUp developed an AI and algorithm-monitored precision pollination system using honeybees and bumbles bees to achieve optimal pollination within indoor farming, which can help diversify the crop species grown and has shown to achieve yields 20% higher than those of non-monitored pollinators (Despommier, 2013).

What about lighting costs?

Highly efficient light-emitting diodes (LEDs) are used in most vertical farms, with special bulbs that use only the red and blue light spectra, the most beneficial for optimizing plant growth. Eliminating the production of other light waves helps reduce energy costs by as much as 15%. However, the total electric bill (and carbon footprint) of a self-contained vertical greenhouse can still be substantial. Recent advancements include tunable LEDs, which adjust light spectra based on the plant growth stage, further improving efficiency and reducing costs. Continued research and development of even more efficient LEDs will help reduce the costs and carbon pollution contribution of LED lighting in vertical farming operations (Katzin et al., 2021).

Large banks of fluorescent lamps provide the spectrum of light that keeps the floating beds of plants alive year-round in The Plant Chicago, a vertical farming facility. Source: Peter Gray/Harvest Public Media

Can Vertical Farms Be Certified Organic?

Farmers value the USDA Certified Organic label, and consumers often pay a premium for certified organic products. The USDA National Organic Program (NOP), under 7 CFR Part 205, sets national standards with guidance from the National Organic Standards Board (OSB). In 2017, NOP regulations were updated to allow hydroponic systems to be certified organic if they use organic inputs, such as organic seeds, natural nutrient sources, and approved pest-control substances, and meet criteria for maintaining natural resources and ecological balance. In 2022, the Ninth Circuit Court of Appeals upheld a ruling allowing hydroponic produce to be sold as organic, continuing the debate over the application of the Organic Foods Production Act (OFPA) to hydroponics. For more information, visit the NOP website or contact accredited certifying agents listed by the USDA.

Farmers value the USDA Certified Organic label, and consumers often pay a premium for certified organic products. The USDA National Organic Program (NOP), under 7 CFR Part 205, sets national standards with guidance from the National Organic Standards Board (OSB). In 2017, NOP regulations were updated to allow hydroponic systems to be certified organic if they use organic inputs, such as organic seeds, natural nutrient sources, and approved pest-control substances, and meet criteria for maintaining natural resources and ecological balance. In 2022, the Ninth Circuit Court of Appeals upheld a ruling allowing hydroponic produce to be sold as organic, continuing the debate over the application of the Organic Foods Production Act (OFPA) to hydroponics. For more information, visit the NOP website or contact accredited certifying agents listed by the USDA.

Although organic certification for hydroponic and aquaponic systems is now permitted under NOP regulations, provided they meet criteria for using organic inputs and maintaining ecological balance, the debate remains intense. Critics argue that true organic farming necessitates soil and biological activity, contending that soil-less systems cannot embody the holistic principles of organic agriculture. This controversy has led to ongoing efforts by some groups to reverse the approval of organic certification for hydroponics, highlighting the persistent division within the organic farming community (NOSB, 2010).

Funding for Vertical Farms

Obtaining startup funding for any farming venture is difficult. This is especially true for farmers and entrepreneurs establishing commercial vertical farming operations. However, both public and private financing sources have funded vertical farms in the past few years and, as the technology matures, more investment in this sector is likely. A well-written business plan, including capital costs, marketing approaches, staffing, and customer base is essential to have on hand before seeking funding.

Federal and state loan and grant programs, typically available to traditional and sustainable agriculture projects, can also be tapped for vertical farm projects. The USDA lists several grants and funding opportunities that could be suitable for indoor vertical farming:

- USDA Agricultural Marketing Service (AMS). The AMS administers programs that support local and regional food systems, which could include vertical farming initiatives. Grants such as the Farmers Market Promotion Program (FMPP) and the Local Food Promotion Program (LFPP) aim to strengthen market opportunities for local producers.

- USDA Rural Development Programs. USDA Rural Development provides various grant and loan programs to support economic development in rural areas. Vertical farming projects in rural regions may be eligible for assistance through programs like the Value-Added Producer Grant (VAPG) or the Rural Energy for America Program (REAP).

- USDA National Institute of Food and Agriculture (NIFA). NIFA supports research, education, and extension activities in agriculture. Funding opportunities may be available through NIFA’s various grant programs, such as the Sustainable Agriculture Research and Education (SARE) program, which promotes sustainable farming practices.

- USDA’s Urban Agriculture and Innovation Production (UAIP). UAIP competitive grants initiate or expand efforts of farmers, gardeners, citizens, government officials, schools, and other stakeholders in urban areas and suburbs. Projects may target areas of food access, education, business and start-up costs for new farmers, and development of policies related to zoning and other needs of urban production.

- USDA Specialty Crop Block Grant Program. Vertical farms specializing in high-value crops like herbs, microgreens, or specialty greens may find support through the Specialty Crop Block Grant Program, which aims to enhance the competitiveness of specialty crops in the marketplace.

- Urban, Indoor, and Other Emerging Agricultural Production Research, Education, and Extension Initiative (UIE). UIE is a NIFA competitive grant program implemented in 2022 to support research, education, and extension activities that facilitate development of urban, indoor, and other emerging agricultural production systems.

Conclusion

The evolution of vertical farming from a novel concept to a thriving phenomenon is evident in the increasing number of vertical farms across the United States and beyond. Unlike its early focus on salad greens, contemporary vertical farms now diversify their crop offerings, catering to local communities and high-end specialty food shops. This global movement proves particularly beneficial in regions prone to hurricanes and grappling with water scarcity, owing to its inherent advantages of space efficiency and reduced water usage.

Looking ahead, vertical farms are anticipated to prioritize high-return and short-rotation crops, aligning with consumer preferences for fresh, locally sourced produce. The active involvement of local communities and specialty food shops plays a crucial role in sustaining these innovative agricultural systems, contributing to their economic viability. Despite challenges in electricity consumption, vertical farming has responded with innovative solutions such as the adoption of highly efficient LED lighting systems and holistic energy management practices.

Notably, the industry has invested in strategies like building insulation, advanced HVAC systems, and solar energy integration to mitigate electricity costs, reducing both ecological footprints and enhancing economic viability. The future of vertical farming appears promising, characterized by a commitment to sustainability, economic efficiency, and resilience in the face of environmental challenges. Urban planners and sustainable agriculture advocates closely monitor these advancements, recognizing the industry’s potential to inspire global agricultural transformation towards a more sustainable and productive future.

Vertical Farms in the United States

As of December 2023, there are hundreds of vertical farms in the United States. Here is an adaptive list of some of the farms listed in this article, as well as other noteworthy U.S. vertical farms.

AeroFarms

Newark, New Jersey

Vertical farming system based on aeroponics. Developing the world’s largest vertical farm (69,000 square feet).

Bowery Farms Inc.

New York, New York

Vertical farming and digital agriculture firm with operational farms in New Jersey, Maryland, and Pennsylvania. Specializing in the cultivation and delivery of pesticide-free lettuce, leafy greens, and herbs.

Dream Harvest

Houston, Texas

Indoor vertical farm growing a variety of leafy greens.

Plenty

Compton, California

Plenty is currently building the world’s most advanced indoor vertical farm providing high-end grocers with year-round, pesticide-free greens.

Area 2 Farms

Arlington, Virginia

A vertical farm that has repurposed an old paper-processing factory and warehouse to grow greens and other vegetables using advanced precision agriculture techniques.

Vertical Harvest

Jackson Hole, Wyoming

A three-story rotating carousel vertical farm attached to a parking garage.

FarmBox Foods

Castle Rock, Colorado

A shipping container vertical farm growing leafy greens. In 2020, they launched a specialty gourmet mushroom container farm.

References

Despommier, Dickson. 2013. Farming up the City: The Rise of Urban Vertical Farms. Trends in Biotechnology. Vol. 31, No. 7. p. 388-389.

Despommier, Dickson. 2011. The Vertical Farm: Feeding the World in the 21st Century. Picador Publishing, New York, NY.

Fletcher, Rob. 2019. Notes from ‘the World’s Largest’ Aquaponics System. The Fish Site. March 20.

Giles, Frank. 2020. Cutting-Edge Agriculture Reaching New Heights in Florida. Growing Produce. April 6.

Gurley, Thomas W. 2020. Aeroponics: Growing Vertical. CRC Press.

Kabir, Md Shaha Nur, Md Nasim Reza, Milon Chordhury, Mohammod Ali Samsuzzaman, Md Razob Ali, Ka Young Lee, and Sun-Ok Chung. 2023. Technological Trends and Engineering Issues on Vertical Farms: A Review. Horticulturae. Vol. 9, No. 11. p. 1229.

Katzin, David, Leo FM Marcelis, and Simon van Mourik. 2021. Energy savings in greenhouses by transition from high-pressure sodium to LED lighting. Applied Energy. January. 281: 116019.

Khandaker, Mohammed and Benz Kotzen. 2018. The Potential for Combining Living Wall and Vertical Farming Systems with Aquaponics with Special Emphasis on Substrates. January. Vol. 49, No. 4. p. 1454-1468.

Kluko, Daniel. How to Get Started in Vertical Farming and Urban Agriculture – the Next Big Thing for Cities. 2018. Sustainable Cities Collective. May 18.

Martinez, Michael. 2023. Vertical Farming: A Bottom-Up Approach. Seattle Journal of Technology, Environmental, and Innovation Law. Vol. 13. p. 1.

National Organic Standards Board (NOSB). 2010. Production Standards for Terrestrial Plants in Containers and Enclosures: Formal Recommendation by the National Organic Standards Board (NOSB) to the National Organic Program (NOP). April 29.

Rajaseger, Ganapathy, Kit Lun Chan, Kay Yee Tan, Shan Ramasamy, Mar Cho Khin, Anburaj Amaladoss, Patel Kadamb Haribhai. 2023. Hydroponics: Current Trends in Sustainable Crop Production. Bioinformation. September 30. Vol. 19, No. 9. p. 925.

Rogers, Jack. Vertical Farming Industry to Grow 25% Annually Through 2030. 2024. Globest. February 1.

Stanghellini, Cecilia and David Katzin. 2024. The Dark Side of Lighting: A Critical Analysis of Vertical Farms’ Environmental Impact. Journal of Cleaner Production. June 15. Vol 458. p. 142359.

Tahir, Faheem. 2024. The Biggest Vertical Farming Company. Yahoo Finance. June 30.

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development. This publication was also made possible in part by funding from the USDA NIFA’s Agriculture and Food Research Grant #2012-68006-30177. ATTRA.NCAT.ORG.

![]()