Returns on Renewable Energy Investments

Interest in renewable energy is running high. Photo: Mike Morris, NCAT

By Mike Morris and Leif Kindberg, NCAT Energy Specialists

Abstract

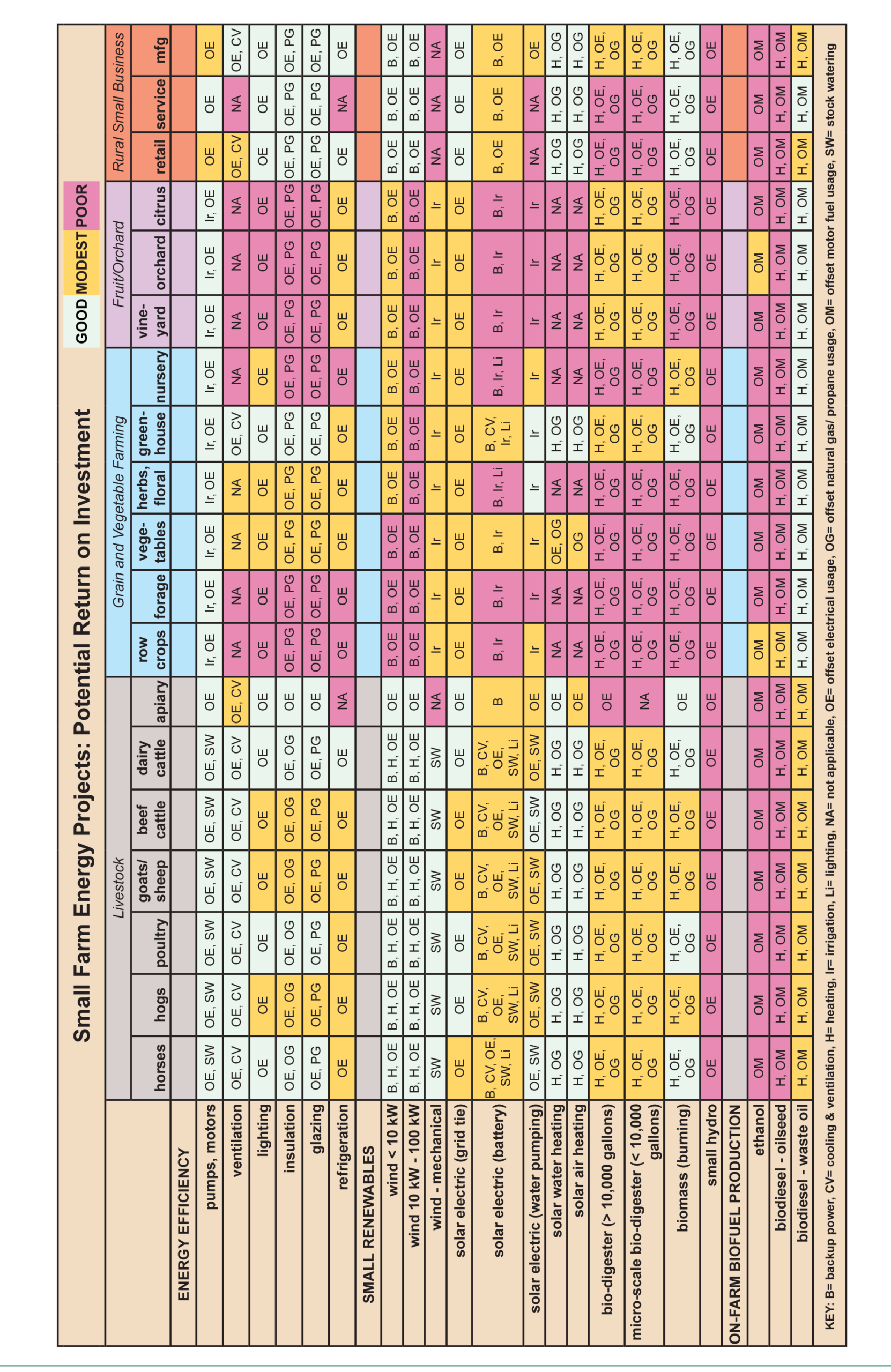

This publication surveys the costs and risks of investing in wind, solar, biofuel, and other small-scale renewable energy systems. Most small-scale renewable energy projects do not generate cheap energy, and these projects often involve significant complications and risks. Nonetheless, there are many good reasons for farmers to consider a small-scale renewable energy system. Small-scale renewable energy projects can be excellent investments for farms and rural businesses, especially those that are looking for new management options or marketing possibilities.

Contents

Introduction

It’s Not (Usually) About Cheap Energy

Five Reasons to Consider a Small-Scale Renewable energy Project

Ballpark Economics and Risks

Conclusion

Small Farm-Energy Projects: Potential Return on Investment

References

Further Resources

Introduction

This publication surveys the costs and risks of investing in small-scale renewable energy systems. If your goal is simply to reduce your power bills or to find the cheapest possible source of energy, most small-scale renewable energy projects will not meet your expectations. But if you are open to other possibilities—such as new management options or enhancing the public image of your business—you may find that a renewable energy project not only makes economic sense but is also deeply satisfying.

This publication was written with agricultural producers in mind, although much of the advice would be equally helpful to a rural landowner or small-business owner. We focus on small-scale projects and a few common renewable energy technologies. We don’t address wind farms, growing bioenergy crops, industrial-scale biofuel production, or other large-scale renewable energy projects.

The authors are advocates for small-scale renewable energy. It concerns us (to say the least) when we hear stories about misleading sales tactics, premature equipment failures, and disappointed customers. We’ve tried to think of a few essential pieces of advice that consumers should know. We’ve also included dollar numbers throughout to give you an idea of what these systems actually cost. If you decide to go down the renewable energy path, we sincerely hope you go in with your eyes wide open and your experience is a happy one.

It’s Not (Usually) About Cheap Energy

Many people assume that wind, solar, biofuel, and other renewable energy technologies make it possible to get cheap, or even free, energy. The truth is that most small-scale renewable energy systems do not generate cheap energy. This point is so important and so widely misunderstood that we will discuss it at length below, taking a realistic look at how some of these projects really “pencil out.”

The reality is that most small-scale renewable energy systems do not generate cheap energy.

Three Factors that Make It Tough to Beat Conventional Energy Prices

One common way to look at the economics of a renewable energy project is to ask whether it will generate cheaper energy over its lifetime than other available sources—such as the local electric utility or the gas station down the street. When you take this approach, there are three factors that tend to make small-scale renewable energy cost more than conventional energy:

Economies of Scale. As everyone knows, large-scale energy-production facilities (such as coal-burning power plants) can drive down tremendously their cost per unit of energy produced. It’s true that wind farms and other large-scale renewable energy projects can compete extremely well with conventional energy sources. But the cost per unit of energy from small-scale renewable energy projects is typically much higher.

Mature Versus Immature Technologies. Across the board, most small-scale uses of renewable energy are still, to some extent, “immature,” meaning that we haven’t figured out the most efficient ways of doing things—or at least the methods aren’t widely known. While the designs and operations of large wind farms and industrial ethanol plants have been honed to fairly precise sciences, small-scale energy producers often need to fabricate pieces of equipment or work out solutions to unique challenges in their own situations.

Subsidies. Direct and indirect subsidies for conventional fuels (such as petroleum, coal, and nuclear fuels) reduce the retail price that the consumer sees. Yes, there are subsidies for renewable energy too. But only a few of these are realistically available to small-scale renewable energy producers.

Most small wind turbines are not going to deliver cheaper electricity than the utility. Photo: National Renewable Energy Laboratory

How the Time Value of Money Also Works Against You

A fourth factor that tends to work against small-scale renewable energy projects, the time value of money, is most easily explained with an example.

Suppose your utility charges you 12 cents per kilowatt hour for electricity (the approximate average U.S. retail price in 2011). You are considering a $15,000 solar electric system that is estimated to generate 6,000 kilowatt hours per year over an expected lifespan of 30 years. During those 30 years, this system would generate 180,000 kilowatt hours. By dividing the installed cost of the system ($15,000) by the total energy produced (180,000 kilowatt hours), you might reach the conclusion that you can generate electricity for 8.3 cents per kilowatt hour, beating the utility’s price of 12 cents per kilowatt hour.

You could also calculate a simple payback for this investment—dividing the capital cost by the value of the energy generated annually. Your $15,000 system generates $720 worth of electricity per year (6,000 kilowatt hours at 12 cents per kilowatt hour), so it has a simple payback of about 21 years.

While it might seem like a good idea to generate your own electricity at 8.3 cents per kilowatt hour, it’s not such a bargain if you realize that you are paying up front for 180,000 kilowatt-hours of electricity. This points to a big limitation of simple payback calculations: they make no allowance for what economists call the time value of money—basically the idea that it’s better to have money available to you now than in the future.

If a 3% rate of interest is available, an economist would say that 100 dollars paid now and 103 dollars paid a year from now have the same value to an investor. Being paid 100 dollars a year from now has a present value of only $97.09 because $97.09 will grow (at 3% interest) to $100 in one year. So that $100 payment expected one year from now should be multiplied by .9709 (a discount factor) to calculate its present value.

Discount factors have a big impact on cash-flow analysis. In our example above, a $15,000 solar electric system that generates $720 per year worth of electricity would take 32 years to pay for itself if we assume a discount factor of .9709 based on an interest rate of just 3% per year. This is much higher than the 21-year simple payback period, and would exceed the expected 30-year lifespan of the equipment.

The time value of money works relentlessly against small-scale renewable energy investments because most of these projects require a substantial up-front cost and deliver their returns in the form of small amounts of energy over long periods of time. As a result, many renewable energy projects are unimpressive from a purely financial point of view even if they generate much cheaper energy than you can buy from the utility.

Some Terminology for Talking about Energy Paybacks

Installed cost. The sum of a product’s purchase price and installation cost.

Life-cycle cost. The total of all costs to the owner over a product’s full lifespan, including the purchase price, installation cost, operating costs, and maintenance costs. It also takes into account any residual or salvage value at the end of ownership or the product’s useful life.

Simple payback. Usually calculated for energy-related products and measures by dividing the installed cost by the value of the energy saved or produced annually. Simple payback calculations give a rough approximation of how long it takes to recover your initial investment but do not factor in the time value of money.

Net present value. The present value of future cash flows minus the purchase price.

Net present cost. A sophisticated measure of a project’s costs—including both the installed cost and such future costs as financing, maintenance, and tax impacts—all discounted to reflect the time value of money.

Net present benefit. A sophisticated measure of the value of a project’s future benefits—such as reduced power bills and tax credits—all discounted to reflect the time value of money.

Internal rate of return. A sophisticated measure of the rate of growth that an investment is expected to generate. It is defined as the interest rate at which the net present value of costs (negative cash flows) of an investment equals the net present value of the benefits (positive cash flows) of the investment. A project with an internal rate of return of 5% has the same value to an investor—considering the size and timing of all of its future cash flows—as putting the money into the bank and receiving a 5% interest rate.

Break-even cost. Basically the purchase price at which a product completely “pays for itself” through the revenue that it generates, with all cash flows discounted to reflect the time value of money. The break-even cost of photovoltaic (PV) systems has been defined as “the point at which the net present cost of the PV system equals the net present benefit realized to its owner” (Denholm, 2010).

Four Factors that Might Work in Your Favor

Although most renewable energy projects have a hard time beating the cost of conventionally generated energy, the following factors may improve the economic picture for renewables:

Rising Cost of Energy. If the cost of energy rises, your investment in renewable energy will look better and better over time. Until recently, this looked like a sure bet. For example, residential natural gas prices increased by an average of 7% to 8% per year over the 30-year period from 1974 to 2004 and then went up around 20% in each of the next two years. This led one author in 2006 to recommend assuming a natural gas “energy inflation rate” of 10% per year (Ramlow, 2006). However, natural gas prices fell the following year, and they are currently (2011) at their lowest point in 10 years.

Incentives. Federal and state tax credits, grants, accelerated depreciation, and utility company rebates can all help a farm or business shorten the payback on a renewable energy project. Incentives change constantly and vary widely depending on your location. Some states and utilities have aggressive incentives, making renewable energy extremely competitive. Three sources of information are local renewable energy dealers and installers; customer-service representatives at your utility; and the excellent Database of State Incentives for Renewables and Efficiency (DSIRE) maintained by the North Carolina Solar Center and the Interstate Renewable Energy Council (IREC).

Financing. Low-interest loans are an attractive option, if they are available, to avoid paying for the entire cost of a renewable energy project up front. However, the fundamental problem presented by the time value of money hasn’t gone away. Whoever is financing the project is still putting up a significant amount of cash for a project that will generate small positive cash flows over a long period of time.

Home or Farm Property Values. It has sometimes been claimed that renewable energy systems increase the value of a home, and one California study found that homes with PV systems sold for an average of $17,000 more than comparable homes without PV. (Hoen et al, 2011) Nonetheless, it’s also worth pointing out that renewable energy systems can decrease a home or farm’s value, especially if they have a negative impact on aesthetics and “curb appeal.” Because most of these technologies are still uncommon in most parts of the country, how they will affect the value of a farm, or farm buildings, is really anyone’s guess at this point.

Two Sweet Federal Incentive Programs…While They Last)

The federal Business Energy Investment Tax Credit allows business, industrial, and agricultural taxpayers to claim a tax credit of 30% of the cost of solar projects, small wind turbines, and fuel cells on their federal income taxes. These tax credits have been in place since 2005, were expanded by the American Recovery and Reinvestment Act of 2009, and will last until December 31, 2016. Lesser tax credits (generally 10%) also are available for several other renewable energy technologies. Various conditions and exclusions apply. See IRS Form 3468 for more information or discuss the credits with your tax professional. There is a similar tax credit for homeowners, the Residential Energy Efficient Property Credit for homeowners. IRS Form 5695 has information on this credit.

Administered by USDA Rural Development, the Rural Energy for America Program (REAP) is a competitive program offering grants, loans, and loan guarantees for many renewable energy projects. Grants are for up to 25% of eligible project costs. From 2003 through 2010, REAP helped nearly 6,000 farmers and rural businesses plan and finance renewable energy and energy-efficiency projects. For more information, visit the USDA Rural Development website or contact the energy coordinator in your state USDA Rural Development office.

Economics for Uncertain Times

The reality is that we live in a time of fluctuating energy costs, interest rates, and real estate prices. So it has become much harder to predict the future or have much confidence in renewable energy cash-flow forecasts. If you tweak your assumptions one way—about interest rates, home prices, energy futures, and so forth—and you can make a project look like a winner. If you tweak your assumptions another way you can make the project look much worse. If you need certainty that a small-scale renewable energy project will generate strong economic returns on your investment, you are probably going to be out of luck.

Five Reasons to Consider a Small-Scale Renewable Energy Project

Even though it’s hard to make a slam-dunk economic argument for most small-scale renewable energy investments, there are many reasons why a farm or rural small business might want to consider one of these projects. Five of these reasons are listed below. It’s often some combination of these reasons that pushes buyers to the “tipping point.”

New Management Possibilities. Renewable energy projects have a tendency to open creative possibilities, especially in off-grid applications and remote locations where power lines are unavailable. For example, a solar- or wind-powered stock-watering system can create drinking-water sources far from streams and ponds. This can extend the grazing season and give livestock access to high-quality forage that would otherwise be inaccessible because it is too far from water.

Hedging Against Energy-Price Increases and Supply Issues. As already noted, the economics of renewable energy projects improve if you assume that energy prices are going to increase or if you have concerns about energy shortages or service-interruption problems. In uncertain times, it can be worth a great deal to know that you will have heat, fuel, or electricity.

Environmental Benefits. Many farmers and ranchers see reducing their use of fossil fuels as a natural expression of their commitment to stewardship and sustainability—the right thing to do.

Image and Marketing. Many farms have discovered that their customers like seeing solar panels on barn roofs and wind turbines in pastures. Projects like these send a message about the farm’s commitment to independence and sustainability, and they become part of the “story behind the food” for consumers. Renewable energy is sexy.

Solar arrays generating 10.8 kilowatts and 12.6 kilowatts greet visitors to this 250-acre California organic vegetable farm. The arrays meet 25% of the farm’s electrical energy needs. Photo: Mike Morris, NCAT

Personal Satisfaction. Many people get intense personal satisfaction from renewable energy projects, especially ones they’ve had a hand in designing or building themselves. One rancher told us that he’s glad he put up a wind turbine because—even though the paybacks are not the greatest—looking up at the spinning blades never fails to lift his spirits. If something gives you delight, makes the world a slightly better place, and you can afford it, maybe that’s all the reason you need to buy it.

Ballpark Economics and Risks

Below are ballpark economics for a few small-scale renewable energy projects. Please keep in mind that prices and incentives are constantly changing, and there are tremendous cost variations for each technology. We’ve also included cautions about some common risks and things that can go wrong. The discussion of risk is admittedly subjective and incomplete. We’ve limited ourselves to a few pieces of advice that we think every consumer would want to know.

Solar Electric (Photovoltaic) Systems

Solar electric or photovoltaic (PV) systems convert sunlight directly to electricity. They can provide stand-alone power or provide backup power by charging batteries. Solar arrays also can be “grid-tied” to the existing utility service with an inverter that allows energy to flow into the grid, offsetting the customer’s electric usage and reducing the customer’s utility bills.

As clean, silent, and portable sources of electricity, solar panels come in very handy on farms, where they are used to power lighting, electric fencing, small motors, aeration fans, gate openers, irrigation-valve switches, automatic supplement feeders, and wheel movers on some pivot and side-roll sprinkler irrigation systems.

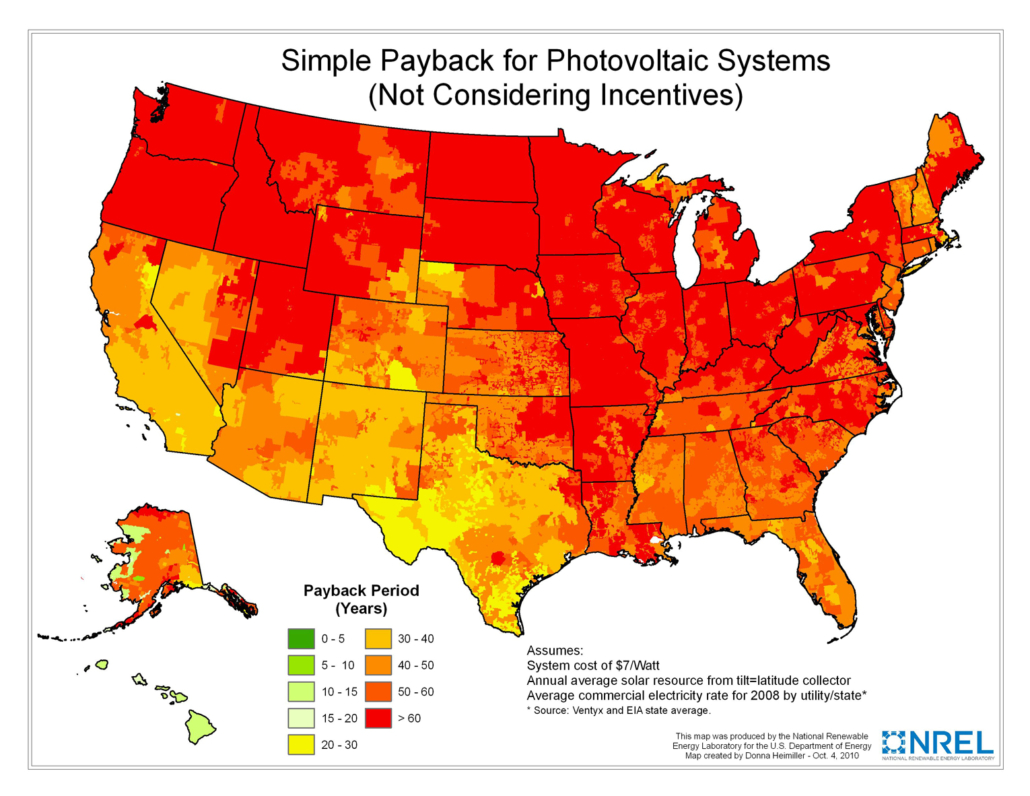

For purposes of this discussion, however, we are focusing mainly on grid-tied solar arrays mounted on rooftops or racks. According to the National Renewable Energy Laboratory (NREL), the average installed cost of photovoltaic systems in the U.S. fell from $10.87 per watt in 1998 to $7.16 per watt in 2010, a drop of 35% (NREL, Open PV Project). Based on the ballpark price of $7.16 per watt, a medium-sized 2-kilowatt residential rooftop PV system would have an installed cost of $14,320 before any rebates or tax credits.

The cost of solar electric projects depends heavily on where you are located. One study found the average installed costs, including incentives, for residential systems in 2009 to be $4.10 per watt, ranging from a low of $2.40 per watt in Texas to a high of $5.50 per watt in Minnesota (Barbose et al., 2010). A 2010 study factored in existing federal, state, local, and utility incentives and found that “break-even” conditions might already exist for $6 per watt PV installations for customers of large utilities in 10 states: Hawaii, New York, Massachusetts, Delaware, New Hampshire, Florida, Louisiana, Vermont, New Jersey, and Maryland. Several other states were not far behind (Denholm, 2010).

This is great news for consumers. Even so, solar electric projects in most parts of the U.S. still have long payback periods. A March 2010 NREL study found that simple paybacks in most parts of the U.S. were longer than 60 years. The study found hardly anywhere with simple paybacks of less than 20 to 30 years (Heimiller, 2010). Note that NREL assumed an installed cost of $7 per watt with no incentives.

Even with dramatic recent price decreases, solar electric projects in most parts of the U.S. still have long payback periods—although maybe not for long.

A valuable tool for looking at PV output in your area is the PVWatts calculator from NREL.

Assuming an installed cost of $4.10 per watt (with incentives), the 4-kilowatt systems above would cost the consumer $16,400 and would have simple paybacks ranging from 22 years (Fresno) to 51 years (Yakima). If we assume a 30-year lifespan for the equipment, these systems would generate electricity for somewhere between 20 and 46 cents per kilowatt hour.

Solar Leasing

Third-party ownership arrangements account for a rapidly growing segment of the solar industry. Here’s how it works: a solar company installs a rooftop solar system for little or no up-front cost, takes care of maintenance and repair, and retains ownership of the equipment. You sign a long-term contract with the company, agreeing to pay a fixed price for the electricity generated by the system over its lifetime. In effect, you are buying solar-generated electricity without owning the solar panels.

Risks

Rooftop or rack-mounted solar panels are among the least risky renewable energy projects and are a fairly “mature” technology. Improvements continue to increase the efficiency of these systems and drive down costs. Maintenance requirements are low, and most solar panels have warranties of 20 years or more. You can now find experienced installers in most parts of the country, although not necessarily in rural areas.

There are a number of common complaints about rooftop PV systems:

- Disappointing energy output. There may be a period of tweaks and adjustments before the system lives up to expectations, and some systems never do. Siting is critical, and even partial shading will drastically reduce output.

• Interconnection complications. Some utilities bend over backwards to be helpful, and others throw up roadblocks. Unfortunately, a lot of rural electric cooperatives still fall into the latter category, although this situation seems to be improving. Before you buy, talk to your installer and utility representative about such considerations as metering options, size restrictions, carry-over credit on monthly bills, outdoor disconnect requirements, insurance requirements, and interconnection costs. - Energy-storage complications. Batteries (if included in the system) add cost, complexity, and maintenance requirements, and they raise some safety issues.

Do-It-Yourself Photovoltaics

If you have strong mechanical and electrical skills, you may be tempted to reduce the cost of a PV system by installing it yourself. Most equipment dealers will work with you to put together a kit that includes all the components you need. Even “big box” stores like Home Depot and Lowes have begun selling solar installation kits. For most people, however, a professional installation remains well worth the cost for the personal safety, convenience, and peace of mind that it provides.

Solar-Powered Water-Pumping Systems

Typically used to water stock, these PV systems power pumps and must be custom designed to fit each situation depending on the well depth, flow requirements, and other factors. You may be looking at anything from $2,000 to $10,000 or higher—not including well-drilling costs. The solar components are sometimes mounted on a trailer and towed between pastures.

Solar pumping is most practical and affordable in low-flow situations that don’t require much power or pressure. Project economics typically have very little to do with the cost per kilowatt generated, and some cost-effective systems are used for only a few months out of each year. These systems pay for themselves by creating watering sources for livestock, making valuable forage available at remote pastures that would otherwise be inaccessible to animals. Another key economic factor is avoiding the cost of power-line extensions, which commonly run $10,000 to $30,000 or more per mile.

For more information, see the ATTRA publication Solar-Powered Livestock Watering Systems.

This 320-watt PV system in Montana pumps 5.5 gallons per minute from a 65-foot deep well, delivering enough water to meet the needs of 100 cow-calf pairs. The cost of its solar components was $5,500. Photo: Mike Morris, NCAT

Risks

The quality of equipment, especially pumps, has improved greatly in recent years. Maintenance requirements are generally low, although pumps—especially inexpensive diaphragm pumps—need regular maintenance.

Almost by definition, these systems are installed in remote areas. Finding an experienced installer who is willing to travel to your location can be difficult or expensive. Most farmers and ranchers are capable of installing a small solar pumping system by themselves, although this is a complex task that combines elements of electrical work, plumbing, and heavy construction (often including earthmoving, concrete-pouring, and welding). Also, written instructions are not always as complete as they should be.

The following are some common problems reported with solar pumping systems:

- Disappointing flow volumes. There are often installation complications and a period of adjustment before the system runs properly. The problem could be related to plumbing, the well, the pump, electrical components (such as the pump controller), partial shading of solar panels, or some combination of the above.

- Vandalism. Unfortunately, unattended solar panels in remote areas are an appealing target for vandals, including some hunters.

- Cold weather issues. Most of these systems are used during summer grazing season. Preventing frozen pipes and water troughs in cold weather can be challenging, especially when temperatures drop at night and the solar panels are generating no power.

Solar Water Heating

Installing a flat plate solar water heating collector. Photo: National Renewable Energy Laboratory

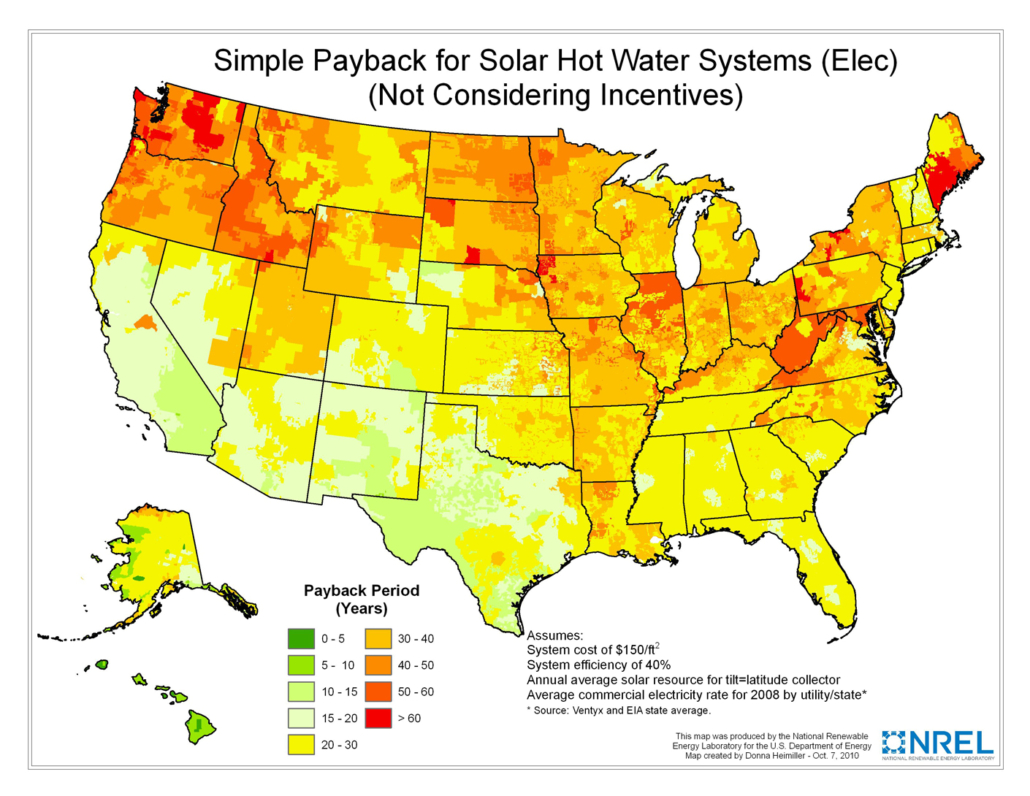

Solar water-heating systems use the sun to heat either water or a heat-transfer fluid, generally a propylene glycol antifreeze mixture, in collectors that are most commonly mounted on a roof.

A 2011 study found the typical cost of a solar water-heating system in the U.S., including installation, to be around $6,000—with the high end of the range being around $10,000 (Hudon et al., 2011). Typical installation costs were split about 50/50 between materials and labor.

Although solar water heating has a tough time competing economically with natural gas, it holds significant potential for farms and rural businesses that are heating water with electricity or propane and do not have ready access to natural gas. According to the California Energy Commission (2011), the cost of heating a gallon of water with natural gas is roughly half the cost of heating the same amount of water with propane and only around a third the cost of heating it with electricity.

This solar water-heating system in North Carolina cost $8,000 to install and saves $2,000 per year in propane costs for space heating. Photo: Mike Morris, NCAT

Solar water-heating systems may pencil out for farms and rural businesses that are heating water with electricity or propane and do not have ready access to natural gas.

The map below shows that even without incentives, solar water heating can compete fairly well with electric water heating in many parts of the country. In most parts of the U.S., simple paybacks from converting from electric water heating to solar water heating are 20 to 30 years or less, and in some areas they are considerably shorter.

Source: National Renewable Energy Laboratory

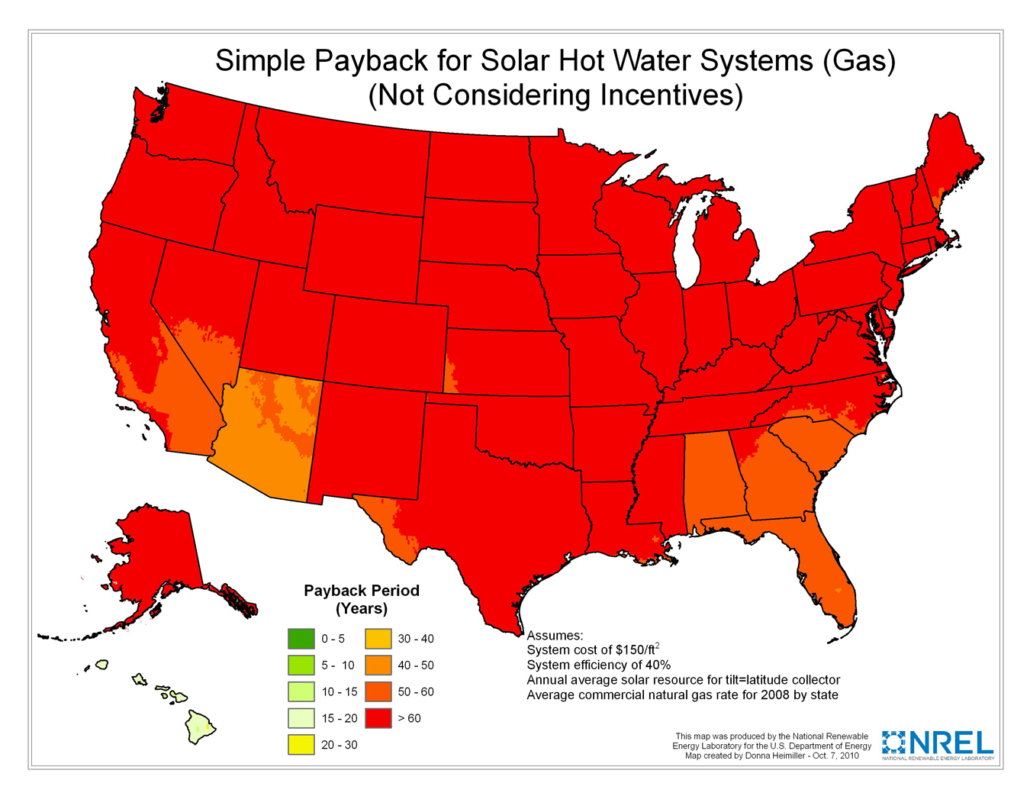

The next map shows that it’s considerably cheaper to heat water with natural gas than with a solar hot-water system in most parts of the country. The simple payback in converting from natural gas to solar is more than 60 years in almost all parts of the U.S. Again, this map does not include incentives.

Source: National Renewable Energy Laboratory

Risks

After meteoric growth (over 30% per year) from 1974 to 1981, the solar water-heating industry crashed with the end of federal subsidies, leaving many disappointed customers who bought systems from fly-by-night installers (Hudon et al., 2011). The industry has come a long way since that time, chalking up steady growth since the early 1990s and greatly improving equipment. The Solar Rating and Certification Corporation (SRCC) rates and certifies solar collectors and systems, testing the collectors for performance, efficiency, durability, and reliability. One indication of reliability is that Hawaii state law requires solar hot-water systems on all homes built after January 1, 2010.

Collectors usually come with a 10- to 20-year warranty. Maintenance requirements are low on well-designed systems, which may be expected to last 30 years or more. It’s a good idea to do a visual inspection of the system once a month or so, along with periodic testing of temperature controllers. Propylene glycol (transfer fluid) normally lasts 10 to 20 years and should be tested for degradation when it is around 10 years old (Ramlow, 2006).

Unfortunately, reports of design problems remain fairly common, and it pays to seek out an experienced installer you can trust. Freezing is a paramount concern, and a poorly designed system with low spots or constrictions in piping can freeze, bursting pipes. Unless you live in a near-tropical climate, you are going to need a freeze-tolerant system.

Most solar water-heating systems are mechanically quite simple, and many do-it-yourselfers with basic plumbing and welding skills have built their own for a fraction of the cost of a commercial system. If you are tempted to go down this path, an excellent source of design ideas and inspiration is the Build It Solar website.

Although we are huge fans of do-it-yourself renewable energy projects, a word of caution is necessary at this point: frozen and bursting pipes in your attic or on your roof are no joke and can do thousands of dollars worth of damage in the blink of an eye. Many people who think they know what they are doing (including some professional installers) make design mistakes that create the conditions for eventual catastrophic failure.

Here are some common complaints about solar water-heating systems:

- Poor system design, leading to disappointing output

- Gradual loss of vacuum in evacuated tube collectors (which may or may not be covered by the warranty)

- Degraded performance over time, especially in parts of the country with hard water (caused by “scale” mineral buildup in “direct” or “open-loop” systems that circulate potable water through the collectors)

- Ice and snow buildup in evacuated tube collectors

These solar water heating collectors froze because of poor design. Photo: Thomas Isaac, Techsun Solar, Inc.

Small Wind

Small wind projects (less than 100 kilowatts in peak output) vary tremendously in cost, but $5 to $15 per watt of installed capacity is probably a reasonable ballpark, including the cost of the tower (Scanlin, 2009).

Wind farms are able to achieve extremely low costs per kilowatt-hour by using enormous turbines that generate one to five megawatts of power. It needs to be stated up front that no small wind turbine is going to come anywhere near those costs. Long paybacks are the norm in the world of small wind. You will probably see alleged paybacks of six to 15 years, but if you read the fine print, you’ll discover that these claims are often based on extremely optimistic assumptions about average wind speeds and financial incentives.

What Do Power Ratings Really Mean?

It’s common to hear people talk about “10-kilowatt” or “100-kilowatt” wind turbines. These estimates of “rated kW” or “installed capacity” are supposed to reflect peak power output. But these numbers are very unreliable and misleading as a guide to the actual energy output you’ll see in the field. There is no standard wind speed used for these ratings. And the ratings are based on extremely high wind speeds in the range of 20 to 30 miles per hour, which are rare at most locations. As a consumer, what matters to you is the annual energy output you can expect based on the prevailing wind speeds at your location.

As a real-life example, consider that Bergey Wind Power estimates a typical installed cost of $48,000 to $65,000 (without any incentives) for its very popular 10-kilowatt BWC Excel-S machine. According to the manufacturer, this turbine has a predicted annual output of 12,000 to 24,000 kilowatt hours, depending on wind speeds and tower height. This represents $1,440 to $2,880 worth of electricity per year, assuming a retail price of around 12 cents per kilowatt hour. That’s a simple payback before any incentives of somewhere between 16 and 45 years. Assuming a 30-year lifespan for the equipment, the electricity generated would cost somewhere between 7 and 18 cents per kilowatt hour without incentives.

Evaluating the economics of a wind project raises issues that are far too complicated to be summarized in this short publication. However, all of the following needs to be evaluated:

- The physical site. In general you’ll need at least an acre of land with few obstructions.

- Legal issues. Among the possibilities are limitations on tower height; setback requirements from buildings or property boundaries; or consent from neighbors.

- Average wind speeds. Professional wind-power siting equipment—such as anemometers on a tower at the height of your turbine—are required to accurately measure wind speed and quality but are not necessarily worth the investment for smaller systems.

• Tower height and economics. For smaller systems, the cost of the tower may easily exceed the cost of the turbine.

• The turbine itself. Factors include predicted energy output and durability, among others.

Risks

There are many risks to consider before investing in a small wind project. To quote one commentator, “Small-scale wind energy is not for the half-hearted, uninvolved, or uncommitted” (Sagrillo and Woofenden, 2007).

Many people have been injured or killed by falls, electric shocks, and other accidents while working around wind towers. No one should ever climb a wind tower without safety training and proper equipment, including a full body harness, helmet, and shock-absorbing lanyard. Stay off the tower in high winds or if you hear thunder.

Small wind-energy systems involve complicated machinery with moving parts, and annual operation and maintenance costs are significant. The system should be inspected and maintained at least every year or two, including all mechanical and electrical connections. Blades and bearings may need to be replaced at around 10 years (Scanlin, 2009). Turbines are designed to last 20 to 30 years before needing a complete rebuild, and warranties are generally for five to 10 years.

We recommend that you look only at turbines with a very good track record—from companies with at least five years in business—and that come with a warranty of at least five years. Purchasing an extended service plan through the manufacturer or a dealer who has been in the business for many years provides greater assurance that you will have support when something fails.

Be wary of novel wind turbines claiming breakthroughs in efficiency or design. For example, many vertical-axis wind turbines are being heavily promoted by manufacturers who claim that this design, since it is nondirectional, should perform better in turbulent conditions. Also heavily promoted these days are rooftop wind turbines marketed on the claim that they avoid the expense, zoning, and aesthetic issues of a tall tower. To date, however, no commercially available vertical-axis or rooftop turbine has performed well enough to compete with traditional horizontal-axis wind turbines.

In the past, the wind-power industry has had an unfortunate reputation for exaggerated claims about power output. This situation improved with the launching in 2010 of the Small Wind Certification Council (SWCC). The mission of the SWCC is “to promote consumer confidence and mainstream acceptance of small wind technology,” through the consistent testing and certification of small wind turbines.

There are a number of common problems with small wind projects:

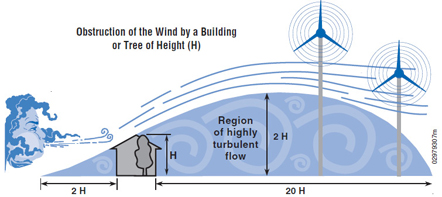

- Disappointing power output. The energy produced will vary tremendously depending on the location, prevailing wind speeds, tower height, and other factors. Siting is critically important, and many people overestimate the average wind speeds at their location. To save money, towers often are not built as tall as they should be—a false economy since wind speeds often increase dramatically with height.

- Zoning and permitting problems. Because renewable energy systems are relatively new technologies, they may fall into gray or undefined areas in the state or local permitting process.

- Maintenance issues. A wind turbine sees as many operating hours in a year as a typical car sees in 200,000 miles (Scanlin, 2009). Any wind turbine operates under tremendous stresses that, over time, take a toll.

Wind turbines need to be as far as possible from trees and buildings to avoid turbulence. Image: National Renewable Energy Laboratory

Biodiesel

North Carolina dairy farmer Phillip Barker runs all of his farm equipment on biodiesel made from used vegetable oil collected from area restaurants. He has reduced his use of petroleum diesel to nearly zero. Photo: Mike Morris, NCAT

Biodiesel is essentially permanently thinned plant or animal-based oil with a viscosity approximating that of standard No. 2 diesel fuel. Biodiesel can be substituted for petroleum-based diesel fuel in nearly any standard unmodified diesel engine. Biodiesel can be made from virtually any plant oil or animal fat through a chemical process that releases glycerine, a thick gooey substance, from the oil molecules and replaces it with a thin light alcohol, usually methanol. A carefully measured amount of sodium hydroxide (lye) or potassium hydroxide is dissolved into either methanol or (less commonly) ethanol. The resulting liquid is then mixed into vegetable oil, causing the glycerine to settle out. A “water wash” step usually follows, in which water is sprayed or bubbled through the biodiesel, removing various impurities.

Reports detailing the costs of home-brewed biodiesel are mainly anecdotal, running as low as $1.40 per gallon for fuel made from waste vegetable oil to anywhere between $1.70 and $4.50 per gallon for fuel made from oilseeds grown and processed on the farm. The basic equipment for small-scale biodiesel production can cost anywhere from $500 to tens of thousands of dollars.

For more information, see the ATTRA publications Biodiesel Use, Handling, and Fuel Quality; Biodiesel: Do-it-yourself Production Basics; Biodiesel: The Sustainability Dimensions; and Oilseed Processing for Small-Scale Producers.

Risks

Purchasing commercially made biodiesel is a low-risk way for almost any farm to use and support renewable energy. The main risks are easily manageable: First, fuel-filter clogging is common when switching to biodiesel, especially in older vehicles, because of the superior solvent properties of biodiesel. Second, biodiesel should be used cautiously in cold weather since it gels at a somewhat higher temperature than conventional No. 2 diesel. And finally, older fuel hoses will sometimes need to be replaced because biodiesel can cause certain types of elastomers and natural rubber compounds to bubble, bleed, soften, and degrade over time.

The techniques for making biodiesel have been widely known only since the 1980s. Although how-to information and equipment have improved tremendously, small-scale production is still largely the realm of creative do-it-yourselfers who enjoy experimenting and swapping ideas about the best ways of doing things.

It’s deceptively easy to make small batches of biodiesel, but it’s challenging to make consistently high-quality fuel in a way that is unambiguously safe, legal, and environmentally benign.

Engine damage is a very real possibility from poor-quality fuel, although inexpensive testing kits are available that allow careful and meticulous fuel makers to maintain high standards of quality.

There are all kinds of things that can go wrong with do-it-yourself biodiesel production, far too many to cover in this publication. Most of these problems are harmless, such as failed or incomplete reactions that result in large batches of soap instead of fuel. Vegetable oil, and especially waste oil, is sticky and messy to handle. There have been explosions and fires at some small biodiesel plants, although biodiesel is much less flammable than petroleum diesel and is (as advocates frequently point out) difficult to light with a match. Bigger health concerns probably come from handling methanol (which can cause blindness) and caustic lye or potassium hydroxide.

Small-scale biodiesel producers report two persistent difficulties:

- Permitting problems. Even more so than wind energy, biodiesel falls into gray or undefined areas in state or local permitting processes, and it often makes local permitting officials nervous. Although some home brewers fly under the radar, it’s a better idea to scrupulously follow local codes. Get to know the local inspectors and educate them about the many safety and health advantages of biodiesel in comparison with petroleum diesel.

- Waste-handling problems. Anyone making biodiesel for any length of time will accumulate sizeable amounts of methanol-contaminated glycerine and wash water and needs to have a realistic plan for disposing of these toxic materials in a safe and legal way.

Other Projects

Micro-scale anaerobic digesters can be built for as little as $50 for an in-ground bag design or a few hundred dollars for an in-ground dome design made of concrete or bricks. These systems generate small amounts of flammable biogas that can replace propane or natural gas for cooking, space heating, or other purposes. While labor intensive and tough to justify on purely economic grounds, these systems represent an intriguing and largely unexplored option for U.S. farms. For more information, see the ATTRA publications Micro-Scale Biogas Production: A Beginners Guide and Anaerobic Digestion of Animal Wastes: Factors to Consider.

Micro-hydro systems typically cost from $1.50 to $4 per watt of installed capacity, with great cost variations possible depending on your site. In a good location, a micro-hydro system will provide a steady year-round supply of electricity. Some farms and ranches are experimenting with putting these systems on irrigation ditches and pipes. Permitting is a sizeable hurdle for many micro-hydro systems, especially if they involve damming or altering free-flowing streams. For more information, see the ATTRA publications Micro-Hydro Power: a Beginners Guide to Design and Installation and Micro-Hydro Power: Is It Right for My Farm?

Working with Dealers and Installers

Trustworthy dealers and installers are a big help in most renewable energy projects, and they are essential for larger and more complicated projects. Ask neighbors who have built this type of project for recommendations. Get more than one bid, and be sure that each bid specifies system type and size, expected energy production, maintenance requirements, and installed cost. Ask for proof of insurance. Be prepared to look outside your state to find a qualified installer.

Here are some questions to ask when interviewing dealers and installers:

- What is your experience designing and/or building this type of system? How many years? How many projects?

- Can you provide references I can contact?

- Is a site assessment part of the bid, and if so, what is included?

- What incentives are available, and who handles the paperwork for these incentives?

- What permits are required, and who is responsible for obtaining them?

- Do you work with my electric utility to complete grid interconnection for grid-tied wind or solar projects? Are there interconnection costs?

- Is the installer who will be doing the work certified by the National American Board of Certified Energy Practitioners (NABCEP)?

- Do you provide a maintenance or service warranty? How do you handle manufacturer warranties?

- Does your bid reflect total costs? Under what conditions would I be charged extra?

Conclusion

Although most small-scale renewable energy projects do not generate cheap energy, they can offer an excellent return on investment in remote locations where few alternatives are available, or where they open new management or marketing possibilities. They may also offer an attractive hedge against rising energy costs, power shortages, or other supply issues. Finally, many will choose these investments for personal and ethical reasons, because they enjoy them, or because they see them as an integral part of their commitment to sustainable agriculture.

References

Barbose, Galen, Naim Darghouth, and Ryan Wiser. December 2010. Tracking the Sun III: The Installed Cost of Photovoltaics in the U.S. from 1998-2009. Lawrence Berkeley National Laboratory, Berkeley, CA.

Build It Solar. No date. The Renewable Energy site for Do-It-Yourselfers.

California Energy Commission Consumer Energy Center. 2011. Water Heaters.

North Carolina Solar Center and the Interstate Renewable Energy Council. No date. Database of State Incentives for Renewables and Efficiency.

Denholm, Paul. July 2010. Breakeven Cost of PV in U.S. Residential Markets: Presentation to the 2010 Residential Building Energy Efficiency Meeting. National Renewable Energy Laboratory, U.S. Department of Energy, Golden, CO.

Gipe, Paul. No date. A Summary of Fatal Accidents in Wind Energy. Adapted from the book Wind Power: Renewable Energy for Home, Farm, and Business.

Heimiller, Donna. October 2010. Simple Payback for Photovoltaic Systems (Not Including Incentives). Federal Energy Management Program Map. U.S. Department of Energy. National Renewable Energy Laboratory, Golden, CO.

Hoen, Ben, Ryan Wiser, Peter Cappers, and Mark Thayer. April 2011. An Analysis of the Effects of Residential Photovoltaic Energy Systems on Home Sales Prices in California. Lawrence Berkeley National Laboratory, Berkeley, CA.

Hudon, Kate, Bill Goetzler, Sean Ong, and Jay Burch. July 2011. Industry Review: Low-Cost Cold Climate Solar Water Heating Roadmap. Webinar presented by U.S. Department of Energy Building Technologies Program.

Ramlow, Bob. 2006. Solar Water Heating: a Comprehensive Guide to Solar Water and Space Heating Systems. New Society Publishers, Gabriola Island, BC, Canada.

Sagrillo, Mick and Ian Woofenden. 2007. Wind Turbine Buyer’s Guide. Home Power. June-July. p. 34-40.

Scanlin, Dennis. 2009. Wind Energy in the South. Presentation given to the Energy Training for Agriculture Professionals workshop, Goldsboro, N.C.

Union of Concerned Scientists. No date. Farming the Wind: Wind Power and Agriculture.

U.S. Department of Energy. Open PV Project. National Renewable Energy Laboratory, Golden, CO.

U.S. Department of Energy. PVWatts Calculator. National Renewable Energy Laboratory, Golden, CO.

Further Resources

Cassard, Hannah, Paul Denholm, and Sean Ong. February 2011. Break-even Cost for Residential Solar Water Heating in the United States: Key Drivers and Sensitivities. U.S. Department of Energy. National Renewable Energy Laboratory Technical Report NREL/TP-6A20-48986.

Home Power Magazine is an excellent source of consumer information and publishes regular buyers guides for wind turbines, solar water heaters, and other renewable energy equipment.

North American Board of Certified Energy Practitioners (NABCEP) website provides a clickable map allowing you to find a complete listing of NABCEP-certified PV, solar thermal, and small wind installers and sales professionals in your state.

Returns on Renewable Energy Investments

By Mike Morris and Leif Kindberg, NCAT Energy Specialists

Published September 2011

© NCAT

IP413

Slot 407

Version 091311

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development. ATTRA.NCAT.ORG.