SIFT 2021: A Small-Scale Urban Intensive Farm Contributes to a Resilient Food System

Onion bed on SIFT farm. Photo: NCAT

By John Wallace and Andrew Coggins, NCAT Agriculture Specialists

Abstract

NCAT’s Small-Scale Intensive Farm Training program (SIFT) operates a high-altitude urban demonstration farm in Butte, Montana, that is focused on production of food for the good of the community. This publication provides details on the role that the farm plays in educating and producing food for the community. It highlights ongoing cover crop experiments, fruit tree propagation, and water-conservation strategies at the farm, as well as construction of a new high tunnel.

Introduction

The National Center for Appropriate Technology’s multiyear, ongoing Small-scale Intensive Farm Training (SIFT) program involves education, outreach, research, and several different types of food production on a three-acre farm in Butte, Montana. The SIFT farm’s primary concerns are maximizing food donations for the good of the community and educating local farmers and gardeners in soil regenerative practices that help protect and grow resilient food systems.

As we detailed in SIFT 2020: A Small-Scale Urban Intensive Farm and a Year of Local Food, COVID-19 significantly highlighted the value of local food networks and outreach into the community. The situation revealed an important role for small-scale intensive farming in making the community more resilient and healthier, in addition to supporting those dependent on food-assistance programs. Though there were fewer empty shelves in 2021, food prices have been steadily rising for the last two years, and COVID-19—or its latest variant—continues to affect the flow of products and food. “Food prices have risen at a faster average rate since the onset of the pandemic than they did over the prior decade. Since April 2020, food prices have increased an average of 3.6% for food bought for at-home consumption and 3.9% for food away-from-home on a monthly year-over-year basis” (Lusk, 2021). As in 2020, the supply chain situation highlighted the importance of local food as we continued to operate through a second year of the pandemic in 2021.

Outreach and Education

The SIFT demonstration farm serves local growers and producers by offering education, as well as providing low-income and disadvantaged community members with food. During the 2021 season, 934 pounds of food were grown on-site and donated to local organizations that address food insecurity. In addition, the SIFT farm hosted many educational events.

The 10th Annual Montana Clean Energy Fair was held at the NCAT headquarters and SIFT demonstration farm on August 14, 2021. During this event, members of the Montana Renewable Energy Association and others spoke on many aspects of renewable energy, including solar panel efficiency and electric cars. The SIFT farm was open all day for self-guided tours, with extensive signage in place and NCAT staff on hand to answer any questions. In addition, NCAT had a booth at the event and staff gave presentations on NCAT’s renewable energy programs, the site’s solar energy system, season extension using high tunnels, and water-conservation techniques with the irrigation system.

Throughout the summer, the SIFT farm held workshops with the Upward Bound program that trains young adults interested in environmental sciences and agriculture. Workshops were held on July 1, July 15, and July 29, addressing season extension and variety selection, equipment and low-cost solutions for small-scale farming, and biodiversity and pest management on the farm.

We partnered with Montana State University Extension’s SNAP-Education program to teach food safety, processing, and storage methods for vegetables, using produce from the demonstration farm. In a workshop held at the Gym Dandy Kitchen operated by Butte-Silver Bow’s Developmental Disability Service, we processed tomatillos for salsa, cleaned lettuces, and taught proper storage techniques for root vegetables.

Building on the experience of previous years, we partnered with the YMCA summer camp program to develop a section of the demonstration farm just for kids to learn about where their food comes from and how to grow it. Each weekday from June 14 through August 27, as many as 15 kids came to the farm to learn about a farming topic and participate in hands-on activities. We have continued to expand the area devoted to this program over the years. In 2021, we built a new high tunnel to extend the season and increase the number of varieties that could be grown. Also, we have increased the farm’s composting system to include three compost bins and a tumbler.

The SIFT demonstration farm has also partnered with the Butte Emergency Food Bank to help introduce fresh local foods into their distribution program. We donated most of the produce grown on-site to this program, totaling more than 900 pounds. We also coordinated a community-wide gleaning day on September 10, when we collected more than 600 pounds of produce for the food bank from community gardens and local farmers at the Butte Farmers Market.

The SIFT farm doesn’t just help the food bank access more fresh produce: we also continue to help the food bank address their food waste issues. We currently take all their compostable food waste material and compost it to make soil amendments for the farm. In the course of this partnership, we have developed plans for the food bank to minimize food-waste by strengthening distribution ties with other organizations and finding ways to process and preserve items with low shelf life. Interestingly, one of the most-wasted products at the food bank was bread. Montana is the breadbasket of the region, and large-scale bread bakeries in the area were donating all the bread that they were having difficulty shipping in their own markets, which led to an oversupply at the food bank. Unfortunately, the number of preservatives put into the bread made it very difficult to break down during composting, and we had to stop accepting excess bread for compost. However, supply chain issues improved over time and the loads of bread donations diminished. It is not uncommon for large companies to donate more of a single product than the food bank can handle, leaving them to manage the waste. We try to help as much as we can to divert the compostable material from the landfill and combine it with locally sourced horse and cow manure to use as soil amendments.

Production

The 2021 growing season posed new obstacles stemming from the pandemic. Seed shortages occurred across the nation, forcing many growers to find new sources of seed. These shortages derived from low staffing in packing warehouses, due to restrictions on personnel. Ironically, this did not affect overall seed availability and price, but rather the quantity available for sale. Based on the principle of economies of scale, larger seed orders were able to be filled more readily than multiple small orders.

At the SIFT farm, we typically use 30 to 50 different varieties of seeds as a goal for increasing biodiversity at the farm and mitigating substantial crop losses. Many of the varieties we sought to order from Johnny’s Selected Seeds were unavailable in 2021, so we looked for other sources. The SIFT farm likes to use Johnny’s seeds because the company is in Maine and selects short-season, cold-tolerant varieties, which can work quite well in Montana. We were able to find a source in Oregon, Siskiyou Seeds, that offered the crops we were seeking in varieties with short days to maturity. We trialed a variety of warm- and cool-season crops from Siskiyou and found that seed germination was hit-and-miss. Many of the warm-season crops, such as peppers, did not germinate efficiently. They took a very long time, and this led to root rot for some. Slow germination was likely due to low soil temperatures that we commonly deal with in early season conditions. We also had an issue with a variety of Chinese cabbage called Nozaki Early. While these seeds had great germination success and took well as spring transplants, the variety did not have any bolt resistance and performed poorly later, when temperatures reached above 70°F. On the other hand, some varieties of corn were particularly successful this year. We grew Hooker’s Sweet and Triple Play varieties, and, for the first time, we had a successful yield of corn in Butte. The corn was seeded in June in a high tunnel and benefited from the exceptionally warm weather during the 2021 growing season.

Yields

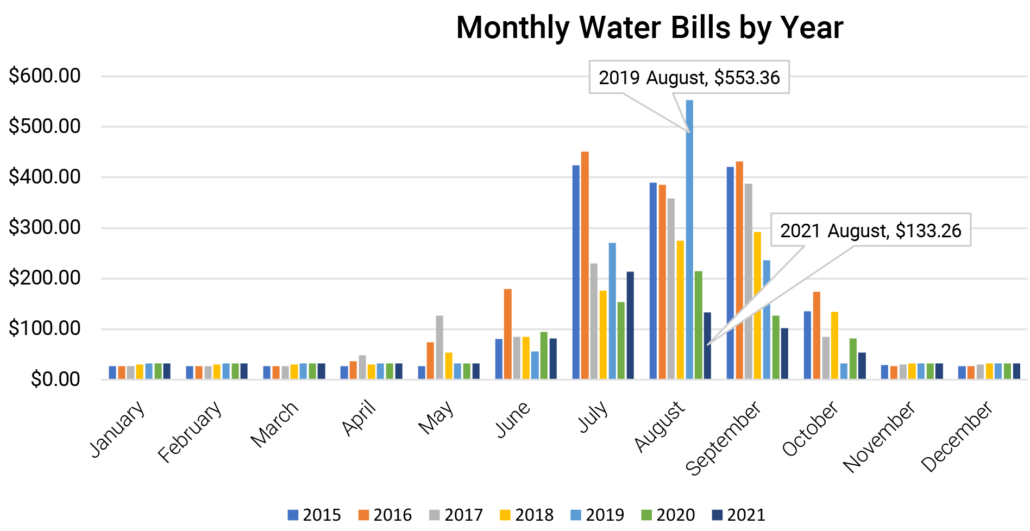

Figure 1.

At the SIFT farm, production in pounds is beginning to level off around the 1,000-pound threshold. The 2021 growing season was marked by considerable drought and a production plan that shifted towards warm-season crops as we hit record highs across the region. The heat caused stress on many leafy greens and brassica crops. We planted more warm-season crops, such as tomatoes and corn, which have lower yields than brassica crops but a higher market value. Due to heat stress, we utilized shade cloth on High Tunnel 2, which we found significantly reduced stress on plants. It also required changes to the irrigation timing because it reduced evapotranspiration compared to the high tunnel without the shade cloth.

Conserving Water

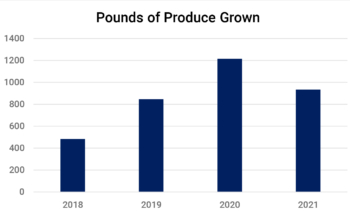

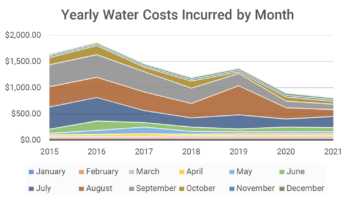

Looking at the yearly water costs incurred by month in Figure 2, you can see that July, August, and September are our most watering-intensive months. However, you can also see a trend over time of reduced water usage during those peak months. Initially, this reduction was the result of improving the efficiency of the drip irrigation system. Ensuring that leaks were repaired and the pressure through the system remained consistent allowed us to fine-tune the timing between each of the three watering zones. This allowed us to reduce watering cycles from 15 to seven minutes in most areas. By increasing the frequency of cycles, we were able to drop indoor drip irrigation times still further, to just three to five minutes every six hours. This proved to be sufficient, even in extreme drought conditions.

Figure 2.

When looking at monthly water bills by year from 2015 to 2021, you can see some anomalies in the trends. For example, in 2019, our main timer failed during June, and we essentially played a game of catch-up to get crops germinated. We resorted to overhead watering for most of the outdoor plots, which is highly inefficient during peak summer months. This resulted in a very high bill because the higher consumption pushed us into a higher tier for pricing. After that incident, we took a much more in-depth look at our water usage and developed a better monitoring plan. Since then, we have successfully cut water usage by 75% during that peak month. After analyzing the pricing structure of the local utility, we also determined that we have more flexibility to use water in the earlier months if needed. The appropriateness of this is highly dependent on the particular season we are dealing with. Weather is highly variable in this region of southwest Montana during the spring, especially when it comes to temperature and precipitation.

Cover Crop Trials

In 2021, we continued our multi-year cover crop trial at the SIFT farm. This trial involves planting eight-species cover crop mixes on two plots with different management. The North Plot is tilled in the spring only, while the South Plot is tilled both spring and fall. Both plots are monitored to track long-term performance.

The water infiltration tests on the two plots were conducted three weeks after the Haney tests, using an 8-inch diameter ring and 824ml of water to simulate an acre-inch. Generally, the results were significantly better than we recorded last year on the second pour, and, in addition to measuring the time, we recorded how far the water had infiltrated down into the soil (a trick learned from Jay Fuhrer). It is interesting to compare the results of this test with a test conducted in the fruit tree area of the farm, which is well trafficked. There, the second pour took nine minutes and 15 seconds for the water to disappear from the surface!

General observations of the cover-crop plots showed roots going straight down for five to six inches and good straight tap roots on the fodder turnips, though they were small. The soil was a healthy dark brown and crumbly down to about eight inches deep, where much of the cover crop area seems to be compacted. There remain some poor areas in both plots, where the plant growth is stunted and thin and water infiltration is poor. (See Photo 1 below, around the soil sampler in the foreground.) Of the eight species in the cover crop mix, the oats, triticale and phacelia did well and the turnips did fair, while the peas and hairy vetch did poorly. No ryegrass or sweet clover was apparent.

One slight change to plot management from previous years was that when we terminated the crops, the south plot was hand clipped, so that all the biomass remained on the surface and was then tilled in. (In the past, the mower tended to blow the clippings off the plot.) The north plot was not cut at all this year, so the biomass was left standing, as is visible in Photo 2.

Photo 1. Stressed area within the cover crop. Photo: NCAT

Photo 2. Pre-winter preparation of the cover crop areas. Photo: NCAT

Soil Testing

Haney testing continues on a yearly basis across the two cover crop areas. We also conducted Haney tests on the sites of the original four hoop houses that became two newly constructed high tunnels in 2018 and 2019. As our NRCS EQIP project closed in 2021, we compiled a summary of the Haney test results from these sites. The NRCS nutrient management plan ran from 2018 to 2020 on High Tunnel 1 and from 2019 to 2021 on High Tunnel 2. The tables below reflect three years of production with High Tunnel 1 and two years of production with High Tunnel 2. We will continue conducting Haney tests across the SIFT farm moving forward, particularly in the cover crop areas, and in other areas where needed.

One observation was that the soil profile in High Tunnel 2 was moist throughout the sampling depth of six inches, whereas the soil in High Tunnel 1 was only moist for two to three inches maximum. Both high tunnels had been on the same timed water cycle, but High Tunnel 2 had been covered with a shade cloth since late June, which may have significantly slowed water evaporation during the hot weather. This practice could indicate potential for further water savings in the future. Also worth noting are the sunflowers grown in High Tunnel 1 as part of our pollinator program. We did not use the shade cloth for High Tunnel 1, and the sunflowers grew so tall they had to be trimmed back, as they were pushing against the roof plastic! All the new high tunnels have shade cloths, all rated at 50% light filtration.

Hydroponics System

The starting point for the hydroponic system in the greenhouse. Photo: NCAT

This was our second year using the hydroponics system in its present smaller configuration, and our plan was to increase the production of tomatoes, herbs, and salad greens, still using compost tea as a nutrient base and continuing with Brix test comparisons with soil-grown fruit. This was partially successful. We have established a system in which all the plants are started in a small hydroponics system indoors (Photo 3) and then moved into the main system in the greenhouse. This process takes three to four weeks on average. On April 23, 2021, three Heinz tomato plants and a combination of parsley and cabbage were moved into the greenhouse hydroponics system, followed by three more Heinz tomatoes on May 28, 2021 (Photo 4). Unfortunately, the frost on June 8, 2021, also caught these plants in the greenhouse and, though the effect was not immediate, eventually the initial batch of tomato plants died without producing fruit.

Photo 4: Various tomatoes and basil growing in the hydroponic system. Photo: NCAT

Notwithstanding, we continued to add plants to the system throughout the summer—primarily Thai basil, Genovese sweet basil, and the occasional lettuce plant—and ended up with four or five harvests of basil, amounting to about 2.4 pounds of Genovese sweet basil and .75 pound of Thai basil in August and September, in addition to some lettuce. Additional tomato plants were seeded directly into the system on July 8, and still more added on August 27, but by this stage it was too late in the season for effective growth, due to shortening daylight hours in Butte.

The hydroponic system was built to provide a practical comparison with soil-grown fruit and vegetables in terms of the criteria listed below (in addition to nutrient density) and is not advocating any one type of production system (organic, sustainable, conventional).

- Efficient water use. Each pipe used .95 gallon (3.6 liters) /week over 22 weeks (x 4 pipes) Total = 83.5 gallons (maximum) over the season.

- Energy consumption = none. The system used natural light in the high tunnels and two solar aeration pumps. The pumps cost $35 each, with a projected life of three years.

- Nutrient costs = none. We have used compost tea throughout, which is a free by-product from composting.

- Build cost = $95 (estimated). Plant capacity= 36 plants. Labor input = minimal.

We acknowledge that this system can only be compared on a like-for-like basis with similar plants grown in soil, and that the range of soil-grown vegetables is far greater: for example, root crops and squashes. The nutritional value of vegetables, herbs, or fruit grown in the hydroponic system is still largely unknown at present (compared to soil grown), and we are still experimenting with different crop types. The system has not been used close to capacity yet, so we haven’t been able to measure its full productivity in a relatively small area. Though we still have many things to understand, we do know that the system involved minimal investment in time.

Fruit Tree Area

Another very dry summer, combined with a frost around blossoming time, meant that the fruit trees at the SIFT farm did not produce much fruit in 2021. The fruit bushes blossomed nearly a month later than the previous year, and the frost arrived early. However, despite the lack of fruit, the bushes actually grew quite well this year, particularly the Carmine Jewel bush cherries. One of the hard lessons we learned was that the bushes needed immediate protection against grazing over the winter. The fruit trees are particularly vulnerable to deer in the riparian area immediately to the east of us, among other hazards. Building a fence around the area in 2020 (better late than never!) largely prevented any grazing damage during the 2020-21 winter, and, therefore, the bushes came out of winter in better condition than in prior years. Chicken wire has been added to the fencing this year as a precaution against rabbits, gophers, and ground squirrels. Our aim remains to water and monitor the bushes until they become large enough to source their own water (as the native hedgerow around the SIFT farm now does) and to fill the gaps in the area where the bushes did not survive. In late 2021, SIFT farm staff visited the Ruby Habitat Ranch just south of Sheridan, Montana, where, amongst other project work, they have established a 1-acre site of heirloom apple trees from the Ruby Valley. We hope to work together in some sort of hardy-fruit project partnership in 2022.

‘New’ YMCA-Area High Tunnel

As documented in the ATTRA blog “Helping a Neighbor—and helping NCAT too,” we dismantled a donated high tunnel in 2020 at Deer Lodge, Montana, to rebuild it at the SIFT farm in 2021, for use by the YMCA as part of their summer camp activities in 2022. In between many other activities, we began reconstructing the high tunnel in March and finished in October, ready for the next growing season. This high tunnel measures 36 feet long by 24 feet wide. Although we covered high tunnel construction in general in previous SIFT publications, there were several factors that made this construction slightly different. The first was that this is a PolyTex Field Pro high tunnel and, therefore, there are subtle differences in construction between this and the two Rimol high tunnels we built in 2018 and 2019.

YMCA high tunnel near completion. Photo: NCAT

First, each hoop comes in seven sections, instead of five like Rimol’s. This makes the 4-foot spacing between the hoops more challenging, as there is more flexibility with the hoops until you secure the purlins. The second challenge was that this high tunnel only came with two purlins, which are attached to the hoop with brackets. The Rimols have five purlins each, and, therefore, we added two additional purlins to the Field Pro for additional strength. We drilled and bolted these to the hoops, as our spare Rimol brackets were too large, because Rimol hoops are 1¾-inch diameter and the Field Pro hoops are 1½-inch diameter. It might seem like a minor detail, but it means that brackets do not fit, and therefore we had to come up with alternative solutions or ways of refabricating some of the spares we had.

The three main SIFT hoop houses. Photo: NCAT

The last point to bear in mind is that the donated high tunnel was, in fact, half of an 80-foot unit (or just under half). This meant that the end walls, door, and wind bracing stayed in Deer Lodge on the 40 feet that remained there, so it was not a complete kit that came to Butte. Luckily, we had enough spare box sections from the Rimol kits to build two new steel end walls on the Field Pro, and we ordered the remaining parts we lacked from Rimol, including a 4-foot door, roll up sides and gearboxes, shade cloth, and 6mm polythene sheeting for the end walls.

In addition to its use for education and food production, this high tunnel will have additional interest for SIFT visitors, as we now have three different designs on the site, from three different manufacturers, for visitors to compare. The total area under plastic is now 3,600 square feet — an increase of 44% over the area available before 2018.

Summary

In 2021, NCAT’s Small-Scale Intensive Farm Training program demonstration farm continued to expand its role in educating and feeding the community, while advancing knowledge about high-altitude urban farming through ongoing research. The farm’s ongoing cover-crop trials, water-conservation techniques, soil testing, and hydroponic demonstration reveal more each year about the potential of small-scale intensive farming. Meanwhile, the farm continues to broaden its community involvement by composting food waste, testing new climate-appropriate crops, and dedicating more space and infrastructure to educational programming.

SIFT 2021: A Small-Scale Urban Intensive Farm Contributes to a Resilient Food System

By Andrew Coggins and John Wallace, NCAT Agriculture Specialists

Published November 2022

© NCAT

IP632

Slot 671

This publication is produced by the National Center for Appropriate Technology through the ATTRA Sustainable Agriculture program, under a cooperative agreement with USDA Rural Development.